JobProfile

advertisement

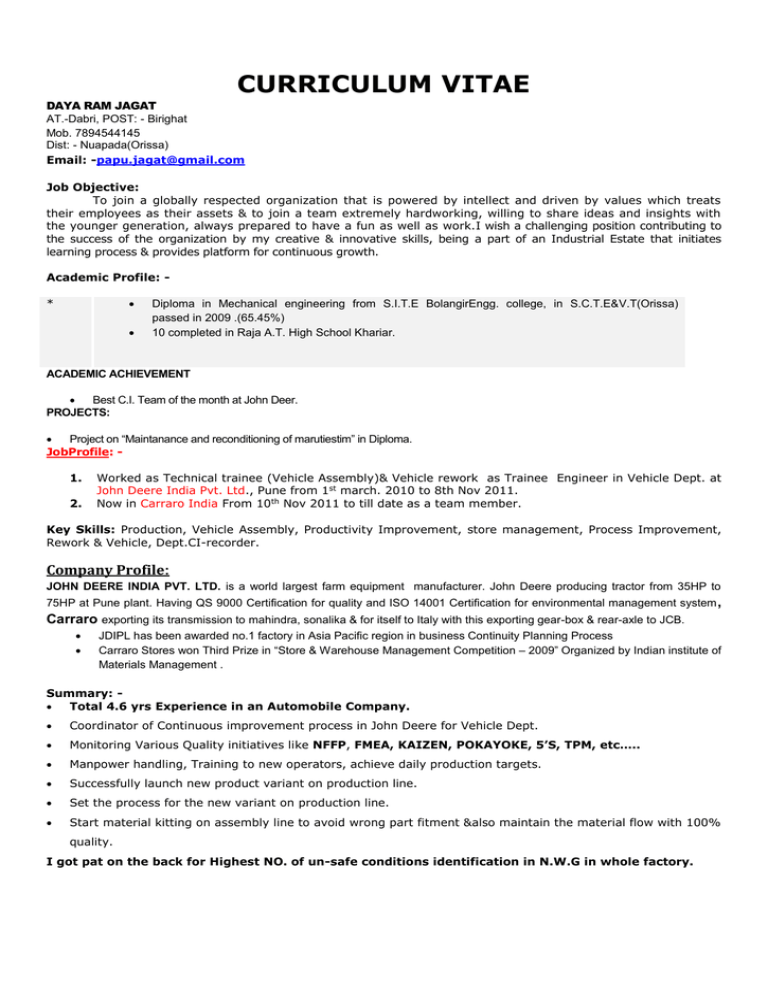

CURRICULUM VITAE DAYA RAM JAGAT AT.-Dabri, POST: - Birighat Mob. 7894544145 Dist: - Nuapada(Orissa) Email: -papu.jagat@gmail.com Job Objective: To join a globally respected organization that is powered by intellect and driven by values which treats their employees as their assets & to join a team extremely hardworking, willing to share ideas and insights with the younger generation, always prepared to have a fun as well as work.I wish a challenging position contributing to the success of the organization by my creative & innovative skills, being a part of an Industrial Estate that initiates learning process & provides platform for continuous growth. Academic Profile: * Diploma in Mechanical engineering from S.I.T.E BolangirEngg. college, in S.C.T.E&V.T(Orissa) passed in 2009 .(65.45%) 10 completed in Raja A.T. High School Khariar. ACADEMIC ACHIEVEMENT Best C.I. Team of the month at John Deer. PROJECTS: Project on “Maintanance and reconditioning of marutiestim” in Diploma. JobProfile: 1. 2. Worked as Technical trainee (Vehicle Assembly)& Vehicle rework as Trainee Engineer in Vehicle Dept. at John Deere India Pvt. Ltd., Pune from 1st march. 2010 to 8th Nov 2011. Now in Carraro India From 10th Nov 2011 to till date as a team member. Key Skills: Production, Vehicle Assembly, Productivity Improvement, store management, Process Improvement, Rework & Vehicle, Dept.CI-recorder. Company Profile: JOHN DEERE INDIA PVT. LTD. is a world largest farm equipment manufacturer. John Deere producing tractor from 35HP to 75HP at Pune plant. Having QS 9000 Certification for quality and ISO 14001 Certification for environmental management system , Carraro exporting its transmission to mahindra, sonalika & for itself to Italy with this exporting gear-box & rear-axle to JCB. JDIPL has been awarded no.1 factory in Asia Pacific region in business Continuity Planning Process Carraro Stores won Third Prize in “Store & Warehouse Management Competition – 2009” Organized by Indian institute of Materials Management . Summary: Total 4.6 yrs Experience in an Automobile Company. Coordinator of Continuous improvement process in John Deere for Vehicle Dept. Monitoring Various Quality initiatives like NFFP, FMEA, KAIZEN, POKAYOKE, 5’S, TPM, etc….. Manpower handling, Training to new operators, achieve daily production targets. Successfully launch new product variant on production line. Set the process for the new variant on production line. Start material kitting on assembly line to avoid wrong part fitment &also maintain the material flow with 100% quality. I got pat on the back for Highest NO. of un-safe conditions identification in N.W.G in whole factory. Functional Expertise: Reporting to superior person, Responsible at department level for: 1. PRODUCTION Strong Orientation towards Productivity rise by using various tools like Kaizen, Motion Loss study, Sequence of operation, VA &NVA, , TPM, POKAYOKE. Coordinator for implementing Kaizens in the area of - Productivity improvement, Breakdown prevention, Energy saving, Cost saving, Cycle time reduction, Fatigue reduction, Safety. Monitoringof 5’S & TPM activities in shop that stimulate Production activity. Hands on experience to the Assembly Line of tractor with various models . Minor & all major rework of tractors. (Related to Hydraulics & functional problem). 2. PREVENTIVE MAINTENANCE ACTIVITY IN SHOP. Continuous watch on 5’S & TPM activity at our Dept. area for better life of Equipments. 3. COST REDUCTION: Implementation of Kaizens, DC tools, Tooling improvement, Reusing Tools, Use of alternative material or sources, elimination of wastes & follow discipline. Control on Scrap & Rejection of components & products by monitoring process. 4. MANAGING MANPOWER Motivating each team member. Strong Exposure towards industrial engineering. Results achieved: in JDIPL & Carraro. Sustaining zero process first pass yield Quality complaint for Assembly contribution. Successfully launch new models on assembly line. Reduce rejection cost of assembly line. Daily inspection & finding the main cause of breakdown & rework the Product. Suggest new changes in parts fitment procedure. Maintain smooth material flow on assembly line by start material kitting to avoid NVA. Trainings attend:1. Training on Total Assembly & Dis-assembly of Tractor & transmission components. 2. Shop Floor practices for Excellent Manufacturing & productivity improvement. o o o o o o o TPM Kaizens 5S Poka-Yoke Material Kanban JDQPS Stop to fix 3. Failure mode effect analysis-FMEA 4. Productivity 5. Safety, Ergonomic& First Aid 6. Personality Development. 7. Fire fighting. 8. Communication Skill. Computer proficiency: Basic Computer, MS –Office. Auto CAD, Strengths: 1. Self - confident and self- motivated. 2. Skilled at taking initiative, leading& motivating the group. 3. Sincere and Hard Working with Positive attitude. 4. I believe in growth through continuous learning and application of knowledge. 5. Result oriented. 6. Adaptability. 7. Ability to mix with people. 8. Good grasping power. PERSONAL PROFILE: Name ; Dayaram Jagat. Father’s Name : Mr. BaishnabaJagat. Permanent Add. : At-Dabri,P.O-Birighat ,P.S- Khariar. Dist- Nuapada (Orissa.). Pin- 766118. Date of birth : 1st AUG 1988 Nationality : Indian Marital status : Married Gender : Male Languages Known : Oriya (mother tongue), and Hindi, English. Hobbies : Listening Music , Playing cricket, Chess, Batminton reading technology & story books. Playing Indoor & Outdoor Games. My area of interest– . Production assembly, Manufacturing ,store, Quality control, I am sure that the synthesis of my technical knowledge and managerial aptitude with people orientation makes me suitable for the required position and would help me play a vital role in the growth of your esteemed organization. Date: Place: Dayaram Jagat