0176503617_313743

advertisement

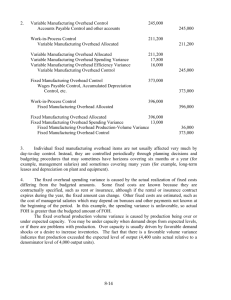

Chapter Eleven Flexible Budgets and Overhead Analysis COPYRIGHT © 2012 Nelson Education Ltd. Learning Objectives 1. Prepare a flexible budget, and use it for performance reporting 2. Calculate the variable overhead variances, and explain their meaning 3. Calculate the fixed overhead variances, and explain their meaning 4. Prepare an activity-based flexible budget 11-2 COPYRIGHT © 2012 Nelson Education Ltd. OBJECTIVE 1 Prepare a flexible budget, and use it for performance reporting Performance Reports • Compare actual costs with budgeted costs • Two ways: – Compare actual costs with budgeted costs for the budgeted level of activity • Based on a static budget – Compare actual costs with the actual level of activity • Based on a flexible budget 11-4 COPYRIGHT © 2012 Nelson Education Ltd. Static Budget • Budget for one particular level of activity • Performance report compares: – Direct materials, direct labour, and overhead costs budgeted for the planned level of activity with – Actual costs for the actual level of activity • Actual costs and expected costs must be compared at the same level of activity 11-5 COPYRIGHT © 2012 Nelson Education Ltd. Example: Cornerstone 11-1 HOW TO Prepare a Performance Report Based on a Static Budget (Using Budgeted Production) Information: From the Master Budget Production for Quarter 1: 1,060 Materials: 1 plain t-shirt @ $3.00 5 grams of ink @ $0.20 Labour: 0.12 hours @ $10.00 Variable overhead: Maintenance: 0.12 hour @ $3.75 Power: 0.12 hour @ $1.25 Fixed overhead: Grounds keeping: $1,200 per qtr Depreciation: $600 per quarter Actual Data for Quarter 1 Production: 1,200 units Materials cost: $4,380 Labour cost: $1,500 Maintenance cost: $535 Power cost: $170 Grounds keeping: $1,050 Depreciation: $600 Required: Prepare a performance report using a budget based on expected production 11-6 COPYRIGHT © 2012 Nelson Education Ltd. Performance Report Example Budgeted 1,060 Units produced Direct materials cost Direct labour cost $4,240 1,272 The plan is to produce 1,060 units. All budgeted costs will be based on 1,060 units ($3.00 t-shirt + (5 grams x $0.20)) x 1,060 units (0.12 hours x $10.00 per hour) x 1,060 units 11-7 COPYRIGHT © 2012 Nelson Education Ltd. Performance Report Example Budgeted Units produced Direct materials cost Direct labour cost Variable overhead: Maintenance 1,060 $4,240 1,272 477 (0.12 hours x $3.75 per hour) x 1,060 units 11-8 COPYRIGHT © 2012 Nelson Education Ltd. Performance Report Example Budgeted 1,060 Units produced $4,240 Direct materials cost Direct labour cost 1,272 Variable overhead: 477 Maintenance (0.12 hours x $1.25 per hour) x 1,060 units 159 Power Fixed overhead: Grounds keeping 1,200 Depreciation 600 Grounds keeping and depreciation are both fixed costs. They will be $1,200 and $600 regardless of the number of units produced 11-9 COPYRIGHT © 2012 Nelson Education Ltd. Performance Report Example Budgeted Units produced Direct materials cost Direct labour cost Variable overhead: Maintenance Power Fixed overhead: Grounds keeping Depreciation Total 1,060 $4,240 1,272 477 159 1,200 600 $7,948 Total budgeted costs for 1,060 units 11-10 COPYRIGHT © 2012 Nelson Education Ltd. Performance Report Example Actual Units produced Direct materials cost Direct labour cost Variable overhead: Maintenance Power Fixed overhead: Grounds keeping Depreciation Total Budgeted 1,200 1,060 Variance 140 F $4,240 1,272 477 159 1,200 600 $7,948 140 more units were produced than originally budgeted 11-11 COPYRIGHT © 2012 Nelson Education Ltd. Performance Report Example Actual Units produced Direct materials cost Direct labour cost Variable overhead: Maintenance Power Fixed overhead: Grounds keeping Depreciation Total Budgeted Variance 1,200 1,060 140 F $4,830 1,500 $4,240 1,272 $590 U 228 U 535 170 477 159 58 U 11 U 1,050 1,200 600 $7,948 (150) F COPYRIGHT © 2012 Nelson Education Ltd. Grounds keeping costs were lower than predicted…a favourable variance! Performance Report Example Units produced Direct materials cost Direct labour cost Actual Budgeted Variance 1,200 $4,830 1,500 1,060 $4,240 1,272 140 F $590 U 228 U 535 170 477 159 58 U 11 U 1,050 1,200 (150) F 600 600 0 $8,685 $7,948 $737 U Variable overhead: Maintenance Power Fixed overhead: Grounds keeping Depreciation Total Overall, actual costs exceeded budgeted costs by $737. Budgeted costs were based on 1,060 units and 1,200 units were actually produced 11-13 COPYRIGHT © 2012 Nelson Education Ltd. Flexible Budget • Enables a firm to compete expected costs for a range of activity levels Two types: – Before-the-fact • Used to generate financial results for a number of plausible scenarios – After-the-fact • Used to compute what costs should have been for the actual level of activity • Expected costs are then compared with the actual costs in order to assess performance 11-14 COPYRIGHT © 2012 Nelson Education Ltd. Example: Cornerstone 11-2 HOW TO Prepare a Flexible Production Budget Information: • Levels of output: 1,000, 1,200 and 1,400 • Materials (1 plain t-shirt @ $3.00 & 5 grams of ink @ $0.20) • Labour: 0.12 hour @ $10.00 per hour • Variable overhead: – Maintenance: 0.12 hours @ $3.75 per hour – Power: 0.12 hours @ $1.25 per hour • Fixed overhead: – Grounds keeping: $1,200 per quarter & Depreciation: $600 per quarter Required: Prepare a budget for 3 levels of unit output: 1,000, 1,200 & 1,400 11-15 COPYRIGHT © 2012 Nelson Education Ltd. Flexible Budget Variable cost Range of Production (units) Production per unit 1,400 costs 1,200 1,000 Variable: $4.00 $4,000 $4,800 $5,600 Direct materials $3.00 t-shirt and $1.00 of ink $4 x # of units 11-16 COPYRIGHT © 2012 Nelson Education Ltd. Flexible Budget Variable cost Range of Production (units) Production per unit 1,400 costs 1,200 1,000 Variable: $4.00 $4,000 $4,800 $5,600 Direct materials 1,200 1,440 1,680 1.20 Direct labour 0.12 hours × $10 per hour $1.20 × # of units 11-17 COPYRIGHT © 2012 Nelson Education Ltd. Flexible Budget Variable cost Range of Production (units) Production per unit 1,400 costs 1,200 1,000 Variable: $4.00 $4,000 $4,800 $5,600 Direct materials 1,200 1,440 1,680 1.20 Direct labour Variable overhead: 540 630 0.45 450 Maintenance 210 0.15 150 Power 180 0.12 hours × $3.75 per hour 0.12 hours × $1.25 per hour 11-18 COPYRIGHT © 2012 Nelson Education Ltd. Flexible Budget Variable cost Range of Production (units) Production per unit 1,400 costs 1,200 1,000 Variable: $4.00 $4,000 $4,800 $5,600 Direct materials 1.20 Direct labour 1,200 1,440 1,680 Variable overhead: 630 540 0.45 450 Maintenance 210 0.15 150 Power 180 $5,800 $6,960 $8,120 $5.80 Total variable costs Fixed overhead: 1,200 1,200 1,200 Grounds keeping Depreciation 600 600 600 Fixed costs do not change when levels of output change COPYRIGHT © 2012 Nelson Education Ltd. 11-19 Flexible Budget continued Variable cost Range of Production (units) Production per unit 1,400 costs 1,200 1,000 Fixed overhead: Grounds keeping 1,200 1,200 1,200 Depreciation 600 600 600 Total fixed costs $1,800 $1,800 $1,800 Total production costs $7,600 $8,760 $9,920 11-20 COPYRIGHT © 2012 Nelson Education Ltd. Example: Cornerstone 11-3 HOW TO Prepare a Performance Report using a Flexible Budget Information: Budgeted Costs Direct Materials: $4 per unit Direct Labour: $1.20 per unit Variable overhead: Maintenance: $0.45 per unit Power: $0.15 per unit Fixed overhead: Grounds keeping: $1,200 per qtr Depreciation: $600 per quarter Actual Costs @ 1200 units Direct Materials: $4,830 Direct Labour: $1,500 Maintenance cost: $535 Power cost: $170 Grounds keeping: $1,050 Depreciation: $600 Required: Prepare a performance report using budgeted costs for the actual level of activity 11-21 COPYRIGHT © 2012 Nelson Education Ltd. Performance Report Example Actual Units produced Budgeted 1,200 Variance 1,200 Budgeted costs are based on actual units produced 11-22 COPYRIGHT © 2012 Nelson Education Ltd. Performance Report Example Actual Units produced Direct materials Budgeted 1,200 1,200 $4,830 $4,800 Variance $ 30 U Direct materials costs to produce 1,200 units were $30 higher than expected 11-23 COPYRIGHT © 2012 Nelson Education Ltd. Performance Report Example Actual Units produced Direct materials cost Direct labour cost Variable overhead: Maintenance Power Total variable costs Fixed overhead: Grounds keeping Depreciation Total fixed costs Total production costs Budgeted Variance 1,200 1,200 $4,830 1,500 $4,800 1,440 $30 U 60 U 535 170 $7,035 540 180 $6,960 (5) U (10) U $ 75 U $1,050 600 $1,650 $1,200 600 $1,800 $8,685 $8,760 $(150) F 0 $(150) F $ (75) F COPYRIGHT © 2012 Nelson Education Ltd. OBJECTIVE 2 Calculate the variable overhead variances and explain their meaning Variance Overhead Anaylsis • Difference between applied and actual overhead • Broken down into: – Total Variable Overhead Variance • Broken further into: – Variable Overhead Spending Variance – Variable Overhead Efficiency Variance – Total Fixed Overhead Variance • Broken further into: – Fixed Overhead Spending Variance – Fixed Overhead Volume Variance 11-26 COPYRIGHT © 2012 Nelson Education Ltd. Example: Cornerstone 11-4 HOW TO Calculate the Total Variable Overhead Variance Information: • Standard variable overhead rate (SVOR) $5.00 per direct labour hour • Actual variable overhead costs – Actual direct labour hours (AH) = 150 hours – Actual Variable Overhead Rate (AVOR) $4.70 per hour • Standard hours (SH) allowed per unit 0.12 hour • Actual production 1,200 units Required: Calculate the total variable overhead variance 11-27 COPYRIGHT © 2012 Nelson Education Ltd. Total Variable Overhead Variance Actual Costs – Applied Costs = Total Variance (AH × AVOR) $705 Actual Hours × Actual Variable Overhead Rate 150 hours × $4.70 11-28 COPYRIGHT © 2012 Nelson Education Ltd. Total Variable Overhead Variance Actual Costs – Applied Costs = Total Variance (AH × AVOR) – (SH × SVOR) $705 – $720 144 hours × $5.00 Hours allowed for production (SH) × Standard Variable Overhead Rate (SVOR) 11-29 COPYRIGHT © 2012 Nelson Education Ltd. Total Variable Overhead Variance Actual Costs – Applied Costs = Total Variance (AH × AVOR) – (SH × SVOR) $705 – $720 = ($15) This is a favourable variance since actual costs were less than expected 11-30 COPYRIGHT © 2012 Nelson Education Ltd. Variable Overhead Spending Variance • Measures the aggregate effect of the differences between – Actual variable overhead (AVOR) – Standard variable overhead rate (SVOR) • Two ways to calculate: – Three-pronged columnar approach – Formula approach • (AVOR – SVOR) AH 11-31 COPYRIGHT © 2012 Nelson Education Ltd. Variable Overhead Efficiency Variance • Measures the change in variable overhead consumption that occurs because of efficient (or inefficient) use of direct labour • Two ways to calculate: – Three-pronged columnar approach – Formula approach • (AH – SH) SVOR 11-32 COPYRIGHT © 2012 Nelson Education Ltd. Example: Cornerstone 11-5 HOW TO Calculate Variable Overhead Variances: Columnar and Formula Approaches Information: • Standard variable overhead rate (SVOR) $5.00 per direct labour hour • Actual variable overhead rate (AVOR) $4.70 • Actual hours worked (AH) 150 hours • Number of tee shirts produced 1,200 units • Hours allowed for production (SH) 144 hours Required: Calculate the variable overhead spending and efficiency variances 11-33 COPYRIGHT © 2012 Nelson Education Ltd. Example Columnar Approach 1. AH × AVOR 150 × $4.70 $705 2. AH × SVOR 150 × $5.00 $750 3. SH × SVOR 144 × $5.00 $720 Spending Variance (1 – 2) $45 F This is a favourable variance since the actual variable overhead rate was less than the expected rate 11-34 COPYRIGHT © 2012 Nelson Education Ltd. Example Columnar Approach 2. AH × SVOR 150 × $5.00 $750 1. AH × AVOR 150 × $4.70 $705 Spending Variance (1 – 2) $45 F 3. SH × SVOR 144 × $5.00 $720 Efficiency Variance (2 – 3) $30 U This is an unfavourable variance since the actual hours exceeded budgeted hours 11-35 COPYRIGHT © 2012 Nelson Education Ltd. Example Columnar Approach 1. AH × AVOR 150 × $4.70 $705 2. AH x SVOR 150 x $5.00 $750 Spending Variance (1 – 2) $45 F 3. SH x SVOR 144 x $5.00 $720 Efficiency Variance (2 – 3) $30 U Variable Overhead (1 – 3) $15 F COPYRIGHT © 2012 Nelson Education Ltd. 11-36 Example Formula Approach VOH spending variance (AVOR – SVOR) AH ($4.70 - $5.00) 150 $45 favourable 11-37 COPYRIGHT © 2012 Nelson Education Ltd. Example Formula Approach VOH efficiency variance (AH - SH) SVOR (150 - 144) $5.00 $30 Unfavourable 11-38 COPYRIGHT © 2012 Nelson Education Ltd. Example: Cornerstone 11-6 HOW TO Performance Report for Variable Overhead Variances Information: • Standard variable overhead rate (SVOR) $5.00 per direct labour hour • Actual costs: Maintenance $535 & Power $170 • Actual hours worked (AH) 150 hours • Number of t-shirts produced 1,200 units • Hours allowed for production (SH) 144 hours • Variable overhead: Maintenance 0.12 hour @ $3.75 & Power 0.12 hour @ $1.25 Required: Prepare a performance report that shows the variances on an item-by-item basis 11-39 COPYRIGHT © 2012 Nelson Education Ltd. Performance Report For the Quarter Ended March 31, 2011 Cost Maintenance Cost Formula Actual Costs $3.75 $535 150 hours × $3.75 Budget for Actual Spending Hours Variance $562.50 $27.50 F $535 - $562.50 11-40 COPYRIGHT © 2012 Nelson Education Ltd. Performance Report (continued) For the Quarter Ended March 31, 2011 Cost Budget for Actual Spending Hours Variance Maintenance $562.50 Budget for Standard Efficiency Hours Variance $540 $27.50 F 144 × $3.75 $22.50 U $562.50 - $540 11-41 COPYRIGHT © 2012 Nelson Education Ltd. Performance Report For the Quarter Ended March 31, 2011 Cost Maintenance Power Budget for Actual Spending Hours Variance Cost Formula Actual Costs $3.75 $535 $562.50 $27.50 F 1.25 170 187.50 17.50 F $1.25 × 150 $170 - $187.50 11-42 COPYRIGHT © 2012 Nelson Education Ltd. Performance Report (continued) For the Quarter Ended March 31, 2011 Cost Budget for Actual Spending Hours Variance Maintenance $562.50 Power 187.50 $27.50 F 17.50 F Budget for Standard Efficiency Hours Variance $540 $22.50 U 180 7.50 U 11-43 COPYRIGHT © 2012 Nelson Education Ltd. Performance Report For the Quarter Ended March 31, 2011 Budget for Actual Spending Hours Variance Cost Formula Actual Costs Maintenance $3.75 $535 $562.50 $27.50 F Power 1.25 $5.00 170 $705 187.50 $750.00 17.50 F Cost Total $45.00 F 11-44 COPYRIGHT © 2012 Nelson Education Ltd. Performance Report (continued) For the Quarter Ended March 31, 2011 Cost Budget for Actual Spending Hours Variance Budget for Standard Efficiency Hours Variance Maintenance $562.50 $27.50 F $540 $22.50 U Power 17.50 F $45.00 F 180 $720 7.50 U Total 187.50 $750.00 $30.00 U 11-45 COPYRIGHT © 2012 Nelson Education Ltd. OBJECTIVE 3 Calculate the fixed overhead variances, and explain their meaning Total Fixed Overhead Variance • Difference between actual and applied fixed overhead – When applied overhead = standard fixed overhead rate × standard hours allowed for the actual output • Broken down into: – Fixed Overhead Spending Variance – Fixed Overhead Volume Variance 11-47 COPYRIGHT © 2012 Nelson Education Ltd. Example: Cornerstone 11-7 HOW TO Calculate the Total Fixed Overhead Variance Information: • Standard fixed overhead rate (SFOR) $10.00 per direct labour hour • Actual fixed overhead costs $1,650 • Standard hours allowed per unit 0.12 hours • Actual production 1,200 units Required: Calculate the total fixed overhead variance 11-48 COPYRIGHT © 2012 Nelson Education Ltd. Total Fixed Overhead Variance Actual Costs AFOH $1605 – Applied Costs = Total Variance – (SH X SFOR) – $1,440 = $210 U This is an unfavourable variance since actual costs exceeded applied costs 11-49 COPYRIGHT © 2012 Nelson Education Ltd. Fixed Overhead Spending Variance • Difference between – Actual fixed overhead rate (AFOH) – Budgeted fixed overhead rate (BFOH) • Two ways to calculate: – Three-pronged columnar approach – Formula approach • AFOH – SFOH 11-50 COPYRIGHT © 2012 Nelson Education Ltd. Fixed Overhead Volume Variance • Difference between – Budgeted fixed overhead (BFOH) – Applied fixed overhead (ApFOH) • Two ways to calculate: – Three-pronged columnar approach – Formula approach • (SHp – SH) SFOR 11-51 COPYRIGHT © 2012 Nelson Education Ltd. Example: Cornerstone 11-8 HOW TO Calculate Fixed Overhead Variances: Columnar and Formula Approaches Information: • Standard fixed overhead rate (SFOR) $10.00 per direct labour hour • Budgeted fixed overhead (BFOH) $1,800 • Number of t-shirts produced 1,200 units • Hours allowed for production (SH) 144 hours Required: Calculate the fixed overhead spending and volume variances 11-52 COPYRIGHT © 2012 Nelson Education Ltd. Fixed Overhead Variances Columnar Approach 2. SH × SFOR 180 × $10 $1,800 1. Actual Fixed Overhead $1,650 Spending Variance (1 – 2) $150 F 3. SHp × SFOR 144 × $10 $1,440 Volume Variance (2 – 3) $360 U Fixed Overhead (1 – 3) $210 U COPYRIGHT © 2012 Nelson Education Ltd. 11-53 Example Formula Approach Fixed Overhead (FOH) Volume Variance AFOH – BFOH $1,650 - $1,800 $150 Favourable 11-54 COPYRIGHT © 2012 Nelson Education Ltd. Example Formula Approach Fixed Overhead (FOH) Efficiency Variance (SHp – SH) SFOR (180 – 144) $10.00 $360 Unfavourable 11-55 COPYRIGHT © 2012 Nelson Education Ltd. OBJECTIVE 4 Prepare an activity-based flexible budget Activity-Based Budgeting • A powerful planning and control tool • Can be used to emphasize cost reduction through the elimination of wasteful activities and improving efficiency of necessary activities • Two types: – Static activity budgets – Activity-based flexible budget 11-57 COPYRIGHT © 2012 Nelson Education Ltd. Example: Cornerstone 11-9 HOW TO Prepare Static Budget for an Activity Information: • Demand for purchase orders based on materials requirements: 15,000 purchase orders • Resources needed: – Five purchasing agents, each capable of processing 3,000 orders per year, salary, $40,000 each – Supplies projected to cost $1.00 per purchase order – Desks and computers: depreciation, $5,000 per year – Office space, rent, and utilities, $6,000 Required: Prepare a budget for the purchasing activity 11-58 COPYRIGHT © 2012 Nelson Education Ltd. Purchasing Budget Salaries $200,000 Depreciation Supplies 5,000 15,000 6,000 Occupancy Total $226,000 5 agents × $40,000 per agent per year $1.00 per purchase order × 15,000 purchase orders COPYRIGHT © 2012 Nelson Education Ltd. Example: Cornerstone 11-10 HOW TO Prepare an Activity Flexible Budget Information: • The individual activities, drivers, their cost formulas, and the output levels are the inputs needed to prepare the budget • For example: – Activity: Maintenance – Driver: Machine hours – Fixed activity cost: $20,000 – Variable activity rate: $5.50 per machine hour Required: Prepare an activity-based flexible budget 11-60 COPYRIGHT © 2012 Nelson Education Ltd. Activity-Based Flexible Budget Formula Fixed Variable Driver: Direct Labour Hours Direct materials $ --- Direct labour Subtotal --$ 0 $ 10 8 $ 18 Fixed Variable $20,000 15,000 $35,000 $ 5.50 2.00 $ 7.50 Level of Activity 20,000 10,000 $100,000 $200,000 80,000 160,000 $180,000 $360,000 Driver: Machine Hours Maintenance Machining Subtotal 8,000 16,000 $64,000 $108,000 31,000 47,000 $95,000 $155,000 11-61 COPYRIGHT © 2012 Nelson Education Ltd. Activity-Based Flexible Budget continued Formula Level of Activity Driver: Number of Setups Fixed Setups Variable $ ---$ 1,800 2,100 80,000 $80,000 $3,900 Inspections Subtotal 25 30 $ 45,000 $ 54,000 132,500 143,000 $177,500 $197,000 Driver: Number of Orders Fixed Purchasing $211,000 Variable $ 1 15,000 30,000 $226,000 $236,000 11-62 COPYRIGHT © 2012 Nelson Education Ltd. Example: Cornerstone 11-11 HOW TO Prepare an Activity-Based Performance Report Information: Direct materials Direct labour Maintenance Machining Inspections Setups Purchasing Actual Costs $101,000 $80,000 $55,000 $29,000 $125,500 $46,500 $220,000 Actual Activity Level 10,000 10,000 8,000 8,000 25 25 15,000 Required: Prepare an activity-based performance report (use budgeted costs from Cornerstone 11-10) COPYRIGHT © 2012 Nelson Education Ltd. 11-63 Activity-Based Performance Report Actual Costs Budgeted Costs Budget Variance $ 1,000 U ---9,000 F 2,000 F 7,000 F 1,500 U 6,000 F Direct materials Direct labour Maintenance Machining Inspections Setups Purchasing $101,000 80,000 55,000 29,000 125,500 46,500 220,000 $100,000 80,000 64,000 31,000 132,500 45,000 226,000 Total $657,000 $678,500 $21,500 F 11-64 COPYRIGHT © 2012 Nelson Education Ltd.