28 LR Pulsed Diode Laser - University of Manchester

advertisement

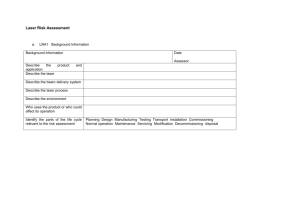

Local Rules for PicoQuant PDF 800-B Laser Review Date: 29-October-2012 Reviewed by: J.Pater March 2015-03-29 Next Review Date: March 2016 Scope These local rules cover the use of the PicoQuant PDF 800-B Picosecond pulsed diode laser inside the Wentworth PML-8000 probe station cabinet in Schuster 5.20. They cover normal use (alignment and operation) only. They implement the University's laser safety policy at a practical level and form part of the University's duties under Section 2(3) of the Health and Safety at Work etc Act 1974. A separate document (attached) describes the risks and operating procedures for the temperature-controlled platform of the probe station (``ThermoChuck’’). Description The PicoQuant PDF 800-B Picosecond pulsed diode laser and its associated heads: LDH-P660 (660nm, 10.6 mW max average power) and LDH-P-1060 (1060 nm, 11.5 mW max average power) constitute a Class 3B Laser. The laser head is mounted on the side of a microscope arrangement so that the beam is transferred through the microscope optics onto the sample on the probe station's working area. The beam travels inside the microscope except for the last few centimetres before impacting the sample, during which time it is in free air. The laser head must be clamped in a heat-dissipating metal bracket during use to avoid over-heating. For alignment work, the visible laser head is used with the probe station cabinet door open, as it is necessary to see the spot that the beam makes on the sample. While using the visible laser in this configuration, the pulse frequency of the laser must be at a low setting (<5.0 MHz), obtained by setting the 'REP FREQUENCY' dial to 8 or 16. When working with the infrared laser head, the laser must be interlocked to the cabinet door as the eye’s blink reflex will not protect the user from the beam, which is outside the visible spectrum. In this instance the device under test will have voltage applied (typically 50-100 V at very low current i.e. microamps) and it may be cooled to as low as a few tens of degrees below zero Celsius (see Appendix A). Authorised Users Only persons who are adequately trained (by attending the University Laser Safety Training Session and being familiar with these Local Rules) and authorised as listed in Appendix B to these local rules may work with the laser. Laser Controlled Area Access to room 5.20 is restricted by a number-code entry system. A key is needed to operate the laser; this key is kept in a locked cabinet on the wall near the probe station. Only authorised users will have a key to this cabinet. Signs indicating the presence of a class 3B laser are mounted on all entry doors to the lab and on the door of the probe station cabinet. During prolonged laser operation the laser head can heat up so it should be securely mounted in the heat-dissipating metal bracket provided (see photo). Procedures Turning laser on: get key from cabinet. Turning laser off: return key to cabinet and lock cabinet. Protection Measures 1. Alignment: if it is necessary to view the beam spot then: Use the visible laser head (LDH-P-660) Unplug the interlock cable from the laser A repetition rate of 5 MHz or less must be used (‘REP FREQUENCY’ dial set to 8 or 16). Once alignment work is finished, replace the interlock cable. 2. Signal generation in sample using the infrared laser head (LDH-P-1060) or the visible laser head at repetition rates > 5 MHz: Verify that the interlock cable is plugged into the laser unit Probe station cabinet doors must be closed Summary of Hazards Class 3B laser beam hazards Low temperatures Voltages of 50-100 V on sample (low currents, order microAmps) Contingency plan In the event of an accident involving eye exposure do the following: 1. Inform the University Laser Safety Officer (Mark Dickinson, 5-4215) 2. Take the person exposed to MRI casualty. 3. Take the laser information sheet with you to the hospital (this is located next to these Local Rules). 4. Leave all equipment as it was when the accident happened. NOTE: In nearly all cases where eye exposure to a class 3 laser has occurred, there is no permanent damage to the eye. The person exposed may experience pain, strong after images and blurred sight. These symptoms tend to disappear with time. It is however important that the person exposed does not rub their eye as this can lead to corneal abrasions. Appendix A :ThermoChuck Precautions and Operating Procedures Turn off power when filling and draining reservoir. Do not overfill. Flood chamber with dry air or nitrogen to avoid ice forming on the coolant pipes. Ice water could flood probing station when temperature brought back to ambient conditions. Procedure for ThermoChuck Switch on ThermoChuck at control box. System will boot up and compressor stage 1 will begin warming up for 5 minutes and 30 seconds. Main menu will now be displayed. All options and temperatures can be selected by moving the directional keys and pressing enter. Press escape to leave any particular menu. Select temp – here you can select one of several set points. Change – input a new value at a specific set point and press enter to save. If the set point changed was the set point currently selected in Select temp then the ThermoChuck will automatically adjust to this new temperature upon exiting the Change menu. Ramp/Cycle – here you can setup the temperature to ramp up or down after a specific time. Setup – displays default factory information and current set points saved to memory. Review – displays current temperature data recorded by the control box. Top Menu – selecting this presents the following options: o Run in engineering mode. o Run in operator mode. o Setup temperature parameters. o Configuration o Calibration o Utilities o Shutdown Hazards High Voltage – To avoid shock hazard the equipment must be grounded with an adequate earth ground per local electrical codes. All potentially dangerous voltages and others hazards are labelled and describe on the equipment. Hot Surface – (Maximum high point 150°C) ThermoChuck Platform should not be touched at temperature greater than 40°C Cold Surface – (Maximum low point -65°C) ThermoChuck Platform should not be touched at temperature lower than 10°C Refrigerant (Ethane, 1, 1, 1, 2-Tetrafluro- (HFC-132a)) Hazards Inhalation (gross overexposure) may cause central nervous system depression with dizziness, confusion, incoordination, drowsiness or unconsciousness. Irregular heart beat with a strange sensation in the chest, possible loss of consciousness and death. Suffocation if air is displaced by vapours. Skin and eye contact, “Frostbite-effects” Use impervious gloves and chemical splash goggles when handling the refrigerant. Under normal conditions no respiratory protection is required when using the device. First Aid Measures - Refrigerant Inhalation If high concentrations are inhaled immediately remove to fresh air. If not breathing give artificial respiration. If breathing difficult give oxygen. Call a physician. Skin Contact In case of contact immediately flush skin with plenty of water for at least 15 minutes and remove all contaminated clothing and shoes. Call a physician. Wash contaminated clothing before reuse. Treat for frostbite if necessary by gently warming affected area. Eye Contact In case of contact immediately flush eyes with plenty of water for at least 15 minutes. Call a physician. Fire and Explosion Hazards Cylinders may rupture under fire condition. Decomposition may occur. Contact of welding or soldering torch flame with high concentrations of refrigerant can result in visible changes in the size and colour of the flames. This flame effect will only occur if the concentration of the product is well above the recommended exposure limit. Stop all work and ventilate to disperse refrigerant vapours from the work area. HFC-134a is potentially combustible in the presence of chlorine. Fire Fighting Media Use media appropriate for surrounding material. Appendix B: list of authorised users Authorized: Iain Haughton Francisca Munoz Joleen R. Pater Pablo Rodriguez