cc39e03633e0f74f9ee59c429c5492c2-1

advertisement

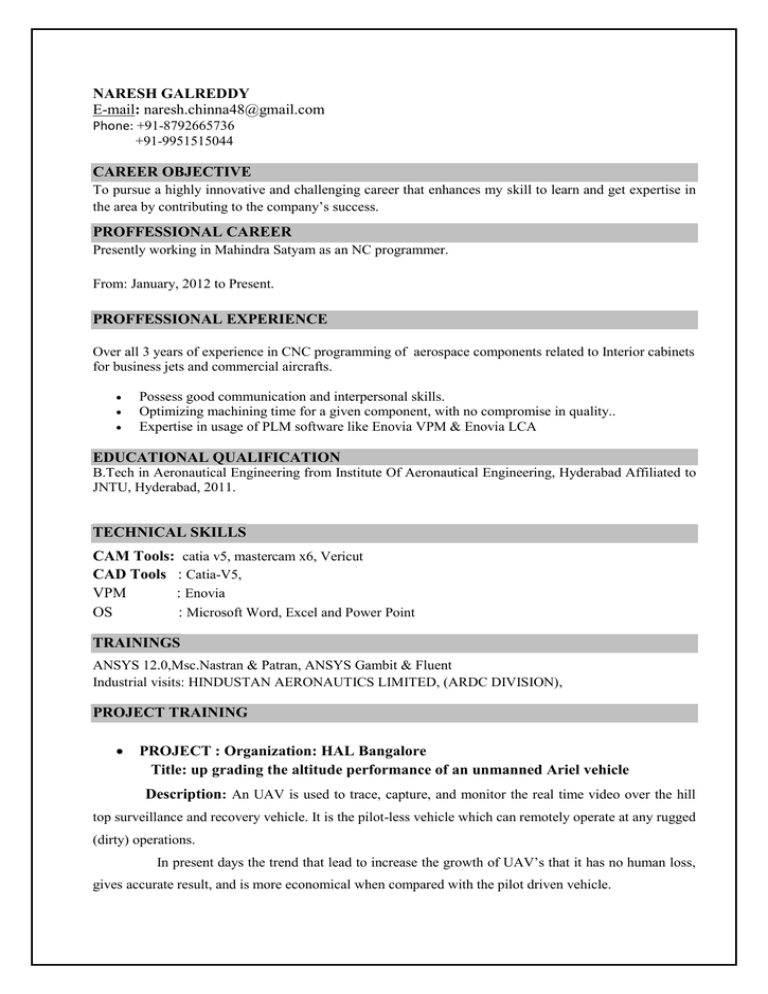

NARESH GALREDDY E-mail: naresh.chinna48@gmail.com Phone: +91-8792665736 +91-9951515044 CAREER OBJECTIVE To pursue a highly innovative and challenging career that enhances my skill to learn and get expertise in the area by contributing to the company’s success. PROFFESSIONAL CAREER Presently working in Mahindra Satyam as an NC programmer. From: January, 2012 to Present. PROFFESSIONAL EXPERIENCE Over all 3 years of experience in CNC programming of aerospace components related to Interior cabinets for business jets and commercial aircrafts. Possess good communication and interpersonal skills. Optimizing machining time for a given component, with no compromise in quality.. Expertise in usage of PLM software like Enovia VPM & Enovia LCA EDUCATIONAL QUALIFICATION B.Tech in Aeronautical Engineering from Institute Of Aeronautical Engineering, Hyderabad Affiliated to JNTU, Hyderabad, 2011. TECHNICAL SKILLS CAM Tools: catia v5, mastercam x6, Vericut CAD Tools : Catia-V5, VPM : Enovia OS : Microsoft Word, Excel and Power Point TRAININGS ANSYS 12.0,Msc.Nastran & Patran, ANSYS Gambit & Fluent Industrial visits: HINDUSTAN AERONAUTICS LIMITED, (ARDC DIVISION), PROJECT TRAINING PROJECT : Organization: HAL Bangalore Title: up grading the altitude performance of an unmanned Ariel vehicle Description: An UAV is used to trace, capture, and monitor the real time video over the hill top surveillance and recovery vehicle. It is the pilot-less vehicle which can remotely operate at any rugged (dirty) operations. In present days the trend that lead to increase the growth of UAV’s that it has no human loss, gives accurate result, and is more economical when compared with the pilot driven vehicle. PROJECTS EXECUTED Project Details: Project Title : NC PROGRAMMING FOR AIRCRAFT INTERIOR PARTS Client : Bombardier Aerospace Software used : Mastercam X6, Enovia LCA Description: Scope • Generating NC programes and posting files to client specified machines. • Work type includes converting Catia 3D to Mastercam 2D, Nesting the parts and NC programs generating in master cam software. • Preparing setup sheets and shop documents. Inputs • Engineering Design with detail Assy. • List of parts to be machined with respect to type of machines. • Type of materials to be used for machining. Technical Approach • Understanding the methodology and material type used for manufacturing and analyzing the CATIA models. • Study the inputs with respect to type of material machine. • Analyze and sorting the parts according to machine type and material type. • Nesting the parts with respect to inputs and selecting the proper sheet size. • Generating tool paths with minimum cycle time by proper selection of cutting tools and cutting parameters. • Posting the files to respective machine and preparing shop documents. Tools used • Catia V5, Master cam X5,X6 • ENOVIA LCA Deliverables • Programmed mastercam files. • NC codes, • Supportive documents for machine shop. Challenges Executing the work independently at offshore. Meeting the schedule and quality. • Adapting best practices for optimized results. Project Title : NC PROGRAMMER FOR AIRCRAFT MACHINED PARTS Client : Bombardier Aerospace Software used : Catia V5 R19, vericut Description: Analysis the part geometry of the Solid/Surface for design study. Selection of suitable Cutting Tools, based on the Cutting Conditions NC Tool Path Generation & Optimization by using 3 and 4 axis machines. Post processing to the client for Machine Specification. Tool Path Simulation and Verification using Vericut. Delivery and documentation. ACHIEVEMENTS − − Credentials for securing 216 State rank in E-CET 2008. Delivering valuable insights, keen analysis and team approach to implement best practices, adept at working in high pressure environments with strict deadlines and multiple deliverables PERSONAL PROFILE Father’s Name : G.CHANDRA SHEKAR REDDY Mother’s Name : G. PUSHPUMMA Gender : Male Date of Birth : 07-08-1990 Languages Known : English, Hindi and Telugu Hobbies : Playing Cricket DECLARATION I hereby declare that the above-furnished information is true up to my knowledge. (G .NARESH)