Two-Dimensional Conduction: Finite

advertisement

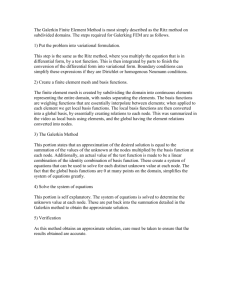

Two-Dimensional Conduction: Finite-Difference Equations and Solutions Chapter 4 Sections 4.4 and 4.5 Finite-Difference Method The Finite-Difference Method • An approximate method for determining temperatures at discrete (nodal) points of the physical system. • Procedure: – Represent the physical system by a nodal network. – Use the energy balance method to obtain a finite-difference equation for each node of unknown temperature. – Solve the resulting set of algebraic equations for the unknown nodal temperatures. Finite-Difference Approximation The Nodal Network and Finite-Difference Approximation • The nodal network identifies discrete points at which the temperature is to be determined and uses an m,n notation to designate their location. What is represented by the temperature determined at a nodal point, as for example, Tm,n? • A finite-difference approximation is used to represent temperature gradients in the domain. How is the accuracy of the solution affected by construction of the nodal network? What are the trade-offs between selection of a fine or a coarse mesh? Energy Balance Method Derivation of the Finite-Difference Equations - The Energy Balance Method • As a convenience that obviates the need to predetermine the direction of heat flow, assume all heat flows are into the nodal region of interest, and express all heat rates accordingly. Hence, the energy balance becomes: Ein E g 0 (4.34) • Consider application to an interior nodal point (one that exchanges heat by conduction with four, equidistant nodal points): 4 q(i ) ( m, n) q x y 0 i 1 where, for example, q m 1, n m, n k y Tm 1, n Tm, n x (4.35) Is it possible for all heat flows to be into the m,n nodal region? What feature of the analysis insures a correct form of the energy balance equation despite the assumption of conditions that are not realizable? Energy Balance Method (cont.) • A summary of finite-difference equations for common nodal regions is provided in Table 4.2. Consider an external corner with convection heat transfer. q m 1, n m, n q m, n 1 m, n q m, n 0 y Tm 1, n Tm, n x Tm, n 1 Tm, n k k x y 2 2 x y h T Tm, n h T Tm, n 0 2 2 or, with x y, Tm 1, n Tm, n 1 2 hx hx T 2 1 Tm, n 0 k k (4.47) Energy Balance Method (cont.) • Note potential utility of using thermal resistance concepts to express rate equations. E.g., conduction between adjoining dissimilar materials with an interfacial contact resistance. q m, n 1 m, n Rtot y / 2 kA x Tm, n 1 Tm, n Rtot Rt, c x y / 2 kB x (4.50) Solution Methods Solutions Methods • Matrix Inversion: Expression of system of N finite-difference equations for N unknown nodal temperatures as: AT C Coefficient Matrix (NxN) Solution Solution Vector (T1,T2, …TN) (4.52) Right-hand Side Vector of Constants (C1,C2…CN) T A1 C (4.53) Inverse of Coefficient Matrix • Gauss-Seidel Iteration: Each finite-difference equation is written in explicit form, such that its unknown nodal temperature appears alone on the lefthand side: N aij C i 1 aij k k Ti i Tj Tj( k 1) (4.55) aii j 1 aii j i 1 aii where i =1, 2,…, N and k is the level of iteration. Iteration proceeds until satisfactory convergence is achieved for all nodes: k k 1 Ti Ti • What measures may be taken to insure that the results of a finite-difference solution provide an accurate prediction of the temperature field? Problem: Finite-Difference Equations Problem 4.41: Finite-difference equations for (a) nodal point on a diagonal surface and (b) tip of a cutting tool. (a) Diagonal surface (b) Cutting tool. Schematic: ASSUMPTIONS: (1) Steady-state, 2-D conduction, (2) Constant properties Problem: Finite-Difference Equations (cont.) ANALYSIS: (a) The control volume about node m,n is triangular with sides x and y and diagonal (surface) of length 2 x. The heat rates associated with the control volume are due to conduction, q1 and q2, and to convection, qc. An energy balance for a unit depth normal to the page yields Ein 0 q1 q 2 qc 0 Tm,n-1 Tm,n Tm+1,n Tm,n k x 1 k y 1 h y x With x = y, it follows that Tm,n-1 Tm+1,n 2 2 x 1 T Tm,n 0. hx hx T 2 2 Tm,n 0. k k (b) The control volume about node m,n is triangular with sides x/2 and y/2 and a lower diagonal surface of length 2 x/2 . The heat rates associated with the control volume are due to the uniform heat flux, qa, conduction, qb, and convection qc. An energy balance for a unit depth yields Ein =0 qa q b qc 0 x x y Tm+1,n Tm,n qo 1 k 1 h 2 T Tm,n 0. x 2 2 2 or, with x = y, Tm+1,n 2 hx x hx T q o 1 2 Tm,n 0. k k k Problem: Cold Plate Problem 4.78: Analysis of cold plate used to thermally control IBM multi-chip, thermal conduction module. Features: • Heat dissipated in the chips is transferred by conduction through spring-loaded aluminum pistons to an aluminum cold plate. • Nominal operating conditions may be assumed to provide a uniformly distributed heat flux of qo 105 W/m2 at the base of the cold plate. • Heat is transferred from the cold plate by water flowing through channels in the cold plate. Find: (a) Cold plate temperature distribution for the prescribed conditions. (b) Options for operating at larger power levels while remaining within a maximum cold plate temperature of 40C. Problem: Cold Plate (cont.) Schematic: ASSUMPTIONS: (1) Steady-state conditions, (2) Two-dimensional conduction, (3) Constant properties Problem: Cold Plate (cont.) ANALYSIS: Finite-difference equations must be obtained for each of the 28 nodes. Applying the energy balance method to regions 1 and 5, which are similar, it follows that y x T2 x y T6 y x x y T1 0 Node 5: y x T4 x y T10 y x x y T5 0 Node 1: Nodal regions 2, 3 and 4 are similar, and the energy balance method yields a finite-difference equation of the form Nodes 2,3,4: y x Tm 1, n Tm 1, n 2 x y Tm, n 1 2 y x x y Tm, n 0 Energy balances applied to the remaining combinations of similar nodes yield the following finite-difference equations. Nodes 6, 14: Nodes 7, 15: x x y T1 y x T7 x y y x hx k T6 hx k T y x T6 T8 2 x y T2 2 y x x y hx k T7 2hx k T y y T19 y x T15 x y y x hx k T14 hx k T x T14 T16 2 x y T20 2 y x x y hx k T15 2hx k T Problem: Cold Plate (cont.) Nodes 8, 16: x Node 11: y x T7 2 y x T9 x y T11 2 x y T3 3 y x 3 x y y x T15 2 y x T17 x y T11 2 x y T21 3 y x 3 x y h k x y T8 h k x y T h k x y T16 h k x y T y T8 x y T16 2 y x T12 2 x y y x hy k T11 2hy k T Nodes 9, 12, 17, 20, 21, 22: x Tm 1, n y x Tm 1, n x y Tm, n 1 x y Tm, n 1 2 x y y x Tm, n 0 y Nodes 10, 13, 18, 23: x x Node 19: Nodes 24, 28: x x Nodes 25, 26, 27: y y Tn 1, m x y Tn 1, m 2 y x Tm 1, n 2 x y y x Tm, n 0 y T14 x y T24 2 y x T20 2 x y y x T19 0 y T19 y x T25 x y y x T24 qo x k y T23 y x T27 x y y x T28 qo x k x Tm 1, n y x Tm 1, n 2 x y Tm, n 1 2 x y y x Tm, n 2qo x k Problem: Cold Plate (cont.) Evaluating the coefficients and solving the equations simultaneously, the steady-state temperature distribution (C), tabulated according to the node locations, is: 23.77 23.41 23.91 23.62 28.90 30.72 32.77 28.76 30.67 32.74 24.27 24.31 25.70 28.26 30.57 32.69 24.61 24.89 26.18 28.32 30.53 32.66 24.74 25.07 26.33 28.35 30.52 32.65 (b) For the prescribed conditions, the maximum allowable temperature (T 24 = 40C) is reached when qo = 1.407 105 W/m2 (14.07 W/cm2). Options for extending this limit could include use of a copper cold plate (k 400 W/mK) and/or increasing the convection coefficient associated with the coolant. With k = 400 W/mK, a value of qo = 17.37 W/cm2 may be maintained. . With k = 400 W/mK and h = 10,000 W/m2K (a practical upper limit), qo = 28.65 W/cm2. Additional, albeit small, improvements may be realized by relocating the coolant channels closer to the base of the cold plate.