M5_Chapter10

advertisement

CHAPTER 10

ENVIRONMENTAL IMPACT

EVALUATION OF A CHEMICAL

PROCESS FLOWSHEET – TIER 3

Goal

To perform a detailed environmental impact

evaluation of a chemical process flowsheet in

order to identify a set of environmental

indexes (metrics) and evaluate the impact o

risk of the entire process to the human

health or to the environmental media

Order of topics :

• Introduction

• Estimation of environmental fates of

emissions and wastes

• Tier 3 metrics for environmental risk

evaluation of process designs

• Conceptual design of an environmental

impact assessment of a chemical process

flowsheet

Introduction

What Information is Needed

to Perform a Tier 3

Environmental Assessment?

• To establish a Process Flowsheet

• To define the boundaries around the

environmental assessment

• To formulate environmental impact indicators

(indexes or metrics)

• To maximize the Mass Efficiency

• To maximize the Energy Efficiency

Indexes or environmental metrics

Can be used for several important engineering

applications related to process designs,

including :

– Ranking of technologies

– Optimizing of in-process waste recycle/recovery

processes

– Evaluation of the modes of reactor operation

Emission assessment: Quantitative

Analyses

EMISSIONS are the most important and basic

information regarding process design flowsheets

because :

impact f (dose(concentration (emission rate)))

Concentration and location are a (emissions,

chemical properties and physical properties)

Transport and fate models can be used to transform

emission values into their related environmental

concentrations

Emission assessment: Quantitative Analyses ... continued

Toxicity and/or inherent impact information is

required to convert concentration-dependent doses

into probabilites of risk

Categories of environmental impact assessment steps :

– Estimates of the rates of release for all chemicals in the

process

– Calculation of environmental fate and transport and

environmental concentration

– Accounting for multiple measures of risk using

toxicology and inherent environmental impact

information

Potential Risk Assessment

...suitable for large scale applications where

potential environmental and health risk

assessment should be follow by quantitative

analysis.

...better suited to compare the environmental risks

of chemical process designs

...of chemical process and their design can be

evaluated by impact benchmarking

Impact Benchmarking

• Is a dimensionless ratio of the environmental impact

caused by a chemical’s release in comparison of the

identical release of a well-studied (benchmark)

compound

• If the benchmark value is greater then 1, then the

chemical has a greater potential for environmental

impact then the benchmarked compound

• Equivalent emission of the benchmark compound (in

terms of environmental impact) = (Benchmarked

enviromental impact potential) * (process emission

rate)

Boundaries for impact assessment

From Allen (2004) Design for the Environment - http://www.utexas.edu/research/ceer/che341

Estimation of Environmental

Fates and Emission Wastes

Goal

To determine the transport and reaction

processes that affect the ultimate

concentration of a chemical released to

the environment (water, air and soil)

The evaluation is done by using

environmental fate and transport models:

-One compartment

- Multimedia compartment

Choosing Types of Models

• Accuracy :

– This parameter varies according to the model’s

method of incorporating environmental

processes in it’s description of mass transfers

and reactions

• Ease of Use :

– This parameter reflects the data and

computational requirements which the model

places on the environmental assessment

One Compartment Models

• Advantages :

– Little chemical and/or

environmentally

specific data required

– Relatively accurate

results using modest

computer resources

• Disadvantages :

– Information is for only

one media (severe

limitation when

multiple environmental

impacts are being

considered)

•Examples :

– Atmospheric dispersion models for predicting air concentrations from

stationary sources

– Groundwater dispersion models for predicting contaminant concentrations

profiles in plumes

Multimedia Compartment Models

(MCMs)

• Advantages :

– Information on transport

and fate in more than one

media

– Minimal data input required

– Relatively simple and

computationally efficient

– Accounts for several

intermediate transport

mechanisms and

degradations

• Disadvantages :

– Lack of experimental data

can be used to verify the

model’s accuracy

– General belief that they

only provide order-ofmagnitude estimates of the

environmental

concentrations

– Large computational

requirements can result in

difficult practical

implementations for routine

chemical process

evaluations.

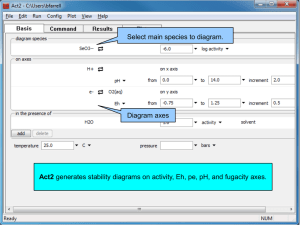

Multimedia Models Example: Level

III Multimedia Fugacity Model

The model predicts steady-state

concentrations of a chemical in four

environmental compartments (1) air,

(2) surface water, (3) soil, (4) sediment

in response to a constant emission into

an environmental region of defined

volume

Allen, A.T., D.R. Shonnard (2002) Green engineering, Prentice Hall

MacKay, D.(2001) Multimedia environmental models: the fugacity approach, CRC Press

Fugacity and Fugacity Capacity

•

•

•

•

Air Phase

Water Phase

Soil Phase

Fugacity Capacity Factors

Fugacity : Air Phase

• Defined as :

f y PT P

Where :

– y is the mole fraction of the chemical in the air phase

– Ф is the dimensionless fugacity coefficient which accounts for nonideal behaviour

– PT is the total pressure (Pa)

– P is the partial pressure of the chemical in the air phase

• Concentration and Fugacity :

Where :

–

–

–

–

–

C1 n / V P /( RT ) f /( RT ) f Z1

n is the number of moles of the chemical in a given volume V (mol)

V is the given volume (m3)

R is the gas constant (8.312 (Pa m3)/(mole K))

T is the absolute temperature (K)

Z1 is the fugacity capacity (=1/(RT))

Fugacity : Water Phase

• Defined as :

Where :

f x P

S

– x is the mole fraction

– y is the activity coefficient in the Raoult’s law convention

– PS is the saturation vapor pressure of pure liquid chemical at the system

temperature (Pa)

S

C

x

/

v

f

/(

v

P

) f / H fZ 2

W

W

• Concentration and Fugacity : 2

• Where :

–

–

–

–

vw is the molar volume of solution (water, 1.8x10-5m3/mole)

H is the Henry’s law constant for the chemical (Pa.*m3/mole)

Z2 is the water fugacity capacity for each chemical (=1/H)

C2 is the concentration in aqueous solution (moles/m3)

Fugacity : Soil Phase

• Defined as :

• Where :

C S K d C2

– Cs is the sorbed concentration (moles/kg soil or sediment)

– C2 is the aqueous concentration (moles/L solution)

– Kd is the equilibrium distribution coefficient (L solution/kg solids)

• Distribution coefficient related to organic content:

K OC K d / 3

• Concentration and Fugacity :

3 CS 1 / H KOC3 3 f / 1000 Z 3 f

• Where :

– р3 is the phase density (kg solid/m3 solid)

– Ф3 is the mass fraction of organic carbon in teh soil phase (g organic

carbon/g soil solids)

– Koc is the organic carbon-based distribution coefficient (L/kg)

– Z3 is the fugacity capacity

Fugacity Capacities for Compartments

and Phases in the Environment

Environmental Phases

Phase Densities (kg/m3)

Air Phase

Z1=1/RT

Water Phase

Z2=1/H

1,000

Soil Phase

Z3=(1/H)KOCΦ3ρ3/1000

2,400

Sediment Phase

Z4=(1/H)KOCΦ4ρ4/1000

2,400

Suspended Sediment Phase

Z5=(1/H)KOCΦ5ρ5/1000

2,400

Fish Phase

Z6=(1/H)0.048ρ6KOW

1,000

Aerosol Phase

Z7=(1/RT)6x106/PSL

Where

1.2

R=Gas constant (8.314Pa*m3/mole*K)

T= Absolute Temperatura (K)

H=Henry’s Law constant (Pa*m3/mole)

KOC=Organic-carbon partition coefficient (=0.41KOW)

KOW=Octanol-water partition coefficient

ρi=phase density for phase i (kg/m3)

Φi=Mass fraction of organic carbon in phase i (g/g)

Environmental Compartments

Air comparment (1)

ZC1=Z1+2x10-11Z7 (Approximately 30 μg/m3 aerosols)

Water comparment (2)

ZC2=Z2+5x10-6Z5+10-6Z6 (5 ppm solids, 1 ppm fish by vol.)

Solid compartment (3)

ZC3=0.2Z1+0.3Z2+0.5Z3 (20% air, 30% water, 50% solids)

Sediment compartment (4)

ZC4=0.8Z2+0.2Z4 (80% water, 20% solids)

Note: For solid aerosols PSL=PSS/exp{6.79(1-TM/T)} where TM is the melting point (K). Adapted from Mackay et. Al. (1992).

Transport between interfaces

Diffusive and Non-Diffusive Processes

• Diffusive Processes

– Can occur in more then one direction, depending on

the fugacity signs of the different compartments

– Rate of transfer : N = D(f)

– Ex. Volatilization from water to air or soil to air

• Non-Diffusive Processes

– Is a one-way transport between compartments

– Rate of transfer : N = GC = GZf = Df

– Ex. Rain washout, wet/dry depositions to water and

soil, sediment depositions and resuspensions

Transport between interfaces... continued

Parameter Derivations : Air-Water Transports

• A two film approach is used with mass transfer coefficients for air

(u1 = 5m/h) and water (u2 = 0.05 m/h). The intermediate transport

parameter for absorption is given as :

DVW 1 /(1 / u1 AW Z1 ) 1 /(u2 AW Z 2 ))

• The D-value for rain washout can be given as :

DRW u3 AW Z 2

• The D-value for wet/dry deposition is given as :

DQW u 4 AW Z 7

• The cumulative D-value for air to water tranfer :

D12 DVW DQW DRW

• The D-value for water to air transfer is :

D21 DVW

Transport between interfaces... continued

Parameter Derivations : Air-Soil Transports

• After development, the d-value equation for air

to soil diffusion is given as :

DVS 1 /(1 / DS 1 /( DSW DSA ))

• With :

DS u5 AS Z1

DSW u6 AS Z 2

DSA u7 AS Z1

• The cumulative D-value for all air-to-soil

processes is given by :

D13 DVS DQS DRS

• And the soil-to-air diffusion transport is :

D31 DVS

Transport between interfaces... continued

Parameter Derivations : Water-Sediment Transports

• Water to sediment D-value can be estimated by :

Where :

D24 u8 AW Z 2 u9 AW Z 5

– u8 is the mass transfer coefficient (m/h)

– AW is the area (m2)

– u9 is the sediment deposition velocity (m/h)

• Sediment to water D-value can be estimated by :

• Where :

D42 u 8 AW Z 2 u10 AW Z 4

– u10 is the resuspension velocity (m/h)

Transport between interfaces... continued

Parameter Derivations : Soil-Water Transports

• The D-value for soil to water transfer is :

• Where :

D32 u11 AS Z 2 u12 AS Z 3

– u11 is the run-off water velocity (m/h)

– u12 is the run-off solid’s velocity (m/h)

• The non-diffusive transport mechanism’s D-value

used to describe the removal of chemical from the

sediment via burial is :

• Where :

DA4 uB AW Z 4

– uB is the sediment burial rate (m/h)

Transport between interfaces... continued

Parameter Derivations : Advective Transports

• The total rate of inputs for each media is :

I i Ei G AiC Bi

• Where :

– Ei is the emission rate (moles/h)

– GAi is the advective flow rate (m3/h)

– CBi is the background concentration external to

compartment i (moles/m3)

• The total rate of bulk flow outputs for each media is :

DAi GAi Z Ci

• Where :

– ZCi is the compartment i fugacity capacity

Reaction Loss Processes

Reaction loss processes occuring in the

environment include :

–

–

–

–

Biodegradation

Photolysis

Hydrolysis

Oxidation

Balance Equations

Mole Balance Equations for the Mackay Level III Fugacity Model.

Air

I1+f2D21+f3D31=f1DT1

Water

I2+f1D12+f3D32+f4D42=f2DT2

Soil

I3+f1D13=f3DT3

Sediment

I4+f2D24=f4DT4

Where the lefthand side is the sum of all gains and the righthand side is the sum of all losses, II=EI+GAICBI, I4 usually being zero. The

D values on the righthand side are:

DT1=DR1+DA1+D12+D13

DT2=DR2+DA2+D21+D24

DT3=DR3+DA3+D31+D32

DT4=DR4+DA4+D42

The solution for the unknown fugacities in each compartment is:

f2 = (I2+ J1J4/J3 + I3D32/DT3 + I4D42/DT4)/(DT2 - J2J4/J3- D24D42/ DT4)

f1 = (J1+ f2J2) /J3

f3 = (I3+ f1D13) /DT3

f4 = (I4+ f2D42)/DT4

Where

J1 = I1 / DT1 + I3D31/(DT3DT1)

J2 = D21/ DT1

J3 = 1 – D31D13/(DT1DT3)

J4 = D12 + D32D13/DT3)

Metrics for environmental risk

evaluation of process design

Tier 3 Metrics for Environmental

Risk Evaluation of Process Designs

• This tier will discuss how to combine data

concerning emission estimation, environmental

fate and transport information and environmental

impact data in order to develop an assessment of

the potential risks caused by the releases of

substances from chemical process designs

• Indices will be used and the multimedia

compartment model example will be source of

environmental concentrations that will be used in

INDEXES

Tier 3 Metrics for Environmental

Risk Evaluation of Process Designs

•

•

•

•

•

•

Environmental Indexes

Global Warming

Ozone Depletion

Acid Rain

Smog Formation

Toxicity and Carcinogenity

Environmental

indexes

Dimensionless Risk Index

• Abiotic Impacts :

– Global Warming

– Stratospheric Ozone

Depletion

– Acidification

– Eutrofiaction

– Smog formation

• Global Implications

– Global Warming

– Stratospheric Ozone

Depletion

• Regional Implications

– Smog Formation

– Acid Deposition

• Local Implications

[( EP)( IIP )]i

(Dimension less Risk Index) i

[( EP)( IIP )] B

B stands for the benchmark compound and i is

the chemical of interest.

– Toxicity

– Carcinogenicity

Global Warming

• GWP is a common index and is the

cumulative infrared energy captured from

the release of 1 kg of greenhouse gas

relative to that from 1 kg of carbon dioxide

GWPi

n

0

n

0

ai Ci dt

aCO2 CCO2 dt

• Index for GW can be estimated using the

I (GWP m )

GWP with :

• Using organic compound effects ...

GW

i

i

i

GWPi (indirect ) N C

MWCO 2

MWi

Ozone Depletion

The Ozone Depletion Potential (ODP) is an integrated

change of the stratospheric ozone caused by a specific

quantity of a chemical.

It is a comparison between the damage caused by a

specific quantity of given chemical and the damage

caused by the same quantity of a benchmark compound.

ODPi

O3 i

O3 CFC 11

I OD (ODPi mi )

i

Acid Rain

The relation between the number of moles of H+ created per

number of moles emitted is called potential of acidification.

The following equation (balance) provides this relationship.

X H

i

i

MWi

i

ARPi

SO

2

I AR ( ARPi mi )

i

Smog Formation

The following equations represent the most important process for

ozone formation in the lower atmosphere (photo-dissociation of NO2)

NO2 hv O(3P) NO

O(3P) O2 M O3 M

O3 NO NO2 O2

VOC's do not destroy O3 but they form radicals which convert NO to

NO2.

VOC OH RO2 other oxidation products

RO2 NO NO2 radicals

radicals OH other oxidation products

Smog Formation Potential

MIRi

SFPi

MIR ROG

Process equivalent emission of ROG

I SF ( SFPi mi )

i

Toxicity

Non-Carcinogenic Toxicity

Non carcinogenic toxicity is controlled by established exposure thresholds.

Above this values a toxic response is manifested. The key parameters for

these chemicals are the reference dose (RfD [mg/kg/d]) or reference

concentration (RfC [mg/m3]).

Toxicity potential for

ingestion route exposure

(C

)( 2 L / d ) /( 70kg)/( RfDi )

INGTPi

(Ctoluene,w )(2L / d ) /(70kg)/( RfDtoluene)

Toxicity potential for

inhalation exposure

Ci ,a / RFC i

INHTPi

Ctoluene,a / RFC toluene

i ,w

Non-carcinogenic toxicity index

for the entire process (ingestion)

I ING ( INGTPi mi )

Non-carcinogenic toxicity index

for the entire process (inhalation)

I INH ( INHTPi mi )

Toxicity

Carcinogenicity

A method similar to the non-carcinogenicity toxicity is used for

measuring cancer related risk; it is based on predicted concentrations of

chemicals in the air and water from a release of 1000 kg/h.

Carcinogenic potential of a chemical determinated by the ratio

of the chemicals risk to that for the benchmark compound.

Ingestion

(C )( SF )

i, w

i

INGCPi

(C

)( SF

)

benzene, w

benzene

Carcinogenic toxicity index for

the entire process (ingestion)

Carcinogenic toxicity index for

the entire process (inhalation)

Inhalation

(C )( SF )

i, a

i

INHCPi

(C

)( SF

)

benzene, a

benzene

I CING ( INGCPi mi )

i

I CINH ( INHCPi mi )

i

Conceptual design of an

environmental impact evaluation

of a chemical process flowsheet

Conceptual design of an environmental

impact evaluation of a process

Proposed by Allen (2004) Design for the Environment - http://www.utexas.edu/research/ceer/che341