General Procedures for deriving Energy balances for Reactive

advertisement

General Procedures for deriving Energy balances for Reactive Processes: (Q1)

Method 1: Heat of Reaction method

1. Compete the material balance calculations on the reactor to the greatest extent

possible

2. Choose reference states for specific enthalpy calculations

- Best choices are generally reactant and product species at 25C and 1atm

3. For a single reaction in a continuous process, calculate the extent of reaction (ξ)

|𝑛𝐴,𝑜𝑢𝑡 −𝑛𝐴,𝑖𝑛 | 𝑛𝐴 ,𝑟

𝜉=

=

|𝜈𝐴 |

|𝜈𝐴 |

𝑤ℎ𝑒𝑟𝑒 𝜈𝐴 𝑖𝑠 𝑡ℎ𝑒 𝑠𝑡𝑜𝑖𝑐ℎ𝑖𝑜𝑚𝑒𝑡𝑟𝑖𝑐 𝑐𝑜𝑒𝑓𝑓𝑖𝑐𝑖𝑒𝑛𝑡 𝑜𝑓 𝑎 𝑟𝑒𝑎𝑐𝑡𝑎𝑛𝑡 𝑜𝑟 𝑟𝑒𝑎𝑐𝑡𝑖𝑜𝑛 𝑝𝑟𝑜𝑑𝑢𝑐𝑡 𝐴

4. Prepare the inlet-outlet enthalpy table, inserting know molar amounts (ni) or flow

rates (nͦ i) for all inlet and outlet stream components.

5. Calculate each unknown stream component enthalpy, Hi, as ΔH for the species going

from its reference state to the process state, and insert the enthalpies in the table.

6. Calculate ΔH for the reactor. Use one of the following formulas:

Δ𝐻 = 𝜉Δ𝐻𝑟 + Σ𝑛𝑜𝑢𝑡 𝐻𝑜𝑢𝑡 − Σ𝑛𝑖𝑛 𝐻𝑖𝑛 (𝑠𝑖𝑛𝑔𝑙𝑒 𝑟𝑒𝑎𝑐𝑡𝑖𝑜𝑛)

Δ𝐻 = Σ𝜉𝑗 Δ𝐻°𝑟 𝑗 + Σ𝑛𝑜𝑢𝑡 𝐻𝑜𝑢𝑡 + Σ𝑛𝑖𝑛 𝐻𝑖𝑛

Method 2: Heat of Formation Method

1. Compete the material balance calculations on the reactor to the greatest extent

possible

2. Choose reference states for specific enthalpy calculations

- Best choices are generally reactant and product species at 25C and 1atm

3. Prepare the inlet-outlet enthalpy table, inserting know molar amounts (ni) or flow

rates (nͦ i) for all inlet and outlet stream components.

4. Calculate each unknown specific enthalpy (use process paths)

- For a reactant or product, start with the elemental species at 25C and 1 atm and

form 1 mol of the process species at 24C and 1 atm

- Then bring the species from 25C and 1 atm to its processs state, calculating the

change in enthalpies, specific enthalpies, and latent heats from their

corresponding tables

5. Calculate ΔH for the reactor

6. Substitute the calculated value of ΔH in the energy balance equation and complete

the required calculations

Question 1:

The Army has, for many years, funded direct methanol fuels cells to power portable

electronic devices like your smartphone because methanol is much more energy dense

than Li-ion batteries. The unbalanced reaction is as follows and occurs isothermally at

25oC and 1 atm:

𝐶𝐻3 𝑂𝐻(𝑙) + 𝑂2(𝑔) → 𝐻2 𝑂(𝑙) + 𝐶𝑂2(𝑔)

In order to determine how long 20 mL of liquid methanol can power your iPhone/Android

device, answer the following questions:

a. (5 pts) Write a stoichiometrically balanced reaction for the process.

7. Count components on each side of the equation

Left side: 1 Carbon, 4 Hydrogen, 3 Oxygen

Right side: 1 Carbon, 2 Hydrogen, 3 Oxygen

8. Hydrogen appears to be unbalanced

9. Use guess & check until balanced:

𝟐𝐶𝐻3 𝑂𝐻(𝑙) + 𝟑𝑂2(𝑔) → 𝟒𝐻2 𝑂(𝑙) + 𝟐𝐶𝑂2(𝑔)

10. Final: 2 Carbons, 8 Hydrogen, 8 Oxygen

b. (5 pts) Determine the initial amount of methanol in g-moles.

NOTE: g-mole is equivalent to “mole” (just another way of writing it to try

and trick you)

11. Use molecular weight to convert based on the balanced equation in part A

𝟏 𝒎𝒐𝒍

𝟐𝟎𝒎𝒍 𝒎𝒆𝒕𝒉𝒂𝒏𝒐𝒍 = 𝟐𝟎𝒈 𝒎𝒆𝒕𝒉𝒂𝒏𝒐𝒍 (

) = 𝟎. 𝟔𝟐𝟒𝒎𝒐𝒍 𝒎𝒆𝒕𝒉𝒂𝒏𝒐𝒍

𝟑𝟐. 𝟎𝟒𝒈

c. (20 pts) Assume that 90% of the methanol is consumed and that all of the change in

enthalpy between the initial and final states of the system goes into usable work

(e.g. efficiency is 100%). If the average power consumption of your device is 34

kJ/day, (𝑷 = 𝑾⁄𝒕) determine how long (in days) your device can be powered. To

help your calculations, please use the inlet-outlet enthalpy table below and

explicitly state your reference state(s) directly on this sheet!!

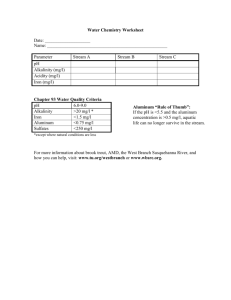

Substance

nin (mol)

Hin (kJ/mol)

nout (mol)

Hout (kJ/mol)

CH3OH(l)

0.624

-238.6

O2(g)

0.936

0

H20(l)

1.124

-285.84

CO2(g)

0.562

-393.5

1. r.s._________________________________________________________________________

12. Solve for change in enthalpy, use to calculate work, then plug work back into power

equation (no heat of reaction calculation necessary for this problem)

13. total methanol consumed = 0.624*0.90 = 0.562 moles

14. begin by filling in “nin” column using the conversion

𝟑𝒎𝒐𝒍 𝑶𝟐

𝟎. 𝟔𝟐𝟒𝒎𝒐𝒍 𝑪𝑯𝟑 𝑶𝑯 (

) = 𝟎. 𝟗𝟑𝟔𝒎𝒐𝒍 𝑶𝟐

𝟐𝒎𝒐𝒍 𝑪𝑯𝟑 𝑶𝑯

𝟒𝒎𝒐𝒍 𝑯𝟐 𝑶

𝟎. 𝟓𝟔𝟐𝒎𝒐𝒍 𝑪𝑯𝟑 𝑶𝑯 (

) = 𝟏. 𝟏𝟐𝟒𝒎𝒐𝒍 𝑯𝟐 𝑶

𝟐𝒎𝒐𝒍 𝑪𝑯𝟑 𝑶𝑯

𝟐𝒎𝒐𝒍 𝑪𝑶𝟐

𝟎. 𝟓𝟔𝟐𝒎𝒐𝒍 𝑪𝑯𝟑 𝑶𝑯 (

) = 𝟎. 𝟓𝟔𝟐𝒎𝒐𝒍 𝑪𝑶𝟐

𝟐𝒎𝒐𝒍 𝑪𝑯𝟑 𝑶𝑯

15. Look of standard heat of formation values for all the compounds (NOTE: standard

heat of formation of an elemental species is always zero) then multiply them by mole

ratios to determine Hin and Hout

𝑯°𝒇,𝑪𝑯𝟑 𝑶𝑯 = −𝟐𝟑𝟖. 𝟔 𝑲𝑱⁄𝒎𝒐𝒍

𝑯𝒊𝒏,𝑪𝑯𝟑 𝑶𝑯 = (𝟎. 𝟔𝟐𝟒)(−𝟐𝟑𝟖. 𝟔) = −𝟏𝟒𝟖. 𝟖𝟗𝑲𝑱

𝑯°𝒇,𝑯𝟐 𝑶 = −𝟐𝟖𝟓. 𝟖𝟒 𝑲𝑱⁄𝒎𝒐𝒍

𝑯𝒊𝒏,𝑯𝟐 𝑶 = (𝟏. 𝟏𝟐𝟒)(−𝟐𝟖𝟓. 𝟖𝟒) = −𝟑𝟐𝟏. 𝟐𝟖𝑲𝑱

𝑯°𝒇,𝑪𝑶𝟐 = −𝟑𝟗𝟑. 𝟓 𝑲𝑱⁄𝒎𝒐𝒍

𝑯𝒊𝒏,𝑪𝑶𝟐 = (𝟎. 𝟓𝟔𝟐)(−𝟑𝟗𝟑. 𝟓) = −𝟐𝟐𝟏. 𝟏𝟓𝑲𝑱

16. Calculate the change in enthalpy given the above values

∆𝑯 = 𝚺𝒑𝒓𝒐𝒅𝒖𝒄𝒕𝒔 − 𝚺𝒓𝒆𝒂𝒄𝒕𝒂𝒏𝒕𝒔

𝚫𝑯 = (−𝟑𝟐𝟏. 𝟐𝟖 − 𝟐𝟐𝟏. 𝟏𝟓) − (−𝟏𝟒𝟖. 𝟖𝟗) = −𝟔𝟗𝟏. 𝟐𝟑KJ

17. Stated that all change in enthalpy is converted into work

18. Plug work into power equation to solve for time

𝑾 𝚫𝑯

𝑷

𝟑𝟒 𝑲𝑱⁄𝒅𝒂𝒚

𝟐𝟒 𝒉𝒐𝒖𝒓𝒔

𝑷=

=

⟹ 𝒕=

=

= 𝟎. 𝟎𝟖𝟔 𝒅𝒂𝒚𝒔 (

)

𝒕

𝒕

𝚫𝑯 𝟑𝟗𝟑. 𝟓𝟒 𝑲𝑱

𝟏 𝒅𝒂𝒚

=𝟐. 𝟎𝟕 𝒉𝒐𝒖𝒓𝒔 (𝟐 𝒉𝒓𝒔 𝟒𝒎𝒊𝒏)

General Guidelines for Single-Unit Material Balance Calculations:

1. Choose as a basis of calculation an amount or flow rate of one of the process streams

2. Draw a flowchart and fill in all known variable values, including the basis of

calculation. Then label unknown stream variables on the chart.

3. Express what the problem statement asks you to determine in terms of the labeled

variables

4. If you are given mixed mass and mole units for a stream, convert all quantities for

one basis or the other

5. Do the degree-of-freedom analysis

6. If the number of unknowns equals the number of equations relating them, write the

equations in an efficient order (minimizing simultaneous equations) and circle the

variables for which you will solve

7. Solve the equations

8. Calculate the quantities requested in the problem statement if they have not already

been calculated

9. If a stream quantity or flow rate ng was given in the problem statement and another

value nc was either chosen as a basis or calculated for this steam, scale the balanced

process by the ratio ng/nc to obtain the final result

Question 2:

Propane (C3H8) can be dehydrogenated to form propylene (C3H6) and H2. The process flow

diagram is shown below. A fresh feed of propane is mixed with a recycle stream containing

70 mol% propylene and the balance propane and fed into a reactor. The reactor products

are fed to an adsorber and distillation column, and three streams emerge: a stream

containing pure hydrogen, a stream of pure propylene, and the stream recycled back into

the front of the column. If the recycle ratio is 8 total moles recycled per mole propane fed,

and using a basis of calculation of 50 kmol/h of propylene product, calculate the single pass

conversion across the reactor by answering the following questions:

Balanced Reaction: 𝑪𝟑 𝑯𝟖 → 𝑪𝟑 𝑯𝟔 + 𝑯𝟐

Assume basis of 50kmol/hr

Multiple-unit process – may have to isolate and write balances on several

subsystems to obtain enough equations to determine all unknown stream variables

-

Need to calculate degrees of freedom (DOF) for the overall process AND on

each subsystem

a. (10 pts) Draw and completely label a process flow diagram.

Feed Stream: 𝒏̇ 𝑭,𝑪𝟑 𝑯𝟖 = 𝟖𝒏̇ 𝑹,𝑪𝟑 𝑯𝟖 , 𝟏. 𝟎 𝑪𝟑 𝑯𝟖

Stream 1 (from mixer to reactor): 𝒏̇ 𝟏,𝑪𝟑 𝑯𝟔 , 𝒏̇ 𝟏,𝑪𝟑 𝑯𝟖 , 𝒙̇ 𝟏,𝑪𝟑𝑯𝟔 , 𝒙̇ 𝟏,𝑪𝟑 𝑯𝟖

Stream 2 (from reactor to absorber): 𝒏̇ 𝟐,𝑪𝟑 𝑯𝟔 , 𝒏̇ 𝟐,𝑪𝟑 𝑯𝟖 , 𝒏̇ 𝟐,𝑯𝟐 , 𝒙̇ 𝟐,𝑪𝟑 𝑯𝟔 , 𝒙̇ 𝟐,𝑪𝟑 𝑯𝟖 , 𝒙̇ 𝟐,𝑯𝟐

Stream 3 (top stream out of absorber):

𝒏̇ 𝟑,𝑯𝟐 = 𝟓𝟎 𝒌𝒎𝒐𝒍⁄𝒉𝒓 (𝒃𝒆𝒄𝒂𝒖𝒔𝒆𝟏: 𝟏 𝒎𝒐𝒍𝒂𝒓 𝒓𝒂𝒕𝒊𝒐 𝒘𝒊𝒕𝒉 𝑪𝟑 𝑯𝟔 ), 𝟏. 𝟎 𝑯𝟐

Product Stream: 𝒏̇ 𝑷,𝑪𝟑 𝑯𝟔 = 𝟓𝟎 𝒌𝒎𝒐𝒍⁄𝒉𝒓 , 𝟏. 𝟎 𝑪𝟑 𝑯𝟔

Recycle Stream: 𝒏̇ 𝑹,𝑪𝟑 𝑯𝟔 , 𝒏̇ 𝑹,𝑪𝟑 𝑯𝟖 , 0.70 C3H6, 0.30 C3H8

(5 pts) Calculate the molar flow rate of the propane feed.

-

-

-

Use stoichiometry and balance around absorber first; ratio between total output

of hydrogen and propylene from absorber column is 1:1

𝐧̇ 𝐏,𝐂𝟑 𝐇𝟔 + 𝐧̇ 𝐑,𝐂𝟑 𝑯𝟔 = 𝒏̇ 𝟑,𝑯𝟐

Use Ratio given for recycle stream and recycle ratio

𝟕𝒏̇ 𝑹,𝑪𝟑 𝑯𝟔 = 𝟑𝒏̇ 𝑹,𝑪𝟑 𝑯𝟖

𝒏̇ 𝑭,𝑪𝟑 𝑯𝟖 = 𝟖𝒏̇ 𝑹,𝑪𝟑 𝑯𝟖

⇒ 𝟕𝒏̇ 𝑹,𝑪𝟑 𝑯𝟔 = (𝟑⁄𝟖)𝒏̇ 𝑭,𝑪𝟑 𝑯𝟖

Combine two red equations above

𝐧̇ 𝐏,𝐂𝟑 𝐇𝟔 + (𝟑⁄𝟓𝟔)𝐧̇ 𝐅,𝐂𝟑 𝑯𝟔 = 𝒏̇ 𝟑,𝑯𝟐

𝟓𝟎 + (𝟑⁄𝟓𝟔)𝐧̇ 𝐅,𝐂𝟑 𝑯𝟔 = 𝒏̇ 𝟑,𝑯𝟐

-

Use overall material balance and input 𝒏̇ 𝟑,𝑯𝟐 calculated above

𝒏̇ 𝑭,𝑪𝟑 𝑯𝟖 = 𝒏̇ 𝑷,𝑪𝟑 𝑯𝟔 + 𝒏̇ 𝟑,𝑯𝟐 = 𝟓𝟎 + 𝒏̇ 𝟑,𝑯𝟐

𝒏̇ 𝑭,𝑪𝟑 𝑯𝟖 = 𝟓𝟎 + {𝟓𝟎 + (𝟑⁄𝟓𝟔)𝒏̇ 𝑭,𝑪𝟑 𝑯𝟔 }

𝒏̇ 𝑭,𝑪𝟑 𝑯𝟖 = 𝟏𝟎𝟓. 𝟔𝟔 𝒌𝒎𝒐𝒍⁄𝒉𝒓

b. (15 pts) Find the single pass conversion of propane across the reactor by solving

for the other material balances.

𝒔𝒊𝒏𝒈𝒍𝒆 𝒑𝒂𝒔𝒔 𝒄𝒐𝒏𝒗𝒆𝒓𝒔𝒊𝒐𝒏 =

-

𝑹𝒆𝒂𝒄𝒕𝒂𝒏𝒕 𝒊𝒏𝒑𝒖𝒕 𝒕𝒐 𝒕𝒉𝒆 𝒓𝒆𝒂𝒄𝒕𝒐𝒓 − 𝒓𝒆𝒂𝒄𝒕𝒂𝒏𝒕 𝒐𝒖𝒕 𝒑𝒖𝒕 𝒕𝒐 𝒕𝒉𝒆 𝒓𝒆𝒂𝒄𝒕𝒐𝒓

𝒓𝒆𝒂𝒄𝒕𝒂𝒏𝒕 𝒊𝒏𝒑𝒖𝒕 𝒕𝒐 𝒕𝒉𝒆 𝒓𝒆𝒂𝒄𝒕𝒐𝒓

Only need to calculate flow rates of reactant (C3H8) for single pass

conversion calculation

A degree of freedom analysis is not necessarily needed here because it’s

obvious where to start based on the order of questions, but some teachers

require it for good measure anyways (not sure what your teacher

prefers)…will ultimately come down to time restraint on the exam though

Material Balances around Mixer

C3H8 Balance:

𝒏̇ 𝑭,𝑪𝟑 𝑯𝟖 + 𝒏̇ 𝑹,𝑪𝟑 𝑯𝟖 = 𝒏̇ 𝟏,𝑪𝟑 𝑯𝟖

𝒏̇ 𝑭,𝑪𝟑 𝑯𝟖 + (𝟏⁄𝟖)𝒏̇ 𝑭,𝑪𝟑𝑯𝟖 = 𝒏̇ 𝟏,𝑪𝟑𝑯𝟖

𝟏𝟎𝟓. 𝟔𝟔 + (𝟏𝟎𝟓. 𝟔𝟔⁄𝟖) = 𝒏̇ 𝟏,𝑪𝟑 𝑯𝟖

𝒏̇ 𝟏,𝑪𝟑 𝑯𝟖 = 𝟏𝟏𝟖. 𝟖𝟕 𝒌𝒎𝒐𝒍⁄𝒉𝒓

-

Calculate flow rates in recycle stream

𝒏̇ 𝑹,𝑪𝟑 𝑯𝟖 = 𝟏𝟎𝟓. 𝟔𝟔⁄𝟖 = 𝟏𝟑. 𝟐𝟏 𝒌𝒎𝒐𝒍⁄𝒉𝒓

𝟕𝒏̇𝑹,𝑪𝟑 𝑯𝟔 = 𝟑𝒏̇ 𝑹,𝑪𝟑𝑯𝟖 = 𝟑(13.21)=39.62

𝒏̇ 𝑹,𝑪𝟑 𝑯𝟔 = 𝟓. 𝟔𝟔 𝒌𝒎𝒐𝒍⁄𝒉𝒓

Balance on C3H6:

𝒏̇ 𝑹,𝑪𝟑 𝑯𝟔 = 𝒏̇ 𝟏,𝑪𝟑 𝑯𝟔 = 𝟓. 𝟔𝟔 𝒌𝒎𝒐𝒍⁄𝒉𝒓

Material Balances around Reactor

Overall Balance:

𝒏̇ 𝟏,𝑪𝟑 𝑯𝟔 + 𝒏̇ 𝟏,𝑪𝟑 𝑯𝟖 = 𝒏̇ 𝟐,𝑪𝟑 𝑯𝟔 + 𝒏̇ 𝟐,𝑪𝟑 𝑯𝟖 + 𝒏̇ 𝟐,𝑯𝟐

𝒏̇ 𝟐,𝑪𝟑 𝑯𝟖 = 𝒏̇ 𝟐,𝑯𝟐 𝒃𝒂𝒔𝒆𝒅 𝒐𝒏 𝒔𝒕𝒐𝒊𝒄𝒉𝒊𝒐𝒎𝒆𝒕𝒓𝒚 𝒐𝒇 𝒓𝒆𝒂𝒄𝒕𝒊𝒐𝒏𝒔

𝟓. 𝟔𝟔 + 𝟏𝟏𝟖. 𝟖𝟕 = 𝒏̇ 𝟐,𝑪𝟑 𝑯𝟔 + 𝟐𝒏̇ 𝟐,𝑪𝟑 𝑯𝟖

𝒏̇ 𝟐,𝑯𝟐 = 𝒏̇ 𝟑,𝑯𝟐 𝒃𝒂𝒔𝒆𝒅 𝒐𝒏 𝒃𝒂𝒍𝒂𝒏𝒄𝒆 𝒐𝒇 𝒂𝒃𝒔𝒐𝒓𝒃𝒆𝒓

𝒏̇ 𝟑,𝑯𝟐 = 𝟓𝟎 + (𝟑⁄𝟓𝟔)𝒏̇ 𝑭,𝑪𝟑 𝑯𝟔 = 𝟓𝟎 + (𝟑⁄𝟓𝟔)(𝟏𝟎𝟓. 𝟔𝟔) = 𝟓𝟓. 𝟔𝟔

⇒ 𝒏̇ 𝟐,𝑪𝟑 𝑯𝟖 = 𝟓𝟓. 𝟔𝟔 𝒌𝒎𝒐𝒍⁄𝒉𝒓

𝒔𝒊𝒏𝒈𝒍𝒆 𝒑𝒂𝒔𝒔 𝒄𝒐𝒏𝒗𝒆𝒓𝒔𝒊𝒐𝒏 =

𝒏̇ 𝟏,𝑪𝟑 𝑯𝟖 − 𝒏̇ 𝟐,𝑪𝟑 𝑯𝟖 𝟏𝟏𝟖. 𝟖𝟕 − 𝟓𝟓. 𝟔𝟔

=

= 𝟎. 𝟓𝟑𝟐

𝒏̇ 𝟏,𝑪𝟑𝑯𝟖

𝟏𝟏𝟖. 𝟖𝟕

Question 4:

Hydrogen can be produced by the shift reaction:

𝐶𝑂 + 𝐻2 𝑂 → 𝐶𝑂2 + 𝐻2

A process diagram is shown below. 52 mol% CO and balance water forms the fresh feed

to the process and is mixed with a recycle stream containing unreacted CO and water.

This combined stream is fed to a reactor where the shift reaction occurs. Downstream

of the reactor, much of the unreacted CO and water is separated from the hydrogen. The

product stream gives an analysis of 48 mol% CO2, 48 mol% H2, and 4 mol% CO. The

water and the remaining CO is recycled and mixed with the fresh feed to the process;

the recycle ratio for CO is 6 (mol CO recycled/mol CO fed). For a basis of 100 mol/s of

the product stream, answer the following questions:

a. (10 pts) Draw and completely label a process flow diagram.

Fresh Feed Stream: 𝒏𝑭 , 𝒙𝑭,𝑪𝑶 = 𝟎. 𝟓𝟐, 𝒙𝑭,𝑯𝟐 𝑶 = 𝟎. 𝟒𝟖

Stream 1 (Mixer to Reactor):𝒏𝟏 , 𝒙𝟏,𝑯𝟐 𝑶 , 𝒙𝟏,𝑪𝑶

Stream 2 (Reactor to Separator): 𝒏𝟐 , 𝒙𝟐,𝑪𝑶𝟐 , 𝒙𝟐,𝑯𝟐 𝑶 , 𝒙𝟐,𝑪𝑶 , 𝒙𝟐,𝑯𝟐

Recycle Stream: 𝒏𝑹 , 𝒙𝑹,𝑪𝑶 , 𝒙𝑹,𝑯𝟐 𝑶

Product Stream: 𝒏𝑷 = 𝟏𝟎𝟎 𝒎𝒐𝒍⁄𝒔 , 𝒙𝑷,𝑪𝑶𝟐 = 𝟎. 𝟒𝟖, 𝒙𝑷,𝑯𝟐 = 𝟎. 𝟒𝟖, 𝒙𝑷,𝑪𝑶 = 𝟎. 𝟎𝟒

b. (5 pts) Determine the molar flow rate of the fresh feed to the process.

Overall Balance:

𝒏𝑭 = 𝒏𝑷 = 𝟏𝟎𝟎 𝒎𝒐𝒍⁄𝒔

𝒏̇ 𝑭,𝑪𝑶 = 𝟎. 𝟓𝟐(𝟏𝟎𝟎) = 𝟓𝟐 𝒎𝒐𝒍⁄𝒔

𝒏̇ 𝑭,𝑯𝟐 𝑶 = 𝟎. 𝟒𝟖(𝟏𝟎𝟎) = 𝟒𝟖 𝒎𝒐𝒍⁄𝒔

c. (10 pts) Determine the single pass conversion of CO by solving some of the

remaining material balances.

Material Balances around Mixer

CO Balance:

𝒏̇ 𝑭,𝑪𝑶 + 𝒏̇ 𝑹,𝑪𝑶 = 𝒏̇ 𝟏,𝑪𝑶

𝒏̇ 𝑭,𝑪𝑶 + (𝟏⁄𝟔)𝒏̇ 𝑭,𝑪𝑶 = 𝒏̇ 𝟏,𝑪𝑶

𝟓𝟐 + (𝟓𝟐⁄𝟔) = 𝒏̇ 𝟏,𝑪𝑶

𝒏̇ 𝟏,𝑪𝑶 = 𝟔𝟎. 𝟔𝟕 𝒌𝒎𝒐𝒍⁄𝒉𝒓

Material Balances on Separator

𝒏̇ 𝑹,𝑪𝑶 = (𝟏⁄𝟔)𝒏̇ 𝑭,𝑪𝑶 = 𝟖. 𝟔𝟕 𝒌𝒎𝒐𝒍⁄𝒉𝒓

𝒏̇ 𝑷,𝑪𝑶 = 𝟎. 𝟎𝟒(𝟏𝟎𝟎) = 𝟒 𝒌𝒎𝒐𝒍⁄𝒉𝒓

CO Balance:

𝒏̇ 𝟐,𝑪𝑶 = 𝒏̇ 𝑹,𝑪𝑶 + 𝒏̇ 𝑷,𝑪𝑶 = 𝟖. 𝟔𝟕 + 𝟒 = 𝟏𝟐. 𝟔𝟕 𝒌𝒎𝒐𝒍⁄𝒉𝒓

𝒔𝒊𝒏𝒈𝒍𝒆 𝒑𝒂𝒔𝒔 𝒄𝒐𝒏𝒗𝒆𝒓𝒔𝒊𝒐𝒏 =

𝒏̇ 𝟏,𝑪𝑶 − 𝒏̇ 𝟐,𝑪𝑶 𝟔𝟎. 𝟔𝟕 − 𝟖. 𝟔𝟕

=

= 𝟎. 𝟖𝟓𝟕

𝒏̇ 𝟏,𝑪𝑶

𝟔𝟎. 𝟔𝟕