Numerical Study of Bottom Water Draw-Off of Stratified Oil

advertisement

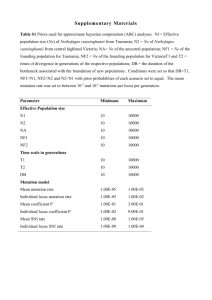

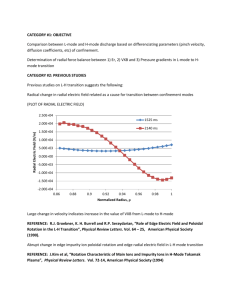

Numerical Study of Bottom Water Draw-Off of Stratified Oil-Water Pipe Flow Yousef Zurigat Bssam Jubran Lyes Khezzar Salam Al-Far Department of Mechanical and Industrial Engineering College of Engineering Plan Introduction & Objectives Oil-water Transport & dehydration issues Simulation Model Results Conclusions Water issues in Oil-Production Well life extension results in increased water Production (98%) Need to separate water from oil (dehydration facilities cost money) Pre-separation may take place in transport pipelines Can we take advantage of it? Concept of Bottom Water Draw Off Depending upon prevailing conditions a water layer may form at the bottom of the pipe. It can then be selectively removed. Oil in Water Emulsion Interface Bottom-Water Draw-off pipe Design Challenge of BWDO Concept What is the maximum water flow rate that can be drawn off (With Acceptable quality)? How can disturbance of the water/oil-in-waterdispersion interface be avoided? If several draw-off points are used, how will the interface and flow regimes in between draw points be affected? Objectives For a single draw-off pipe, investigate the variation of oil concentration in the draw-off pipe as a function of draw-off flow rate and interface position.(Interface location not known a priori!!) Investigate the maximum possible water flow rates with acceptable quality (oil concentration) for two consecutive draw-off pipes. Flow Regimes of Oil-Water Mixtures Depending upon the oil superficial velocity several regimes are possible for horizontal water dominated flows: Stratified Flow Stratified Flow with Mixing at the interface Dispersion of oil in water and water layer Oil in water Emulsion Geometry and Flow Parameters Main pipe Diameter = 0.68 m Draw-Off Pipe Diameter = 0.240 m Oil-flow rate = 8049 m3/day Water flow rate = 43614 m3/day Interface Location 25 cm from bottom of main pipe. Simulation conducted with one and two draw-off pipes Modelling challenges Flow is complex and two-phase (dispersions present) Two Approaches: 1. Single-Phase Flow Modeling: If negligible slip between the phases and hold-up take place--In the present regime!! (watercut=85%, water superficial velocity=1.3 m/s)! 2. Two-Fluid Flow Modeling: Actual Flow Mathematical Model SINGLE-PHASE FLOW MODEL Steady, Single-phase, incompressible and turbulent flow. Pressure drop approaches that of single phase flow Flow dynamics very similar to single phase flow Full three-D simulation Quantitative analysis of draw-off water quality-Single : Phase Flow Model Initial oil concentrations in the pipe regions above and below the interface are based on experimental data. The concentration of oil in free water assumed equal to 600 ppm in accordance with field data. The amounts of oil in the areas above- and below-theinterface streams which make up the draw-off flow are calculated based on the flow rates and the concentrations calculated in the first step above. Second Tapping Draw-Off (m3/d) Cut-off flow rates with water quality <2000 ppm from two tappings 11000 o/w 20000ppm o/w 40000ppm 9000 o/w uniform 7000 5000 3000 7000 9000 11000 First Tapping Draw-Off (m3/d) Two-Fluid Modeling In the PHOENICS, the concept of thermodynamic phase is used, i.e., the water and oil are treated as two different phases in the mixture. These two phases are in motion relative to each other due to the buoyancy effect, which leads to inter-phase momentum transfer. The Inter-Phase Slip Algorithm (IPSA) is adopted to predict the phenomenon in this work. Phase equations Each phase is regarded as having its own distinct velocity components. Phase velocities are linked by interphase momentum transfer - droplet drag, film surface friction etc. Each phase may have its own temperature, enthalpy, and mass fraction of chemical species. Phase concentrations are linked by interphase mass transfer. Phase equations (Cont.) d ( Ri ii ) Ri iVii Ri , i i Ri S , i dt t Ri i i time volume fraction of phase i density of phase i any conserved property of phase i Vi ,i S,i velocity vector of phase i exchange coefficient of the entity in phase i source rate of i Results Results (Cont.) Results (Cont.) Pipe 1 Pipe 2 Results (Cont.) 1.00E+00 9.00E-01 x=1.9, KEP 8.00E-01 x=1.9, Level Model 7.00E-01 x=1.9, Model KL x=1.9, KECHEN 5.00E-01 4.00E-01 3.00E-01 2.00E-01 1.00E-01 0.00E+00 0 0.2 0.4 0.6 h/D 0.8 1 R2 6.00E-01 Results (Cont.) 9.00E-03 8.00E-03 7.00E-03 R2 6.00E-03 5.00E-03 Q2 4.00E-03 3.00E-03 2.00E-03 1.00E-03 0.00E+00 0 2000 4000 6000 8000 Flow Rate From The First Draw -off pipe (m ^3/day) 10000 12000 Results (Cont.) 1.000E+00 9.000E-01 8.000E-01 7.000E-01 x=1.9 R2 6.000E-01 x=4.5 5.000E-01 x=6.9 x=9 4.000E-01 3.000E-01 2.000E-01 15% oil 1.000E-01 0.000E+00 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 h/D R2 distributions along the main pipe, KEP, BD1=7000, BD2=3000 0.8 0.9 1 Results (Cont.) 7.00E-01 6.00E-01 5.00E-01 R2 4.00E-01 3.00E-01 R2 @ 3000 m^3/day R2 @4000 R2 @5000 R2 @6000 R2 @7000 R2 @8000 R2 @9000 R2 @10000 2.00E-01 1.00E-01 0.00E+00 0.00E+00 1.00E-01 2.00E-01 3.00E-01 4.00E-01 5.00E-01 6.00E-01 7.00E-01 8.00E-01 9.00E-01 1.00E+00 h/D R2 at x=8.74 for 2nd BWDO pipe w ith 1st pipe colsed Results (Cont.) 0.35 0.3 0.25 h/D 0.2 0.15 h/D at 1200ppm for 95% water cut h/D at 1200ppm for 85% water cut 0.1 0.05 0 2000 3000 4000 5000 6000 7000 BWDO 8000 9000 10000 11000 Acknowledgements PDO’s FUNDING OF THIS WORK IS GRATEFULLY ACKNOWLEDGED