Biomass Refining CAFI

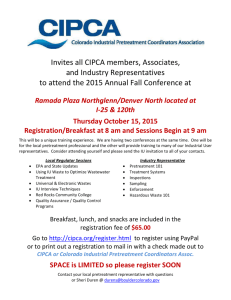

advertisement

Enzymatic Hydrolysis of Cellulose and Hemicellulose in Solids Prepared by Leading Pretreatment Technologies Charles E. Wyman, Dartmouth College Y. Y. Lee, Auburn University Mohammed Moniruzzaman, Genencor International Bruce E. Dale, Michigan State University Tim Eggeman, Neoterics International Richard T. Elander, National Renewable Energy Laboratory Michael R. Ladisch, Purdue University Mark T. Holtzapple, Texas A&M University John N. Saddler, University of British Columbia Bioprocessing of Agricultural Feedstocks: Report on Pretreatment for Biomass Refining 2nd World Congress on Industrial Biotechnology and Bioprocessing Orlando, Florida Biomass Refining CAFI April 20, 2005 USDA IFAFS Project Tasks • • • • • Apply leading pretreatment technologies to prepare biomass for conversion to products Characterize resulting fluid and solid streams Close material and energy balances for each pretreatment process Determine cellulose digestibility and liquid fraction fermentability Compare performance of pretreatment technologies on corn stover Biomass Refining CAFI Pretreatment and Enzymatic Hydrolysis Stages Cellulase enzyme Biomass Chemicals Stage 1 Pretreatment Solids: cellulose, hemicellulose, lignin Dissolved sugars, oligomers, lignin Biomass Refining CAFI Stage 2 Enzymatic hydrolysis Dissolved sugars, oligomers Residual solids: cellulose, hemicellulose, lignin Calculation of Sugar Yields • Comparing the amount of each sugar monomer or oligomer released to the maximum potential amount for that sugar would give yield of each • However, most cellulosic biomass is richer in glucose than xylose • Consequently, glucose yields have a greater impact than for xylose • Sugar yields in this project were defined by dividing the amount of xylose or glucose or the sum of the two recovered in each stage by the maximum potential amount of both sugars – The maximum xylose yield is 24.3/64.4 or 37.7% – The maximum glucose yield is 40.1/64.4 or 62.3% – The maximum amount of total xylose and glucose is 100%. Biomass Refining CAFI Pretreatment Yield Comparisons at 60 FPU/g Glucan Increasing pH Pretreatment system Xylose yields* Glucose yields* Total sugars* Stage 1 Stage 2 Total xylose Stage 1 Stage 2 Total glucose Stage 1 Stage 2 Combined total Maximum possible 37.7 37.7 37.7 62.3 62.3 62.3 100.0 100.0 100.0 Dilute acid 32.1/31.2 3.3 35.4/34.5 3.9 53.3 57.2 36.0/35.1 56.6 92.6/91.7 Flowthrough 36.3/1.7 0.8/0.7 37.1/2.4 4.5/4.4 57.0 61.5/61.4 40.8/6.1 57.8/57.7 98.6/63.8 Controlled pH 21.8/0.9 9.0 30.7 3.5/0.2 54.7 58.2 25.3/1.1 63.6 88.9 ND/30.2 ND/30.2 61.8 61.8 ND/92.0 ND/92.0 59.4 59.4 17.8/0 76.4 94.2/76.4 59.5 60.5/59.8 10.2/0.6 79.7 89.9/80.3 AFEX ARP 17.8/0 17.0 34.8/17.0 Lime 9.2/0.3 20.2 29.4/20.5 1.0/0.3 *Cumulative soluble sugars as total/monomers. Single number = just monomers. St ag e St 1 ag e2 St ag e St 1 ag e2 St ag e St 1 ag e2 0 Maximum possible Lime ARP AFEX Controlled pH Flowthrough 50 St ag e St 1 ag e2 Dilute acid 25 St ag e St 1 ag e2 St ag e St 1 ag e2 Sugar yields, % of max total - Pretreatment Yield Comparisons at 15 FPU/g Glucan 100 75 Oligoxylose Monoxylose Oligoglucose Monoglucose St ag e St 1 ag e2 St ag e St 1 ag e2 St ag e St 1 ag e2 0 Maximum possible Lime ARP AFEX Controlled pH Flowthrough 50 St ag e St 1 ag e2 Dilute acid 25 St ag e St 1 ag e2 St ag e St 1 ag e2 Sugar yields, % of max total - Pretreatment Yield Comparisons at 15 FPU/g Glucan 100 75 Oligoxylose Monoxylose Oligoglucose Monoglucose St ag e St 1 ag e2 St ag e St 1 ag e2 St ag e St 1 ag e2 0 Maximum possible Lime ARP AFEX Controlled pH Flowthrough 50 St ag e St 1 ag e2 Dilute acid 25 St ag e St 1 ag e2 St ag e St 1 ag e2 Sugar yields, % of max total - Pretreatment Yield Comparisons at 15 FPU/g Glucan 100 75 Oligoxylose Monoxylose Oligoglucose Monoglucose St ag e St 1 ag e2 St ag e St 1 ag e2 St ag e St 1 ag e2 0 Maximum possible Lime ARP AFEX Controlled pH Flowthrough 50 St ag e St 1 ag e2 Dilute acid 25 St ag e St 1 ag e2 St ag e St 1 ag e2 Sugar yields, % of max total - Pretreatment Yield Comparisons at 15 FPU/g Glucan 100 75 Oligoxylose Monoxylose Oligoglucose Monoglucose St ag e St 1 ag e2 St ag e St 1 ag e2 St ag e St 1 ag e2 0 Maximum possible Lime ARP AFEX Controlled pH Flowthrough 50 St ag e St 1 ag e2 Dilute acid 25 St ag e St 1 ag e2 St ag e St 1 ag e2 Sugar yields, % of max total - Pretreatment Yield Comparisons at 15 FPU/g Glucan 100 75 Oligoxylose Monoxylose Oligoglucose Monoglucose St ag e St 1 ag e2 St ag e St 1 ag e2 St ag e St 1 ag e2 0 Maximum possible Lime ARP AFEX Controlled pH Flowthrough 50 St ag e St 1 ag e2 Dilute acid 25 St ag e St 1 ag e2 St ag e St 1 ag e2 Sugar yields, % of max total - Pretreatment Yield Comparisons at 15 FPU/g Glucan 100 75 Oligoxylose Monoxylose Oligoglucose Monoglucose St ag e St 1 ag e2 St ag e St 1 ag e2 St ag e St 1 ag e2 0 Maximum possible Lime ARP AFEX Controlled pH Flowthrough 50 St ag e St 1 ag e2 Dilute acid 25 St ag e St 1 ag e2 St ag e St 1 ag e2 Sugar yields, % of max total - Pretreatment Yield Comparisons at 15 FPU/g Glucan 100 75 Oligoxylose Monoxylose Oligoglucose Monoglucose Pretreatment Yield Comparisons at 15 FPU/g Glucan 75 Oligoxylose S1 Monoxylose S1 Monoxylose S2 Oligoglucose S1 50 Monoglucose S1 Monoglucose S2 25 le os s ib M ax p Li m e AR P AF EX nt ro lle d pH h Co th ro ug Fl ow ea cid 0 Di lu t Sugar yields, % of max total - 100 Observations from IFAFS Project for Corn Stover • All pretreatments were effective in making cellulose accessible to enzymes • Lime, ARP, and flowthrough remove substantial amounts of lignin and achieved somewhat higher glucose yields from enzymes than dilute acid or controlled pH • However, AFEX achieved slightly higher yields from enzymes even though no lignin was removed • Cellulase was effective in releasing residual xylose from all pretreated solids • Xylose release by cellulase was particularly important for the high-pH pretreatments by AFEX, ARP, and lime, with about half being solubilized by enzymes for ARP, two thirds for lime, and essentially all for AFEX Biomass Refining CAFI Caveats • The yields can be further increased for some pretreatments with enzymes a potential key • Mixed sugar streams will be better used in some processes than others • Oligomers may require special considerations, depending on process configuration and choice of fermentative organism • The conditioning and fermentability of the sugar streams must be assessed • These results are only for corn stover, and performance with other feedstocks will likely be different Biomass Refining CAFI Tasks for the DOE OBP Project • Corn stover and poplar pretreated by leading technologies to improve cellulose accessibility to enzymes • Conditioning methods developed as needed to maximize fermentation yields by a recombinant yeast, the cause of inhibition determined, and fermentations modeled • Cellulose and hemicellulose in pretreated biomass enzymatically hydrolyzed, as appropriate, and models developed to understand the relationship between pretreated biomass features, advanced enzyme characteristics, and enzymatic digestion results • Capital and operating costs estimated for each integrated pretreatment, hydrolysis, and fermentation system and used to direct research Biomass Refining CAFI Tasks for the DOE OBP Project • Corn stover and poplar pretreated by leading technologies to improve cellulose accessibility to enzymes • Conditioning methods developed as needed to maximize fermentation yields by a recombinant yeast, the cause of inhibition determined, and fermentations modeled • Cellulose and hemicellulose in pretreated biomass enzymatically hydrolyzed, as appropriate, and models developed to understand the relationship between pretreated biomass features, advanced enzyme characteristics, and enzymatic digestion results • Capital and operating costs estimated for each integrated pretreatment, hydrolysis, and fermentation system and used to direct research Biomass Refining CAFI Enzymatic Hydrolysis Plan • Measure enzymatic hydrolysis of cellulose and hemicellulose as a function of cellulase and xylanase loadings and beta glucosidase and beta xylosidase supplementation • Apply fractional factorial experimental design to determine key trends and interactions • Characterize enzyme and substrate features for each feedstock and pretreatment • Develop kinetic models to better understand key factors impacting performance • Define routes to improve cellulose and hemicellulose conversion with less enzyme Biomass Refining CAFI Enzymatic Hydrolysis of Cellulose from Pretreated Poplar Wood 100 90 Glucose yield, % 80 70 60 50 40 30 20 POP-1-Severity -3.01 POP-2-Severity -3.25 POP-3-Severity -3.31 POP-4-Severity -3.55 10 0 0 10 Biomass Refining CAFI 20 30 40 Time, hours 50 60 70 80 2% glucan concentration 50 FPU/g glucan, no β-glucosidase supplementation Pretreated Substrate Schedule Pretreatment/Substrate Dilute Acid/Corn Stover Dilute Acid/Poplar (Bench Scale) Dilute Acid/Poplar (Pilot Plant) SO2/Corn Stover Controlled pH/Poplar SO2/Poplar Ammonia Fiber Explosion/Poplar Ammonia Recycled Percolation/Poplar Expected Date September 2004 October 2004 December 2004 March 2005 May 2005 August 2005 September 2005 October 2005 Flowthrough/Poplar March 2006 Lime/Poplar April 2006 Biomass Refining CAFI Kinetic Models* • Non-mechanistic (NM): 2 – Based on data correlation without an explicit calculation of adsorbed enzyme concentration. • Semi-mechanistic (SM): 8 – Based on single enzyme activity and single substrate feature (concentration). • Functionally-based (FB): 3 – Featuring an adsorption model, multiple enzyme activities, and substrate variables. • Structurally-based (SB): 0 – Structural features of cellulase and interaction between substrate and enzyme. Biomass Refining CAFI *Zhang and Lynd ( in press) Predictions of Effect of Lignin by Selected Models 100 g substrate/L, 50% cellulose, 10 FPU cellulase/g cellulose, 2 CBU/FPU 100 Cellulose conversion, % 90 NM, 5 FPU/gm 80 70 Phillipidis et al. 60 50 South et al. 40 30 Holtzapple et al. 20 0 10 Biomass Refining CAFI 20 30 40 Lignin concentration ( g/l) 50 60 Acknowledgments US Department of Agriculture Initiative for Future Agricultural and Food Systems Program, Contract 00-52104-9663 US Department of Energy Office of the Biomass Program, Contract DE-FG36-04GO14017 Natural Resources Canada Our team from Dartmouth College; Auburn, Michigan State, Purdue, and Texas A&M Universities; the University of British Columbia; Genencor International; and the National Renewable Energy Laboratory Biomass Refining CAFI Questions? Stop Pretreatment Yield Comparisons at 15 FPU/g Glucan Increasing pH Pretreatment system Xylose yields* Glucose yields* Total sugars* Stage 1 Stage 2 Total xylose Stage 1 Stage 2 Total glucose Stage 1 Stage 2 Combined total Maximum possible 37.7 37.7 37.7 62.3 62.3 62.3 100.0 100.0 100.0 Dilute acid 32.1/31.2 3.2 35.3/34.4 3.9 53.2 57.1 36.0/35.1 56.4 92.4/91.5 Flowthrough 36.3/1.7 0.6/0.5 36.9/2.2 4.5/4.4 55.2 59.7/59.6 40.8/6.1 55.8/55.7 96.6/61.8 Controlled pH 21.8/0.9 9.0 30.8/9.9 3.5/0.2 52.9 56.4/53.1 25.3/1.1 61.9 87.2/63.0 34.6/29.3 34.6/29.3 59.8 59.8 94.4/89.1 94.4/89.1 56.1 56.1 17.8/0 71.6 89.4/71.6 57.0 58.0/57.3 10.2/0.6 76.6 86.8/77.2 AFEX ARP 17.8/0 15.5 33.3/15.5 Lime 9.2/0.3 19.6 28.8/19.9 1.0/0.3 *Cumulative soluble sugars as total/monomers. Single number = just monomers.