1585 KB - Plymouth

advertisement

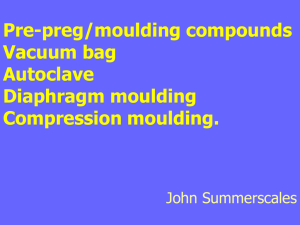

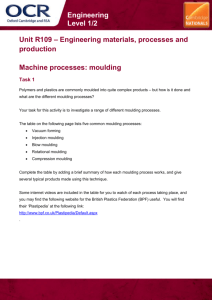

Pre-preg/moulding compounds Vacuum bag Autoclave Diaphragm moulding Compression moulding. John Summerscales Pre-preg (usually epoxy matrix) • Reinforcement is pre-impregnated with B-staged resin o A-stage: o o soluble and fusible B-stage: swollen but not dissolved by a variety of solvents C-stage: rigid, hard, insoluble, infusible • safer than liquid resins • mixing done by suppliers > better quality • expensive relative to dry reinforcements Pre-preg • use before date: there will be a finite life o if out-of-date should not be used for applications which may result in injury, loss or damage. • out-life: o time outside cold storage will reduce its useful life • normal to allow the material to warm to ambient temperature before use as condensation may form on cold material Pre-preg systems • cold-cure (not normally prepreg) o cure at ambient temperature • low temperature systems: o cure at ~60ºC, out-life ~3 months • medium temperature systems: o cure at ~120ºC, out life ~6 months, • high temperature systems: o cure at ~180ºC, out-life ~12 months. … above temperatures may be ±20ºC Out-life increases with cure temperature NB: the above times are indicative, check the manufacturers’ recommendation Pre-preg • key considerations include: o drape o … and conformability o ability to be (manually) formed to complex curvature tack o natural ability to follow complex curvature stickiness debulk the laminate stack is subject to vacuum every few layers in temporary bag or vacuum table. Vacuum bag (VB) • VB procedures as in lecture C5 (hand-lay), but reinforcement now pre-impregnated Pearce compressibility curves • 625 gsm plain weave E-glass • one (black) or five (red) layers http://dx.doi.org/10.1016/0956-7143(95)93709-S Compressibility of fabrics • Quinn and Randall: o Vf = a + b √P i.e. P Vf2 • Toll and Månson o P = kE(Vfn – Vfon) k = power-law coefficient E = elastic modulus of fibres (normal to plane!) Vf = fibre volume fraction Vfo = limiting fibre volume fraction, below which P=0 n = power-law exponent • also Freundlich equation (see C8 webpage) Toll and Månson exponents • Fibre kE Vfo % n • • • • • • • • • • • • 13 420 4500 820 260 700 500 115 100 500 8 15 1.45 2 3 Wool Wool Planar spun glass roving fluffy glass roving straight glass roving graphite roving Mat Mat Weave Weave Weave 3 3 5 8.5 7 15.5 14.5 3.5 4.5 11 7 9 Reference J Schofield, J Textile Institute, 1938 [3] CM van Wyk, J Textile Institute, 1946 [4] S Toll et al, ICCM-9, 1993 [5] YR Kim et al, Polymer Composites, 1991 [6] YR Kim et al, Polymer Composites, 1991 [6] YR Kim et al, Polymer Composites, 1991 [6] YR Kim et al, Polymer Composites, 1991 [6] R Gauvin & Chibani, SPI-43, 1988 [7] JA Quinn and Randall, FRC-4, 1990 [1] YR Kim et al, Polymer Composites, 1991 R Gauvin & Chibani, SPI-43, 1988 [7] JA Quinn and Randall, FRC-4, 1990 [1] Autoclave • only possible to apply ~1000 mbar pressure with a vacuum bag • greater levels of consolidation require an autoclave: advanced pressure cooker • autoclave is a pressure vessel with pipework to allow a vacuum to be maintained in the bagged work-piece. • temperature control is normally by gas- or electric-heating, o proportional-integral-derivative (PID) controller o Autoclaves images from Google search “autoclave + image” Autoclave Autoclave temp./pressure cycle Autoclave • dwell to get correct resin viscosity • cure to achieve optimum properties • • • • high capital cost equipment long cycle times economics demands high autoclave loading mould tools must be designed to permit circulation of heated air • VB consumables may be a thermal barrier Pressclave • pressclave: alternative relatively inexpensive technology o normally a hinged frame with an elastomeric membrane so vacuum can be drawn under the membrane via perforations in the pressclave base and external pressure applied outside membrane. Diaphragm forming (DF) • autoclave technique used solely for thermoplastic matrix composites • laminate laid up flat between 2 diaphragms superplastic aluminium sheets, or o high-temperature polymeric films o • diaphragms are clamped in a frame o the laminate is not clamped • laminate is formed over mould tool using heat, vacuum and pressure in the autoclave. Diaphragm forming (DF) • disadvantages diaphragms are normally a disposable item o rubber membranes can be used for limited production runs o o considerable literature on (avoiding) wrinkling of the reinforcement Compression moulding • two matched (usually steel) mould halves mounted in a (normally hydraulic) press • movement limited to one axis normal to the plane of the mould Compression moulding: materials Several materials suitable: • prepreg continuous fibres in epoxy resin • prepreg short fibres in polyester resin sheet moulding compound (SMC) o dough moulding compound (DMC) o bulk moulding compound (BMC) o • prepreg short fibre in a thermoplastic matrix o continuous random orientation filament glass mat thermoplastics (GMT) Compression: moulding compounds • normally unsaturated polyester resin matrix • normally short fibre reinforcement • normally supplied "just in time" for production of composite components usually by compression moulding • Compounds marketed in three major forms: bulk moulding compound (BMC) o dough moulding compound (DMC) o sheet moulding compound (SMC) o Compression moulding • unlike VB/autoclave processes, no consolidation pressure on vertical surfaces X X X X moulding • near vertical surfaces subject to wrinkling • may be resolved by the use of rubber-block moulding, or o hydroforming (pressurised liquid) o substituting the male mould half Any questions ? Summary of lecture •pre-preg/moulding compounds •vacuum bag •autoclave •diaphragm moulding •compression moulding