File

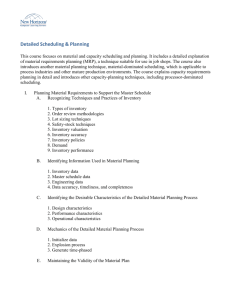

advertisement

Chapter 14 The Production Cycle 14-1 Learning Objectives Describe the major business activities and related information processing operations performed in the production cycle. Identify major threats in the production cycle and evaluate the adequacy of various control procedures for dealing with those threats. Explain how a company’s cost accounting system can help it achieve its manufacturing goals. Discuss the key decisions that must be made in the production cycle and identify the information required to make those decisions. 14-2 Production Cycle 14-3 The Production Cycle Business activities and information processing activities Related to manufacturing of products CIM Computer integrated manufacturing 14-4 The Production Cycle Business activities and information processing activities Related to manufacturing of products CIM Computer integrated manufacturing 14-5 Production Cycle Activities 1. Product design 2. Planning and scheduling 3. Production operations 4. Cost accounting 14-6 Production Cycle General Threats Inaccurate or invalid master data Unauthorized disclosure of sensitive information Loss or destruction of data 14-7 Production Cycle General Controls Inaccurate or invalid master data Data processing integrity controls Restriction of access to master data Review of all changes to master data 14-8 Production Cycle General Controls Unauthorized disclosure of sensitive information Access controls Encryption 14-9 Production Cycle General Controls Loss or destruction of data Backup and disaster recovery procedures 14-10 Product Design Create a Product that meets a customer’s requirement Quality Durability Functionality Minimize production cost Creates two outputs Bill of Materials Operations List 14-11 Product Design Creates two outputs Bill of Materials Specifies part number, description, and quantity of each component used in a finished product Operations List 14-12 Product Design Creates two outputs Bill of Materials Operations List Specifies the sequence of steps to follow in making the product, which equipment to use, and how long each step should take 14-13 Product Design Product life-cycle management (PLM) software Helps improve the efficiency and effectiveness of the product design process Three key components Computer aided design (CAD) software to design new products. Digital manufacturing software that simulates how those products will be manufactured. Product data management software that stores all data associated with products. 14-14 Product Design Threats Poor product design resulting in excess costs 14-15 Product Design Controls Poor product design resulting in excess costs Accounting analysis of costs arising from product design choices Analysis of warranty and repair costs 14-16 Planning and Scheduling Two common methods of production planning Manufacturing resource planning Balance existing production capacity and raw materials needs to meet forecasted sales demands. Push Manufacturing Goods are produced in expectations of customer demand. Lean Manufacturing Just in time inventory Goal is to eliminate inventories of raw materials, and finished goods Pull manufacturing Goods are produced in response to customer orders. 14-17 Planning and Scheduling Master Production schedule (MPS) Contains information about customer orders, sales forecast, and inventory levels of finished goods Specifies How much product to produce When to produce Used to develop a detailed timetable that specifies daily production, and raw materials needed. Production order Lists the operations to be performed Quantity to be produce Delivery location 14-18 Planning and Scheduling Materials requisition Authorizes the removal of the necessary quantity of raw materials Contains detailed information about the raw materials used Order number Date of issue Part numbers quantities 14-19 Planning and Scheduling Threats Over- or underproduction 14-20 Planning and Scheduling Controls Over- or underproduction Production planning systems Review and approval of production schedules and orders Restriction of access to production orders and production schedules 14-21 Production Operations Computer Integrated manufacturing (CIM) Various forms of IT Robots, computer controlled machinery, etc. 14-22 Production Operations Threats Theft of inventory Theft of fixed asset Poor performance Suboptimal investment in fixed assets Loss of inventory or fixed assets due to fire or other disasters Disruption of operations 14-23 Production Operations Controls Theft of inventory Physical access control Documentation of all inventory movement Segregation of duties—custody of assets from recording and authorization of removal Restriction of access to inventory master data Periodic physical counts of inventory and reconciliation of those counts to recorded quantities 14-24 Production Operations Controls Theft of fixed asset Physical inventory of all fixed assets Restriction of physical access to fixed assets Maintaining detailed records of fixed assets, including disposal 14-25 Production Operations Controls Poor performance Training Performance reports 14-26 Production Operations Controls Suboptimal investment in fixed assets Proper approval of fixed asset acquisitions, including use of requests for proposals to solicit multiple competitive bids 14-27 Production Operations Controls Loss of inventory or fixed assets due to fire or other disasters Physical safeguards (e.g., fire sprinklers) Insurance 14-28 Production Operations Controls Disruption of operations Backup and disaster recovery plans 14-29 Cost Accounting Threats Inaccurate cost data Inappropriate allocation of overhead costs Misleading reports 14-30 Cost Accounting Controls Inaccurate cost data Source data automation Data processing integrity controls 14-31 Cost Accounting Controls Inappropriate allocation of overhead costs Time-driven activity-based costing 14-32 Cost Accounting Controls Misleading reports Innovative performance metrics 14-33 Assigning Production Costs Job-Order Costing Assigns costs to specific production batches, or jobs If the product or service is uniquely identifiable Process Costing Assigns costs to each process, or work center, in the production cycle, and then calculates the average cost for all units produced. If the product or service is similar and produced in mass quantities Activity-Based Costing Traces costs to the activities that create them Uses a greater number of overhead pools Batch Product Organization Identifies cost drivers Cause-and-effect relationship 14-34 Quality Control Measures Quality control costs can be divided into four areas: Prevention costs – associated with changes to production process designed to reduce the product defect rate. Inspection costs – are associated with testing to ensure that products meet quality standards Internal failure costs – are associated with reworking, or scrapping, products identified as being defective prior to sale. External failure costs – result when defective product are sold to customers. They include such costs as product liability claims, warranty and repair expenses, loss of customer satisfaction, and damage to the company’s reputation. 14-35