Final Report

advertisement

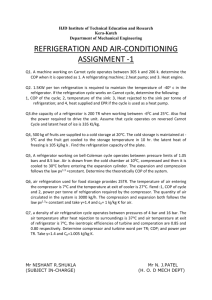

Innovative Cooling Engineering Heat Pump and Refrigeration Design Final Report 5/6/2011 Executive Summary The purpose of the Innovative Cooling Engineering group’s design project was twofold. The first portion of the project had the group develop and present an informative module on heat pumps and their benefit to both Maine’s environment and its economy. This module was addressed towards those without an extensive thermodynamic background. The second portion and lion’s share of the I.C.E. group’s design project was the creation of a heat reclaiming refrigeration system for a grocery store in Farmington, Maine. The major design points for this system were to use an innovative, new compressor head design for a Carlyle compressor to improve the refrigeration’s cycle by about thirty percent. Additionally the system was designed to reclaim heat from the refrigeration cycle to heat domestic hot water and to heat the store; further design improvements were made to be able to place the refrigeration system in the store near the cooling load. This additionally reduces the cost of refrigerant piping, as well as eliminates the need to install ductwork for the space heat reclaiming portion of the system. 1 Contributors Luc Chabot – Primary Editor and Compiler Executive Summary Introduction Concept Design Process (Refrigeration Heat Reclaim System) Design Results and Evaluation (Refrigeration Heat Reclaim System) Appendix A – Heat Pump Experimental Report Colin Wood – All sections pertaining to Thumbnodes/electronics Nicholas Gramlich – Concept Design Process (Heat Pump Systems) Design Description (Heat Pump Systems) Design Results and Evaluation (Heat Pump Systems) Conclusion (Heat Pump Systems) Appendix A – Heat Pump Experimental Report Appendix B – Refrigeration System Budget Alexander Norton - Design Description (Refrigeration Heat Reclaim System) Design Results and Evaluation (Refrigeration Heat Reclaim System) Conclusion (Refrigeration Heat Reclaim System) References 2 Table of Contents Executive Summary......................................................................................................................... 1 Contributors .................................................................................................................................... 2 Introduction .................................................................................................................................... 5 A Dual Focus ................................................................................................................................ 5 Heat Pump Systems..................................................................................................................... 5 Refrigeration Heat Reclaim System ............................................................................................ 6 Concept Design Process .................................................................................................................. 7 Heat Pump System ...................................................................................................................... 7 Refrigeration Heat Reclaim System .......................................................................................... 11 Design Description ........................................................................................................................ 18 Heat Pump Systems................................................................................................................... 18 Refrigeration Heat Reclaim System .......................................................................................... 23 Refrigeration Components .................................................................................................... 24 Electronics.............................................................................................................................. 33 Design Results and Evaluation ...................................................................................................... 35 Heat Pump Systems................................................................................................................... 35 Refrigeration Heat Reclaim System .......................................................................................... 35 Conclusion ..................................................................................................................................... 36 Heat Pump Systems................................................................................................................... 36 Refrigeration Heat Reclaim System .......................................................................................... 36 References .................................................................................................................................... 37 Appendix A – Heat Pump Experimental Report............................................................................ 38 Introduction: ............................................................................................................................. 38 Objective ................................................................................................................................... 38 Apparatus & Instruments: ......................................................................................................... 38 Data Methods and Procedure: .................................................................................................. 42 Expected Results: ...................................................................................................................... 43 Plan of Work From 1/19 to 4/25 ............................................................................................... 43 Results ....................................................................................................................................... 44 Appendix B – Refrigeration System Budget .................................................................................. 48 3 Table of Figures Figure 1 Duct work design for heat pump ...................................................................................... 9 Figure 2 Experimental layout ........................................................................................................ 10 Figure 3 Refrigeration Cycles without and with new compressor head design ........................... 11 Figure 4 Finished Solidworks drawing with key ............................................................................ 14 Figure 5 Piping Diagram ................................................................................................................ 16 Figure 6 Powerpoint Slide for Cold Climate Heat Pump Analysis ................................................. 18 Figure 7 Fujitsu 9RLS Indoor Unit Electrical Panel ........................................................................ 20 Figure 8 Comparison of Mass Flow Rate and Voltage .................................................................. 21 Figure 9 Velocity Profile for High setting ...................................................................................... 22 Figure 10 New Compressor Head Design(Left) and Standard Compressor Head (Right) ............ 23 Figure 11 06DR725 Carlyle Compressor ....................................................................................... 24 Figure 12 Vibration Eliminator on Compressor Exhaust............................................................... 25 Figure 13 Muffler on Compressor Exhaust ................................................................................... 25 Figure 14 Desuperheater from Refrigeration Research Catalogue .............................................. 26 Figure 15 C10T Microchannel Heat Exchanger ............................................................................. 27 Figure 16 C-489-G Filter ................................................................................................................ 28 Figure 17 SER6 Expansion Valve ................................................................................................... 29 Figure 18 Custom Receiver Tank Solidworks Drawing.................................................................. 30 Figure 19 RSF-489-T Filter ............................................................................................................. 31 Figure 20 Grundfos Magna 40-120 Pump..................................................................................... 32 Figure 21 Various devices attached to Thumbnodes™Thumbnode modules .............................. 33 Figure 22 Single Thumbnodes™ mounted on a custom DIN Rail ................................................. 34 Figure 23 Initial printed circuit board layout ................................................................................ 34 Figure 24 Original LIN node concept............................................................................................. 34 4 Introduction A Dual Focus The Innovative Cooling Engineering group has had two major areas of focus throughout the academic year. The first area of focus was a community outreach program on heat pump systems. The second area of focus was the creation of a heat reclaiming refrigeration system for a grocery store located in Farmington Maine. Each of these focus areas will be further discussed in this introduction. Heat Pump Systems The state of Maine, as other New England states, is situated in a portion of the country with the harshest winter months. The additional months of cold require the residents of these states to spend a large portion of their energy budgets in heating their living spaces. In the state of Maine, 80% of households use oil fired boilers as their heating source. As the price of fossil fuels is expected to rise over the following years, it is imperative to seek alternative ways to heat homes, businesses, and industrial areas. The I.C.E. group was presented with the task to prepare an educational module to help inform the general populace of Maine about the benefits of heat pump systems. The educational module has the following focus areas to properly inform Maine residents of the advantages of using heat pump technology: 1. The Heat Pump informational module will compare the economic advantages and disadvantages of heat pump systems, traditional oil boiler systems, as well as renewable residential energy sources. 2. The informational module will compare energy usage to heat ratio using a heat pump with energy usage to heat ratios using conventional oil systems. 3. The informational module will explain the basic workings of the refrigeration cycle and make basic comparisons between heat pumps, refrigerators, and air conditioner units. 4. The informational module will use an example of an existing heat pump system available to consumers, the Fujitsu 9RLS mini-split heat pump. In addition to the learning module, there will be a working example of a heat pump to be used during presentations to the public. To accomplish this, a Fujitsu 9RLS mini-split heat pump was donated to the senior design project. The Fujitsu 9RLS mini-split heat pump came with published data detailing the coefficient of performance (COP) of the units given certain outside temperatures and certain indoor temperatures. However, these numbers were given regardless of the amount of heat the heat pump was actually providing. Without a reference room size, or any data correlating to heat transfer or mass flow rate of the air exiting the indoor unit, the given information was lacking. 5 Thus, a secondary task involving heat pumps was formed. A way to measure the COP in real time was to be formulated by the group. Refrigeration Heat Reclaim System The refrigeration industry is a mature business, having existed for over one hundred years. According to the senior design advisor for the ICE group, Jim LaBrecque, many systems in place across supermarkets today are old and outdated. They have existed since a time where energy was inexpensive and plentiful. While energy is still plentiful, the cost has gone up substantially. The purpose for this product was to implement new technology and engineering innovation to improve existing refrigeration systems and reclaim much of the “waste” energy associated with refrigeration systems. Several areas were focused on to improve refrigeration systems. 1. Using a modified Carlyle compressor head. This modification allows for a second suction input into the compressor and is mainly used for non-peak load operations. It has the possibility to increase the efficiency of the refrigeration cycle using the 06DR75 compressor by 30%. 2. Improving the electronics and control system for the refrigeration components. This was done using new Thumbnode™ technology developed by Jim LaBrecque. 3. Designing a modular case system to house the components of the refrigeration cycle and its heat reclaim components. 4. Using the new components to provide domestic hot water heating and space heating for the grocery store using the product. The ICE group developed this product by first selecting all of the components needed to run a system with several different areas for heat reclaim. To further minimize the waste energy from the systems, the system was designed to that it could be placed next to the refrigeration cases within a grocery store. This would minimize the amount of piping needed and would allow the system to supply space heat to the store area without having to install expensive, bulky ductwork. The group also assisted in designing the packaging for the electronic Thumbnode™ system. 6 Concept Design Process Heat Pump System The first thing that had to be considered when preparing the heat pump presentation was the target audience. It was to be assumed that the majority of persons viewing the heat pump module would not have an extensive technical thermodynamic background. Thus, many common energy terms were needed to be defined and explained. The heat pump and several different alternative energy sources were compared to using heating oil for space heat and domestic hot water heating. A simple economic payback was devised for each energy alternative. To properly analyze the total economic impact on society, no tax credits were factored into the economic payback time. Further development of the learning module was relatively straight forward. The module was made in Microsoft PowerPoint and broken up into two parts. One part compared the different supplemental energy sources and their economic analysis. The second portion explained the workings of the refrigeration cycle and coupled them with the specifications and construction of the mini-split system. The largest development hurdle was in the communication of engineering terms to a non-technical audience. In addition to the heat pump module, the ICE group utilized the Fujitsu 9RLS mini-split heat pump as a working example with the presentation of the module. One problem arose with this. With the given information supplied by the manufacturer it was impossible to tell how much heat was being rejected into the area being heated, and how the machine was performing. A way to obtain COP while the system was operating was needed. First, the basic concepts of a heat pump had to be considered. A heat pump moves heat energy from a thermal reservoir to a desired location by evaporating and condensing a fluid. Heat is absorbed by the fluid when it is evaporated, and heat is rejected when it is condensed back into a liquid. For the case of the 9RLS unit, the thermal reservoir is the outdoor air, while the area of heat rejection is the inside of a building. Electrical power is required to run the compressor that causes the unit to function. However, the electricity is not used to create the primary source of heat. The electricity is simply used to move the energy from one place to another. That means for every unit of electrical energy purchased, you can move several units of heat to a desired location. This is known as the Coefficient of Performance. The coefficient of performance is given by the equation Eq. 1. Qindoor-unit is the heat transfer into the desired space; in the case of the 9RLS system, this is done by the “indoor unit”. Wentireunit is the work done by the system provided by electricity. COP = Qindoor-unit/Wentireunit Eq. 1 7 To move further on the heat pump project, the two variables in Eq. 1 needed to be measured. Measuring the electrical power into the heat pump was simple. From Eq. 2 it can be seen that the electrical power input is the product of the current and voltage being supplied to the unit. Wentireunit = V*I Eq. 2 The difficult portion of this problem was obtaining the heat transfer into the heated area. By taking the indoor unit as a control volume, the first law of thermodynamics can be applied to obtain the heat transfer; this is shown in Eq. 3. Qindoor-unit = m*Cp*(TOutlet-TInlet) Eq. 3 In this equation Q is the heat transfer, m is the mass flow rate of air travelling through the unit, Cp is the specific heat of air (a known constant), Toutlet is the temperature of air exiting the indoor unit, and Tinlet is the temperature of the air entering the indoor unit. The two temperatures could be measured easily by thermocouples, but measuring the mass flow rate of air would be more difficult. There were two major obstacles in reliably finding the mass flow rate of air through the indoor unit. The first was the variable speed of the fan, which controls the amount of air being drawn through the unit. The mini-split heat pump can change the speed of the fan by using an internal control system. The second obstacle was the shape of the fan outlet. The air outlet on the minisplit heat pump is slightly biased to one side; this makes it difficult to obtain a consistent mass flow rate measurement, as the flow of the air would not be fully developed. The solution to both of these problems became simple; construct a duct long enough to get fully defined flow, then use known measuring points to find a correlation between the control system and the mass flow rate of air through the duct. Another factor in this design was the positioning of the indoor and outdoor units. At first, the indoor unit and outdoor units were setup in the same large room with plenty of ventilation and run in set point temperature mode for various temperatures. However, this failed to give accurate readings, as the system more or less ran at full capacity and never reached the steady state required when it reaches the designated set point temperature. To obtain the mass flow rate through the duct work, the average velocity of air moving through the duct must be found. This can then be used to calculate the volumetric flow of air through the duct. Once the volumetric flow of the duct is known, it can be multiplied by the density of air to obtain the mass flow rate. Equations Eq. 3 and Eq. 4 depict these two relations. Volf = Vav * Aduct Eq. 4 8 m = ρ*Volf Eq. 5 In these two equations Volf is the volumetric flow rate of air through the duct. Vav is the average velocity of air through the duct, measured by the anemometer. Aduct is the cross sectional area of the duct, which was calculated from figure 1. ρ is the density of air, a known value. Using equations 3, 4 and 5, the heat transfer done by the indoor unit can be calculated. Figure 2 shows the set up of the ductwork in relation to the heat pump, as well as a diagram of instrumentation used. Figure 1 Duct work design for heat pump 9 Figure 2 Experimental layout 10 Refrigeration Heat Reclaim System The refrigeration system was designed with the primary concern of reclaiming energy. Before any design work was done to the system, Mr. LaBrecque took the design group to see current examples of refrigeration systems that exist in the state of Maine. The ICE group visited two independent grocery stores that Mr. LaBrecque is affiliated with. One store in Farmington, Maine, currently uses the Food-o-Thermal™ system that Mr. LaBrecque helped design with a previous group of seniors several years ago. The system was inexpensive, lightweight, and compact, but tended to be inefficient when the compressor was operating at non peak loads. This was due to the nature of the scroll compressor selected for the product. When operating at non peak loads, i.e. when the system needs to reject less heat, the scroll compressors would disengage the compressor from doing useful work, yet the compressor would still be drawing the same amount of electrical power and continue running. To solve this problem, Mr. LaBrecque developed a modification to a different type of compressor. This was done with support from The University of Maine’s Advanced Manufacturing Center. The part created was a reverse engineered head for one of the pistons in a Carlyle 6 cylinder compressor. The new head design allowed for a second suction input to the compressor. This allows for the compressor to be more efficient at non peak loads by reducing the amount of work required to increase the pressure of the vapor in the compressor. Additionally, the compressor is controlled by a Yaskawa V1000 variable frequency drive to vary the speed of the compressor under different load conditions. Figure 3 displays information on standard refrigeration systems and systems using the modified head, both with the same compressor. Figure 3 Refrigeration Cycles without and with new compressor head design 11 Mr. LaBrecque had the theoretical thermodynamic analysis of the system already completed at the beginning of the ICE group’s involvement with the project. The maximum output of the compressor was calculated to be about 120,000 BTU per hour, which is equivalent to ten tons of cooling. Knowing the total amount of cooling that could be accomplished, heat exchangers were selected for the system. A desuperheater was selected to cool the refrigerant to saturated vapor state. A counter flow of water is used in the desuperheater to remove heat from the refrigerant and transfer it to heating domestic water lines. As the goal of the project was to reclaim as much heat as possible from the refrigeration system, it was decided that two additional heat exchangers would be used. The first was a flat plate heat exchanger. This heat exchanger is similar to the desuperheater in that it uses a counter flow of water to remove heat from the refrigerant. The model that was selected was the C30G flat plate heat exchanger from GEA. This model can be used in systems with up to 30 tons of cooling. The choice to oversize the heat exchanger was made to have an increased amount of water being heated by the refrigerant, at the tradeoff of a reduced change in temperature for the water. The second heat exchanger to be used was a micro channel coil. This heat exchanger would be used in conjunction with a fan, which would draw air through the micro channel coil; this would cool the refrigerant and heat the air. The air would then be used to heat the grocery store. The micro channel coil selected was the Alcoil C10T heat exchanger. This part was selected due to the aluminum construction of the coil. The use of an aluminum coil reduces the amount of weight used in the system and prevents corrosion. The layout of the system planned to use these heat exchangers in series. This way, the amount of heat going to water or air through the heat exchangers could be regulated. By increasing the amount of water going through the flat plate heat exchanger, all of the heat can be reclaimed through it. If the water flow is reduced, the flat plate heat exchanger must reclaim the rest of the heat. The next part that was designed was the receiver tank. After the refrigerant passes through the three heat exchangers, it becomes a saturated liquid. The liquid then undergoes a pressure drop by passing through an expansion valve and entering a receiver tank. The rapid pressure drop causes the appearance of flash gases. These flash gases rise to the top of the tank, while the liquid falls to the bottom and passes through refrigerant cases out in the grocery store. Due to the modifications in the compressor, a new receiver tank was designed. This new design put an outlet near the top of the tank to allow flash gases to flow out and into the modified compressor head. This process is the major component increasing the efficiency of the refrigeration cycle under non peak loads. Once component selection was completed and the dimension of each of the parts was known, design of the equipment housing began. One design concept was for the unit to be able to be 12 placed next to existing refrigeration cases out on the floor of the grocery store. A design was initially created using two inch steel tubing as the frame to house the refrigeration components; however, this was reduced to one inch steel tubing to both reduce the weight and cost of the case. The basic frame was designed first in SolidWorks. Panels were added to the design to isolate the components from customers. Additionally, it was decided that the lower compartment that housed the compressor would be lined with sound dampening insulation so that customers would not be disturbed by the loud refrigeration compressor within the unit. Each of the components that had been selected for the design were drawn in SolidWorks and placed within the case. Certain components, such as the Carlyle compressor and the Rosenberg fan used to draw air through the micro channel coil had drawings available on the company websites. After the major components were added to the system, a piping layout was prepared in SolidWorks. Additional equipment necessary for refrigerant lines were then drawn and added to the piping diagram. These included refrigeration filters and water pumps for the desuperheater and flat panel heat exchanger. Figure4 shows the finished SolidWorks model for the refrigeration system (some parts were removed for visibility). 13 1. Carlyle 06DR725 Compressor 2. 5839 Desuperheater from Refrigeration Research 3. C30G Flat Plate Heat Exchanger 4. C10T Microchannel Coil 5. C-489-G Refrigerant filter 6. Receiver Tank (No model number, custom made) 7. Grundfos Magna 40-120 water pump 8. Grundfos water pump 9. RSF-489-T Refrigerant Filter 10. Rosenberg Centrifugal Fan Figure 4 Finished SolidWorks drawing with key 14 During the final stages of SolidWorks design, members of the team began to fabricate the housing for the components. This was performed in Crosby Laboratory at the University of Maine. During construction, the fabrication team decided to add gussets to the frame of the housing for greater structural integrity. In addition to the basic construction of the casing, the fabrication team crafted custom mounting brackets for several of the components. The case will also be placed on rubber matting to reduce vibration and noise and to protect the flooring. After completing the housing structure, aluminum sheet metal panels were affixed to the outside of the case. The panels were made to be easily removable if certain areas requiring maintenance are not easily accessible by the main doorways into the case. The compressor and heat exchangers were then affixed to the case. The compressor was set in place using a Carlyle mounting kit; this kit included hardware to reduce the vibrations of the large compressor. Once the major components were installed, the piping process began. Pipe vibration reducers were added to the system near each of the inlets and the single outlet to the compressor. These vibration reducers needed to be clamped into place, so additional unistrut channels were installed into the unit. Figure 5 shows the pipe sizing diagram with components. 15 Bushing (7/8” x 1 3/8”) 5/8” 5/8” Bushing (1 3/8” x 2 1/8”) 7/8” Muffler 1 3/8” 1 3/8” 7/8” 2 1/8” 2 1/8” 7/8” Compressor Bushing (7/8” x 1 1/8”) 1 1/8” 2 1/8” 7/8” 1 1/8” 1 1/8” RSF-489-T with RC-4864 filter 5/8” Bushing (7/8” x 1 1/8”) 1 1/8” Bushing (1 1/8” x 5/8”) 1 1/8” CDST-9 7/8” CD ST-9 CDST-9 CDST-9 C-489-G with RPE-48-BD filter CDST-9 1 1/8” Bushing (1 1/8” x 5/8”) 5/8” CD ST-9 CD ST-9 CD ST-9 SER-11-5/8 x 7/8 ODF-10-S 7/8” 7/8” 7/8” SER-6- 5/8 x 5/8 ODF10-S CDST-9 7/8” Bushing (7/8” x ½”) 7/8” Piping Diagram 5/8” 5/8” Receiver Tank Purple-1/2 Blue-5/8 Red-7/8 Green -1 1/8 Yellow -1 3/8 Black -2 1/8 BV Figure 5 Piping Diagram 16 Instrumentation was then needed for the refrigeration system. Mr. LaBrecque brought the group his idea for the Thumbnode™ system. Controlling a compact, high capacity refrigeration system with multiple variable speed motors and electronic valves requires a compact and powerful electronics system. Existing electronics systems are either bulky, or custom built, and in all cases are expensive. Thumbnodes™ are being designed as a compact modular electronic components that when combined can control refrigeration and other HVAC system. The initial concept for the Thumbnodes™ began as a Google Sketchup drawing of the smallest possible package that could fit on a standard DIN rail using existing components. Despite the small size of the printed circuit board carrier, cost and availability of the carrier prevented its use. A new plastic printed circuit board holder was designed to the smallest dimensions possible and still fit on a DIN rail with a four-position Phoenix connector on one end. Then, the design of the holder was modified to be machinable. Because the initial drawings were made in Sketchup, and could not be directly used for CNC machining, they were redrawn into SolidWorks and sent to the Advanced Manufacturing Center for machining. Two circuit boards were designed initially. First a large relay board was drawn up, but not completed because it was not intended to fit on a Thumbnode™. Attention was instead shifted to a similar solid-state relay board that operated fewer relays in a smaller package and could fit on a Thumbnode™. This board was designed first because it is predicted to have the tightest fitting components. The circuit board for the solid-state relay board was designed to the dimensions of the holders with connectors placed on the ends. The relays were placed next to the component specific four-pin connector. A low cost LIN microcontroller made by Atmel was placed in the middle of the free area board. The Atmel chip requires a number of support components such as resistors and capacitors to operate as desired. Therefore, the instruction manual had to be dissected and catalogues scoured to find components that would be suitable for the board. These components were placed and replaced on a circuit board diagram using ExpressPCB and ExpressSCH and traces drawn and redrawn to connect all the components until they all fit. 17 Design Description Heat Pump Systems As mentioned before, the heat pump learning module was broken up into two sections. The first section involved an explanation of basic energy and efficiency terms and an economic and ecological comparison of 5 different supplemental energy systems. The second section involved an explanation as to how heat pumps work and the definition of COP. Most slides included an explanation of the topic in bullet point form with an accompanying picture for visual aid, e.g. Figure 6. Figure 6 PowerPoint Slide for Cold Climate Heat Pump Analysis 18 List of PowerPoint Slide Titles: Mini Split Heat Pumps (Introduction Slide) A Mini Split Heat Pump Can Help You... What is a Mini-Split Heat Pump? Basic Energy Terms (Part 1) Basic Energy Terms (Part 2) Household Energy Use Ways Mainers Heat Their Homes How Mini-Split Heat Pumps Affect Energy Usage Traditional Oil Heaters (Part 1) Traditional Oil Heaters (Part 2) Solar Thermal Water Heating Residential Wind Turbines Cold Climate Heat Pumps Mini-Split Heat Pumps COP vs. Outdoor Temp Heat Pump Benefits Energy Efficiency Economic Efficiency Heat Pump Temperature Efficiencies Heat Pump Principles and Definitions (Section 2 Intro. Slide) What is a Heat Pump? The Compressor The Condenser The Expansion Valve The Evaporator Putting It All Together: The Heat Pump Cycle Examples of Heat Pump Style Systems Air Conditioning Refrigerator Mini-Split Heat Pump Efficiency of Heat Pumps More On The COP Factors That Effect Efficiency 19 Accessing the electrical panel on the 9RLS Fujitsu heat pump led the experiment group to find that there was a constant voltage power supply leading to the indoor unit fan motor. From this, it could be inferred that the device that regulated the actual power being drawn by the fan itself was built into the motor and could not be accessed. However, it was also found that there was a low voltage control wire also going into the motor. This voltage regulated the velocity of the fan, which directly correlates with the mass flow rate of air. Figure 7 shows the electrical panel of the unit, and where the control voltage was measured. The wires in the bottom right have been repaired with electrical tape after the experiment. Figure 7 Fujitsu 9RLS Indoor Unit Electrical Panel Through experimentation, a relationship between air mass flow rate and control voltage has been found. Figure 8 depicts this comparison graphically, with air mass flow rate in lbm/hr and voltage in volts. It is clear that there is a direct linear correlation between voltage and mass flow rate, with an R2 of .9981. The slope of the curve is negative, meaning mass flow increases as voltage decreases. As Figure 8 shows, the equation relating control voltage of the indoor unit fan to mass flow rate can be found as equation Eq. 6, where VC is the control voltage and mD is the average mass flow 20 rate of air in the duct: mD = -920.5* VC + 5109.3 Eq. 6 Mass Flow Rate vs. Voltage for a Fujitsu RLS90 Mini-Split Heat Pump 1800 Mass Flow Rate (lbm/hr) 1600 y = -920.5x + 5109.3 R² = 0.9981 1400 1200 Mass Flow Rates 1000 800 Linear (Mass Flow Rates) 600 400 200 0 0 1 2 3 4 5 Voltage (V) Figure 8 Comparison of Mass Flow Rate and Voltage This inverse relationship between control voltage and mass flow exists due to the nature of the indoor unit fan motor. A constant 208 volt power is supplied to the fan motor, which has a speed regulator built into the motor. To vary the fan speed, a control system build into the heat pump sends a small voltage signal to this regulator within the motor. As the voltage and current supplied to the fan at any one setting are constant, it is impossible to tell how much power the fan is using in relation to its mass flow rate at any one time. However, by measuring the control voltage, the above curve could be correlated. To measure these values, the control voltage was taken for each of the programmable fan settings of High, Medium, Low and Quiet. The mass flow rate was then calculated for each fan setting using a velocity profile such as in Figure 9, which is comprised of actual measurements of the flow across the duct’s width. Figure 9 specifically shows the velocity profile for the High fan setting. 21 Velocity Profile for Air Flowing from a MiniSplit Heat Pump Through a Duct 600 Velocity (ft/min) 500 400 300 Velocity Profile 200 100 0 0 5 10 15 20 25 30 Position from Right of Duct (in.) Figure 9 Velocity Profile for High setting 22 Refrigeration Heat Reclaim System As mentioned previously a new compressor head design will be used by the heat reclaim refrigeration system. The new compressor head and the one being replaced are shown in Figure 10. This new head will drastically increase the efficiency of the whole system. It works by dedicating one cylinder to a suction line connected to the receiver tank. This keeps the gas and liquid within the tank at a low pressure and low temperature. This keeps the refrigerant entering the evaporator at a lower temperature, therefore increasing the efficiency of the cycle. Figure 10 New Compressor Head Design (Left) and Standard Compressor Head (Right) 23 Refrigeration Components Compressor: Figure 11 06DR725 Carlyle Compressor A 06DR725 Carlye Compressor was selected for use in the designed system. This specific compressor was selected due to its higher efficiency than the scroll compressor in last year’s Food-O-Thermal system and its compatibility with the redesigned head. The major concern with this compressor will be the noise and vibration caused by it. Vibration Eliminator and Muffler Vibration eliminators are attached near each of the three pipe connections on the compressor. Additionally, a muffler will be installed on the exhaust section of the compressor. These are shown in figures 12 and 13. 24 Figure 12 Vibration Eliminator on Compressor Exhaust Figure 13 Muffler on Compressor Exhaust 25 Desuperheater: A 5839 desuperheater from Refrigeration Research was selected to handle the waste recovery part of this system. This will help provide hot water to the store this system will be used in. Figure 14 Desuperheater from Refrigeration Research Catalogue Flat Plate® Heat Exchanger: A C30G Flat Plate® Heat Exchanger from GEA PHE Systems North America, Inc. sized for the I.C.E. Refrigeration System was selected. This acts as a condenser in the system. It also contributes to the heating of water within the store. 26 Microchannel Heat Exchanger: Figure 15 C10T Microchannel Heat Exchanger A C10T Microchannel heat exchanger was ordered for the refrigeration project. This device is the other condenser in the cycle. It is composed of numerous channels of aluminum that allow for maximum surface area for the refrigerant to flow through. Rather than using a conventional fin and tube system like the radiator in a car, the micro channel heat exchanger channels the flow of the vapor through multiple, small orifices instead of one large tube. This allows for a larger surface are for heat transfer to occur. A fan draws air through the micro channel heat exchanger which transfers its absorbed heat to the air. The I.C.E. Refrigeration cycle is composed of two condensers for efficiency of operation. In Maine there is a variety of changes we experience seasonally. The Flat Plate® Heat Exchanger and micro channel heat exchanger will work in unison for 100% heat reclaim. During the winter months, the room air may be cold and uncomfortable. In this case 100% heat reclaim will occur in the micro channel heat exchanger where warm air can be distributed throughout. During the summer months, room temperature may be fine leaving 100% heat reclaim for the Flat Plate® Heat Exchanger to distribute for domestic hot water. On normal days both of the heat exchangers will be working together. 27 Liquid Line Filter: Figure 16 C-489-G Filter A C-489-G shell and RPE-48-BD core were chosen. This filter is attached to the condensers and is used in refrigeration to clean the system of any impurities that may exist. 28 Expansion Valve: Figure 17 SER6 Expansion Valve A SER 6 expansion valve was used from Sporlan. The Expansion Valve is a device for controlling the flow of refrigerant by regulating the pressure in the cycle. A large pressure drop occurs over the Expansion Valve. 29 Receiver Tank: Figure 18 Custom Receiver Tank SolidWorks Drawing In order for the custom compressor head to work, a custom receiver tank had to be designed and ordered from Refrigeration Research. The vapor in the tank will be sucked to a single cylinder of the compressor which will keep the pressure low inside the walls of the tank that keeps the temperature of the liquid low. The liquid will continue through an outlet port in the receiver tank. 30 Suction Filter: Figure 19 RSF-489-T Filter The suction filter is on the suction line just before the compressor. The suction filter is used to clean any impurities in the system so they don’t enter the heads of the compressor. A RSF-489T shell and a RC-4864 core were selected for use in the I.C.E. system. 31 Water Pump: Figure 20 Grundfos Magna 40-120 Pump In order for water to flow through the Flatplate® heat exchanger a pump had to be ordered and installed. A Grundfos MAGNA variable speed water pump was chosen for its ability to easily control the mass flow rate of the water. 32 Electronics The foundation of the electronics modules comes from an automotive technology called the Local Interconnect Network or LIN. LIN is originally designed as a low cost, lightweight network to control systems such as windows and door locks in cars. A single master LIN node controls up to fifteen different nodes. In this case these nodes are called Thumbnode™ modules. Each module controls and monitors a single device. As shown in figure 21, some devices that Thumbnode™ can drive are: thermocouples, relays, MEMS valves, thermocouples, pressure transducers, combined pressure temperature transducers, actuators, and electronic expansion valves. Figure 21 Various devices attached to Thumbnodes™ modules 33 Physically, each module consists of a printed circuit board and a holder. The plastic holder has been designed to mount on a standard DIN rail. Both the Thumbnode™ and the custom DIN rail are shown in Figure 22. A spring-loaded tab similar to those found on other DIN rail devices holds the module to the DIN rail. The module is just wide enough to hold a board with a fourposition phoenix connector on one end. To aid in cost and simplicity, a set of custom plastic DIN rails hold the Thumbnodes™ in specified positions. Figure 22 Single Thumbnodes™ mounted on a custom DIN Rail The printed circuit board contains two connectors, one for the three wire LIN communication system, and the other for the device. In between, the board has two sections. The first section on the LIN side of the board contains all the LIN microcontroller, and all of its accessories. Due to size, all the components are very small and surface mounted. All of the application specific components reside on the opposite side of the board and attach to a four-position connector. Figure 23 Initial printed circuit board layout Figure 24 Original LIN node concept 34 Design Results and Evaluation Heat Pump Systems The learning module was tested on three different occasions: once in the John Hill Auditorium, once at the UMaine energy convention, and once at the Engineering Expo in Augusta. For the latter two, the audience for the presentation wasn't present, and the presentation couldn't be judged as such. The first presentation in the Hill Auditorium did have an audience. However, the audience was not primarily lay people; rather, it was comprised of engineers and engineering students who already had a general understanding of the material being presented. Thus, a definite understanding of the module's effectiveness hasn't been discovered. The test run for calculating COP was for a temperature difference of 80 F on the indoor end and 76 F on the outdoor end, and the calculations for indoor unit mass flow rate and heat transfer were found via Equation 2. This yielded an expectedly high Coefficient of Performance of 11.48. This was obtained by having a compressor work of 596.14 Btu/h, an indoor unit heat transfer of 6845.2 Btu/hr, and an indoor unit air mass flow rate of 1022.28 lbm/hr. This mass flow rate puts the fan speed at about “Low” for this application. The high efficiency is expected because of the relatively low temperature difference between the condenser (outdoor unit) and evaporator (indoor unit). As this experiment was performed in part for another class, full details of this experiment can be seen in Appendix A. Refrigeration Heat Reclaim System The major concern in the design of this case and in the final product is the potential for the case to be very noisy. Even with the sound suppression steps detailed earlier in the report, the team expects the system may be too noisy for installation in customer shopping areas. Additionally, problems with fabrication caused the frame to not sit perfectly flat, which might result in unwanted vibrations with the compressor running. There is also potential for the aluminum paneling to rattle from the vibrations caused by the compressor. For teams working on this project next year, it would be a good idea to take a deeper look into the issues of noise and vibration suppression. Another issue the team ran into was in ordering parts. The parts were not ordered as soon as preferred, which set back the fabrication the process. The team’s advice to future teams working on this project would to be order parts as soon as possible. This is especially true when ordering custom parts, as it can take up to 8 weeks for the part to arrive. Ordering early can also help reduce delays that occur when incorrect parts are inadvertently ordered or shipped. 35 Conclusion Heat Pump Systems The learning module was built in a logical manner. However, the lack of an appropriate audience made it difficult to gauge the success or failure of the module. The team recommends that this module be tested on an appropriately interested audience as a way to fine-tune the presentation. Perhaps enticing people to come to the module's presentation with food and beverages or presenting the module in a classroom setting would be best. The real time COP measurement method worked quite well. With the removal of the outside case and measurement of the control voltage, one can find the mass flow rate of the indoor unit. After the mass flow rate is found, other measurements are found and used in the various equations presented to arrive at a real-time COP. Refrigeration Heat Reclaim System The size of the case ended up being a little bulkier than expected. This could be easily fixed if this were put into production by having a mircochannel heat exchanger custom built to wrap around the case so it doesn’t have to be as tall. This is another issue a future team could look at. The design of the Thumbnodes™ began towards the beginning of the spring semester, and therefore a prototype could not be completed within the semester. However, the design is relatively simple and is likely to be successful once completed. More boards must be designed to make a complete set of Thumbnodes™ that can operate an entire system. In addition, these nodes must be programmed and tested appropriately to operate an entire system. Overall this design looks to be a good design. The team will not get a chance to install it and analyze it, so it can’t be said for sure if this design will increase efficiency as intended. But with the new compressor head and placing the unit close to the food cases, the results look very promising. If the new compressor head works as planned, it could very well be a major game changer within the industry and help in reducing the cost of refrigeration. The same applies to being able to pack all of the hardware into one case and locate it as close to the product as possible. Paired together, these two innovative ideas can drastically reduce the cost for stores to refrigerate their product. Even though further work will be needed to improve noise and vibration levels, this heat reclaim system represents a positive step toward greatly increasing the efficiency of refrigeration systems in grocery stores. 36 References [1] CCRP REFRIGERATION PARTS AND EQUIPMENT CATALOG 2008, Carlyle Certified Refrigeration Partners, Syracuse, NY. [2] Grundfos MAGNA Brochure, Grundfos, Bjerringbro, Denmark. [3] Alcoil Aluminum Heat Exchangers Brochure, Alcoil, Jacobus, PA. [4] Refrigeration Product & Application Catalog, GEA PHE Systems, York, PA. [5] Refrigeration Research Inc. Catalog, Refrigeration Research Inc., Brighton, Michigan. [6] Axial Fans for cooling and air handling catalog, Rosenburg Group, Künzelsau-Gaisbach, Germany. [7] Wes Taylor, CMS, Part 1: Preventing Refrigeration Line Vibration, RSES Journal, April 2006 [8] Wes Taylor, CMS, Part 2: Good Design Impedes Bad Vibrations, RSES Journal, May 2006 [9] Matthew Cummings and Christopher Dubois, Food-o-Thermal Refrigeration System, May 2010 [10] Carlyle Compressor Company, Carlyle Compressor Selection Software Version 4.1.1. Available: http://www.carlylecompressor.com/corp/details/0,2938,CLI1_DIV24_ETI1240,00.html [11] Condensed Catalog of Sporlan Products - Parker Sporlan Division - #54, Parker Sporlan Division 37 Appendix A – Heat Pump Experimental Report Introduction: The 9RLS Fujitsu mini-split heat pump is a device intended to supplement or replace conventional methods of heating. A heat pump moves heat energy from a thermal reservoir to a desired location by evaporating and condensing a fluid. Heat is absorbed by the fluid when it is evaporated, and heat is rejected when it is condensed back into a liquid. For the case of the 9RLS unit, the thermal reservoir is the outdoor air, while the area of heat rejection is the inside of a building. Electrical power is required to run the compressor that causes the unit to function. However, the electricity is not used to create the primary source of heat. The electricity is simply used to move the energy from one place to another. That means for every unit of electrical energy purchased, you can move several units of heat to a desired location. This is known as the Coefficient of Performance. Fujitsu has several different values of COP published for this unit based on varying temperatures of the thermal reservoir and the desired temperature of the indoor space to be heated. However, these values seem vague, as they do not take into account the fan settings that may be changed by the operator. Therefore, it would be extremely useful to the consumer to be able to easily measure the COP of the system. The coefficient of performance is given by the equation Eq. 1. Qindoor-unit is the heat transfer into the desired space; in the case of the 9RLS system, this is done by the “indoor unit”. Wentireunit is the work done by the system provided by electricity. COP = Qindoor-unit/Wentireunit Eq. 1 Objective The objective of this experiment is to obtain real time coefficient of performance data for the 9RLS Fujitsu mini split system. To do this there must be a reliable way to calculate the two variables from Eq. 1. As it is difficult to constantly measure the mass flow rate of air through the indoor unit of the heat pump a correlation between the input voltage to the indoor and fan speed must be obtained. Apparatus & Instruments: Figure 1 is the apparatus that is going to be used to test the COP of the 9RLS Fujitsu mini-split heat pump. The work into the entire heat pump unit is simply the electrical power input to the system. To measure this electrical input an ammeter and multimeter will be used to measure the current and voltage respectively. 38 To measure the heat transfer of the indoor unit three measurements are to be made. A hot wire anemometer will be utilized to measure the velocity of the air flowing through the duct, as well as the temperature of the air in the latter section of the duct. A type K thermocouple will be used to measure the temperature of the air intake into the indoor unit of the heat pump. The following list describes the instrumentation to be used in the experiment: Figure 25 Mini-split COP experimental setup 39 Hot wire Anemometer: Brand: ALNOR Model #: CF8585 Range: 20-9999 fpm 1-140 ºF Accuracy: ±3% of face value (fpm) or ± 3 fpm whichever is greater ±0.5ºF Thermometer: Brand: OMEGA Model #: HH509 Digital Thermometer Range: -328ºF to 1999ºF Accuracy: ±(0.1% rdg +2ºF) Ammeter: Brand: UEI Model #: DL39 Clamp on Current Meter Range: 20A (AC) Accuracy: ±2% +10 digits Multimeter: Brand: Electronic Specialties Model #: 501 Range: 500V 40 Accuracy: ±0.05% rdg ± 5 digits Figure 2 shows the precise specifications for the ductwork that is going to be made for this experiment. To obtain an accurate velocity profile across the face of the duct the flow must be measured ten duct diameters from the inlet fan into the duct as well as the flow regulating damper of the heat pump unit. The hydraulic diameter of the duct shown in figure 2 is 8.4 inches. Ten duct diameters would make a duct length of seven feet. An extra foot of duct length was added onto the end of the duct for an easy place to attach the anemometer for data taking. Figure 26 Duct work specifications 41 Data Methods and Procedure: The final goal of the experiment is to measure the COP of the 9RLS system. This will be done using the aforementioned Eq. 1. As one cannot directly measure the two variables in the equation, they must be broken down further. Equation Eq. 2 is an adaptation of the first law of thermodynamics for an ideal gas. In this equation m is the mass flow rate of air through the indoor unit. Cp is the specific heat of air, a known constant. TOutlet is the temperature of the air exiting the duct work, measured by the anemometer. TInlet is the temperature of the air entering the indoor unit of the 9RLS unit, measured by a thermocouple. Qindoor-unit = m*Cp*(TOutlet-TInlet) Eq. 2 Unfortunately, the mass flow rate of air cannot be easily measured directly. To obtain the mass flow rate through the duct work, the average velocity of air moving through the duct must be found. This can then be used to calculate the volumetric flow of air through the duct. Once the volumetric flow of the duct is known, it can be multiplied by the density of air to obtain the mass flow rate. Equations Eq. 3 and Eq. 4 depict these two relations. Volf = Vav * Aduct Eq. 3 m = ρ*Volf Eq. 4 In these two equations Volf is the volumetric flow rate of air through the duct. Vav is the average velocity of air through the duct, measured by the anemometer. Aduct is the cross sectional area of the duct, which is a known value from figure 2. ρ is the density of air, a known value. Using equations 2, 3 and 4 are all that is needed to calculate the heat transfer done by the indoor unit. The next piece of data that must be obtained to use Eq. 1 is the power input to the 9RLS system from electricity. This can be simply calculated via Joule’s law, Eq. 5. The two variables in this equation are easily measureable. V is the voltage of the electrical line going into the 9RLS system; this will be measured with a digital multi-meter. I is the current running through the same line; this will be measured with an ammeter. Wentireunit = V*I Eq. 5 This experiment will be set up in Crosby Laboratory between two of the fabrication rooms. The outdoor unit and the indoor unit will be attached to a frame and placed in a doorway between the two rooms. In one room, the heat will be turned off and the windows will be opened to simulate an outdoor temperature; this room will be the thermal reservoir for the outdoor unit. In the other room, the windows, blinds, and doors will be closed; this is the space where heat will be rejected. The two units will be separated by a layer of pink insulation foam which will block off all air flow through the door between the two rooms. The edges of 42 the foam will be sealed with plastic to ensure the blockage of air flow between the rooms. Thus, all heat transfer will be done by the heat pump. Expected Results: For this experiment it is expected that for any given temperature difference between the inlet and outlet of the indoor unit, an increase in mass flow will result in a decrease in overall COP. It is expected that the increase in power required to create a higher mass flow rate through the indoor unit will consume more power into the system when compared to the increase in heat transfer into the heated space. The following is a schedule followed by the testing group to prepare the experiment and to collect and interpret the data. Plan of Work From 1/19 to 4/25 43 Results Accessing the electrical panel on the 9RLS Fujitsu heat pump led the experiment group to find that there was a constant voltage power supply leading to the indoor unit fan motor. From this, it could be inferred that the device that regulated the actual power being drawn by the fan itself was built into the motor and could not be accessed. However, it was also found that there was a low voltage control wire also going into the motor. This voltage regulated the velocity of the fan, which directly correlates with the mass flow rate of air. Figure 3 shows the electrical panel where the control voltage was measured. Figure 4 gives a much closer look at the wires where the voltage measurement was taken. Figure 27 Electrical Panel of Indoor Unit 44 Figure 28 Close Up of Measurement points Through experimentation a relationship between air mass flow rate and control voltage has been found. Figure 5 depicts this comparison graphically, with air mass flow rate in lbm/hr and voltage in volts. It is clear that there is a direct linear correlation between voltage and mass flow rate, with an R2 of .9981. The slope of the curve is negative, meaning mass flow increases as voltage decreases. As Figure 5 shows, the equation relating control voltage of the indoor unit fan to mass flow rate can be found as Equation Eq. 6, where VC is the control voltage and mD is the average mass flow rate of air in the duct: mD = -920.5* Vc + 5109.3 Eq. 6 45 Mass Flow Rate vs. Voltage for a Fujitsu RLS90 Mini-Split Heat Pump 1800 Mass Flow Rate (lbm/hr) 1600 y = -920.5x + 5109.3 R² = 0.9981 1400 1200 Mass Flow Rates 1000 800 Linear (Mass Flow Rates) 600 400 200 0 0 1 2 3 4 5 Voltage (V) Figure 29 Comparison of Mass Flow Rate and Voltage 46 This inverse relationship between control voltage and mass flow exists due to the nature of the indoor unit fan motor. A constant 208 volt power is supplied to the fan motor, which has a speed regulator built into the motor. To vary the fan speed a control system build into the heat pump sends a small voltage signal to this regulator within the motor. As the voltage and current supplied to the fan at any one setting are constant, it is impossible to tell how much power the fan is using in relation to its mass flow rate at any one time. However, by measuring the control voltage, the above curve could be correlated. To measure these values, the control voltage was taken for each of the programmable fan settings of High, Medium, Low and Quiet. The mass flow rate was then calculated for each fan setting using a velocity profile such as in Figure 6, which is comprised of actual measurements of the flow across the duct’s width. Figure 6 specifically shows the velocity profile for the High fan setting. Velocity Profile for Air Flowing from a MiniSplit Heat Pump Through a Duct 600 Velocity (ft/min) 500 400 300 Velocity Profile 200 100 0 0 5 10 15 20 25 30 Position from Right of Duct (in.) Figure 30 Velocity Profile for the Mini-Split Unit at a High Fan Setting The test run for calculating COP was for a temperature difference of 80 F on the indoor end and 76 F on the outdoor end, and the calculations for indoor unit mass flow rate and heat transfer were found via Equation 2. This yielded an expectedly high Coefficient of Performance of 11.48. This was obtained by having a compressor work of 596.14 Btu/h, an indoor unit heat transfer of 6845.2 Btu/hr, and an indoor unit air mass flow rate of 1022.28 lbm/hr. This mass flow rate puts the fan speed at about “Low” for this application. The high efficiency is expected because of the relatively low temperature difference between the condenser (outdoor unit) and evaporator (indoor unit). 47 Appendix B – Refrigeration System Budget Part # Price per 1 Amount Price 06DA660063 $42.00 1 $42.00 06DA660062 06DA605604 06DA660057 $21.00 $43.00 $12.00 2 1 1 $42.00 $43.00 $12.00 240 V Crank Case Heater Plate Kit Terminal Box Kit 06EA660168 06EA660096 06DA660078 $23.00 1 1 1 $23.00 $0.00 $0.00 VF Water Pump MAGNA 4--120-F $1,326 2 $2,652 Part 1-1/8'' Service Valve (suction) 7/8'' Service Valve (discharge) 7/8'' Muffler Suspension Kit Structural Steel Ball Valve 1/2" Ball Valve 5/8" Ref. Line Filter Welding Stainless Steel SER Valve Yaskawa V1000 Fan to Duct Microchannel HE Flat Plate HE Desuperheater $450 EBVT-1040 EBVT-1050 C-489-G $21.92 2 $43.84 $262.30 2 SER-6/SER-11 $170 4 $524.60 $100 $800 $680 CIMRVU2A0040FAA $1,030 1 C30G 1 Total: $1,030 $2,500 $923 $3,144 $1,000 $14,009 48