File

advertisement

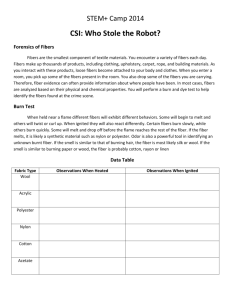

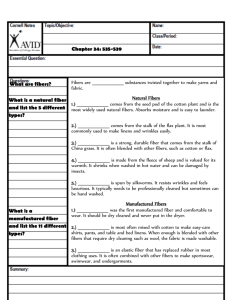

Textile Science Page 1 Fiber: The basic beginning structure of a textile. A fiber is an individual, fine, hair-like structure. Fibers are usually twisted together to make yarns, which are then woven to create a textile. Fiber is classified into two categories Natural or Synthetic Page 2 Natural Fiber Natural fibers come from plants or animals. •Plant fibers can come from stems, leaves, or even seeds of plants. •Animal fiber is produced from the fur of animals. •And even though silk comes from the cocoon of a silk worm it is still consdiered an animal fiber In this class we will focus on four natural fibers. Cotton, Wool, Linen, and Silk Page 3 Cotton Advantages •Low cost •Cool (Absorbs moisture) •Machine Washable •Soft Characteristics •Made from the cotton plant. •Least expensive of all natural fibers. •Absorbs moisture. (hydrophilic) •One of the most popular natural fibers because of its comfort level •Accepts dyes easily Disadvantages •Shrinkage •Little resiliency (ability of fabric to spring back into shape Lots of lint because of short fibers When creating clothing cotton is often mixed with another fiber to create a blend, why would this be? Proper Care •Press with Moisture •Wash on cooler temperatures to prevent shrinking Page 4 Cotton Fabrics •Canvas •Corduroy •Denim (Jeans) •Flannel •Knits Page 5 Proper Care •Care varies from washable to dry clean only • See the care label for specific care techniques Advantages •Keeps warm because of crimp and slow absorbing water vapor •Very high crimp •Durable •Repels outside moisture Keeps shape well Characteristics •Comes from animals (sheep, rabbits, goats) •Natural fire-retardant characteristics. •Absorbs moisture (Hydrophilic). •It is often used for coats, outer clothing, quality suits, etc. •Temperature Regulation Wool Disadvantages •Loses strength when wet •Wash with care •Expensive (Generally because of a •limited quantity) •Shrinks and mats Page 6 . Linen/Flax Proper Care • Varies from washable to dry cleanable only, dependent upon the quality • See the care label. • Press at highest temperatures. •Hydrophilic Advantages •Strong Looks Expensive Characteristics • Made from the flax plant. • Similar Characteristics of cotton Stronger than cotton. • Dyes easily. • Intricate weaving process • It is commonly used for spring/summer wear and fine suits Disadvantages •Wrinkles very easily •Expensive Sheer How can we tell that linen is a natural fiber? Page 7 Characteristics • Fiber is made by a silk worm • Luxury fabric. •Very hydrophobic Silk Proper Care • Varies from washable to dry cleanable only, dependent upon the quality. • See the care label. • Do not iron using moisture—water spots will not go away. Advantages •Natural luster! •Thinnest of all natural fibers •Dyes well •Excellent Drape Disadvantages •Degrades over time. •Extreme care in cleaning Sensitive to sunlight = fiber damage & Yellowing Based on what we know about silk, what will it do when put next to a flame? Page 8 How is Silk made? Page 9 A few questions about natural fibers! 1. What are two advantages of natural fibers? They are breathable, they feel good on your skin, they tend to be of a higher quality, and better for the environment in production than synthetic fibers. 2. What are the benefits of using blended fibers in fabrics? It helps provide beneficial qualities where natural fibers may lack them. For example when we mix cotton with polyester (cotton/poly blend) the garment will be much less likely to stretch and will have a higher resiliency. Blended fibers are also a cheaper option because synthetic fibers easier to produce. You will see mostly blends in clothing at department stores. Page 10 The Burn Test Tests such as a burn test help to identify different types of fiber. When burning fabric you can tell the difference between cellulose based, protein based, and synthetic based groups by looking at the ash, residue, smoke color, and odor that the fiber produced when lit. Cellulose fibers (Natural Plant based fibers) Cotton Linen *produces fine gray ash, burns only, wispy smoke* Protein fibers (Natural animal based fibers) Wool Silk *produces very strong odor, ashes in beads that can be crushed to form a black powder* Page 11 Synthetic Fibers Synthetic fibers are manufactured through the use of chemicals. They are Man Made Fibers. Synthetic fibers are made from chemical solutions that are forced through tiny holes, similar to water passing through a shower head. The device that allows this process to happen and allows the chemicals to become a filament strand is called a spinerette. In this class we will learn about 6 of these synthetic fibers Nylon Acetate Rayon Acrylic Polyester Spandex Page 12 Nylon Characteristics •Strongest synthetic fiber •Very light weight •Tears easily •The first chemically man-made fiber, invented to be used in parachutes during the war. •After the war it created a nylon craze Proper Care Advantages •When pressing, use very low temperature to prevent melting •Need to be kept clean for best performance •Can be machine washed in warm water •Tends to attract static, in order to prevent this add a fabric softener sheet during the drying cycle •Excellent strength •Lightweight •Excellent abrasion resistance •Washable Disadvantages •Doesn’t absorb moisture (hydro phobic) •Melts instead of burning •Static and pilling problems Poor resistance to prolonged and continuous sunlight Page 13 How nylon fiber is made: Nylon is made when molten nylon is forced through very small holes in a device called a spinneret. The streams of nylon harden once they come in contact with air. They are then wound onto bobbins, and sewn to create fabric. Page 14 Acrylic How acrylic fiber is made: Acrylic fabric is made of manmade acrylic fibers. Acrylic fibers are made of synthetic polymers which essentially are a soft fibrous plastic. Acrylic fiber was invented in the 1940’s and is mainly manufactured in Asia. Acrylic fabric can be made by wet or dry spinning methods. Disadvantages •Usually dry cleaned •Never use a hot iron •Fair strength, Characteristics •weak when wet Created to be similar to wool •hydrophobic •Less expensive Advantages •static and pilling problems •Washable •Light weight, but warm •Washable Proper Care •Soft •Never Iron acrylic fabric •Machine washable Page 15 Acetate Advantages •Looks like silk •Drapes well •Inexpensive •No pilling, little static •Rarely wrinkles Disadvantages •Poor strength •May fade •May wrinkle •Poor abrasion resistance •Laundering (weak when wet) Characteristics •Man made silk alternative •Soft Great drape •Resistant to shrinking •As a chemical, acetate is found in nail polish and nail polish remover. •From cellulose of deconstructing wood or cotton •Found in formal wear and clothing lining Proper Care •Usually dry clean only •Never treat with acetone How acetate fiber is made: Acetate is made from filaments of wood shavings that are extruded as liquid and set to form a fiber. The fibers are woven together to create a fabric that is similar to silk in texture and appearance. Since acetate is derived for wood, which is a natural occurring substance it is the most ecological friendly synthetic fabric. Page 16 Characteristics How rayon fiber is made: Rayon is the oldest manufactured fiber. It is Polyester alternative, and has similar qualities produced when the compound cellulose is converted to a soluble compound. The liquid of Made from wood pulp this compound is passed through a spinneret to form fiber filaments, Which are then spun into fabric Many different types by a wet or Proper Care • Some fabrics are machine washable but most are cry clean only Advantages • • Inexpensive Absorbs moisture Disadvantages Weak when wet Should be dry cleaned Not very strong Rayon Page 17 Spandex Characteristics Can stretch at least 100%, but can snap back into shape. Often blended with rayon, wool or silk Commonly used in active wear Provides elasticity to clothing Proper Care • When cleaning avoid chlorine, drying, or a hot iron. Advantages • Excellent stretch • Great recovery • Washable How spandex fiber is made: Spandex is made of numerous polymer strands. During production the polymers are stretched to their fullest capacity. After the force is removed the fibers return to its relaxed state. By using the elastic properties of the spandex fibers we can create fabrics that can have stretching capabilities. Disadvantages Not as strong when combined with other fibers Have to avoid high heat Have to avoid chlorine bleach Page 18 Polyester Characteristics Most used synthetic fiber in the US Polymer created from coal, water, and petroleum Fine to heavy weight Often mixed with other fibers to create a blended fabric Proper Care • • Disadvantages Advantages Holds oily stains Static and pilling problems Hydrophobic • • What do you predict will happen when polyester is ignited? Why? What would happen if it was mixed with another fiber? • • • • • • Washes easily on any temperature The more often you wash polyester the more likely piling is to occur Best “wash and wear” fabric Very good strength and abrasion resistance Will not shrink or stretch Resists wrinkles Washable Page 19 • Pick a Partner and Pick any Fiber of your choice • Pretend your Fiber is a person. Create a Dating profile for you fiber. Include: • • • • Likes(good characteristics about the fiber) Dislikes (bad characteristics about the fiber) A drawn picture of what that fiber would look if it were a person (BE CREATIVE HERE) What it is in search of (how we would care for that particular fiber). • Prepare a poster that would be similar to what a dating profile page would look like. • Promote your fabric, make it look good Page 20 How polyester fiber is made: Polyester is made from petroleum byproducts creating a polymer. Fibers are derived chemical reactions involving coal, petroleum, air, and water. When making polyester fabric the polymers are extruded and heated to create long, thin fibers. They are stretched when hot until they are five times their original length making a strong fiber. What is Pilling? Why does it happen? Pilling is the formation of group of short or broken fibers on the surface of a fabric. These broken fibers then tangle together to form ball called a pill. Pills usually form after the garment has been worn several times. Pilling occurs more likely on hydrophobic fibers because they have greater electrical static attraction than hydrophilic fibers do. What natural fiber is polyester normally blended with? Page 21 Burn tests on synthetic fibers All synthetic fibers because of there chemical make up will melt when contacted with heat. Most synthetic fibers, especially polyester will also create a thick black smoke when ignited. When the fiber is still hot, you will usually be able to pull long plastic strands (filaments) out of the fabric. Which type of fabric would you rather be wearing if caught in a fire? Natural or synthetic? What will nylon do will it’s exposed to flame? Let’s make a prediction. Page 22 The Acetone Test The acetone test is completed to determine if the fabric is 100% acetate or if it is a blended fabric with acetate in it. The test in administered by dropping droplets of acetone onto the fabric or by placing the fabric in a acetone solution. What do you predict will happen if we place acetate fabric in a acetone solution? Page 23