Disposal of HAZChem

advertisement

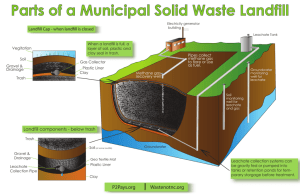

Hazardous Waste Management Hierarchy SECURED LANDFILL A controlled site for disposal of wastes on land, run in accordance with safety and environmental requirements laid down by a regulatory authority A FACILITY WHERE WASTES ARE PLACED PERMANENTLY IN SECURED MANNER WASTE IS ENCAPSULATED FROM THE ENVIRONMENT BY IMPERMEABLE BARRIERS/ LINERS LEACHATE IS COLLECTED, REMOVED & TREATED THROUGHOUT ITS LIFE. WHY LANDFILL ? All hazardous waste treatment options result in residues and One of the safer methods for disposal of them Best techno-economic option for some wastes. SECURED LANDFILL FACILITY • Last Option • Primarily Containment of contaminants TYPES OF LANDFILL ATTENUATE & DISPERSE: Sites where leachate and waste is allowed to escape into the environment at a controlled rate. Pollution is reduced by degradation and attenuation within the landfills and by dilution of the leachate in the aquifer Containment : Sites are aimed at isolating wastes and leachate from the surrounding environment for a considerable time. Archival : Sites are specifically engineered to contain wastes indefinitely, but also to permit later identification and retrieval. METHODS OF LANDFILL Co-disposal : Disposal with M.S.W or similar wastes to take advantage of attenuation processes occuring in such wastes; Critical assessment for compatibility Mono-disposal: Disposal of wastes having same general physical and chemical form Multi-disposal: Disposal of chemically different wastes in the same site MULTI-BARRIER SYSTEM FOR SLF DESIGN Barrier No: 1 Degradation or fixation of pollutants in the waste prior to disposal Barrier No: 2 Suited location of the landfill site with regard to the geological/ hydro-geological situation of the area Barrier No: 3 Leachate collection and treatment system Barrier No: 4 : Bottom Liner System Interface between waste body & subsoil hinders leachate percolation. Barrier No: 5 Cover Liner System Avoids penetration of surface and rain water into waste body avoiding formation of leachate Barrier No: 6 Proper operation and maintenance of SLF Barrier No: 7 Post Closure measures & Repairability of barriers BASIC COMPONENTS OF LANDFILL • Impermeable Liner System on the base and side • Top cover • Leachate collection, removal and treatment scheme • Surface Water Control Systems • Other site infrastructure Landfill Why the Liner is required ? Isolate the waste body from the environment Contain the toxic leachate within landfill Prevent contamination of Land and Groundwater Avoid remediation in future Which liner systems are available? Mineralic Geo-membrane Composite (Mineralic + Geo-membrane) Geo-synthetic Clay/ Bentonite Mats Bituminous Membrane Asphalt Concrete Liner BOTTOM LINER • Prevent migration of wastes or ‘by-products’ out of the landfill into subsoil, ground or surface water • Should have chemical properties, sufficient strength and thickness to prevent failure due to : - Pressure gradients - Physical contact with the waste or leachate - Climatic conditions - Stress of installation and - Stress of daily operation TYPICAL BOTTOM LINER COMBINATIONS CLAY LINER ONLY ASPHALTIC CONCRETE LINER COMPOSITE LINERS ONE CLAY LINER & ONE FLEXIBLE MEMBRANE LINER ONE CLAY LINER & TWO FLEXIBLE MEMBRANE LINERS Single Composite liner system (As per CPCB) Waste Body Leachate collection layer thickness> = 30 cm., k>=10-2 cm/s HDPE Geomembrane thickness> = 1.5 mm or more. Compacted clay/ compacted amended soil thickness >= 45 cm, k<=10-7 cm/s Sub soil Total Thickness # 45 - 60 cm DOUBLE COMPOSITE LINER (AS PER CPCB GUIDELINE) ASPHALTIC CONCRETE LINER WASTE BODY 3 SEAL LAYERS 2 BASE LAYERS FOUNDATION LAYER USEPA SPECIFICATION FOR BOTTOM LINERS Three type of liners are specified by USEPA • Flexible Membrane Liners (FMLs) • Compacted Clay Liners • Composite Clay Liners (FML + Compacted Low permeability soil liners) MATERIALS FOR FMLs Chlorosulfonated Polyethylene Linear LDPE / Very LDPE Polypropylene Ethylene Inter polymer alloy Neoprene Poly Vinyl Chloride Thermoplastic elastomers HDPE Key factors considered for selection of FML • Chemical compatability with waste leachate • Ageing and durability • Stress and strain characteristics • Ease of installation • Water permeation CPCB Specification for Geomembrane Liner Special Physical and Mechanical Requirements: 1. Performance under tensile load 2. Tear Resistance 3. Puncture Resistance Requirements with respect to Combined Physical and Chemical Attack 1. Stress Crack Resistance CPCB Specification for Geomembrane Liner Specifications of HDPE Geomembrane (thickness 1.5 mm or more) Tensile Strength at yield = > 18 kN/m. Tensile Strength at break = > 30 kN/m. Tear Resistance = > 150 N Puncture Resistance = > 250 N CLAY LINER –USEPA SPECIFICATION Thickness of compacted clay bottom liner = 3 feet Permeability of soil liners < 1 x 10-7 cm/sec To achieve this, following characteristics of soil should be met. • Soil should have at-least 20% fines i.e. fine silt and clay sized particles • Plasticity Index (PI) > 1% (soils with PI higher than 30 to 40% are sticky and difficult to work within the field) • Coarse fragments should be screened to no more than about 10% gravel size particle. • No soil particles or chunks of rock larger than 1 – 2 inches in diameter. BLENDED SOILS –USEPA SPECIFICATION • On-site soils can be blended with imported clay minerals. (e.g on-site sandy soils + imported sodium bentonite) • Calcium bentonite, lime, cement, clay soil from nearby or other areas ,etc are also used. • Clay soil is likely to form chunks and difficult and hence easier to blend on-site sandy soils with dry bentonite powder. COVER LINER (AS PERCPCB GUIDELINE) Slope 3% Cover Liner 2m Soil Bund 2m 2:1 HDPE Liner A A 0.5m 375 m 0.7 m Gravels Storm Water Drain Channel Section USEPA GUIDELINES FOR TOP LINER VEGETATIVE COVER – MIN. 60 CM THK (UPPER SLOPE : 2 TO 5 % SOIL DRAINAGE LAYER – MIN. 30 CM THK FLEXIBLE MEMBRANE LINER (MIN. 20 MILS ) COMPACTED SOIL – MIN. 60 CM THK WASTE BODY TOP LINER – NPC DESIGN VEGETATION 2 X 25 CM THK MODERATELY COMPACTED SOIL 2 X 25 CM THK WELL COMPACTED SOIL 3 MM THK POLYESTER BASED MODIFIED BITUMINOUS FELT 25 CM THK COMPACTED SOIL WASTE BODY SIDE LINER – NPC DESIGN WASTE BODY MASTIC ASPHALT LAYER 2CM THK 3 MM THK POLYESTER BASED MODIFIED BITUMINOUS FELT 75 MM THK P.C.C 1:3:6 COMPACTED SUBBASE LEACHATE COLLECTION & REMOVAL •Drainage Layer •Granular (Sand or gravel, no fine, 2-5 cm dia particle, thk, min K=1 cm/s) min.30 cm •Synthetic (nets, mats, geo-textiles) •Pipes and Appurtenances •Cushions LEACHATE STORAGE & TRANSFER Epoxy coated RCC Sump with level control submersible pump LEACHATE TREATMENT SURFACE WATER CONTROL SYSTEMS RUN-OFF Collect and control run-off from active and inactive portions of the landfill from 24 hour – 25 year storm Collect and contain leachate contaminated storm water that accumulates in active fill area Protect integrity and effectiveness of landfill cover system RUN-ON Intercept and divert run-on away from active and closed land fill cells from peak discharge of 25 year storm Minimise site erosion GROUND WATER MONITORING Designed to detect contaminant leakage shortly after its occurrence and before significant contamination of ground water Hydraulically up-gradient and down-gradient wells Placed around perimeter of fill area within several hundred feet of SLF No. of wells- Site specific, depends on Size of SLF, Hydro-geology Minimum Requirements 1 well in up-gradient (Background) 3 wells in down-gradient IDENTIFICATION OF WASTES THAT CAN BE LANDFILLED 1.Wastes that will definitely need to be landfilled as no other options are practicable e.g. Asbestos 2. Wastes that could be safely landfilled without prior treatment e.g. Bio-degradable wastes – technically possible; Better options often exist. 3.Wastes which could be landfilled after pre-treatment e.g., Liquid wastes; heavy metal salts.Pretreatment options can include detoxification, precipitation, solidification as appropriate 4. Wastes that should not be landfilled e.g., Explosives, Compressed toxic gases, Liquid PCBs for technical reasons CRITERIA FOR DISPOSAL OF H.W IN SLF • To be dewatered up to the level of 60 – 70% solids • Following are not be allowed to dispose of directly in SLF if waste - Is a fluid, slurry or paste - Is delivered under pressure or under vacuum - Has an obnoxious odour - Reacts with moisture to generate high heat or gases - Is highly inflammable (flash point < 40oC) - Contains very strong oxidising agents - Contains volatile substances of significant toxicity CRITERIA FOR DISPOSAL OF H.W IN SLF - Contains > 10 mg/Kg Cyanide in the original sample - Contains > 10 mg/kg Chromate in the original sample - Contains > 0.5% (Wt.) Mercury - Falls below a pH value of 2, if eluated 1/10 - Contains > 10 mg/1 of water soluble Arsenic in a 1/10 eluate - Contains > 10 mg/1 of water soluble Mercury in a 1/10 eluate - Contains > 3% solvents free from Halogen - Contains more than 0.5% Halogenated solvents - Contains > 0.1% poly-halogenated substances of Significant toxicity (PCBs) Criteria for Hazardous Waste Landfilling in Germany due to “Technical Instructions for HWM” 1991 ELUATE QUALITY PARAMETER VALUE pH 4 – 13 Conductivity <100,000 Total Organic Carbon <200 mg/1 Phenols <100 mg/1 Arsenic <1 mg/1 Lead <2 mg/1 Cadmium <0.5 mg/1 Chromium VI <0.5 mg/1 Copper <10 mg/1 Nickel <2 mg/1 Mercury <0.1 mg/1 Zinc <10 mg/1 Fluoride <50 mg/1 Ammonia <1,000 mg/1 S/cm ELUATE QUALITY PARAMETER VALUE Chloride <10,000 mg/1 Cyanide <1 mg/1 Sulphate <5,000 mg/1 Nitrite <30 mg/1 AOX <3 mg/1 Water sol. Content <10% STRENGTH Transversal Strength (Vane Testing) >25 kN/m2 Unconfined Compression Test >50 kN/ m2 Axial Deformation >20% DEGREE OF MINERALISATION OR CONTENT OF ORGANIC MATERIALS Annealing loss of the dry residue at 550oC <10 W.% CPCB CRITERIA FOR NON- ACCEPTANCE OF WASTE IN SLF Bulk or non-containerized liquid hazardous waste Slurry type hazardous waste containing free liquid or waste sludge Incinerable / compostable waste or any other type of waste from which energy recovery is feasible In-compatible wastes not to be placed in same landfills CPCB CRITERIA FOR NON-ACCEPTANCE OF WASTE IN SLF Wastes in-compatible with liner material without containerisation Extreme hazardous waste (e.g radioactive waste) Non-hazardous waste deposited in HW Landfills (e.g MSW) not to LIST OF INCOMPATIBLE WASTES 1 Oxidising mineral acids 1 2 Caustics H 3 Aromatic hydrocarbons H,F Halogenated organics H,F, GT 4 2 3 H, GF Metals 6 Toxic metals 7 Sat. Aliphatic Hydrocarbons H,F 8 Phenols and cresols H,F 9 Strong oxidising agents 10 Strong reducing agents 11 12 S ExPLOSIVE F FIRE GF FLAMMABLE GAS GT TOXIC GAS H HEAT GENERATION S SOLUBILISATION 4 GF, H,F 5 E H,F 5 S OF TOXINS 6 7 8 H H,F H,F H 9 GF, H H,F GT H, GT Water and mixtures containing water H H,E Water reactive substances Extremely reactive: do not mix with any chemical or waste material S H,F E 10 GF, GT 11 12 CPCB SPECIFIED DESIGN REQUIREMENTS FOR LINERS Stability at base of landfill (in soft soil) & in sides Strength to withstand construction loads/ vehicle loads Permeability and material properties as specified in guidelines Compatibility with leachate & waste Transition filters bt. Waste & leachate collection layer to prevent clogging of leachate collection layer CRITERIA FOR HAZ. WASTE LANDFILLS CONSTRUCTION & OPERATION CRITERIA INSPECTION, MONITORING & RECORD KEEPING CRITERIA POST-CLOSURE CRITERIA FINANCIAL ASSURANCE CRITERIA CONTIGENCY PLAN FOR EMERGENCIES CRITERIA FOR HAZ. WASTE LANDFILLS LOCATIONAL CRITERIA SITE SELECTION SITE INVESTIGATION CRITERIA PLANNING & DESIGN CRITERIA WASTE ACCEPTANCE CRITERIA LANDFILL CRITERIA LINER CRITERIA & COVER CPCB SPECIFIED DESIGN REQUIREMENTS FOR LINERS Protection layer / transition layer between each component of liner system may be provided Between Leachate collection layer & HDPE With Silt / local earth (15 cm thk) / Geo-textile Adequate clay additive in amended soils ASPECTS CONSIDERED IN THE DESIGN OF SLF Selection of appropriate liner system for SLF Desired design period of the SLF in years Type of landfill desired Pit (cell wise development) / continuous Depth of hard stratum from G.L. Total lay out size & total area of the SLF Nearest G.W.T. reported in monsoon season Depth of landfill below ground level Height of stock pile above ground level Inner side, bottom – longitudinal & transverse slopes Provision and layout of roads, storm water drain, green belt, office, security, lab, weigh bridge, Vehicle washing area, leachate sumps, etc around the SLF BROAD DESIGN BASIS FOR SECURED LANDFILL FACILITY Quantity of sludge generated Evolving specific sludge generation factor (I.e. ton of sludge / ton of product) Sludge generation for envisaged production in future Characteristics of sludge generated Specific gravity of dry solids in sludge Bulk density of raw sludge Sludge treatment requirements Moisture content of sludge Results of Eluation tests Chemical composition of sludge Moisture content, density & other characteristics of sludge after treatment SITE CRITERIA • Topography of the site area • Geological / Hydro-geological (characteristics of the subsoil, situation the site presence of aquifers layers, ground water table etc.) • of Rainfall situation in the region of the site area AREA REQUIREMENT FOR SLF Height of Landfill = 5- 20 m Infrastructure, support facilities & green belt = 15 -20 % of landfill Landfill size classification Small : < 5 hectares Medium : 5- 20 hectares Large : > 20 hectares QA/QC Plan during construction of SLF Permeability check of Mineralic Liner Material Testing as per specifications Compaction, Moisture content of Mineralic Liner Vacuum Testing for HDPE Joints Why does well designed SLF fail ? Improper operating practices Allowed too much liquid to enter into the landfill Cracks, punctures and physical failure of liners Clogging of leachate collection systems Consolidation may result in breaks in the liner or the cover material Disposal of solvents which affects the liner Improper Joints