Overview of Injury Research

advertisement

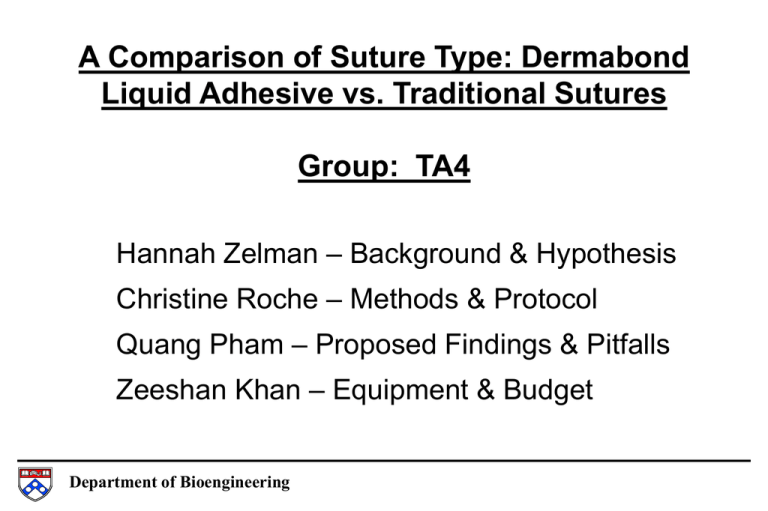

A Comparison of Suture Type: Dermabond Liquid Adhesive vs. Traditional Sutures Group: TA4 Hannah Zelman – Background & Hypothesis Christine Roche – Methods & Protocol Quang Pham – Proposed Findings & Pitfalls Zeeshan Khan – Equipment & Budget Department of Bioengineering Background: Dermabond Liquid Adhesive is used by doctors today to close superficial wounds to the skin. It is applied as a thin layer of ‘purple glue’ over the wound while the doctor holds the skin together. Dermabond forms a strong but flexible bond over the area to which it is applied and protects the wound from infection-causing bacteria. BioBrane is a biosynthetic wound dressing which, in this experiment, serves as a substitute for human skin. Hypothesis(es) & Aim(s) or Objective(s): The purpose of this experiment is to compare the responses of Dermabond and traditional sutures to stress by applying various masses to BioBrane samples reconnected with one of the two methods. It is hypothesized that the Dermabond samples will exhibit less vertical deformation than the suture samples in the gap between the connected pieces of BioBrane. Department of Bioengineering Hannah Zelman Methods & Protocol: • Ten 7/8 x 2 inch BioBrane samples divided length-wise into 7 equal segments. Cut through each sample along the forth line. • Suture four samples together using 100% cotton thread with each sample containing three equally spaced pulley stitches. • Apply 2 layers of Dermabond (one minute apart) over the 7/8 inch width of the remaining four samples. Keep stationary three minutes. • Clamp top and bottom of Sample #1 to the system with each clamp covering ¼ inch. Take picture of sample. • Attach individual masses of 100, 250, 500 & 1000 grams to bottom clamp taking a picture after the system has equilibrated following the addition of each mass. Repeat for Samples #2 - #8. • Measure segment vertical deformation using BE310 Camera VI. Determine stronger connective method by comparing mean ± SD. Analyze difference between methods with two-tailed paired t-test. Compare axial strains in both methods for Middle Section. Department of Bioengineering Christine Roche Proposed Deliverables/Findings: •The application of Dermabond to the sample will provide a stronger hold between two pieces of BioBrane than a pulley suture. (Figure A below provides a graphical example using predicted data based on earlier experiment.) Figure A Department of Bioengineering Quang Pham Potential Pitfalls: •Stretching of the BioBrane material could cause: 1. Negligible gap to be produced from applied stress. 2. Material to break under the applied stress before any measurements could be recorded. •The stress-bearing capacity of Dermabond might have been overestimated and the application of the adhesive to BioBrane could be ineffective in holding two pieces of the material together under applied stress. Alternative Approach: The interwoven white material used in Experiment 5 can be substituted for BioBrane. Based on previous results, this material will undergo minimal deformation, allowing for any measured deformation in the sample to be attributed to the suture/Dermabond connection. Department of Bioengineering Quang Pham Equipment/Materials and Budget & Justification: Equipment: 1. BE310 Camera VI (to take pictures of the equilibrated system and measure the length of the gap) 2. Weights of different masses (to cause vertical deformation in the system Supplies: 1. Thread and needles (to make sutures) Newly Purchased Equipment: 1. BioBrane 5 x 5” box of 5 (substitute for skin, more uniform in structure leading to constant deformation throughout sample) price: $245.00 (www.allegromedical.com) 2. Dermabond (substitute for sutures) price: $46.95 (www.chinookmed.com) Total Cost of purchasing new materials is $291.95 which is well under the budget constraint of $2,000, and the number of samples which can be made from one box of BioBrane are enough for ten trials. All products are easily available from the websites mentioned at the quoted prices. Taxes and shipping charges may apply. Department of Bioengineering Zeeshan Khan