University of California, Irvine

advertisement

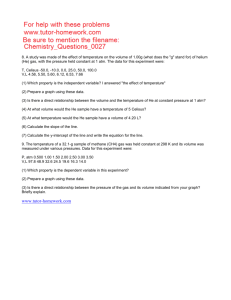

ARO 103 — Introduction to Aerospace Propulsion California State Polytechnic University, Pomona Aerospace Engineering Department Assignment #3- Recip Engine Propeller Performance 1. A reciprocating engine for a light aircraft has the following mechanical characteristics: bore = 11.1 cm number of pistons = 4 engine mechanical efficiency mech 0.83 stroke = 9.84 cm compression ratio = 6.75 propeller efficiency prop 0.85 The fuel-air ratio is 0.06 by mass, and the pressure and temperature in the intake manifold are 1 atm and 285 K respectively. Using the same procedure as demonstrated in class, calculate the power available from this engine-propeller combination at an engine speed of 2800 RPM. You may use the same values for , cv, and qfuel that we used in the class example (1.4, 720 J/(kg K), 4.29 107 J/kg respectively). Provide your work, and also fill in the blanks in the spreadsheet below. 2. Calculate the effective pressure, pe, for the engine in Problem 1 using an Excel spread sheet. no. cylinders, N stroke s bore b no units Compression ratio (CR) no units mechanical no units displacement d m3 rev/min propulsion no units RPM ambient pressure ambient temp fuel/air ratio m m 2800 (gamma) qfuel 1.4 no units ATM K 0.06 (by mass) 4.29E+07 J/kg cv Calculations Piston/Cylinder dimensions & volumes x V2 = notes m b2/4(x+s) V3 = V2/CR m distance, cyl top to piston top 3 volume of area above piston, BDC m3 volume of area above piston, TDC atm input pressure atm K pressure, end of compression stroke K J temperature, end of compression stroke Compression Stroke calculations p2 = p1 p3 = p2 CR T2 = T1 T3 = T2 CR(-1) Wcompression stroke input temperature includes ATM/Pa conversion Power Stroke calculations q = qfuel*(fuel/air)/[1+(fuel/air)] (remember, V4 = V3 and V5 = V2) J/kg K atm atm J of mixed fuel & air temp of gases after ignition from PV = RT, V = const. pressure, end of power stroke includes ATM-Pa conversion Net thermodynamic work / cycle PA=Thrust Power Available (W) PA=Thrust Power Available (HP) J watts HP = Wpower - Wcompression = prop*mech*RPM*N*W/120 = above / 746 W/HP Mean pressure pe ATM = Power*120/mech/prop/RPM/d/101325 T4 = q/cv + T3 p4 = p3 (T4/T3) p5 Wpower stroke Total Power Calculation 3. Expand problem 2 and plot the engine OTTO cycle (P,atm vs. Volume) and Pe. Document1 720 J/kg K