Development

advertisement

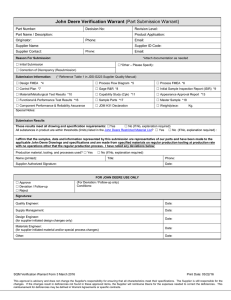

McLaughlin Body Company John Deere February 21, 2005 Company History McLaughlin Body Company Corporate Office East Moline Operations 1400 5th Street (250,000 square feet / 23,225 square meters) Rock Island Operations 350-44th Street (450,000 sq. ft. / 32,516 sq. meters) Most Valuable Resource Dedicated employees at McLaughlin Body Co. 235 Hourly 83 Salaried Renewed relationship with U.A.W 1414 Newly signed 6 year contract Lessons learned on both sides from a 4 week work stoppage Our Vision Committed to being the premier supplier of cabs and attachments by providing products and services of the highest quality and value to our customers. Our Mission / Value Statement Our Mission Our mission is to be the Quality, Service, Technology and Value leader in our industry. The focus on leading in all these areas will allow McLaughlin to exceed our customer’s expectations and mutually prosper. Our Values The integration of our people and processes to provide products of high value and high quality. The continual support of our community by providing valued jobs and participating in charitable activities. Continuous improvement through employee development, training and education. Competencies McLaughlin Body Company is a supplier of cabs, bodies and attachments to the ag, construction, industrial, military, mining, municipal and truck markets Expertise in Design and development Program management Prototyping ROPS certification Fabrication Weld Paint Assembly Delivery JIT to line set Fabrication Capabilities Various lasers including a Mazak FMS (Flexible Manufacturing System) featuring (2) 4000 watt lasers 2500 watt Mazak multi-axis laser with sheet loader Straight side and double action draw presses to 1000 tons – bed sizes up to 144” X 90” and 56” shut height 5” OD capacity CNC controlled roll bender for complex sweeps CNC controlled press brakes nearly eliminate setup Robotic Welding 13 Existing robotic weld stations ABB Panasonic Fanuc 9 integrated weld positioners 3 flexible cells Continued dedication to expansion of automation Paint Capabilities Current dual paint systems handle parts of any size Current E-coat Cab line 8 stage zinc phosphate pretreatment with non-chrome seal 8th generation low cure cathodic epoxy e-coat material Acrylic top coat 6’ X 8’ X 6’ part size 2000# capacity Large line Minimal shrink / edge pull Reduced VOCs and improved performance 5 stage iron phosphate pretreatment Polyester top coat over thermally cured spray primer 10’ X 10’ X 50’ part size 10,000# capacity All new cab line will be operational in April of 2005 MBC Customers Quality Customer Quality Metrics Quality Delivery Customer A 5.1σ 6.0σ Customer B 6.0σ 6.0σ Customer C 4.8σ 6.0σ Customer D 6.0σ 6.0σ Customer E 98% All Others 99% (MBC, VOC Report Ratings) Supplier of the Year Award Deere & Company, North American Ag Division, 2004 Supplier of the Year Award Customer Communications Tools Customer Quality Status Reports (VOC) NetMeeting or WebEx Capabilities Internal quality rating system Quality Engineers communicate with customers and report to the McLaughlin organization on a weekly basis. Provides the opportunity for the design, process, manufacturing and quality engineers plus supply management to work as a team on cost reduction, corrective and preventive activities from multiple remote locations. Caterpillar Connect / Deere Supplier Collaboration Customer specific web based access to specs, drawings, quality performance reports and other communication information. Electronic posting of PPAP documentation Materials Testing Two local certified laboratories for chemical and physical testing of metals. Chemical supplier performs periodic system audits of cleaning and phosphating processes Paint supplier performs monthly analysis of E-coat bath. In-house testing: Dry film paint thickness Zinc phosphate pre-treatment coating weights Specular gloss of topcoat paints Cross hatch paint adhesion, ASTM B117 salt fog accelerated corrosion resistance GM9540P cyclic accelerated corrosion resistance Ultra phonic leak testing Ultra sonic weld evaluation Surface hardness of metals (Rb) CQTS Completed Checklist CQTS Component Pareto Analysis Corrective & preventive action New reports automatically sent via internal e-mail to specific employees Focus on Direct & Root Causal factors, Mistake Proofing and other Prevention Activities Complete sort capability by date range, originator or report status Completed reports are electronically transmitted to the customer Cost Containments Pricing Methodology A specific formula is applied that both MBC and our customer know and understand Separate markups for purchased content vs. manufactured content Departmental overhead rates are applied for press room, weld, trim, and paint Changes are processed at variable cost only Cost Benchmarking Initiatives John Deere Steel Cat Logistics MRO Supplies Cost Containment Analysis McLaughlin Enterprise McLaughlin Body Company Cab Manufacturer Bee Line Company Laser Alignment McLaughlin Motors Auto Dealership SE National Bank Banking MBC Financial Leasing MBC Working to reduce costs? Major investments in equipment Info Systems Initiatives Continuous improvement initiatives Monthly cost reduction meetings Consolidation efforts Operations Consolidation Rock Island facility has been selected as the primary manufacturing facility Operations centered around world-class paint system Integration of all weld, paint and assembly operations Streamlined material flow between processes Integrated fabrication of components Operational in 4-6 months New system capabilities System will be isolated in separate, pressurized building Provide superior pretreatment 15 Stage immersion pretreatment with Zinc Phosphate Alkaline / Acid / Alkaline w/reverse polarity cleaning stages for best in class laser oxide and weld smut removal Include powder coat in addition to e-coat and wet spray top coat capabilities 8th Generation improved performance e-coat Low-E powder for reduced VOC emissions and reduce energy consumption Consolidation Goals Increased competitiveness Reduce waste associated with non-value added activities Reduce overhead by establishing multifunctional focus teams Accelerate throughput and reduced inventories Improve quality through streamlined processes and direct communication between functional groups Consolidation Goals Improved communication Integration of product support personnel Electronic data collection and online access to process instructions and drawings Open layout without “departmental” barriers Committed team focused with clear mission for the future Consolidation Goals Establish positive image within QCIC complex Segregation and distinction of MBC Exterior revitalization New visitor center and product showroom Clean and comfortable work areas for all employees Renewed emphasis on housekeeping What are the results? Material burden reduced 20% Paint costs reduced 5% Laser costs reduced 17% Improved quality and capabilities Freight costs reduced 19% Representative Price History – 1 45% 35% 25% PRICE WITH INFLATION 15% ACTUAL PRICE ACTUAL LESS IMPROVEMENTS 5% Base Price 5% 15% Representative Price History – 2 12.5% 7.5% 2.5% Base Price 2.5% Inflation Price 7.5% Actual Price 12.5% 17.5% 22.55% Inventory Controls Forecasting Delivery PPM scores Customer forecast and order requirements In the past 12 months, of the 8092 trimmed and sequenced cabs produced, 100% were delivered on time Sequencing of delivered cabs to machine line set Releases for fully trimmed cabs with a wide variety of options are received into the planning system via EDI Electronic configuration of models and options (EDI data / web portal) Unique BOMs generated for each cab serial number Build card system for assembly instructions Order Process – Trimmed Cab Order Received EDI • Sequence # • Options Required • 30 Day Ship Notice • 7 Day Firm Notice MBC Create Work Order with Sequence # • Details Optional Equipment • Software Program Review Available Options for Acceptance Build Ticket • Creates SubAss’y Reports • Reviews Inventory Requirements Software and Test Download • Software Downloaded • Test Requirements • Sub-Assembly Test Documented Daily Shipments to Customer • Daily Shipments by Customer Ass’y Sequence • Invoiced Supplier Communication Supplier Forecasting Requirements Expedited Freight From MBC suppliers Quarterly forecasting meeting with suppliers to review our estimated requirements for the next six months Unscheduled customer volume increases Customer controller supplier late shipments Customer expedites cab shipments Supplier Quality Rating Reviewed with supplier on quarterly basis Development Engineering Support Current group consists of 5 Manufacturing Engineers, 4 Industrial Engineers, 4 Quality Engineers, 3 Design Engineers, 2 Tooling Engineers and 1 Weld Engineer This group can manage any product introduction from a complete design from the ground up to a straight forward transfer Average Quotation Lead Time 1 week turn on Engineering Changes 3 to 4 weeks Cab Product Development Process • Provide acceptable quotation • Establish target price Contract Feasibility Review • X-functional • Capacities • Capabilities • Competencies • Strategy Design and Develop • Assign Team • Develop Project Plan • INPUT review • Product design • Supplier selection • Design reviews • DFMA/ FMEA reviews • Tooling Design • Process Plan Prototype Validate Pilot • Proto build • Confidentiality • Mfg validation • Tooling build • Tooling validation Release Launch • OUTPUT review • Key features ID • IMS development • Preliminary process docs (routings / process instructions) • Control plans • Facility prep • Training • Product approval • FAI / Capability Studies Engineering Support Project Management Projects are tracked through production start up with detailed Gantt chart Responsibilities defined and communicated Key milestone reviews scheduled Critical path tracked and managed Summaries and updates are circulated to entire internal and external project team on predetermined intervals Engineering Support Project Management Tooling and product cost budgets are carefully tracked using development tracking summary Products broken down by functional group such as frame, glass, door, etc Costs tracked and monitored against initial frozen budgets Immediate visibility to budget creep Miscellaneous items such as hardware budgeted initially as a “kit” and tracked as defined Design Capabilities (7) Seats of Pro-Engineer (Maintain use of previous versions to support customer needs) Pro-Process for Assemblies (used by IE) Pro-Intralink (Data Management software) Pro-Mechanica 2001 (for FEA analysis) Ability to import IGES, STEP, DXF models Flexible and will adapt to customer needs Design Capabilities - Tooling Tooling design in can be done in Pro/E concurrent with product development Speed launch time, simplify changes Create permanent revision controlled record of tools Design Capabilities - FEA Linear FEA capabilities using Pro/Mechanica Analysis for potential hot spots Frame / joint optimization Product Expertise ROPS expertise with active members on both construction and Ag ROPS subcommittees. Bill Johnson – Advance Engineering Manager, Current vice chair of SAE Operator Protection Technical Committee - OPTC Active member of OPTC SC4 - Protective Structures Active member of ASAE PM-23-2-2 Agricultural ROPS subcommittee Change Process Request for Change Identify Impact • Customer request • Internal Change • Unit cost impact • Tooling • Obsolescence Standard time = 1 Week (~300 Changes in 2004) • Customer approval Authorization Implement • Internal approval • New parts • ISIRs • Process Instructions • Training Implementation Specific lead time requirement Management 2004 Five Year Strategic Plan Retain current customer base through superior customers service Diversify business by obtaining new business in new markets and additional business from key customers Improve customer communications with quarterly reviews Position ourselves as a Key Supplier all Deere Division Supplier of the Year for Deere Ag Division 2004 Utilize adjacency strategies to grow key segments with valued customers Achieve high value status (low cost, high quality, exceptional services) Evaluate current supply base and look at offshore sources. Evaluate current supplier deliver process for inventory reduction Leverage supplier expertise and develop strategy for significant reductions 2004 Five Year Strategic Plan Operations consolidation Successfully address key management succession issues Utilize lean tools and methods to sustain continuous improvements Pursue technology advancements to improve quality Identify key people and skills and develop appropriate plan Achieve ongoing company wide commitment to strategic direction Schedule timely review, update and measurement against strategic plan Thank You From McLaughlin Body Company