CSE241 VLSI Digital Circuits Winter 2003 Lecture 03:ASIC prototyping

advertisement

CSE241

VLSI Digital Circuits

Winter 2003

Lecture 06: Timing

CSE241 L3 ASICs.1

Kahng & Cichy, UCSD ©2003

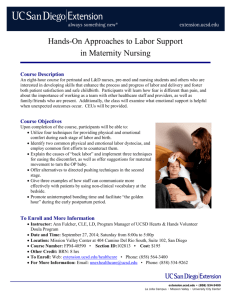

This Class + Logistics

Timing

Reading

Storage elements, Clock distribution, Clock tree synthesis

Whitepapers/datasheets on STA; papers on clock tree synthesis

Schedule

MT in one week (lab/recitation fair game); Lab #2 due Mon 1/27

HW #9: As a block’s layout is compacted down to fit into a smaller and smaller

region, the timing of the block at first improves, but then worsens. Explain.

HW #10: Hold time violations mean that the chip doesn’t work at any frequency.

Propose several distinct methods for fixing hold time violations (guided by postrouting static timing analysis), and explain the pros and cons of each.

HW #11: Compare DEC’s first Alpha and first StrongArm processors (look up

transistor counts, supply voltage, frequency, etc.). (a) How much of

StrongArm’s power efficiency can be attributed to process, supply, and

frequency scaling? (b) What factors might contribute to the remainder?

CSE241 L3 ASICs.2

Slide courtesy of S. P. Levitan, U. Pittsburg

Kahng & Cichy, UCSD ©2003

Review

Static timing analysis (Lecture 4)

Pin-based timing graph

Directed acyclic graph (DAG) of timing arcs

Longest path in DAG time linear in #arcs (edges)

Slack = required arrival time – actual arrival time (long path

analysis)

Logic synthesis (Lecture 5)

CSE241 L3 ASICs.3

Slide courtesy of S. P. Levitan, U. Pittsburg

Kahng & Cichy, UCSD ©2003

Static Analysis vs. Dynamic Analysis

Why static analysis when dynamic simulation is more

accurate?

Drawbacks of simulation

Requires input vectors (stimuli for circuit)

Long runtimes

Example: calculate worst-case rising delay from a to z

Exponential explosion with number of possible design input states

a

b

z

c

b=0

b=1

CSE241 L3 ASICs.4

c=0

a-z delay1

a-z delay3

c=1

a-z delay2

a-z delay4

Kahng & Cichy, UCSD ©2003

STA Terminology

(Actual) arrival time (AAT, or AT) = time at which a pin

switches state

Usually 50% point on voltage curve, i.e., AT = t50

Slew time = time over which signal switches

Usually difference between 10% and 90% on voltage curve, i.e.,

tslew = t90 – t10

Required arrival time (RAT) = time at which a signal must

arrive in order to avoid a chip fail

Slack = RAT – AAT

Positive slack good (= margin), negative slack bad

Vdd

CSE241 L3 ASICs.5

90

50

10

Time

Kahng & Cichy, UCSD ©2003

Example: What is slack at PO?

d=1

at=0

temp at=3

at=1

d=2

d=2

at=0

at=2 d=3

at=5

at=6

temp at=7

d=1

d=1

at=5 d=3

at=0

CSE241 L3 ASICs.6

d=5

at=8

d=3

at=11

rat=10

Slack= -1

Kahng & Cichy, UCSD ©2003

Example: Incremental Timing Analysis

d=1

at=0

temp at=3

at=1

d=2

d=2

at=0

at=2 d=3

at=0

d=1

d=5

at=5

at=6

temp at=7

d=1

d=1

at=5 d=3

d=1

at=3

d=1

at=8

at=7

at=10

d=3

at=11

rat=10

Slack = 0

Amount of work is bounded by sizes of fanin, fanout

cones of logic

CSE241 L3 ASICs.7

Kahng & Cichy, UCSD ©2003

Early-Mode Analysis

Definitions change as follows

RAT = lower bound on arrival time

Propagate shortest possible instead of longest possible delays

Slack = Arrival – Required

Example: negative slack because ATc is too small (early)

SL y 1 1 0

SLa 0 0 0

ATa 0

a

ATb 1

b

RATx 2

y

1

SLb 1 0 1

CSE241 L3 ASICs.8

AT y 1

1

c

ATc 0

SLc 0 1 1

x

ATx 1

SLx 1 2 1

Kahng & Cichy, UCSD ©2003

Enhancements of STA

Incremental timing analysis

Nanometer-scale process effects – variation (

probabilistic timing analysis)

Interference – crosstalk

Multiple inputs switching

Conservatism of delay propagation

(Old: HW #8: Suppose you change the size of one (combinational) gate in

your design, thus invalidating the previous timing analysis. How much work

must be done to regain a correct timing analysis?)

CSE241 L3 ASICs.9

Courtesy K. Keutzer et al. UCB

Kahng & Cichy, UCSD ©2003

Timing Correction

Driven by STA

Fix electrical violations

“Incremental performance analysis backplane”

Resize cells

Buffer nets

Copy (clone) cells

Fix timing problems

Local transforms (bag of tricks)

Path-based transforms

CSE241 L3 ASICs.10

DAC-2002, Physical Chip Implementation

Kahng & Cichy, UCSD ©2003

Local Synthesis Transforms

Resize cells

Move critical signals forward

Buffer or clone to reduce load on critical nets

Decompose large cells

Swap connections on commutative pins or among

equivalent nets

Pad early paths

Area recovery

CSE241 L3 ASICs.11

DAC-2002, Physical Chip Implementation

Kahng & Cichy, UCSD ©2003

Transform Example

…..

Double Inverter

Delay = 4

Removal

…..

…..

Delay = 2

CSE241 L3 ASICs.12

DAC-2002, Physical Chip Implementation

Kahng & Cichy, UCSD ©2003

Resizing

?

b

0.2

e

0.2

f

0.3

d

a

d

0.05

0.04

0.03

0.02

0.01

0

0

a

0.2

A

b

0.8

0.6

0.4

1

load

0.035

A

B

C

a

C

b

CSE241 L3 ASICs.13

0.026

DAC-2002, Physical Chip Implementation

Kahng & Cichy, UCSD ©2003

d

Cloning

0.05

0.04

0.03

0.02

0.01

0

0

0.2

0.4

0.6

0.8

1

load

A

a

?

b

d

0.2

e

0.2

f

0.2

g

h

CSE241 L3 ASICs.14

0.2

0.2

B

C

d

A

e

f

a

B

b

DAC-2002, Physical Chip Implementation

g

h

Kahng & Cichy, UCSD ©2003

d

Buffering

0.05

0.04

0.03

0.02

0.01

0

0

0.2

0.4

0.6

0.8

1

load

A

a

?

b

d

0.2

e

0.2

f

0.2

g

h

CSE241 L3 ASICs.15

B

C

d

0.2

e

0.2

a

B

b

0.2

0.2

DAC-2002, Physical Chip Implementation

0.1

B

f

0.2

g

0.2

0.2

h

Kahng & Cichy, UCSD ©2003

Redesign Fan-in Tree

Arr(a)=4

Arr(b)=3

a

b

1

e

1

Arr(c)=1

Arr(d)=0

c

Arr(e)=6

1

d

a

b

c

d

CSE241 L3 ASICs.16

1

e

1

Arr(e)=5

1

DAC-2002, Physical Chip Implementation

Kahng & Cichy, UCSD ©2003

Redesign Fan-out Tree

3

3

1

1

1

1

1

1

1

1

2

1

Longest Path = 5

CSE241 L3 ASICs.17

1

Longest Path = 4

Slowdown of buffer due to load

DAC-2002, Physical Chip Implementation

Kahng & Cichy, UCSD ©2003

Decomposition

CSE241 L3 ASICs.18

DAC-2002, Physical Chip Implementation

Kahng & Cichy, UCSD ©2003

Swap Commutative Pins

1

0

a

1

1

2

b

5

1

c

2

Simple sorting on arrival times and delay works

1

2

3

c

1

1

0

b

1

a

2

CSE241 L3 ASICs.19

DAC-2002, Physical Chip Implementation

Kahng & Cichy, UCSD ©2003

Outline

Clocking

Storage elements

Clocking metrics and methodology

Clock distribution

Package and useful-skew degrees of freedom

Clock power issues

Gate timing models

CSE241 L3 ASICs.20

Kahng & Cichy, UCSD ©2003

Why Clocks?

Clocks provide the means to synchronize

By allowing events to happen at known timing boundaries, we

can sequence these events

Greatly simplifies building of state machines

No need to worry about variable delay through

combinational logic (CL)

All signals delayed until clock edge (clock imposes the worst

case delay)

FSM

Comb

Logic

register

register

CSE241 L3 ASICs.21

register

Comb

Logic

Dataflow

Kahng & Cichy, UCSD ©2003

Clock Cycle Time

Cycle time is determined by the delay through the CL

Signal must arrive before the latching edge

If too late, it waits until the next cycle

- Synchronization and sequential order becomes incorrect

tcycle > tprop_delay + toverhead

Can change circuit architecture to obtain smaller Tcycle

CSE241 L3 ASICs.22

Kahng & Cichy, UCSD ©2003

Pipelining

For dataflow:

Instead of a long critical path, split the critical path into chunks

Insert registers to store intermediate results

This allows 2 waves of data to coexist within the CL

Can we extend this ad infinitum?

Overhead eventually limits the pipelining

- E.g., 1.5 to 2 gate delays for latch or FF

Granularity limits as well

- Minimum time quantum: delay of a gate

t

cycle

> tpd + toverhead

A

tpd1

CL

B

register

CSE241 L3 ASICs.23

CL

> max(tpd1, tpd2) + toverhead

register

tpd

register

A+B

register

register

CL

t

cycle

tpd2

Kahng & Cichy, UCSD ©2003

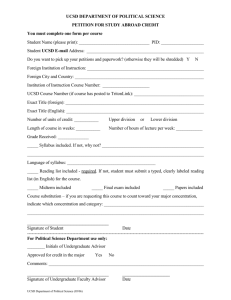

FO4 INV Delays Per Clock Period

Number of FO4 inverter delays

120.00

100.00

386

486 DX2 DX4

80.00

Pentium

Pentium MMX

Pentium Pro

60.00

Pentium II

Celeron

40.00

Pentium III

Pentium 4

20.00

0.00

1982

1987

1993

1998

2004

Year

FO4 INV = inverter driving 4 identical inverters (no interconnect)

Half of frequency improvement has been from reduced logic stages, i.e., pipelining

CSE241 L3 ASICs.24

Kahng & Cichy, UCSD ©2003

Outline

Clocking

Storage elements

Clocking metrics and methodology

Clock distribution

Package and useful-skew degrees of freedom

Clock power issues

Gate timing models

CSE241 L3 ASICs.33

Kahng & Cichy, UCSD ©2003

Clock Skew

t1 t2

Most “high-profile” of

clock network metrics

Skew

Maximum difference in

arrival times of clock

signal to any 2

latches/FF’s fed by the

network

CLK2 Time

Skew = max | t1 – t2 |

Sylvester

/ Shepard,

2001

CSE241

L3 ASICs.37

CLK1

Clock Source (ex. PLL)

Time

Time

Latency

Fig. From Zarkesh-Ha

Kahng & Cichy, UCSD ©2003

Clock Skew Causes

Designed (unavoidable) variations – mismatch in buffer load

sizes, interconnect lengths

Process variation – process spread across die yielding

different Leff, Tox, etc. values

Temperature gradients – changes MOSFET performance

across die

IR voltage drop in power supply – changes MOSFET

performance across die

Note: Delay from clock generator to fan-out points (clock

latency) is not important by itself

BUT: increased latency leads to larger skew for same amount of

relative variation

Sylvester

/ Shepard,

2001

CSE241

L3 ASICs.38

Kahng & Cichy, UCSD ©2003

Clock Jitter

Clock network delay uncertainty

From one clock cycle to the next, the period is not exactly the same

each time

Maximum difference in phase of clock between any two periods is

jitter

Must be considered in max path (setup) timing; typically O(50ps) for

high-end designs

Sylvester

/ Shepard,

2001

CSE241

L3 ASICs.39

Kahng & Cichy, UCSD ©2003

Clock Jitter Causes

PLL oscillation frequency

Various noise sources affecting clock generation and

distribution

E.g., power supply noise dynamically alters drive strength of

intermediate buffer stages

Jitter reduced by minimizing IR and L*(di/dt) noise

Courtesy Cypress Semi

Sylvester

/ Shepard,

2001

CSE241

L3 ASICs.40

Kahng & Cichy, UCSD ©2003

Clocking Methodology (Edge-Triggered)

Logic

FlipFlop

Comb

tper

Max(tpd) < tper – tsu – tc2q – tskew

Delay is too long for data to be captured

Min(tpd) > th-tc2q+tskew

Delay is too short and data can race through, skipping a state

CSE241 L3 ASICs.41

Kahng & Cichy, UCSD ©2003

Example of tpdmax Violation

Suppose there is skew between the registers in a dataflow

(regA after regB)

“i” gets its input values from regA at transition in Ck’

CL output “o” arrives after Ck transition due to skew

To correct this problem, can increase cycle time

Ck’

i

Comb

Logic

o

regB

regA

tskew

Ck

tpdmax

Ck

Too late!

Ck’

i

CSE241 L3 ASICs.42

o

tpdmax

Kahng & Cichy, UCSD ©2003

Example of tpdmin Violation: Race Through

Suppose clock skew causes regA to be clocked before regB

“i” passes through the CL with little delay (tpdmin)

“o” arrives before the rising Ck’ causes the data to be latched

Cannot be fixed by changing frequency have rock instead of chip

Ck’

Ck

tskew

Comb

Logic

o

regB

regA

i

tpdmin

Ck

Ck’

i

Too early!

tpdmin

o

CSE241 L3 ASICs.43

Kahng & Cichy, UCSD ©2003

Outline

Clocking

Storage elements

Clocking metrics and methodology

Clock distribution

Package and useful-skew degrees of freedom

Clock power issues

Gate timing models

CSE241 L3 ASICs.45

Kahng & Cichy, UCSD ©2003

Clock Distribution

General goal of clock distribution

Deliver clock to all memory elements with acceptable skew

Deliver clock edges with acceptable sharpness

Clocking network design is one of the greatest challenges

in the design of a large chip

Clocks generally distributed via wiring trees (and meshes)

Low-resistance interconnect to minimize delay

Multiple drivers to distribute driver requirements

Use optimal sizing principles to design buffers

Clock lines can create significant crosstalk

CSE241 L3 ASICs.46

Kahng & Cichy, UCSD ©2003

Clock Distribution Problem Statement

Objective

Minimum skew (performance and hold time issues)

Minimum cell area and metal use

(sometimes) minimal latency

(sometimes) particular latency

(sometimes) intermixed gating for power reduction

(sometimes) hold to particular duty cycle: e.g. 50:50 +- 1 percent

Subject to:

Process variation from lot-to-lot

Process variation across the die

Radically different loading (ff density) around the die

Metal variation across the die

Power variation across the die (both static IR and dynamic)

Coupling (same and other layers)

CSE241 L3 ASICs.47

Kahng & Cichy, UCSD ©2003

Issues in Clock Distribution Network Design

Skew

Process, voltage, and temperature

Data dependence

Noise coupling

Load balancing

Power, CV2f – (no ½ or a)

Clock gating

Flexibility/Tunability

Compactness – fit into existing layout/design

Reliability

Electromigration

CSE241 L3 ASICs.48

Kahng & Cichy, UCSD ©2003

Skew: Clock Delay Varies With Position

CSE241 L3 ASICs.49

Kahng & Cichy, UCSD ©2003

Clock Distribution Methods

RC-Tree

Less capacitance

More accuracy

Flexible wiring

CSE241 L3 ASICs.50

Grids

Reliable

Less data dependency

Tunable (late in design)

Shown here for final stage drivers driving F/F loads

Kahng & Cichy, UCSD ©2003

RC-Trees

H-Tree

X-Tree

Binary-Tree

Asymmetric trees can and are used due to uneven sink

distribution, hard macros in floorplan ( hierarchical clock

distribution), etc.; the basic goal is to have even RC delays

CSE241 L3 ASICs.51

Kahng & Cichy, UCSD ©2003

Grids

Gridded clock distribution common on

earlier DEC Alpha microprocessors

Advantages:

Skew determined by grid density, not

too sensitive to load position

Clock signals available everywhere

Tolerant to process variations

Usually yields extremely low skew

values

Disadvantages:

Predrivers

Global

grid

Huge amount of wiring and power

To minimize such penalties, need to

make grid pitch coarser lose the grid

advantage

Sylvester

/ Shepard,

2001

CSE241

L3 ASICs.52

Kahng & Cichy, UCSD ©2003

Trees

H-tree (Bakoglu)

One large central driver, recursive structure to

match wirelengths

Halve wire width at branching points to reduce

reflections

Disadvantages

Slew degradation along long RC paths

Unrealistically large central driver

courtesy of P. Zarkesh-Ha

- Clock drivers can create large temperature

gradients (ex. Alpha 21064 ~30° C)

Non-uniform load distribution

Inherently non-scalable (wire R growth)

Partial solution: intermediate buffers at branching

points

Sylvester

/ Shepard,

2001

CSE241

L3 ASICs.53

Kahng & Cichy, UCSD ©2003

Buffered Tree

L2

Drives all clock

loads within its

region

L3

NGBuf

WGBuf

PLL

Sylvester

/ Shepard,

2001

CSE241

L3 ASICs.54

EGBuf

SGBuf

Other regions

of the chip

Kahng & Cichy, UCSD ©2003

Buffered H-tree

Advantages

Ideally zero-skew

Can be low power (depending on skew requirements)

Low area (silicon and wiring)

CAD tool friendly (regular)

Disadvantages

Sensitive to process variations

- Devices Want same size buffers at each level of tree

- Wires Want similar segment lengths on each layer in each source-sink

path !!!

Local clocking loads inherently non-uniform

Sylvester

/ Shepard,

2001

CSE241

L3 ASICs.55

Kahng & Cichy, UCSD ©2003

Tree Balancing

Some techniques:

Con: Routing area

often more valuable

than Silicon

a) Introduce dummy loads

b) Snaking of wirelength to match delays

Sylvester

/ Shepard,

2001

CSE241

L3 ASICs.56

Kahng & Cichy, UCSD ©2003

Examples From Processor Chips

H-Tree, Asymmetric

RC-Tree (IBM)

Grids

DEC [Alphas]

Serpentines

Intel x86

[Young ISSCC97]

CSE241 L3 ASICs.57

Kahng & Cichy, UCSD ©2003

Examples From Processor Chips

DEC-Alpha 21064 clock spines

DEC-Alpha 21064 RC delays

DEC-Alpha 21164 RC local delays

DEC-Alpha 21164 RC delays for Global

Distribution

(Spine + Grid)

CSE241 L3 ASICs.58

Kahng & Cichy, UCSD ©2003

ReShape Clocks Example (High-End ASIC)

Balanced, shielded H-tree for pre-clock distribution

Mesh for block level distribution

CSE241 L3 ASICs.59

Kahng & Cichy, UCSD ©2003

Pre-clock 2 Level H-tree

All routes 5-6u M6/5,

shielded with 1u

grounds

~10 buffers per node

E.g., ganged BUFx20’s

Output mesh must hit

every sub-block

output mesh

CSE241 L3 ASICs.60

Kahng & Cichy, UCSD ©2003

Block Level Mesh (.18u)

Clumps of 1-6 clock buffers, surrounded by

capacitor pads

Shielded input and output m6 shorting straps

Pre-clock connects to input shorting straps

1u m5 ribs every 20 - 30 u

(4 to 6 rows)

Max 600u stride

CSE241 L3 ASICs.61

Kahng & Cichy, UCSD ©2003

Problems with Meshes

Burn more power at low frequencies

Difficult for ‘spare’ clock domains that will not tolerate

regioning

Post placement (and routing) tuning required

Blocks more routing resources (solution, integrated

power distribution with ribs can provide shielding for

‘free’)

No ‘beneficial skew’ possible

CSE241 L3 ASICs.62

Kahng & Cichy, UCSD ©2003

Problems with Meshes (#2)

Clock gating only easy at root

Fighting tools to do analysis:

Clumped buffers a problem in Static Timing Analysis tools

Large shorted meshes a problem for STA tools

What does Elmore delay calculation look like for a non-tree?

Need full extractions and spice-like simulation (e.g.

Avant! Star-Sim) to determine skew

CSE241 L3 ASICs.63

Kahng & Cichy, UCSD ©2003

Benefits of Meshes (#3)

Deterministic since shielded all the way down to rib

distribution

No ECO placement required: all buffers preplaced

before block placement

Low latency since uses shorted (= ganged, parallel)

drivers, therefore lower skew

ECO placements of FFs later do not require rebalance of

tree

“Idealized” clocking environment for concurrent RTL

design and timing convergence dance

CSE241 L3 ASICs.64

Kahng & Cichy, UCSD ©2003

Mesh Example

~ 100k flops

6 blocks

CSE241 L3 ASICs.65

Kahng & Cichy, UCSD ©2003

Clock Skew Thermal Map

Pre-tuning

CSE241 L3 ASICs.66

Kahng & Cichy, UCSD ©2003

Clock Skew Thermal Map #2

50ps block/ 100ps global skew, post tuning

CSE241 L3 ASICs.67

Kahng & Cichy, UCSD ©2003

Alternative Clock Network Strategy

Globally – Tree

Power requirements

reduced relative to global

grid

Smaller routing

requirements, frees up

global tracks

Trees balanced easily at

global level

Keeps global skew low

(with minimal process

variation)

Sylvester

/ Shepard,

2001

CSE241

L3 ASICs.68

Kahng & Cichy, UCSD ©2003

Vertex Locations in a Bounded-Skew Tree

Given a skew bound, where can internal nodes of the given topology

(e.g., a, b, v) be placed?

skew

0

a

2

4

6

6

2

4

2

2

v

6

s0

v

a

CSE241 L3 ASICs.69

4

skew

0

b

Topology

s1 s2 s3 s4

4

b

6

Kahng & Cichy, UCSD ©2003

Deferred-Merge Embedding (DME) Algorithm

Bottom-Up: build tree of merging

regions corresponding to given

topology

B=4

s0

a

b

mr(a)

mr(v)

s3

mr(b)

Special case: skew = 0 merging segments

CSE241 L3 ASICs.70

Topology

s1 s2 s3 s4

s2

s0

s1

v

s4

Kahng & Cichy, UCSD ©2003

Top-Down Embedding Phase of DME

s0

Top-Down: choose embedding

points within merging regions

a

s0

s1

a

b

Topology

s1 s2 s3 s4

s2

B=4

v

v

s3

b

s4

CSE241 L3 ASICs.71

Kahng & Cichy, UCSD ©2003

Zero-Skew Example (555 sinks, 40 obstacles)

CSE241 L3 ASICs.72

Kahng & Cichy, UCSD ©2003

Outline

Clocking

Storage elements

Clocking metrics and methodology

Clock distribution

Package and useful-skew degrees of freedom

Clock power issues

Gate timing models

CSE241 L3 ASICs.73

Kahng & Cichy, UCSD ©2003

Skew Reduction Using Package

• Most clock network

latency occurs at global

level (largest distances

spanned)

• Latency Skew

• With reverse scaling,

routing low-RC signals

at global level becomes

more difficult & areaconsuming

Sylvester

/ Shepard,

2001

CSE241

L3 ASICs.74

Kahng & Cichy, UCSD ©2003

Skew Reduction Using Package

mP/ASIC

Solder bump

substrate

System

clock

Incorporate global

clock distribution into the

package

Flip-chip packaging

allows for high density,

low parasitic access from

substrate to IC

Sylvester

/ Shepard,

2001

CSE241

L3 ASICs.75

• RC of package-level wiring up

to 4 orders of magnitude smaller

than on-chip wiring

• Global skew reduced

• Lower capacitance lower

power

• Opens up global routing tracks

• Results not yet conclusive

Kahng & Cichy, UCSD ©2003

Useful Skew (= cycle-stealing)

Zero skew

FF

fast

FF

Useful skew

slow

FF

FF

fast

FF

slow

FF

Timing Slacks

hold

setup

hold

setup

Zero skew

• Global skew constraint

• All skew is bad

W. Dai,

UC Santa

Cruz

CSE241

L3 ASICs.76

hold

setup

hold

setup

Useful skew

• Local skew constraints

• Shift slack to critical paths

Kahng & Cichy, UCSD ©2003

Skew = Local Constraint

Timing is correct as long as the signal arrives in the

permissible skew range

FF

-d + thold

race condition

<

D : longest path

d : shortest path

Skew

FF

<

safe

Tperiod - D - tsetup

cycle time violation

permissible range

W. Dai,

UC Santa

Cruz

CSE241

L3 ASICs.77

Kahng & Cichy, UCSD ©2003

Skew Scheduling for Design Robustness

Design will be more robust if clock signal arrival time is in

the middle of permissible skew range, rather than on edge

Can solve a linear program to maximize robustness =

determine prescribed sink skews

FF

FF

2 ns

6 ns

4

FF

T = 6 ns

0

“0 0 0”: at verge of violation

4

0

“2 0 2”: more safety margin

2

W. Dai,

UC Santa

Cruz

CSE241

L3 ASICs.78

-2

Kahng & Cichy, UCSD ©2003

Potential Advantages of Useful Skew

Reduce peak current consumption by distributing the FF switch

point in the range of permissible skew

CLK

CLK

0-skew

U-skew

Affords extra margin to increase clock frequency or reduce sizing

(= power)

W. Dai,

UC Santa

Cruz

CSE241

L3 ASICs.79

Kahng & Cichy, UCSD ©2003

Conventional Zero-Skew Flow

Synthesis

Placement

0-Skew Clock Synthesis

Clock Routing

Signal Routing

Extraction & Delay Calculation

Static Timing Analysis

W. Dai,

UC Santa

Cruz

CSE241

L3 ASICs.80

Kahng & Cichy, UCSD ©2003

Useful-Skew Flow

Permissible range generation

Existing Placement

Initial skew scheduling

U-Skew Clock Synthesis

Clock tree topology synthesis

Clock net routing

Clock Routing

Clock timing verification

Signal Routing

Extraction & Delay Calculation

Static Timing Analysis

W. Dai,

UC Santa

Cruz

CSE241

L3 ASICs.81

Kahng & Cichy, UCSD ©2003

Outline

Clocking

Storage elements

Clocking metrics and methodology

Clock distribution

Package and used-skew degrees of freedom

Clock power issues

Gate timing models

CSE241 L3 ASICs.82

Kahng & Cichy, UCSD ©2003

Clock Power

Power consumption in clocks due to:

Clock drivers

Long interconnections

Large clock loads – all clocked elements (latches, FF’s) are driven

Different components dominate

Depending on type of clock network used

Ex. Grid – huge pre-drivers & wire cap. drown out load cap.

Sylvester

/ Shepard,

2001

CSE241

L3 ASICs.83

Kahng & Cichy, UCSD ©2003

Clock Power Is LARGE

P = a C Vdd2 f

Not only is the clock capacitance large, it

switches every cycle!

Sylvester

/ Shepard,

2001

CSE241

L3 ASICs.84

Kahng & Cichy, UCSD ©2003

Low-Power Clocking

Gated clocks

Prevent switching in areas of chip not being used

Easier in static designs

Edge-triggered flops in ARM rather than transparent latches

in Alpha

Reduced load on clock for each latch/flop

Eliminated spurious power-consuming transitions during latch flowthrough (transparency)

Sylvester

/ Shepard,

2001

CSE241

L3 ASICs.85

Kahng & Cichy, UCSD ©2003

Clock Area

Clock networks consume silicon area (clock drivers, PLL,

etc.) and routing area

Routing area is most vital

Top-level metals are used to reduce RC delays

These levels are precious resources (unscaled)

Power routing, clock routing, key global signals

Reducing area also reduces wiring capacitance and power

Typical #’s: Intel Itanium – 4% of M4/5 used in clock routing

Sylvester

/ Shepard,

2001

CSE241

L3 ASICs.86

Kahng & Cichy, UCSD ©2003

Clock Slew Rates

To maintain signal integrity and latch performance, minimum

slew rates are required

Too slow – clock is more susceptible to noise, latches are slowed

down, setup times eat into timing budget [Tsetup = 200 + 0.33 * Tslew

(ps)], more short-circuit power for large clock drivers

Too fast – burns too much power, overdesigned network, enhanced

ground bounce

Rule-of-thumb: Trise and Tfall of clock are each between 1020% of clock period (10% - aggressive target)

1 GHz clock; Trise = Tfall = 100-200ps

Sylvester

/ Shepard,

2001

CSE241

L3 ASICs.87

Kahng & Cichy, UCSD ©2003

Example: Alpha 21264

Grid + H-tree approach

Power = 32% of total

Wire usage = 3% of

metals 3 & 4

4 major clock quadrants, each with a large driver

connected to local grid structures

Sylvester

/ Shepard,

2001

CSE241

L3 ASICs.88

Kahng & Cichy, UCSD ©2003

Alpha 21264 Skew Map

Ref: Compaq, ASP-DAC00

Sylvester

/ Shepard,

2001

CSE241

L3 ASICs.89

Kahng & Cichy, UCSD ©2003

Power vs. Skew

Fundamental design decision

Meeting skew requirements is easy with unlimited

power budget

Wide wires reduce RC product but increase total C

Driver upsizing reduces latency ( reduces skew as well)

but increases buffer cap

SOC context: plastic package power limit is 2-3 W

Sylvester

/ Shepard,

2001

CSE241

L3 ASICs.90

Kahng & Cichy, UCSD ©2003

Clock Distribution Trends

Timing

Clock period dropping fast, skew must follow

Slew rates must also scale with cycle time

Jitter – PLL’s get better with CMOS scaling but other sources of noise

increase

- Power supply noise more important

- Switching-dependent temperature gradients

Materials

Cu reduces RC slew degradation, potential skew

Low-k decreases power, improves latency, skew, slews

Power

Complexity, dynamic logic, pipelining more clock sinks

Larger chips bigger clock networks

Sylvester

/ Shepard,

2001

CSE241

L3 ASICs.91

Kahng & Cichy, UCSD ©2003

Outline

Clocking

Storage elements

Clocking metrics and methodology

Clock distribution

Package and useful-skew degrees of freedom

Clock power issues

Gate timing models

CSE241 L3 ASICs.92

Kahng & Cichy, UCSD ©2003

Gate Timing Characterization

A

CL

B

D

F

CL

“Extract” exact transistor characteristics from layout

Transistor width, length, junction area and perimeter

Local wire length and inter-wire distance

Compute all transistor and wire capacitances

CSE241 L3 ASICs.93

Kahng & Cichy, UCSD ©2003

Cell Timing Characterization

Delay tables generated using a detailed transistor-level

circuit simulator SPICE (differential-equations solver)

For a number of different input slews and load

capacitances simulate the circuit of the cell

Propagation time (50% Vdd at input to 50% at output)

Output slew (10% Vdd at output to 90% Vdd at output)

tslew

Vdd

tpd

Time

CSE241 L3 ASICs.94

Kahng & Cichy, UCSD ©2003

Delay and Transition Measurement

Transition

80%

50%

20%

Cell Delay

CSE241 L3 ASICs.95

Kahng & Cichy, UCSD ©2003

Non-linear effects reflected in tables

DG = f (CL, Sin) and Sout = f (CL, Sin)

Non-linear

Interpolate between table entries

Interpolation error is usually below 10% of SPICE

Output

Capacitance

Output

Capacitance

Input

Slew

Intrinsic

Delay

Delay at the gate

CSE241 L3 ASICs.96

Input

Slew

Output

Slew

Resulting waveform

Kahng & Cichy, UCSD ©2003

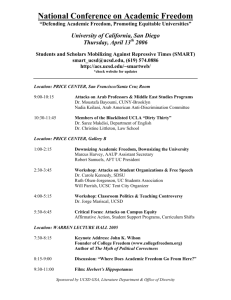

Timing Library Example (.lib)

library(my_lib) {

fall_transition(load) {

delay_model : table_lookup;

cell("INV") {

library_features (report_delay_calculation);

pin(A) {

index_1( "0.0326, 0.1614, 0.4192, 1.5017" );

time_unit : "1ns";

max_transition : 1.500000;

index_2( "0.0010, 0.4249, 2.1491, 8.1881" );

voltage_unit : "1V";

direction : input;

values ( \

current_unit : "1mA";

rise_capacitance : 0.0739000;

leakage_power_unit : 1uW;

fall_capacitance : 0.0703340;

capacitive_load_unit(1,pf);

"0.011974, 0.071668, 0.317800, 1.189560", \

"0.033212, 0.101182, 0.328540, 1.189562", \

capacitance : 0.07278646;

pulling_resistance_unit : "1kohm";

}

default_fanout_load : 1.0;

pin(Z) {

"0.059282, 0.155052, 0.389900, 1.202360", \

"0.162830, 0.317380, 0.628160, 1.441260" );

default_inout_pin_cap : 1.0;

direction : output;

default_input_pin_cap : 1.0;

function : "!A";

}

default_output_pin_cap : 0.0;

max_transition : 1.500000;

rise_transition(load) {

default_cell_leakage_power : 0.0;

max_capacitance : 5.1139;

index_1( "0.0375, 0.1650, 0.5455, 1.5078" );

timing() {

nom_voltage : 1.08;

related_pin : "A";

index_2( "0.0010, 0.4449, 1.7753, 5.1139" );

nom_temperature : 125.0;

cell_rise(load) {

values ( \

nom_process : 1.0;

index_1( "0.0375, 0.2329, 0.6904, 1.5008" );

slew_derate_from_library : 0.500000;

index_2( "0.0010, 0.9788, 2.2820, 5.1139" );

"0.016690, 0.115702, 0.418200, 1.189060", \

"0.038256, 0.139336, 0.422960, 1.189081", \

values ( \

operating_conditions("slow_125_1.08") {

process

"0.013211, 0.071051, 0.297500, 0.642340", \

: 1.0 ;

temperature : 125 ;

voltage

}

"0.170992, 0.353120, 0.694740, 1.384760" );

"0.053289, 0.165930, 0.496550, 0.860400", \

: 1.08 ;

tree_type : "worst_case_tree" ;

"0.076248, 0.213280, 0.491820, 1.203700", \

"0.028657, 0.110849, 0.362620, 0.707070", \

}

"0.091041, 0.234440, 0.661840, 1.091700" );

}

}

cell_fall(load) {

default_operating_conditions : slow_125_1.08 ;

index_1( "0.0326, 0.1614, 0.5432, 1.5017" );

index_2( "0.0010, 0.4249, 3.6538, 8.1881" );

lu_table_template("load") {

values ( \

variable_1 : input_net_transition;

"0.009472, 0.072284, 0.317370, 0.688390", \

variable_2 : total_output_net_capacitance;

"0.009992, 0.095862, 0.360530, 0.731610", \

index_1( "1, 2, 3, 4" );

"0.009994, 0.126620, 0.477260, 0.867670", \

index_2( "1, 2, 3, 4" );

}

"0.009996, 0.144150, 0.644140, 1.127700" );

}

CSE241 L3 ASICs.97

Kahng & Cichy, UCSD ©2003

Delay Calculation

Cell Fall

Cap\Tr

0.05

0.2

0.5

0.01

0.02

0.16

0.30

0.5

0.04

0.32

0.60

2.0

0.178

0.08

0.64

1.20

0.147ns

0.1ns

Cell Rise

Cap\Tr

0.05

0.2

0.5

0.01

0.03

0.18

0.33

0.5

0.06

0.36

0.66

2.0

0.09 0.261

0.72

1.32

Fall Transition

Cap\Tr

0.05

0.2

0.5

0.01

0.01

0.09

0.15

0.5

0.03

0.27

0.45

2.0

0.06 0.147

0.54

0.90

CSE241 L3 ASICs.98

0.12ns

1.0pf

Fall delay = 0.178ns

Rise delay = 0.261ns

Fall transition = 0.147ns

Rise transition = …

Kahng & Cichy, UCSD ©2003

PVT (Process, Voltage, Temperature) Derating

Actual cell delay = Original delay x KPVT

CSE241 L3 ASICs.99

Kahng & Cichy, UCSD ©2003

PVT Derating: Example + Min/Typ/Max Triples

Proc_var (0.5:1.0:1.3)

Voltage (5.5:5.0:4.5)

Temperature (0:20:50)

KP = 0.80 : 1.00 : 1.30

KV = 0.93 : 1.00 : 1.08

KT = 0.80 : 1.07 : 1.35

KPVT = 0.60 : 1.07 : 1.90

Cell delay = 0.261ns

Derated delay = 0.157 : 0.279 : 0.496 {min : typical : max}

CSE241 L3 ASICs.100

Kahng & Cichy, UCSD ©2003

Conservatism of Gate Delay Modeling

True gate delay depends on input arrival time

patterns

STA will assume that only 1 input is switching

Will use worst slope among several inputs

Vdd

A

A

B

tpd

F

B

D

F

CL

Time

Vdd

A

CSE241 L3 ASICs.101

tpd

F

Time

Kahng & Cichy, UCSD ©2003