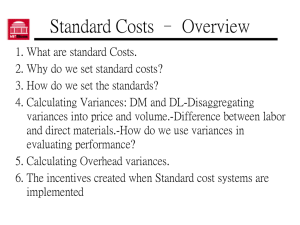

Budgeting and Standard Cost Systems

advertisement

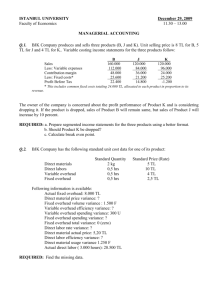

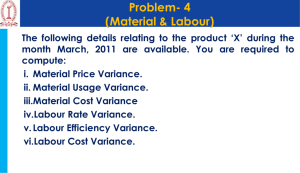

Budgeting and Standard Cost Systems Chapter 13 Budgeting A budget is a financial and quantitative plan for the acquisition and use of resources Use for Establishing goals Executing plans to achieve the goals Comparing actual results with planned results Budgeting Types of budgets Static budget Prepared for one level of activity Useful for planning Not useful for controlling or evaluation of results Flexible budget Prepared for several different levels of activity Useful for planning, controlling and evaluation of results Separates variable costs from fixed costs Master Budget Overall plan for the organization expressed in unit and dollar terms Begins with the sales budget All activities exist to support the sales budget Sales budget and current and desired finished goods inventory levels determine the production budget Sales + desired ending inventory – beginning inventory = production Master Budget Sales budget determines the selling and administrative expense budget Sales budget contributes to the cash budget Master Budget Production budget determines resources needed to support production levels Production budget and current and desired materials inventories determine the materials purchase budget Production needs + desired ending material inventory – beginning material inventory = purchases Production budget also determines the labor needs and overhead costs Master Budget Cash budget lists expected cash inflows and outflows Collections from customers Payment for material purchases, labor and overhead Payment for selling and administrative expenses Payment for capital expenditures Borrowing or repayment of loans Miscellaneous items Dividends, investment income, etc. Master Budget Information from the budgets can be used to prepare a budgeted income statement and a budgeted balance sheet The master budget is a plan The financial statements show the results of operations and financial position if the plan is achieved Standards A standard is a measure of what should occur Quantity standard How much of a resource should be used to produce a certain level of output Often determined by engineering specifications Price standard How much the resource should cost Assumes the resource is acquired in normal quantities, from the normal supplier, etc. Standards Standards provide a benchmark to use in evaluating performance Comparison of actual results to standards results in variances which may indicate where there are problems Did we pay more (or less) than the normal cost? Did we use more (or less) of the resource than we should have? Standards Types of standards Theoretical (ideal) standard Indicate what can be achieved under perfect conditions Unrealistic, seldom used May be used to motivate employees to improve performance, but if used as a goal, they are demotivating Currently attainable (normal) standard Standard that can be achieved with reasonable effort Allows for normal inefficiencies Variance Analysis Comparison of actual results to standards results in variances “Favorable” variance occurs when the actual amount is less than the standard “Unfavorable” variance occurs when the actual amount is greater than the standard “Favorable” and “unfavorable” are not necessarily good or bad Both represent deviations from what should have occurred Variance Analysis General formulas Standard cost = standard quantity * standard price Actual cost = actual quantity * actual price Total variance = standard cost – actual cost Variance Analysis Material and labor variances Materials price variance Labor rate variance Actual quantity * (standard price – actual price) Material quantity variance Labor time variance Standard price * (standard quantity – actual quantity) Variance Analysis Overhead variances Variable overhead controllable variance Measures the efficiency of using variable overhead resources Budgeted variable overhead at the standard hours allowed – actual variable overhead Fixed overhead volume variance Measures the use of fixed overhead resources by analyzing capacity utilization Standard fixed overhead rate * (Standard hours at output achieved - 100% of normal capacity)