Predicting the Probability of Achieving a 7

advertisement

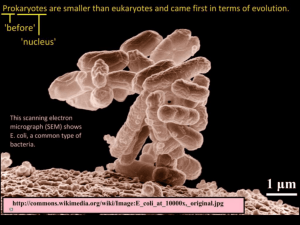

Process Validation Updates… and a reminder about Food Defense Steve Ingham Food Safety Extension Specialist UW-Madison Areas of Validation Emphasis Beef carcass dry-aging interventions Slow-cooking of whole-muscle beef roasts Kim Wiegand Ground & formed beef jerky process lethality Ryan Algino Alena Borowski Shelf-stability of RTE products Darand Borneman Validating Beef Carcass Dry-Aging – the Microbial Performance Standard E. coli O157:H7 must be undetectable If slaughter process is hygienic or animal is not a carrier, standard could be met without an intervention The intervention adds assurance or overcomes slaughter hygiene lapses There is no specified “log reduction” Validating Beef Carcass Dry-Aging – the Microbial Performance Standard A practical approach to meeting this standard: use an intervention that would cause a statistically significant decrease in the number of E. coli O157:H7 cells Our goal: help you validate your intervention process Show that your intervention would cause a significant decrease in the number of E. coli O157:H7 cells Validating Beef Carcass Dry-Aging Challenges Inoculation studies using pathogens aren’t possible in plants Dry-aging conditions vary Weather Size and number of carcasses in cooler Air movement % Relative Humidity Length of dry-aging period Validating Beef Carcass Interventions – a new approach Inoculate beef carcass with harmless bacteria that survive the same (or better) compared to E. coli O157:H7 Take a “before” sample Take an “after” sample Lactic acid bacteria starter culture = “LAB” How much did levels of LAB decrease? If LAB decrease enough, E. coli O157:H7 would have decreased, too How much do the LAB levels have to drop? The Least Significant Difference (LSD) for E. coli O157:H7 in simulated dry-aging studies is 0.3 logs (50% decrease) This LSD corresponds to an LAB decrease of at least 0.25 logs Accuracy of LAB performance standard in predicting adequate reduction of E. coli O157:H7 during dry-aging Part Accurate Fail-safe Fail-dangerous Brisket - fat 15/15 0 0 Brisket – lean 12/15 3/15 0 Heart 12/15 3/15 0 Liver 15/15 0 0 Tongue 13/15 2/15 0 Kit for Evaluating Beef Carcass Intervention Treatments LAB culture and Diluent Add diluent to LAB Mix Add LAB solution to sponge Squeeze sponge 10 X Get ready to inoculate brisket Inoculate both halves of the carcass One is sampled “before” The other is sampled “after” Inoculate brisket Score sample with sterilized scalpel Peel sample away with sterilized scalpel and forceps “Before” sample is ready to ship Ship sample to lab (same way as you ship generic E. coli samples) The “after” sample Use dead locks to pin the large template to the second carcass half Take sample when dry-aging is complete Ship to the lab Next step: Determine E. coli O157:H7 LSD and LAB reductions needed to validate acid-spray interventions Acetic acid Lactic acid Fresh Bloom Predicting the Probability of Achieving a 7-Log Reduction of Escherichia coli O157:H7 During Roast Beef Slow-cooking Processes Beyond THERM… Slow cooked beef roasts have unique food safety concerns Temperature abuse growth before cooking? Heat shocked pathogens tougher to kill? Slow come-up times growth before cooking? Salt and spices tougher pathogens? Need predictive tools to evaluate heat lethality associated with meat processing Slow-cooking of beef: microbial performance standards 6.5 log reduction in Salmonella USDA recommends no more than 6 h between 50 and 130°F Besides killing Salmonella, we must also provide adequate lethality against E. coli O157:H7 We’ve chosen a 7-log lethality target Allows for a small amount of growth before cooking (0.5 log) Evaluating slow cook processes: our model system Unseasoned ground beef 4 simulated commercial slow-cook schedules Simulated Cook Schedules 140 130 120 Set Temperature (deg F) 110 Commercial Process 100 90 Slow come-up time 80 Fail to reach 130F 70 Potential heat shock 60 0 60 120 180 200 240 270 Time (min.) 300 330 360 390 405 Evaluating slow-cook processes Inoculation studies of 4 cook schedules each 6 h 45 min. 25 g ground beef 9 sampling times each schedule. Evaluating slow cook processes Overlaid plates with MEMB – recover injured cells Determined cumulative F-value based on time and temperature history Used E. coli O157:H7 CFU/g plate counts to create model Cumulative Process Lethality D-value: number of minutes at constant temperature needed to destroy 90% of organisms Z-value: change in temperature (°F) needed to change the D-value by 10-fold Lethal Rate: shown below, equivalent heating rate per minute; expressed for reference temperature. Cumulative process lethality (F-value): cumulative lethal rate over a given cooking/heating process. F 10 ( T Tr ) / Z • T = internal temperature • Tr = Reference temperature • Z = reference z value Logistic Regression Analysis Z = 10.4°F and Tr = 130°F F-value determined at each sampling point If process was successful, the sample achieved an E. coli O157:H7 reduction of 7logs. Logistic regression used to determine probability of achieving 7-log reduction for any given F-value Logistic Regression Curve for Predicting 7-log Kill 1.2 1 Pr(7 log red) 0.8 0.6 0.4 0.2 0 100 150 200 250 Lethality 300 350 400 1.2 1 Pr(7 log red) 0.8 95% probability of achieving a 7-log reduction of E. coli O157:H7 0.6 0.4 Heat equivalent to 308 min. at 130oF 0.2 0 100 150 200 250 Lethality 300 350 400 Tool development Representative samples E. coli O157:H7 kill < 7.0 log E. coli O157:H7 kill ≥ 7.0 log Lethality <308 Lethality ≥308 113/124 0/20 11/124 20/20 A sneak peek at the finished product… Core temperature 160 140 Temperature (F) 120 100 80 60 • Easy-to-use Excel worksheet calculations produce two graphs 40 20 0 0 100 200 300 400 Time (min) • Lethality outlines the cumulative lethal rate Lethality 450 400 • Interpretation for processor: probability that process would attain the 7-log kill 350 F-value (min) • Core temperature shows the total cooking process 300 250 200 150 100 50 0 0 100 200 Time (min) 300 400 •Above an established F-value (based on temperature and time combination) process has high probability of 7-log kill Comparison of adequate and inadequate cooking processes Cooking process not brought up to temperature (e.g. undercooked at 130oF) Cooking process brought up to 135oF (e.g. rare roast beef) Lethality Lethality 450 450 400 350 350 300 300 F-value (min) F-value (min) 400 250 200 150 250 200 150 100 100 50 50 0 0 0 100 200 Time (min) 300 400 0 100 200 300 Time (min) Process lethality calculations greatly highlight inadequate cooking processes 400 Next Steps Seasoned ground beef model system Model validation with actual roasts Without seasoning With seasoning Validating Lethality of Processes for Making Ground & Formed Jerky Jerky Process Lethality Issues Evaporative cooling Adaptation of pathogens if drying is before high temperature Seemingly infinite number of processes being used by processors Microbial Performance Standards for Jerky-Making 5-log reduction of Salmonella 5-log reduction of E. coli O157:H7 (beef) Validating Ground & Formed Jerky Process Lethality – a new approach Inoculate jerky mix with harmless bacteria that survive the same (or better) compared to E. coli O157:H7 and Salmonella Take a “before process” sample Take an “after process” sample Lactic acid bacteria starter culture = “LAB” How much did levels of LAB decrease? If LAB decreases enough, pathogens would have decreased, too Process 1 (Cabela Dehydrator), Hot 10 9 8 log CFU 7 Salmonella 6 E. coli 5 Saga 200 4 Biosource 3 2 1 0 0 210 Time (min) 420 Process 1 (Cabela Dehydrator), Cold 10 9 8 log CFU 7 Salmonella 6 E. coli 5 Saga 200 4 Biosource 3 2 1 0 0 210 Time (min) 420 Process 2- no smoke (Alkar smokehouse) 10 9 8 log CFU 7 Salmonella 6 E. coli 5 Saga 200 4 Biosource 3 2 1 0 0 30 90 150 Time (min) 180 210 240 Process 2- with smoke (Alkar smokehouse) 9 8 7 log CFU 6 Salmonella 5 E. coli 4 Saga 200 Biosource 3 2 1 0 0 30 150 Time (min) 240 Process 3- no smoke (Alkar) 10 9 8 log CFU 7 Salmonella 6 E. coli 5 Saga 200 4 Biosource 3 2 1 0 0 30 45 75 Time (min) 105 135 175 Process 3- with smoke (Alkar) 9 8 7 log CFU 6 Salmonella 5 E. coli 4 Saga 200 Biosource 3 2 1 0 0 30 Time (min) 45 175 Process 4- no smoke (Alkar) 10 9 8 log CFU 7 Salmonella 6 E. coli 5 Saga 200 4 Biosource 3 2 1 0 0 45 90 Time (min) 150 270 Process 4- with smoke (Alkar) 9 8 7 log CFU 6 E. coli 5 Salmonella 4 Biosource Saga 200 3 2 1 0 0 30 90 Time (min) 180 270 Process 5- no smoke (Alkar) 10 9 8 log CFU 7 Salmonella 6 E. coli 5 Saga 200 4 Biosource 3 2 1 0 0 90 150 210 Time (min) 270 330 Process 6- no smoke (Alkar) 10 9 8 log CFU 7 Salmonella 6 E. coli 5 Saga 200 4 Biosource 3 2 1 0 0 75 105 Time (min) 180 210 How does LAB kill relate to pathogen kill? Pediococcus spp. Death (logs) E. coli Death (logs) <4 >4 <5 84 0 >5 37 51 How does LAB kill relate to pathogen kill? Pediococcus spp. Death (logs) Salmonella Death (logs) <4 >4 <5 98 1 >5 23 50 How does LAB kill relate to pathogen kill? P. acidilactici Death (logs) E. coli Death (logs) <4 >4 <5 83 3 >5 32 54 How does LAB kill relate to pathogen kill? P. acidilactici Death (logs) Salmonella Death (logs) <4 >4 <5 95 5 >5 20 52 Shelf-stability of RTE meat products Issue is whether Staphylococcus aureus will grow Pathogen that best tolerates reduced water activity Shelf-stability of RTE meat products Gathered wide range of commercial products Made several “substandard” versions of summer sausage, jerky Inoculated all products Vacuum-packaged Stored at room temperature Monitored S. aureus levels Where we’re going with this topic Determine algorithm for calculating a shelf-stability score pH Water activity MPR % Water-Phase Salt Determine minimum shelf-stability score needed for no S. aureus growth Develop computer worksheet for processors to enter their product characteristics Some thoughts on Food Defense Prevention of tampering, terrorism via commercially processed foods No regulations…yet Do an evaluation and take some basic steps to prevent problems Info will be on our website: www.meathaccp.wisc.edu Need more information or help? Phone me: 608-265-4801 E-mail me: scingham@wisc.edu Check our website: www.meathaccp.wisc.edu THANK YOU!