Fundamental PLC Programming

advertisement

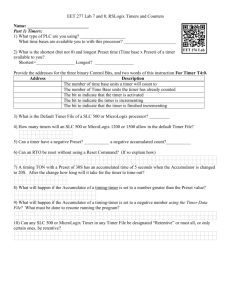

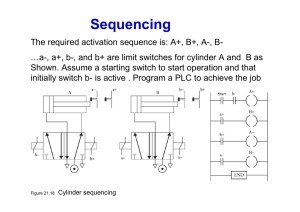

Chapter 19 Fundamental PLC Programming 1 PLC Program Execution • PLCs monitor input devices, execute instructions, and update output devices sequentially during the processor scan cycle • The steps of the scan cycle are: – Update the input image – Reads the CPU for instructions – Update the output terminals 2 Ladder Diagram Programming Language • The programming language most commonly used with programmable logic controllers is the ladder diagram • Ladder diagram programming is built into the software of most PLCs 3 Ladder Diagram Programming • Ladder logic language closely resembles hardwired relay circuits • The symbols represent an instruction set that perform various logic and on-off functions • There are five categories of instructions – – – – – Relay Logic Timers Counters Data Manipulation Arithmetic 4 Relay Logic Instructions • These are the most common instructions found in PLCs • The relay logic instructions are: – – – – – – Examine On -| |Energize Output -( )Branching - used to implement parallel inputs Examine Off -|/|Latch On Output -(L)Unlatch Output -(U)5 Timer Instructions • Timers are internal instructions to the PLC • Timers are activated by changes in the logic continuity of the rung • Types of timers found are: – Timer-On Delay – Timer-Off Delay – Retentive Timer-On Delay 6 Timer Programming • A separate address file for timers is provided in PLCs • File addresses begin at T4:0 • Once the address is entered, the following characteristics are entered: – Time base – Preset value – Accumulated value 7 Timer Words • Each timer in a PLC uses three words to store data • The second and third words store the preset and accumulated values • The first word contains status bits related to time status 8 Timer On-Delay • The Timer On-delay begins timing when rung conditions go true • When the accumulated value equals the preset value, the timer stops timing and the output is energized as bit 13 is set 9 Timer On-Delay Application 10 Timer Off-Delay • When the condition of the rung goes false, the timer off-delay begins timing • When the accumulated value equals the preset value, the output is energized • When the rung goes true, the counter is reset to zero 11 Retentive Timer-On Delay • The accumulated value of a retentive time is held until a reset command is given, regardless of rung conditions 12 Cascading Timers • If the time valued needed exceeds the maximum value of a single timer, timers may be cascaded using the done bit of previous timers 13 Counter Instructions • Counters are output instructions internal to the PLC • Counters are incremented or decremented by changes in the logic continuity of the rung • Types of counters found are: – Up Counter – Down Counter 14 Counter Programming • A separate file is used for counter functions • Counter instructions begin with the address C5:0 • The following information must be entered – Counter and address – Preset value – Accumulated value 15 Counter Words • Each counter in a PLC uses three words to store data • The second and third words store the preset and accumulated values • The first word contains status bits related to count status 16 Up Counter Application • The count-up instructions are useful for repeating processes • The drilling application at the right makes use of an up counter which then activates a robotic arm 17 The Down-Counter • The down counter decrements with each false-true transition of the ladder rung • The down counter is often used to end a cycle 18 Data Manipulation Instructions • Data manipulation instructions allow words to be moved within the PLC • Data manipulation instructions permit more complex operations than relay type instructions • These instructions are divided into three categories: – Data Transfer – Data Conversion – Data Compare 19 Data Transfer Instructions • Data Transfer Instructions are implemented by the move (MOV) instruction • Contents from one register are moved to another based on rung conditions 20 Data Conversion • Data conversion is available as: – Convert to BCD (TOD) – Convert from BCD (FRD) • Both are output instructions and convert data from or to binary coded decimal • A typical application would be the implementation of BCD encoded thumbwheel switches to input data into a PLC 21 Data Compare Instructions • These commands instruct the PLC to compare the numerical contents of two registers and make decisions based upon their values and the results of the comparison • Compare instructions: – – – – – – Compare Equal Compare Not Equal Compare Less Than Compare Less Than or Equal Compare Greater Compare Greater Than or Equal (EQU) (NEQ) LES) (LEQ) (GRT) (GEQ) 22 Arithmetic Functions • Most PLCs have the capability to carry out arithmetic operations • The output of an arithmetic instruction is stored in a specified location • Arithmetic functions available are: – – – – Addition (ADD) Subtraction (SUB) Multiplication (MUL) Division (DIV) 23 Writing a Program • Use the following steps when developing a PLC program: – Choose the sequence you want the I/O devices to operate in – Write a description and make a drawing showing the sequence and conditions for each operation – Use the description to write the ladder diagram – Connect and label the I/O devices – Make a written record of each address used and what the address represents. Document all counters, timers, data instructions, etc. – Enter the program into the PLC 24