File - Mechatronics 2k14

advertisement

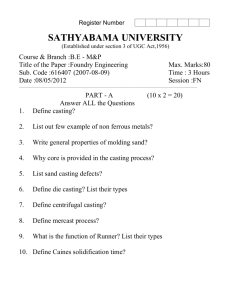

Annexure-I 4.2 Moulding and casting Process of making cavity is called Moulding. And pouring the molten metal to produce desired shape is called Casting. The cavity in the sand is formed by using a pattern (an approximate duplicate of the real part), which are typically made out of wood, sometimes metal Most versatile form of production processes There is no limit to the size and shape of the components Production cost is considerably low All metals can be cast Green Sand Casting- steps Pattern Ramming process Molten box Vent holes making Pattern into the box Pattern into the sand Applying parting powder Rapping the Pattern Cutting the Funnel Around the Sprue Pin Cutting the Gates Cutting the Funnel Around the Sprue Pin Melting Metal Pouring Metal in to mould cavity Green SAND MOLD FEATURES Destroy the sand Final Casting Product Pattern: A Pattern is a model or the replica of the object to be cast. Patterns may be in two or three pieces, where as casting are in a single piece. A pattern is required even if one object has to be cast. The quality of casting and the final product will be effected to a great extent by the planning of pattern. Functions of Patterns: A Pattern prepares a mould cavity for the purpose of making a casting. A Pattern may contain projections known as core prints if the casting requires a core and need to be made hollow. Risers, runners and gates may form a part of the pattern. Patterns properly made and having finished and smooth surfaces reduce casting defects. Properly constructed patterns minimize overall cost of the casting. Selection of Pattern Materials: The following factors assist in selecting proper pattern material: No. of castings to be produced. Metal to be cast. Dimensional accuracy & surface finish. Shape, complexity and size of casting. Casting design parameters. Type of molding materials. The chance of repeat orders. Nature of molding process. Position of core print. The pattern material should be: 1. 2. 3. 4. 5. Easily worked, shaped and joined. Light in weight. Strong, hard and durable. Resistant to wear and abrasion . Resistant to corrosion, and to chemical reactions. 6. Dimensionally stable and unaffected by variations in temperature and humidity. 7. Available at low cost. Materials for making patterns: a. b. c. d. e. Wood Metal Plastic Plaster Wax. Types of patterns depend upon the following factors: i. The shape and size of casting ii. No. of castings required iii. Method of moulding employed iv. Anticipated difficulty of moulding operation Types of Patterns: 1. 2. 3. 4. 5. 6. 7. 8. 9. Single piece pattern. Split piece pattern. Loose piece pattern. Match plate pattern. Sweep pattern. Gated pattern. Skeleton pattern Follow board pattern. Cope and Drag pattern. 1. Single piece (solid) pattern: • Made from one piece and does not contain loose pieces or joints. • Inexpensive and used for large size simple castings. • Pattern is accommodated either in the cope or in the drag. Examples: Bodies of regular shapes. Stuffling box of steam engine. 2. Split piece pattern: • Patterns of intricate shaped castings cannot be made in one piece because of the inherent difficulties associated with the molding operations (e.g. withdrawing pattern from mould). • The upper and the lower parts of the split piece patterns are accommodated in the cope and drag portions of the mold respectively. • Parting line of the pattern forms the parting line of the mould. • Dowel pins are used for keeping the alignment between the two parts of the pattern. • Examples: 1. Hallow cylinder 2. Taps and water stop cocks etc., 3.Loose piece pattern: • Certain patterns cannot be withdrawn once they are embedded in the molding sand. Such patterns are usually made with one or more loose pieces for facilitating from the molding box and are known as loose piece patterns. • Loose parts or pieces remain attached with the main body of the pattern, with the help of dowel pins. • The main body of the pattern is drawn first from the molding box and thereafter as soon as the loose parts are removed, the result is the mold cavity. 4. Match plate pattern: • It consists of a match plate, on either side of which each half of split patterns is fastened. • A no. of different sized and shaped patterns may be mounted on one match plate. • The match plate with the help of locator holes can be clamped with the drag. • After the cope and drag have been rammed with the molding sand, the match plate pattern is removed from in between the cope and drag. • Match plate patterns are normally used in machine molding. • By using this we can eliminate mismatch of cope and drag cavities. Fig: Match plate pattern 5. Sweep pattern: • A sweep pattern is just a form made on a wooden board which sweeps the shape of the casting into the sand all around the circumference. The sweep pattern rotates about the post. • Once the mold is ready, Sweep pattern and the post can be removed. • Sweep pattern avoids the necessity of making a full, large circular and costly three-dimensional pattern. • Making a sweep pattern saves a lot of time and labour as compared to making a full pattern. • A sweep pattern is preferred for producing large casting of circular sections and symmetrical shapes. 6. Gated pattern: • The sections connecting different patterns serve as runner and gates. • This facilitates filling of the mould with molten metal in a better manner and at the same time eliminates the time and labour otherwise consumed in cutting runners and gates. • A gated pattern can manufacture many casting at one time and thus it is used in mass production systems. • Gated patterns are employed for producing small castings. castings Gating system 7. Skeleton pattern: • A skeleton pattern is the skeleton of a desired shape which may be S-bend pipe or a chute or something else. The skeleton frame is mounted on a metal base • The skeleton is made from wooden strips, and is thus a wooden work. • The skeleton pattern is filled with sand and is rammed. • A strickle (board) assists in giving the desired shape to the sand and removes extra sand. • Skeleton patterns are employed for producing a few large castings. • A skeleton pattern is very economical, because it involves less material costs. 8. Follow board pattern: • A follow board is a wooden board and is used for supporting a pattern which is very thin and fragile and which may give way and collapse under pressure when the sand above the pattern is being rammed. • With the follow board support under the weak pattern, the drag is rammed, and then the fallow board is with drawn, The rammed drag is inverted, cope is mounted on it and rammed. • During this operation pattern remains over the inverted drag and get support from the rammed sand of the drag under it. • Follow boards are also used for casting master patterns for many applications. 9. Cope and Drag patterns: • A cope and drag pattern is another form of split pattern. • Each half of the pattern is fixed to a separate metal/wood plate. • Each half of the pattern(along the plate) is molded separately in a separate molding box by an independent molder or moulders. • The two moulds of each half of the pattern are finally assembled and the mould is ready for pouring. • Cope and drag patterns are used for producing big castings which as a whole cannot be conveniently handled by one moulder alone. Fig: Cope and drag pattern Properties of moulding sand Refractoriness : It is the ability of the moulding sand to with stand the high temperature of molten metal. Strength: The moulding sand should have sufficient strength to retain mould. Flowability: Flowability is the ability of the moulding sand to get compacted to take up the required shape Permeability: the moulding sand should be porous enough to allow the gases picked up by the molten metal while transferring or gases generated in the mould to escape from mould Cohesiveness: It is ability of the moulding sand grains to adhere to each other. Adhesiveness: Adhesiveness is the property of moulding sand to adhere to the walls of moulding boxes Collapsibility: Collapsibility is the readiness of the moulding sand to get collapsed after the solidification of the casting Durability: It is ability of the moulding sand to with stand the heating and coolong during repeated usage. Melting furnaces - Cupola and Electric Furnace Cupola Furnace Charge – the metal and fuel put into the furnace. A charge is made up of coke, iron, and limestone. Stack – where the charges sit until they reach the melt zone. Melt Zone- the area in the furnace where the cold iron melts. Cast iron melts at about 2,700 degrees Fahrenheit. Well – where the molten iron pools until the furnace is ready to be tapped. Wind Belt – distributes air evenly from blower to all tuyeres. Tuyeres - openings in the furnace that allow blast air to enter furnace ELECTRIC ARC FURNACE • Various are available which can carry from 1 ton to 400 ton of melting works • The rod penetrated in furnace can be 2 or 3 • The roof can be fixed or tilting with the furnace CONSTRUCTION • An electric arc furnace used for steelmaking consists of a refractory-lined vessel, usually water-cooled in larger sizes, covered with a retractable roof, and through which one or more graphite electrodes enter the furnace. The furnace is primarily split into three sections: • the shell, which consists of the sidewalls and lower steel 'bowl'; • the hearth, which consists of the refractory that lines the lower bowl; • the roof, which may be refractory-lined or water-cooled, and can be shaped as a section of a sphere, or as a frustum (conical section). The roof also supports the refractory delta in its centre, through which one or more graphite electrodes enter. Electric Arc Furnace • A current is passed from separate electrodes creating arcs of ionized gas • Heat is transferred from the arc into the charge material • Can be either DC or AC Resistance Furnace • A current passed through a material resulting in ohmic heating • Radiation heats charge material • Some convection and conduction occurs Mind Map (Annexure II) Mind Map (Annexure II) Copola Furnace Working Principle Electric Arc Furnace Constructions Induction Furnace Advantages Resistance Furnace Dis advantages Oxygen fuel Furnace Summary • Annexure III Casting is a process in which molten metal flows into a mold where it solidifies in the shape of the mold cavity. The part produced is also called casting. • A Pattern is a model or the replica of the object to be cast. • Risers, runners and gates may form a part of the pattern. • The following factors assist in selecting proper pattern material • Metal to be cast, accuracy & surface finish, Shape, complexity and size of casting, Casting design parameters, Type of molding materials, The chance of repeat orders, Nature of molding process, Position of core print. • Materials for making patterns: Wood, Metal, Plastic, Plaster and Wax. • Types of Patterns: Single piece pattern. Split piece pattern. Loose piece pattern. Match plate pattern. Sweep pattern. Gated pattern. Skeleton pattern, Follow board pattern. Cope and Drag pattern. • Advantages and applications are discussed Summary Annexure III • Furnace is used to melt the workspace to be casted. • Types of Furnace – Cupola – Electric Arc – Induction – Oxy-fuel – Resistance • All the furnace construction and working principle are discussed. Questions • • • • • • • • • What is casting? • What is the use of pattern? • What are used for making pattern? What is the composition of green sand? • Write some defects in casting? What is the use of runner? What is the use of riser? Give some advantage of sand casting What is metal spinning process? Define casting? • When do you make core (or) what is function of core in moulding sand? • Mention the specific advantages of carbon di oxide process? • Write the composition of good moulding sand? Annexure III What are the reasons for the casting defects of cold shuts and misrun? Name four different casting defects. How casting defects are identified? Questions • • • • • • • • • • • Annexure III What is meant by furnace? Mention the main parts of cupola furnace. Mention the main parts of Electric arc furnace. Mention the main parts of induction furnace. Write the advantages of cupola furnace. Write the advantages of electric arc furnace. Write the advantages of induction furnace. Write the disadvantages of cupola furnace. Write the disadvantages of electric arc furnace. Write the disadvantages of induction furnace. List the factors to be considered in the choice of metal melting furnace? Annexure IV Multiple Objective Questions 1. _________________ is an added projection on a pattern and forms a seat to support and I locate the core in the mould a) Mould print b) Core print c) Drag d) Cope 2. The maximum quantity of moisture content in the moulding sands can be upto a) 20% b) 14%) c) 8% d) 2% 3. Cope in foundry practice refers to: a) Bottom half of moulding box b) Top half of moulding box c) Middle portion of the moulding box d) Coating on the mould face 5. The process in which the casting is removed from the mould is called…….. (Ans: Shake out) Multiple Objective Questions 5. In foundry technology, hollow castings are produced by using……. (Ans: Cores) 6. "Drag" in foundry practice refers to: a) The top-half of the moulding box b) The middle portion of the moulding box c) The bottom-half of the moulding box d) The coating on the moulding surface. 7. What is the most suitable size for the coke that is charged into the blast-furnace? a) 8 to 25 mm b) 25 to 75 mm c) 75 to 150 mm d) Over 150 mm 8. The metal after being extracted from its ore is in the form of: a) Slabs b) Billets c) Ingots d) Castings 9. __________________ is the flux added with cupola charge to form slag. a) Lime b) Sand c) Coke d) Pig iron Annexure IV Annexure V Higher Order Questions 1. What are the pattern allowances? Explain briefly each. 2. Explain different type of patterns. 3. Write the advantages of different type of patterns. 4. Discuss the properties of moulding sand. 5. Explain the core making state its advantages and applications. 6. State the different type of mould. Write a short note on Green sand mould and shell Moulding 7. Explain briefly the various moulding method used in foundries. 8. Enumerate the casting defects and suggest suitable remedies. 9. Explain the various inspection methods of cast products. Annexure V Higher Order Questions 11. Can all the machine parts manufacture by casting? If no . why? 12. How can make the Mirror surface finish casting parts? 13. How to avoid the complication to make the large size of components in casting? 14. How to make irregular contour profile in casting? 15. How can combined heat treatment techniques with casting? Brain Activation Answer: