Resume

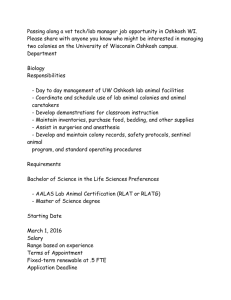

advertisement

Douglas R Nieskes (920) 948-8455 dnieskes@gmail.com W5113 Kennedy Drive Fond du Lac, Wisconsin 54935 OBJECTIVE / PROFESSIONAL SUMMARY Successfully managed 7-50 employees as a Manager/Department Shift Leader. Implemented Lean 5s Manufacturing/MDI(Managing for Daily Improvement) in different companies to increase profitability. I was voted by membership of a non-profit BMX Club "Track Operator", did many new printing press installations and start-ups (sheetfed, flexographic, web offset and gravure), went to many manager 3 day (overnight) conferences, worked with many customers insuring customer satisfaction. WORK EXPERIENCE 2/2015 to present OEC Graphics Oshkosh, Wisconsin Seamex Technician Preparing flexographic printing sleeves, documentation of final product information, prepare for final shipping to customers. 9/2014 to 1/2015 Solucion, LLC Huntersville, North Carolina Production Support/Quality Technician Supports production by overseeing the equipment to include complete area set-up, assist in production team assignments, running samples, quality checks, assisting Line Leaders as needed, and help with scheduling production. Support all equipment in production area. Building relationships, be visible, communicate, and train employees/team members to resolve conflict in a fair, consistent, and empowered manner with a team environment. Through employee involvement. 7/2014 to 9/2014 Amerequip Kiel, Wisconsin Assembly Pulling and gathering parts, hardware and the assembly of backhoes of many versions of John Deere and Mahindra. 12/2007 to 7/2014 Oshkosh Corporation Oshkosh, Wisconsin Assembly Have worked in several different areas of the company. Participated in teams as Leader, SMS, Kronos (time clock) lead, and safety representative Currently working on a moving assembly line producing 23-26 vehicles per day Great Attendance Record Safety Conscious-Accident free Safety Record 4/1985 to 12/2007 Quad/Graphics Lomira, Wisconsin Manager/Press Operator Communicated Company policies/procedures to ensure safety of person, environment and equipment Excellent attention to detail to meet specifications, tolerances for quality of customer products Collaborated with customers to guarantee that produced products met their expectations Worked and maintained a LEAN environment on a daily basis Manager/Night shift lead, go to person for the department, customers, other departments and scheduling. Installation and start-up of printing presses and add-on equipment. CERTIFICATIONS, LICENSES, AWARDS Lock-Out/ Tag-out SKILLS Trained in hazardous waste, OSHA, SMS (Safety Management Systems), Fire extinguisher use, Lock Out and LEAN 5s Manufacturing As a manager, insisted on a quality product Focused on reducing employee injuries. During my work history I have operated many different printing presses of all different formats and processes, operated overhead cranes, torque/stall gun and tools. Also have experience in packaging equipment, such as Blister and Plastic Film. EDUCATION 1 yr M.A.T.C. Printing and Publishing courses West Bend East High School Grad-Diploma