Bast Fibers

advertisement

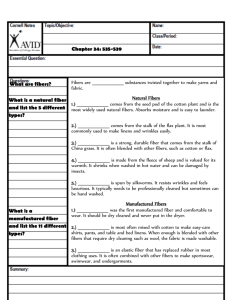

FASH 15 textiles bast fibers bast fibers bast fibers come from the stem of the plant, near the outer edge harvested: • by hand where labor is cheap • by pulling up entire plant (10% longer than cut) • by cutting as close to the ground as possible after harvesting: • seeds removed using a rippling machine • retting decomposes pectin holding fibers together • woody portion is removed by scutching • short and irregular fibers removed by hackling http://www.youtube.com/watch?v=HCJQCWDIozk http://www.youtube.com/watch?v=KwfIhPAcrcU&NR=1 flax one of the oldest documented textile fibers—Egyptian tombs more than 3000 years old prestige fiber due to limited production & relatively high cost—linen most flax is produced in Western Europe: • • • • Belgium France Italy Ireland • • • • United Kingdom Germany The Netherlands Switzerland flax—structure individual fiber cells—ultimates—are spindle-shaped with pointed ends and a central lumen primary fiber averages 5.0-21.5 inches in length & 1216 micrometers in diameter can be identified microscopically by crosswise markings— nodes or joints cross-section is many-sided or polygonal with round edges flax—structure fibers are slightly grayish when dew retted; more yellow when water retted stronger than cotton due to highly oriented molecular structure similar to cotton in chemical Composition—71% cellulose short flax fibers are called tow long, combed, better-quality fibers are called line flax—aesthetics flax has a high natural luster that is softened by its irregular fiber bundles—luster can be increased by flattening stiffer in drape and harsher in hand than cotton— finishes can produce softer, more drapeable fabrics flax—durability strong for a natural fiber—higher breaking tenacity when wet • very low elongation • elasticity is poor • stiff fiber repeatedly folding a linen in the same place will cause fabric to break nodes contribute to flexibility but are the weakest part of the fiber flax—comfort & care • high moisture regain of 12%—absorbent • good conductor of heat better for hot or cool weather? • resistant to alkalis, organic solvents, & high temps • can be dry-cleaned, machine-washed & bleached with chlorine bleach for upholstery & wall coverings, careful steam cleaning is recommended to avoid shrinkage • low resiliency—often require pressing • more sunlight resistant than cotton • store dry otherwise will mildew flax—environmental concerns/sustainability less of an environmental impact than cotton requires fewer chemicals & seldom irrigated pulling plants at harvest contributes to soil erosion depending upon retting practiced, disposal of chemicals & contaminated water are of concern—dew & enzyme retting are more sustainable than water retting hand labor needs to be monitored to avoid exploitation of workers flax—identification burns readily in manner similar to cotton fiber length is easy way to differentiate between cotton & flax—cotton seldom longer than 2.5 inches; flax almost always longer than that soluble in strong acids http://textilemania.textilefabric.com/u_1/u_1_5.html flax—uses used in bed, table, and bath items for residential & commercial use as well as apparel & technical products ideal for wall coverings up to 120 inches wide due to irregular texture which: • • • • adds visual interest hides nail holes wall damage muffles noise used in upholstery & window treatments due to: • durability • interesting & soil-hiding textures • versatility flax—uses linen apparel includes items for: • warm-weather use • high fashion • casual • professional wear technical products include: • luggage • bags • purses • sewing thread ramie also known as rhea, grasscloth, China grass, Army/Navy cloth—used for several thousand years in China ramie plant is a tall perennial shrub—requires hot, humid climate—cut, not pulled fast-growing & can be harvested as frequently as every 60 days separated from stalk by decortication—bark & woody stalk separated from fiber— became more commercially important once mechanized ramie • relatively inexpensive • can be cottonized and blends well with other fibers produced in China, Brazil, the Phillipines, South Korea, Taiwan, Thailand, & India must be degummed by boiling in weak alkaline solution to remove wax & pectin and separate fiber bundles ramie—properties white, long, fine fiber with a silklike luster similar to flax in absorbency, density & microscopic appearance because of high molecular crystallinity and orientation, ramie is stiff and brittle like flax, will break if folded repeatedly in same place—lacks resiliency, low in elasticity & elongation potential ramie—properties one of the strongest natural fibers know—strength increases when wet resistant to insects, rotting, mildew & shrinkage absorbency is good, does not dye as well as cotton— can be mercerized to enhance dye absorbency does not retain color well unless it is dry-cleaned ramie—uses used in many imported apparel items—sweaters, shirts, blouses & suits important in interiors for window treatments, pillows & table linens often blended with other natural fibers used in ropes, twines, nets, banknotes, cigarette paper, and geotextiles for ground-cover fabrics (erosion control) hemp resembles flax in macroscopic & microscopic appearance—some varieties very difficult to distinguish from flax hemp is coarser & stiffer than flax—processing & cottonizing minimizes these differences hemp fibers can be very long—3-15 feet processed similar to flax with similar environmental issues—depending on processing, fiber may be creamy white, brown, gray, almost black, or green 78% cellulose & can be machine washed and dried hemp plant produces 3 types of fibers: • • • bast fibers from outer region—longest & finest; most often used in 100% hemp and blend fabrics with linen, cotton or silk for apparel & interiors inner two fibers are shorter & most often used in nonwovens & other technical applications innermost woody core fibers are used for mulch and pet & animal bedding resistant to ultraviolet light, mold & rotting high strength makes it particularly suitable for twine, cordage & thread fell out of popularity in 40s due to drug regulations— new varieties grown for fiber have less than 1% THC hemp used for some apparel & interiors—found in hats, shirts, shoes, backpacks, t-shirts & jeans environmentally friendly— • • • • does not require pesticides; grows so quickly that it smothers weeds root systems minimize soil erosion 20-30% of plant is fiber—produces 250% more than cotton; 600% more than flax on same land being grown on land to extract pollutants—zinc, mercury most imported from China & Philippines; also grown in Italy, France, Chile, Russia, Poland, India & Canada jute 61% cellulose—one of cheapest & weakest natural fibers—primary fibers in bundle are short & brittle grown throughout Asia, chiefly India & Bangladesh creamy white to brown in color—white, soft, lustrous & pliable when first removed from stalk; quickly turns brown, weak & brittle used to produce sugar & coffee bagging, carpet backing, rope, cordage, & twine—facing strong competition from olefin deteriorates quickly when exposed to water; low sunlight resistance; poor colorfastness kenaf soft bast fiber from kenaf plant fiber is long, light yellow to gray and harder & more lustrous than jute like jute, used for twine, cordage & other technical purposes produced in Central Asia, India, Africa, & some Central American countries being investigated by researchers as paper fiber source & in blends with cotton hibiscus from same general botanical family as cotton—grows as a tall shrub in tropical & subtropical regions commercially grown & used for clarifying sugar cane juice—waste material studied for fiber potential retting is required to extract fiber from plant stem can be bleached; has good fastness when dyed with direct dyes stronger than jute—has potential for use in bags, rugs & some apparel items when used in blends nettle two types—Himalayan giant nettle plant or stinging nettle hollow fiber look and feels similar to raw flax—has good insulating characteristics perennial that grows without use of fertilizers or pesticides—studied as potentially sustainable fiber used for technical products like bags & ropes as well as apparel & interior textiles 48% cellulose—similar in shape to ramie but stronger; coarser than jute bamboo two types—one removed from above-ground stems; other regenerated from bamboo pulp (ch. 7) naturally resistant to microbes; absorbent; coarse hand not usually found in apparel or interiors type of grass—grows quickly without use of chemicals most harvested regularly from managed farms—does not threaten wild bamboo forests or natural habitats leaf fibers obtained from leaf of a plant—fiber is split or pulled from leaf during processing most are long and stiff and have limited dye affinity pina from leaves of pineapple plant—fiber is soft, lustrous & white or ivory highly susceptible to acids & enzymes—hand washing is recommended fiber produces lightweight, sheer, stiff fabrics—often embroidered used for formal & wedding wear in Philippines, also to make mats, bags, table linens & other apparel current research aimed at making a pina fiber that blends well and is commercially competitive abaca comes from member of banana tree family fibers are coarse, very long—up to 15 feet, strong, durable & flexible off-white to brown in color used for ropes, cordage, floor mats, table linens, some wicker furniture and apparel produced in Central America and the Philippines sisal & henequen closely related plants grown in Africa, Central America, and the West Indies fibers are smooth, straight and yellow used for better grades of rope, twine and brush bristles—degraded by salt water Sisal is used for upholstery, wall coverings, carpet & custom rugs—provides interesting textures for many interior styles used in blends with wool & acrylic for a softer hand dry extraction cleaning is recommended—tends to shed & fade; absorbs waterborne stains other cellulosic materials used in accent rugs due to resistance to heat & soil: • • • rush—stems of marsh plant sea grass—from China & Vietnam maize—cornhusks rush & palm fiber seat are used on chairs wooden slats & grasses used in window coverings grasses are used in wallcoverings wicker furniture is made from tightly twisted paper yarns, rattan, sea grass, abaca, and raffia bacteria cellulose is used in medicine as a covering for sever burns & other skin injuries