sachin d - insight alpha

advertisement

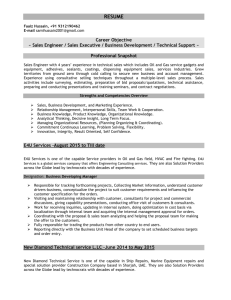

SACHIN D. SAPAR Sachin.sapar@gmail.com DOB: 25th December 1975 Address:”Kimaya”, Plot No-153, Sector No-27A, Pradhikaran, Nigadi, Pune, Pin- 410044, INDIA Residence Phone No- +91 20 2764 1104 Mobile No+91 99754 95610 Key Skill Business development for Adhesives, Polymers & Chemicals Application development for Industrial & Automotive business. Strong Technical expertise in Adhesive, Foams, Plastics & Fluids. Strong Analytical Skills Techno-commercial Background Project & Key account Management. Strengths Strong Technical-Engineering Capability Business acumen Strong Interpersonal & Communication Skills Creativity & Innovative Assertive Self Starter Decision making ability even in stressful situations Educational Qualification 1. Symbiosis Institute of Management Studies July 2009 to Jan 2012 Executive MBA-Finance First Class with Distinction (74%) 2. Pune University 1994-1997 Bachelor of Polymer Engineering (B.E.) First Class (63%) 3. Cusrow Wadia Institute of Technology 1991-1994 Diploma in Mechanical Engineering (D.M.E.) First Class (82%) Work Experience September 2007 to till date 1. Dow Automotive - Dow Chemical International Pvt. Ltd, Pune Designation: Commercial Manager (Automotive) Job Profile a. Develop & Implement the Business plan for Automotive Industry in INDIA (Car & Commercial Transport) i. ii. iii. iv. v. Structural Adhesives for Metal & Composite bonding Windshield Bonding Adhesives - PU Structural Reinforcement Foams, coating and Pads for BIW Structure NVH Foams for BIW structure (baffles and alternate technology etc) Brake Fluids & Refrigerant Lubricants for Automotive b. Technologies supported – 1 & 2 Part (Epoxy & PU), MMA, MS-Polymer, Poly-ethylene-glycols etc c. Competition analysis & market mapping. d. Evaluate feasibility for local manufacturing & Tolling options for sustainable growth. e. Key Account & Sales Management for OEM business f. Introduce new concepts & engineering solutions as per local needs. (Identify opportunities, conduct feasibility studies, Submit proposals, validation, Implementation.) g. Develop relationship with OEM & Tiers for New Technology Introduction h. Conduct technical seminars & training. i. Monitor the New vehicle program launches & identify opportunities for business development (new initiative, Follow Source, Replication etc.) Key Achievements a. Developed excellent relationship with OEM for business growth in short period b. Shifted all business to direct sale for Sustainable growth c. Successfully secured & increased business by ~40% for last three year d. New opportunity identification & Successful Commercialization. e. Supported wide product portfolio as business needs in DOW – Performance Plastics, Elastomers, Specialty Films, Adhesives, EP, Composites, Plastic Compounds, Adhesives, Fluids & Foams. f. Presented technical paper on “Cost Effective, High Performance NVH Foam solution for BIW Cavity Sealing” at MM&T-2011 Conference in Mumbai September 2002 to September 2007 2. Henkel Adhesive Technologies India Pvt. Ltd, Pune. Designation: Territory Technical Manager Job Profile a. Headed the Technical Services department for Central INDIA (Maharashtra, MP, Gujarat, CG & Rajasthan) b. Identify & work in key major market segments & projects for new business opportunities. c. Training on New Products / Technology to Subordinates, Sales Engineer & Channel Partners & Customers d. Troubleshooting & Product Failure Analysis, if any. e. Technical Evaluation of competitor products. f. Giving Technical & Design Input to the customers regarding product design g. Coordinate for Product Validation Testing in various Test laborites. h. Coordinate with Internals Customers (R&D, Quality, and Production) & External customers for major projects. Key Achievements a. Received Prestigious “UT Excellence Performance Award 2004” in Malaysia. b. Received “Employee of the quarter” award for Q3-2006. c. Identified major applications of Adhesive bonding for metal to metal replacing conventional brazing method in Refrigerator. d. Lead the project on “Pump Efficiency Program” to support MRO Business e. Working with all major OEM customers in different industries like White Good Appliances, Medical, Defense, Automotive, Electrical, Electronics, Heavy Industries, Machinery, Fabrication, Railways etc. f. Supporting Loctite Maintenance, Repair & Overhaul businesses in various process industries like steel, Cement, Power, Petrochemicals, Chemical, and Mines etc. g. Presented papers on “Loctite Assembly solutions” in various Trade Exhibitions. September 2001 to August 2002 3. TATA Auto Plastics Pvt. Ltd, Pune QS 9000 Company supplying Automotive Plastic Molded components & Assemblies to various automotives OEM’s like Telco, Bajaj, GM, John Deere etc. Designation: Member - Engineering Job Profile Key customer – Bajaj & Telco Studying various customer drawings, performance specifications Preparing techno commercial proposal Finalizing testing and validation plan based on OEM requirement. Project /Program Management on APQP guidelines Preparation of Process flow diagram, FMEA, control plan and work instructions. g. Finalizing & Release of Engineering Bill of Material, Material Specification. h. Part Approval as per PPAP i. Sub Contractor & Supplier Developments j. Preparing Documentation for QS Requirements like APQP & PPAP k. Cost Analysis & Cost Reduction projects. a. b. c. d. e. f. Achievements a. Successful Implementation of Bajaj – Pulsar Plastic molding project b. Successful Implementation of Telco – Indigo Interior & Exterior Plastic molding components project. January 1998 to September 2001 4. Gharda Chemicals Ltd, Gujarat (Polymer Division) This Company is manufacturing Specialty Engineering Thermoplastics like PES, PSU, PPSU, PEEK, etc. (Now Solvay Specialty Polymers) Designation: Executive (R&D – Application Development) Job Profile a. Product & Application development of PES, PSU, PPSU, PEEK & allied blends/composites. b. Processing, Testing, Evaluation & Characterization of these polymers. c. Hands on through Experience in Plastic Injection molding & Extrusion d. Customer support activities Polymer Processing & Product validations. e. Vendor Development activities for Polymer processing. f. Plastic molding stimulation using C-Mold Software. g. Hands on experience on various material characterization equipments like Instron UTM, Haake Rheometer, Ceast Impact tester, Ceast Electrical & Thermal testing equipments, DSC, TGA, DMA, Mac-Beth color Photo spectrometer and MFI etc. Achievements a. Nylon 66 Replacement - Developed PES-Nylon 6 Blend for Transformer Coil Core Molding b. SMC Compression molding Replacement – Injection moldable Electrical MCB with PES Glass Filled Composites c. Glass Replacement - Sterilization Trays & Electronic Chip Curing trays from PES d. Product validation for Submersible Pump Impeller molding for Grundfos (Used for Hot Water Pumping in Europe) e. Worked for USP Class VI Approvals for Polysulfone for Baby milk feeding bottle. July 1997 to December 1997 5. Nilkamal Plastics Ltd, Nasik Designation: Graduate Engineer Trainee –Production & Maintenance Shift In charge for Handling Production for Plastic Injection Molding parts like Furniture, Plastic Crates Hobbies Reading, Listening Music, Travelling & spending time with Family etc