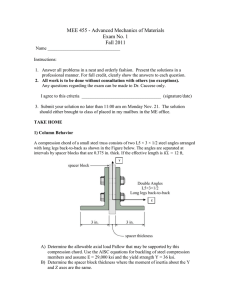

Column Buckling

advertisement

Column Buckling - Inelastic

A long topic

Effects of geometric imperfection

EIx v Pv 0

EIy u Pu 0

Leads to bifurcation buckling of

perfect doubly-symmetric columns

P

M x P(v v o ) 0

EIx v P(v v o ) 0

v Fv2 (v v o ) 0

v o o sin

z

L

vo

v

v

v Fv2v Fv2v o

Mx

v Fv2v Fv2 ( o sin

z

L

)

Solution v c v p

v c A sin( Fv z) B cos( Fv z)

P

v p C sin

z

L

Dcos

z

L

Effects of Geometric Imperfection

Solve for C and D first

v p Fv2v p Fv2o sin

z

L

2

z

z

z

z

z

C sin Dcos Fv2 C sin Dcos Fv2o sin

0

L

L

L

L

L

L

2

2

z

z

2

2

2

sin C Fv C Fv o cos D Fv D 0

L L

L L

2

2

2

2

2

C Fv C Fv o 0 and D Fv D 0

L

L

Fv2o

C

2

2

Fv

L

Solution becomes

and D 0

Fv2o

z

v A sin( Fv z) Bcos( Fv z)

sin

L

2

2

Fv

L

Geometric Imperfection

Solve for A and B

Boundary conditions v(0) v(L) 0

v(0) B 0

v(L) A sin Fv L 0

A0

Solution becomes

Fv2o

z

v

sin

2

L

2

Fv

L

Fv2

2 o

P

z PE o

z

L

v

sin

sin

Fv2

L 1 P

L

1

PE

2

L

P

z

PE

v

o sin

P

L

1

PE

Total Deflection

P

z

z

PE

v vo

o sin o sin

P

L

L

1

PE

P

P

z

1

z

E 1o sin

o sin

L 1 P

L

1 P

PE

PE

z

AFo sin

L

AF = amplification factor

Geometric Imperfection

AF

1

P

1

PE

amplification factor

M x P(v v o )

M x AF (Po sin

z

)

L

i.e., M x AF (moment due to initial crooked)

12

10

Amplification Factor AF

Increases exponentially

Limit AF for design

Limit P/PE for design

8

6

Value used in the code is 0.877

This will give AF = 8.13

Have to live with it.

4

2

0

0

0.2

0.4

0.6

P/PE

0.8

1

Residual Stress Effects

Residual Stress Effects

History of column inelastic buckling

Euler developed column elastic buckling equations (buried

in the million other things he did).

Take a look at: http://en.wikipedia.org/wiki/EuleR

An amazing mathematician

In the 1750s, I could not find the exact year.

The elastica problem of column buckling indicates elastic

buckling occurs with no increase in load.

dP/dv=0

History of Column Inelastic Buckling

Engesser extended the elastic column buckling theory in

1889.

He assumed that inelastic

buckling occurs with no

increase in load, and the

relation between stress

and strain is defined by

tangent modulus Et

Engesser’s tangent modulus theory is easy to apply. It

compares reasonably with experimental results.

PT=ETI / (KL)2

History of Column Inelastic Buckling

In 1895, Jasinsky pointed out the problem with Engesser’s

theory.

If dP/dv=0, then the 2nd order moment (Pv) will produce

incremental strains that will vary linearly and have a zero

value at the centroid (neutral axis).

The linear strain variation will have compressive and tensile

values. The tangent modulus for the incremental

compressive strain is equal to Et and that for the tensile

strain is E.

History of Column Inelastic Buckling

In 1898, Engesser corrected his original theory by

accounting for the different tangent modulus of the tensile

increment.

This is known as the reduced modulus or double modulus

The assumptions are the same as before. That is, there is

no increase in load as buckling occurs.

The corrected theory is shown in the following slide

History of Column Inelastic Buckling

The buckling load PR produces

critical stress R=Pr/A

During buckling, a small curvature

d is introduced

The strain distribution is shown.

The loaded side has dL and dL

The unloaded side has dU and dU

dL ( y y1 y) d

dU ( y y y1 ) d

d L E t ( y y1 y) d

dU E( y y y1 ) d

History of Column Inelastic Buckling

d v

d L E t ( y y1 y) v

dU E( y y y1 ) v

But, the assumption is dP 0

y

y y1

y y1

( d y )

dU dA d L dA 0

y

y y1

y y1

( d y )

E( y y y1 ) dA E t ( y y1 y) dA 0

ES1 E t S2 0

y

where, S1 ( y y y1 ) dA

y y1

and S 2

y y1

( y y1 y) dA

( d y )

History of Column Inelastic Buckling

S1 and S2 are the statical moments of the areas to the left

and right of the neutral axis.

Note that the neutral axis does not coincide with the centroid

any more.

The location of the neutral axis is calculated using the

equation derived ES1 - EtS2 = 0

M Pv

y

y y1

y y1

( d y )

M dU ( y y y1) dA d L ( y y1 y) dA

M Pv v ( EI1 E t I2 )

y

where, I1 ( y y y1 ) 2 dA

y y1

and I 2

y y1

( y y1 y) 2 dA

( d y )

History of Column Inelastic Buckling

M Pv v ( EI1 E t I2 )

Pv ( EI1 E t I2 )v 0

P

v

v 0

EI1 E t I2

v Fv2v 0

P

P

EI1 E t I2 EIx

I1

I2

and E E E t

Ix

Ix

where, Fv2

PR

2 EI x

E is the reduced or double modulus

(KL) 2

PR is the reduced modulus buckling load

History of Column Inelastic Buckling

For 50 years, engineers were faced with the dilemma that

the reduced modulus theory is correct, but the

experimental data was closer to the tangent modulus

theory. How to resolve?

Shanley eventually resolved this dilemma in 1947. He

conducted very careful experiments on small aluminum

columns.

He found that lateral deflection started very near the

theoretical tangent modulus load and the load capacity

increased with increasing lateral deflections.

The column axial load capacity never reached the calculated

reduced or double modulus load.

Shanley developed a column model to explain the

observed phenomenon

History of Column Inelastic Buckling

History of Column Inelastic Buckling

History of Column Inelastic Buckling

History of Column Inelastic Buckling

Column Inelastic Buckling

Three different theories

Tangent modulus

Reduced modulus

Shanley model

P

dP/dv=0

Tangent modulus theory

assumes

Perfectly straight column

Ends are pinned

Small deformations

No strain reversal during

buckling

Slope is zero at buckling

P=0 with increasing v

v

Elastic buckling analysis

PT

Tangent modulus theory

Assumes that the column buckles at the tangent modulus load such

that there is an increase in P (axial force) and M (moment).

The axial strain increases everywhere and there is no strain

reversal.

Strain and stress state just before buckling

PT

T

Mx - Pv = 0

T=PT/A

Strain and stress state just after buckling

v

v

Mx

T

T

T

T=ETT

Curvature = = slope of strain diagram

PT

T

h

h

T y

where y dis tance from centroid

2

h

T y ET

2

Tangent modulus theory

Deriving the equation of equilibrium

M x ydA

A

T T

T ( y h / 2) E T

M x T ( y h / 2)E T ydA

A

M x T y dA E T y 2 dA h / 2)E T y dA

A

A

A

M x 0 E T Ix 0

M x E T Ix v

The equation Mx- PTv=0 becomes -ETIxv” - PTv=0

2

2

Solution is PT= ETIx/L

Example - Aluminum columns

Consider an aluminum column with Ramberg-Osgood

E 10100 ksi

stress-strain curve

40.15 ksi

0 .2

n

0.002

E

0.2

1 0.002 n1

n n

E 0.2

1

0.002

n

0.2

E

n1

1

nE

0.2

0.2

E

E

n1 E T

0.002

1

nE

0.2

0.2

0.002

nE n1

n

0.000E+00

1.980E-04

3.960E-04

5.941E-04

7.921E-04

9.901E-04

1.188E-03

1.386E-03

1.584E-03

1.782E-03

1.980E-03

2.178E-03

2.376E-03

2.575E-03

2.775E-03

2.979E-03

3.198E-03

3.458E-03

3.829E-03

4.483E-03

5.826E-03

8.771E-03

1.529E-02

2.949E-02

5.967E-02

1.221E-01

18.55

0

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

50

ET

ET

differences

equation

10100.0

10100.0

10100.0

10100.0

10100.0

10100.0

10100.0

10100.0

10100.0

10100.0

10100.0

10100.0

10100.0

10100.0

10100.0

10100.0

10100.0

10099.9

10099.8

10099.5

10098.8

10097.6

10094.2

10088.7

10075.1

10054.2

10005.7

9934.0

9779.8

9563.7

9142.0

8602.6

7697.4

6713.6

5394.2

4251.9

3056.9

2218.6

1488.8

1037.0

679.2

468.1

306.9

212.4

140.8

98.5

66.3

46.9

32.1

23.0

Tangent Modulus Buckling

Ramberg-Osgood Stress-Strain

Stress-tangent modulus relationship

60

12000

Tangent Modulus (ksi)

50

Stress (ksi)

40

30

20

10000

8000

6000

4000

2000

10

0

0

0.000

0

0.010

0.020

0.030

Strain (in./in.)

0.040

0.050

10

20

30

40

Stress (ksi)

ET differences

ET equation

50

Tangent Modulus Buckling

(KL/r) c r

223.2521046

157.8630771

128.8946627

111.6260523

99.84137641

91.1422898

84.3813604

78.93150275

74.41710153

70.59690679

67.3048795

64.4113691

61.77857434

59.17430952

56.09208286

51.5097656

44.14566415

34.1419685

24.00464013

15.9961201

10.48827475

6.902516144

4.596633406

3.105440361

2.129145204

Column Inelastic Buckling Curve

60

Tangent Modulus Buckling Stress

0

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

50

PT

50

2 E T Ix

L2

PT

2 E T Ix

2 ET

T

2

A

AL2

KL / r

40

KL / rcr

30

2 ET

T

20

10

0

0

30

60

90

KL/r

120

150

Residual Stress Effects

Consider a rectangular section

with a simple residual stress

distribution

Assume that the steel material

has elastic-plastic stress-strain

curve.

Assume simply supported end

conditions

Assume triangular distribution

for residual stresses

b

x

d

rc

y

rt

y

y/b

rc

y

y

y

E

Residual Stress Effects

One major constrain on residual

stresses is that they must be

such that r dA 0

2

0.5 y y

b

b / 2

b / 2

2 y

x d dx 0.5 y

x d dx

b

0

2d y b 2 2d y b 2

0.5 y d b 2 0.5 y d b 2

b 8

b 8

0

0

Residual stresses are produced

by uneven cooling but no load

is present

Residual Stress Effects

b

Response will be such that elastic behavior when

x

d

0.5 y

Px

2 EIx

2

and Py

2 EIy

L

Yielding occurs when

L2

b

b

x

0.5 y i.e., P 0.5PY

Inelastic buckling will occur after 0.5 y

y

Y

2

Y Y b Y (1 2 )

b

y

Y

Y/b

Residual Stress Effects

Total axial force corresponding to the yielded sec tion

Y (1 2 )

Y b 2bd Y

bd 2

2

Y 1 2 bd Y (2 2 )bd

Y bd 2bd Y 2 Y bd 2 2bd Y

Y bd(1 2 2 ) PY (1 2 2 )

If inelastic buckling were to occur at this load

Pcr PY (1 2 2 )

1 Pcr

1

2 PY

If inelastic buckling occurs about x axis

2E

d3

Pcr PTx 2 (2b)

L

12

2 EIx

PTx

2

L2

1 Pcr

PTx Px 2

1

2 PY

PTx Px 2

1 PTx

1

2 PY

PTx Px

1 PTx

2

1

PY PY

2 PY

PTx 1

1 PTx

2

1

PY 2x

2 PY

2x

PTx

21

PY

PTx

PY

b

b

x

y

Pcr PTx

2

P

1

E

r

Let, x 2 2 x

PY x

Y K x Lx

If inelastic buckling occurs about y axis

Pcr PTy

2E

(2b) 3

d

12

L2

2 EIy

3

PTy

2

L2

3

1

P

PTy Py 2 1 cr

2 PY

PTy Py

Pcr PTy

3

PTy

21

P

Y

PTy 1

PY 2y

PTy

21

P

Y

3

3

PTy

21

PY

PTy

PY

x

y

3

PTy

21

PY

PTy Py

PY PY

2y

b

b

r 2

Py

1

E

y

Let, 2 2

PY y

Y

K

L

y y

Residual Stress Effects

x

2.236

2.000

1.826

1.690

1.581

1.491

1.414

1.313

1.221

1.135

1.052

0.971

0.889

0.803

0.705

0.577

0.317

y

2.236

2.000

1.826

1.690

1.581

1.491

1.414

1.246

1.092

0.949

0.815

0.687

0.562

0.440

0.315

0.182

0.032

Column Inelastic Buckling

Normalized column capacity

P/PY

0.200

0.250

0.300

0.350

0.400

0.450

0.500

0.550

0.600

0.650

0.700

0.750

0.800

0.850

0.900

0.950

0.995

1.200

1.200

1.000

1.000

0.800

0.800

0.600

0.600

0.400

0.400

0.200

0.200

0.000

0.000

0.0

0.5

1.0

Lambda

1.5

2.0

Tangent modulus buckling - Numerical

1

Discretize the cross-section into fibers

Think about the discretization. Do you need the flange

To be discretized along the length and width?

2

For each fiber, save the area of fiber (Afib), the

distances from the centroid yfib and xfib,

Ix-fib and Iy-fib the fiber number in the matrix.

Afib

yfib

Centroidal axis

3

Discretize residual stress distribution

4

Calculate residual stress (r-fib)

each fiber

5

Check that sum(r-fib Afib)for

Section = zero

Tangent Modulus Buckling - Numerical

14

6

Calculate effective residual

strain (r) for each fiber

r=r/E

13

7

Assume centroidal strain

Calculate the critical (KL)X and (KL)Y for the

(KL)X-cr = sqrt [(EI)Tx/P]

(KL)y-cr = sqrt [(EI)Ty/P]

Calculate the tangent (EI)TX and (EI)TY for the

(EI)TX = sum(ET-fib{yfib2 Afib+Ix-fib})

(EI)Ty = sum(ET-fib{xfib2 Afib+ Iy-fib})

Calculate average stress = = P/A

8

Calculate total strain for each fiber

tot=+r

Calculate Axial Force = P

Sum (fibAfib)

9

12

Assume a material stress-strain

curve for each fiber

Calculate stress in each fiber fib

11

10

Tangent modulus buckling - numerical

Section Dimension

b

d

y

12

4

50

No. of fibers

20

A

Ix

Iy

48

64

576.00

fiber no.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Afib

2.4

2.4

2.4

2.4

2.4

2.4

2.4

2.4

2.4

2.4

2.4

2.4

2.4

2.4

2.4

2.4

2.4

2.4

2.4

2.4

xfib

-5.7

-5.1

-4.5

-3.9

-3.3

-2.7

-2.1

-1.5

-0.9

-0.3

0.3

0.9

1.5

2.1

2.7

3.3

3.9

4.5

5.1

5.7

yfib

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

r-fib

-22.5

-17.5

-12.5

-7.5

-2.5

2.5

7.5

12.5

17.5

22.5

22.5

17.5

12.5

7.5

2.5

-2.5

-7.5

-12.5

-17.5

-22.5

r-fib

-7.759E-04

-6.034E-04

-4.310E-04

-2.586E-04

-8.621E-05

8.621E-05

2.586E-04

4.310E-04

6.034E-04

7.759E-04

7.759E-04

6.034E-04

4.310E-04

2.586E-04

8.621E-05

-8.621E-05

-2.586E-04

-4.310E-04

-6.034E-04

-7.759E-04

Ix fib

3.2

3.2

3.2

3.2

3.2

3.2

3.2

3.2

3.2

3.2

3.2

3.2

3.2

3.2

3.2

3.2

3.2

3.2

3.2

3.2

Iy fib

78.05

62.50

48.67

36.58

26.21

17.57

10.66

5.47

2.02

0.29

0.29

2.02

5.47

10.66

17.57

26.21

36.58

48.67

62.50

78.05

Tangent Modulus Buckling - numerical

Strain Increment

Fiber no.

-0.0003

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

tot

fib

-1.076E-03

-9.034E-04

-7.310E-04

-5.586E-04

-3.862E-04

-2.138E-04

-4.138E-05

1.310E-04

3.034E-04

4.759E-04

4.759E-04

3.034E-04

1.310E-04

-4.138E-05

-2.138E-04

-3.862E-04

-5.586E-04

-7.310E-04

-9.034E-04

-1.076E-03

-31.2

-26.2

-21.2

-16.2

-11.2

-6.2

-1.2

3.8

8.8

13.8

13.8

8.8

3.8

-1.2

-6.2

-11.2

-16.2

-21.2

-26.2

-31.2

Efib

Tx-fib

Ty-fib

Pfib

29000

92800 2.26E+06

-74.88

29000

92800 1.81E+06

-62.88

29000

92800 1.41E+06

-50.88

29000

92800 1.06E+06

-38.88

29000

92800 7.60E+05

-26.88

29000

92800 5.09E+05

-14.88

29000

92800 3.09E+05

-2.88

29000

92800 1.59E+05

9.12

29000

92800 5.85E+04

21.12

29000

92800 8.35E+03

33.12

29000

92800 8.35E+03

33.12

29000

92800 5.85E+04

21.12

29000

92800 1.59E+05

9.12

29000

92800 3.09E+05

-2.88

29000

92800 5.09E+05

-14.88

29000

92800 7.60E+05

-26.88

29000

92800 1.06E+06

-38.88

29000

92800 1.41E+06

-50.88

29000

92800 1.81E+06

-62.88

29000

92800 2.26E+06

-74.88

Tangent Modulus Buckling - Numerical

P

-0.0005

-0.0006

-0.0007

-0.0008

-0.0009

-0.001

-0.0011

-0.0012

-0.0013

-0.0014

-0.0015

-0.0016

-0.0017

-0.0018

-0.0019

-0.002

-0.0021

-0.0022

-0.0023

-0.0024

-0.00249

Tx

-417.6

-556.8

-696

-835.2

-974.4

-1113.6

-1252.8

-1384.8

-1510.08

-1624.32

-1734.72

-1832.16

-1924.8

-2008.32

-2083.2

-2152.8

-2209.92

-2263.2

-2304.96

-2340.48

-2368.32

-2386.08

-2398.608

Ty

1856000

1856000

1856000

1856000

1856000

1670400

1670400

1484800

1299200

1299200

1113600

1113600

928000

928000

742400

556800

556800

371200

371200

185600

185600

16704000

16704000

16704000

16704000

16704000

12177216

12177216

8552448

5729472

5729472

3608064

3608064

2088000

2088000

1069056

451008

451008

133632

133632

16704

16704

KLx-cr

KLy-cr

T/Y

209.4395102

628.3185307

0.174

181.3799364

544.1398093

0.232

162.231147 486.6934411

0.29

148.0960979 444.2882938

0.348

137.1103442 411.3310325

0.406

128.254983

384.764949

0.464

120.9199576 362.7598728

0.522

109.11051 294.5983771

0.577

104.4864889 282.1135199

0.6292

94.98347542

227.960341

0.6768

85.97519823 180.5479163

0.7228

83.65775001

175.681275

0.7634

75.56517263 136.0173107

0.802

73.97722346 133.1590022

0.8368

66.30684706 99.46027059

0.868

65.22619108 97.83928663

0.897

57.58118233

69.0974188

0.9208

49.27629185 44.34866267

0.943

48.8278711 43.94508399

0.9604

39.56410897 23.73846538

0.9752

39.33088015 23.59852809

0.9868

27.70743725 8.312231176

0.9942

27.63498414 8.290495243

0.99942

(KL/r) x

(KL/r) y

181.3799364 181.3799364

157.0796327 157.0796327

140.4962946 140.4962946

128.254983

128.254983

118.7410412 118.7410412

111.0720735 111.0720735

104.7197551 104.7197551

94.49247352 85.04322617

90.48795371 81.43915834

82.25810265 65.80648212

74.45670576 52.11969403

72.44973673 50.71481571

65.44135914 39.26481548

64.06615482 38.43969289

57.423414

28.711707

56.48753847 28.24376924

49.86676668 19.94670667

42.67452055 12.80235616

42.28617679 12.68585304

34.26352344 6.852704688

34.06154136 6.812308273

23.99534453 2.399534453

23.9325983

2.39325983

Tangent Modulus Buckling - Numerical

Inelastic Column Buckling

1

( T/ Y)

Normalized critical stress

1.2

0.8

0.6

0.4

0.2

0

0

20

40

60

80

100

120

KL/r ratio

(KL/r)x

(KL/r)y

140

160

180

200

Normalized column capacity

Column Inelastic Buckling

1.2

1.2

1

1.0

0.8

0.8

0.6

0.6

0.4

0.4

0.2

0.2

0

0.0

0.0

0.5

Num-x

Elastic

1.0

Num-y

Lambda

AISC-Design

1.5

Analytical-x

Analytical-y

2.0