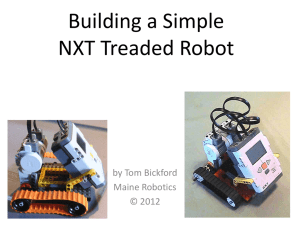

Hobby motor and robot chasses construction

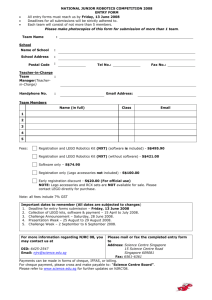

advertisement

Robot Chassis Building Instructions 1. Assemble motor according to instructions. Trim ~ 1/8” from each end of metal axle with metal shears. 2. Glue hobby motor to Lego 16-tooth gear with clutch. Do not allow epoxy to get inside axle hole of hobby motor gear (yellow), but if possible do fill in space between hobby gear and lego gear. Finished chassis (no legs attached) Example battery pack 3. Slide assembled gear onto axle and down to motor housing. Component Parts 4. Insert a black Technic pin in the 3rd hole of a 15hole Lego beam. This is where the glued gears will align to the lego structure. Note that a small washer may be used to improve spacing between hobby motor and lego parts. 6. Assemble the driving gear as shown, with a thin Technic bushing, 2 hollow Technic spacers, the plain 16-tooth gear, and a wide Technic bushing on a 12stud long lego axle. 5. Insert a second black Technic pin in the 3rd hole of the other 15-hole-long lego beam, this time facing towards motor, and slide over other end of axle. 7. Insert the driving gear assembly as shown, and secure with two wide Technic bushings. This requires removing one long Lego beam to first slide the driving gear assembly into place. 8. Assemble the motor support. This consists of two technic pins with axle holes and 4-stud-long Lego axle. This support is a bit loose, but only serves to keep the motor from scraping the ground. It can be assembled with the drive gear secured, though it may be easier to do this step before step 7. 10. Add two Technic disks to the base axle. This helps secure the frame and prevent interference with the moving parts. Align the ends of the axle flush with the disks; the long Lego beams will angle out slightly relative to the gear assembly. 11. Assemble the leg fulcrum points using Technic halfpins/half-axles (blue) and Technic connectors shown. 9. Slide the 10-stud-long Lego axle through the last holes of the long Lego beam to complete frame, securing in place with two wide Technic bushings. 12. Attach the fulcrum points to the frame. Placement of these connectors is very important. They should be adjacent to the lower axle and midway between the motor support and motor axle (holes in the fulcrum connectors will be aligned with the 13th and 6th holes in the long beams, respectively, as counted from the driving gear assembly). 14. Insert Technic pins with ball joints in the 6th hole of the long beam, even with the holes in the fulcrum connectors adjacent to the motor. 15. Insert the fulcrum pins into the fulcrum connectors. The pins have a Lego axle portion, to be inserted into the connector from underneath the chassis, and a Lego axle connection point. Once inserted, secure from above with a narrow Technic bushing. 16. Begin linkage assembly by inserting a Technic friction pin (black) and 3-length free-spinning Technic pin (tan) into two of the 9-hole-long Lego beams, as shown. 17. Attach the second pair of 9-hole-long lego beams as shown, then the 5-hole-long lego beams to the remaining length of the freely-spinning Technic pins. 19. Begin assembly of leg guides with ¼ round lego hubs as shown, by inserting 2-stud-long Technic axles in each corner hole. 18. Add two ¾ Technic pins and a 2-length freelyspinning technic pin to each linkage as shown. 20. Attach leg guides as shown, using ¾ technic pins from step 18 to secure in place. 21. Reinforce leg guide connections with narrow Technic bushings attached on opposite side of linkages. 22. Assemble two linkage cams for connecting the driving gear assembly to the linkages from Step 21. Each cam will consist of two Technic discs held together with 2-3 Technic ½ pins, with a freely-spinning technic pin attached from the opposite side. It is important that the slots in each pair of Technic disks are aligned, so that an axle can pass through eac. 24. Connect the linkage to the frame using the freely spinning pin in each cam (to the end of the linkage) and the freely-spinning pin in the 5-long beam portion of the linkage (to the 8th, center, hole in the 15-long Lego beam). 23. Add the assembled cams to the exposed axle on each end of the driving gear assembly. Preferably, have the freely-spinning pins oriented on opposite sides of the axle, although advanced students may wish to experiment with other pin locations. (Opposite-side view) 25. Begin leg assembly by inserting Technic half-pin/half- 27. For better stability, a rubber band may be added spinning-axles (tan) into right-angle Technic connectors, between the motor axle, pin with ball-joint, and leg attached to 6-long Technic axles, as shown below. beginning for each of the legs closest to the axle. 26. Connect the beginnings of the robot legs from Step 25 to the fulcrum pins, being sure to slide the legs through the ¼ circle hubs. 28. Attach the Technic pin-to-pin connectors to each leg beginning, as a place for students to add their own robot leg designs. If assembled correctly, the leg beginnings should swing back and forth in a roughly circular motion from the fulcrum pins when the motor is powered.