ME33: Fluid Flow Lecture 1 - McGraw Hill Higher Education

advertisement

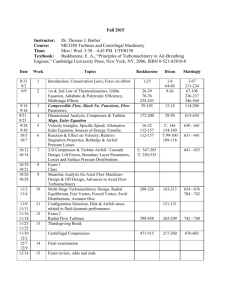

Chapter 14: Turbomachinery Eric G. Paterson Department of Mechanical and Nuclear Engineering The Pennsylvania State University Spring 2005 Note to Instructors These slides were developed1, during the spring semester 2005, as a teaching aid for the undergraduate Fluid Mechanics course (ME33: Fluid Flow) in the Department of Mechanical and Nuclear Engineering at Penn State University. This course had two sections, one taught by myself and one taught by Prof. John Cimbala. While we gave common homework and exams, we independently developed lecture notes. This was also the first semester that Fluid Mechanics: Fundamentals and Applications was used at PSU. My section had 93 students and was held in a classroom with a computer, projector, and blackboard. While slides have been developed for each chapter of Fluid Mechanics: Fundamentals and Applications, I used a combination of blackboard and electronic presentation. In the student evaluations of my course, there were both positive and negative comments on the use of electronic presentation. Therefore, these slides should only be integrated into your lectures with careful consideration of your teaching style and course objectives. Eric Paterson Penn State, University Park August 2005 1 These slides were originally prepared using the LaTeX typesetting system (http://www.tug.org/) and the beamer class (http://latex-beamer.sourceforge.net/), but were translated to PowerPoint for wider dissemination by McGraw-Hill. ME33 : Fluid Flow 2 Chapter 14: Turbomachinery Objectives Identify various types of pumps and turbines, and understand how they work Apply dimensional analysis to design new pumps or turbines that are geometrically similar to existing pumps or turbines Perform basic vector analysis of the flow into and out of pumps and turbines Use specific speed for preliminary design and selection of pumps and turbines ME33 : Fluid Flow 3 Chapter 14: Turbomachinery Categories Pump: adds energy to a fluid, resulting in an increase in pressure across the pump. Turbine: extracts energy from the fluid, resulting in a decrease in pressure across the turbine. ME33 : Fluid Flow 4 Chapter 14: Turbomachinery Categories For gases, pumps are further broken down into Fans: Low pressure gradient, High volume flow rate. Examples include ceiling fans and propellers. Blower: Medium pressure gradient, Medium volume flow rate. Examples include centrifugal and squirrelcage blowers found in furnaces, leaf blowers, and hair dryers. Compressor: High pressure gradient, Low volume flow rate. Examples include air compressors for air tools, refrigerant compressors for refrigerators and air conditioners. ME33 : Fluid Flow 5 Chapter 14: Turbomachinery Categories Positive-displacement machines Closed volume is used to squeeze or suck fluid. Pump: human heart Turbine: home water meter Dynamic machines No closed volume. Instead, rotating blades supply or extract energy. Enclosed/Ducted Pumps: torpedo propulsor Open Pumps: propeller or helicopter rotor Enclosed Turbines: hydroturbine Open Turbines: wind turbine ME33 : Fluid Flow 6 Chapter 14: Turbomachinery Pump Head Net Head Water horsepower Brake horsepower Pump efficiency ME33 : Fluid Flow 7 Chapter 14: Turbomachinery Matching a Pump to a Piping System Pump-performance curves for a centrifugal pump BEP: best efficiency point H*, bhp*, V* correspond to BEP Shutoff head: achieved by closing outlet (V=0)$ Free delivery: no load on system (Hrequired = 0) ME33 : Fluid Flow 8 Chapter 14: Turbomachinery Matching a Pump to a Piping System Steady operating point: Energy equation: ME33 : Fluid Flow 9 Chapter 14: Turbomachinery Manufacturer Performance Plot ME33 : Fluid Flow 10 Chapter 14: Turbomachinery Pump Cavitation and NPSH Cavitation should be avoided due to erosion damage and noise. Cavitation occurs when P < Pv Net positive suction head NPSHrequired curves are created through systematic testing over a range of flow rates V. ME33 : Fluid Flow 11 Chapter 14: Turbomachinery Dynamic Pumps Dynamic Pumps include centrifugal pumps: fluid enters axially, and is discharged radially. mixed--flow pumps: fluid enters axially, and leaves at an angle between radially and axially. axial pumps: fluid enters and leaves axially. ME33 : Fluid Flow 12 Chapter 14: Turbomachinery Centrifugal Pumps Snail--shaped scroll Most common type of pump: homes, autos, industry. ME33 : Fluid Flow 13 Chapter 14: Turbomachinery Centrifugal Pumps ME33 : Fluid Flow 14 Chapter 14: Turbomachinery Centrifugal Pumps: Blade Design ME33 : Fluid Flow 15 Chapter 14: Turbomachinery Centrifugal Pumps: Blade Design Side view of impeller blade. ME33 : Fluid Flow 16 Vector analysis of leading and trailing edges. Chapter 14: Turbomachinery Centrifugal Pumps: Blade Design Blade number affects efficiency and introduces circulatory losses (too few blades) and passage losses (too many blades) ME33 : Fluid Flow 17 Chapter 14: Turbomachinery Axial Pumps Open vs. Ducted Axial Pumps ME33 : Fluid Flow 18 Chapter 14: Turbomachinery Open Axial Pumps Blades generate thrust like wing generates lift. ME33 : Fluid Flow Propeller has radial twist to take into account for angular velocity (=r) 19 Chapter 14: Turbomachinery Ducted Axial Pumps Tube Axial Fan: Swirl downstream Counter-Rotating Axial-Flow Fan: swirl removed. Early torpedo designs Vane Axial-Flow Fan: swirl removed. Stators can be either pre-swirl or post-swirl. ME33 : Fluid Flow 20 Chapter 14: Turbomachinery Ducted Axial Pumps: Blade Design Relative frame of reference Absolute frame of reference ME33 : Fluid Flow 21 Chapter 14: Turbomachinery Dimensional Analysis analysis gives 3 new nondimensional parameters Head coefficient Capacity coefficient Power coefficient Reynolds number also appears,but in terms of angular rotation Reynolds number Functional relation is Head coefficient Power coefficient ME33 : Fluid Flow 22 Chapter 14: Turbomachinery Dimensional Analysis If two pumps are geometrically similar, and The independent ’s are similar, i.e., CQ,A = CQ,B ReA = ReB A/DA = B/DB Then the dependent ’s will be the same CH,A = CH,B CP,A = CP,B ME33 : Fluid Flow 23 Chapter 14: Turbomachinery Dimensional Analysis When plotted in nondimensional form, all curves of a family of geometrically similar pumps collapse onto one set of nondimensional pump performance curves Note: Reynolds number and roughness can often be neglected, ME33 : Fluid Flow 24 Chapter 14: Turbomachinery Pump Specific Speed Pump Specific Speed is used to characterize the operation of a pump at BEP and is useful for preliminary pump selection. ME33 : Fluid Flow 25 Chapter 14: Turbomachinery Affinity Laws For two homologous states A and B, we can use variables to develop ratios (similarity rules, affinity laws, scaling laws). Useful to scale from model to prototype Useful to understand parameter changes, e.g., doubling pump speed (Ex. 14-10). ME33 : Fluid Flow 26 Chapter 14: Turbomachinery