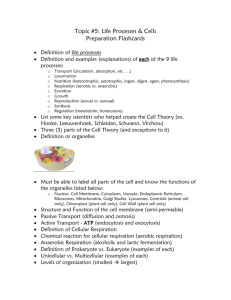

06.1 Respiration

advertisement

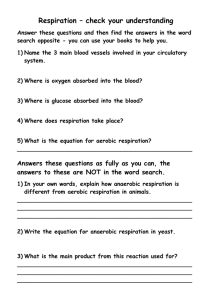

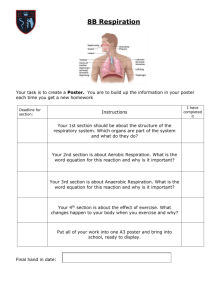

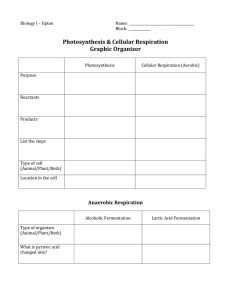

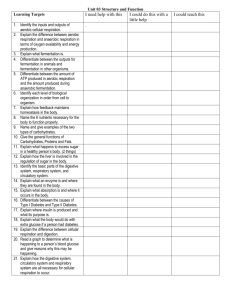

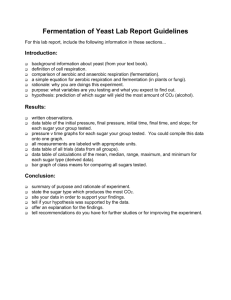

Respiration The controlled release of energy from glucose, within a cell - 24 hour process. 1 Contents Aerobic respiration Stage 1 Stage 2 Anaerobic respiration Aerobic – Biochemistry Aerobic Vs Anaerobic Industrial Fermentation Yoghurt Manufacture Beer Manufacture Use of Immobilised yeast 2 Aerobic respiration The controlled release of energy from glucose, within a cell, using oxygen. In general (aerobic respiration): Glucose + oxygen Energy + waste products Waste products = carbon dioxide + water 3 Balanced equation for Aerobic Respiration C6H1206 + 6O2 Energy + 6CO2 + 6H20 2820 kJ 4 Respiration – a one or two stage process Stage 1 does not require oxygen and releases a small amount of energy – called glycolysis. - glucose (6 carbon carbohydrate) broken down into two 3 carbon compounds (pyruvate or pyruvic acid) in the cytosol (cytoplasm minus the organelles) of the cell, with the release of ATP. - this process releases very little energy (2 5 ATP). Stage one – aerobic & anaerobic respiration 6 Respiration – a one or two stage process Stage 2 does require oxygen and releases a large amount of energy. - this process takes place in the mitochondria of the cell. Note: the rate of both processes are controlled by enzymes. 7 Anaerobic Respiration The controlled release of energy from glucose, within a cell, without using oxygen. Oxygen may be present but oxygen will not be used. This is a Stage 1 process. In general (anaerobic respiration): Glucose Energy + waste products 8 Anaerobic Respiration – waste products Waste products = lactic acid Occurs in humans – causes cramps OR Waste products = carbon dioxide + ethanol Occurs in yeast – fermentation 9 Balanced equations for Anaerobic Respiration C6H12O6 Energy + 2CH3CH(OH)COOH 150 kJ Lactic acid C6H12O6 Energy + 2C2H5OH + 2CO2 210 kJ Ethanol 10 Anaerobic respiration – summary chart OR 11 Aerobic respiration – Stage 2 (1/3) • Oxygen must be present. • The pyruvate molecule (3C) enters a mitochondrion • The pyruvate is broken down to one molecule of CO2 (1C) and Acetyl Coenzyme A (2C). 12 Aerobic respiration – Stage 2 (2/3) • Acetyl Co-enzyme A enters a series of chemical reactions, Kreb’s Cycle where it is broken down to CO2 and H. • During Kreb’s Cycle an electron transfer system operates to remove electrons from the hydrogen (H+ + e-) • Electrons from the cycle are transferred through an electron transport chain 13 Aerobic respiration – Stage 2 (3/3) • The energy released by the transport of the electrons is used to make ATP from ADP and P. ADP + P ATP • Finally the electrons are transferred to oxygen which combines with hydrogen to form water 14 Stage two – summary chart 15 Types of Respiration – comparison Aerobic Anaerobic Complete this yourself – a minimum of four points See slide 27 for solution 16 Industrial fermentation Fermentation is important in the food and drink industries. Brewing, baking, yoghurt and cheese making all depend on micro-organisms fermenting the original food to produce the desired product. These are examples of biotechnology. 17 Complete this table Original food Microorganism used Desired product Brewing Baking Yoghurt making Cheese making 18 Completed table Brewing Baking Yoghurt making Cheese making Original food Starch, sugar Microorganism used Desired product yeast Alcohol Starch yeast Carbon dioxide Milk Bacteria Lactic acid Bacteria e.g. Danish blue 19 Milk Yoghurt Manufacture (1/2) • Made from milk. • Sugar and/or powdered milk may be added. • Skimmed milk use for making low-fat yoghurt. • Milk pasteurised – kills pathogenic (disease causing) bacteria e.g. Tuberculosis bacillus, and stops growth of bacteria that sours milk. 20 Yoghurt Manufacture (2/2) • Milk cooled to 46°C and a starter culture of lactic acid bacteria is added. • Yoghurt cooled after 4 to 5 hours at 46°C – to allow growth of yoghurt microbes. • Fruit added – in a starch and sugar suspension. • Colours & flavours added. • Packed, cool and store in fridge. 21 Industrial production of Yoghurt 22 Beer Manufacture (1/2) • Made from grain – barley – food stored as starch in grain – contains the enzyme amylase – enzyme produces as it germinates. • Grain dampened, kept warm and allowed to germinate (= malting) – malt dried and stored. • Malt ground with water – allows amylase convert starch to sugar – more barley can be 23 added to increase starch supply. Beer Manufacture (2/2) • Solution boiled to stop amylase activity. • Mixture filtered. • Hops added – for flavour and to reduce the growth of unwanted bacteria. • Yeast (fungus) is added – Saccharomyces cerevisiae – fermentation begins. • Yeast removed after about a week – by filtering. • Beer bottled for distribution and sale. 24 Industrial production of Beer 25 Use of immobilised yeast Yeast cells are immobilised in sodium alginate beads. Sugar solution passed down through a bioreactor of S. cerevisiae containing beads. Alcohol produced and runs out the bottom of the column. Bioreactor can be used continuously – do not have to stop to separate yeast from alcohol. 26 Advantages of immobilised yeast • Gentle procedure • Easily recovered • Reduction in filtration procedure • Reusable 27 Types of Respiration – comparison Aerobic Oxygen necessary Anaerobic Oxygen not necessary Produces a lot of energy Produces very little energy Occurs in cytosol and mitochondria Occurs in cytosol only Consists of two stages Consists of one stage only Produces energy, CO2 and H2O Produces energy, ethanol + CO2 or energy +lactic acid 28 Back to slide 15 END 29