Beyond ERP - towards Dashboards of information

advertisement

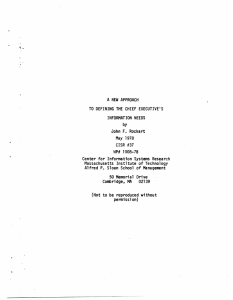

Beyond ERP - towards Dashboards of information • • • • • Decision Support / Monitoring Information cost Information overload Push versus pull model Concept of control room – Analogy with process control or driving a car – Focus on most important factors CSF - Theory • Definition: Limited number of areas where satisfactory results will ensure successful competitive performance for the individual, the department or the firm • Monitored on the basis of a set of measures specific standards that allow the calibration of performance • Measures can be soft or hard - ie: objective or subjective CSF method diagram • Identification of a hierarchy of performance measures that lead to identification of Critical Factors and Issues that will determine a The business mission statement business’ success The business vision statement multiple business goals multiple business objectives for each goal multiple CSFs for each objective Implementation: multiple business objectives for each goal multiple CSFs for each objective Central Database - Data Warehouse Data Preparation Layer / Data Mart Common Interface Dashboard Indicators KPI 1 KPI 2 KPI 3 KPI 4 Sources of CSFs • Industry • Competitive strategy and industry position (leader / follower; big / small…) • Environmental factors (eg: economic fluctuations and national government policies) • Temporal factors (temporary CSFs) • Managerial position (more specific to one manager) Classification of CSFs • Internal versus external • Monitoring versus Building / Adapting (eg: implementing of major corporate plan) • Evolution over time - eg: motor industry + / - of the CSF technique • Small number of CSFs • Managers normally aware of them - make them explicit is possible • Specific to firm / dept / manager • But; not all CSFs are measurable at all (access to data) • Known CSFs may be trivial • Time consuming to go beyond the obvious • Will managers make time for CSF analysis? Dashboards of information • A CSF analysis can be turned into a dashboard of info • indication in real time of what is happening • Concentration on the most important + visual impact (e.g. colour coding) • But data has to be very reliable and design of interface must be good : – three mile island Some Problems with 3 mile Island • Layout of control not consistent with use of indicators • no consistency on where associated controls are situated or how they operated • layout of controls did not reflect layout of plant • indicators and alarms were not sorted by degree of importance • no consistency in use of colour • Cl: the layout of the dashboard and what indicators represent (+ how they do it) requires much attention The Control Room • Monitoring complex processes through technology mediated systems • Controlling without seeing directly • Not completely similar to business management • But useful anyway to measure performance in a specific and acccurate fashion Key issues for dashboard development • Limited attention - selection of indicators (CSF) • Accurate performance measurement methods (models) and data used • Operator / user training - consensus / awareness • Dashboard layout - avoid confusion / be consistent Good Food Limited case study Read and Prepare solutions Discussion Conclusions Framework for dashboard development Question 1: Who will use this indicator? Question 2: Can it be mapped out to a specific objective at a higher level? Question 3: How frequently will managers need to monitor it? Question 4: What calculation methods? What unit of measurement? Question 5: What data source exists? What should be created? Question 6: How detailed should the analysis be? How can the indicators be broken down? Question 7: What threshold values should be used to differentiate between adequate and inadequate performance? What comparisons can be made to assess the company’s performance? Question 8: How can it be represented for maximum visual impact? Question 9: What action must be taken when good or bad performance is measured? Question 10: How will it be monitored / archived in the long term Question 11: Is there any potential bias with the methods and data used for calculations? What incentives may be given to organizational actors? Overall method • Rigorous procedures for reporting and monitoring • Set up a complete Budget framework • Budget broken down per responsibility - e.g. buyers give prices, production gives productivity • once a year = > budget put together – – – – expected levels are put proposed by each area full report compiled (p/l for the year ahead) negotiated with top management final budget used to benchmark activity of the firm General Indicators • Focus on 3 key indicators compared with budget makes it easier to analyse responsibilities: • • • • – volume V (Vb for budget and Va for actuals) – price P – formula F total variance = Va Pa Fa - Vb Pb Fb volume variance = Va Pb Fb - Vb Pb Fb = (Va-Vb) Pb Fb Price variance = Va Pa Fa - Va Pb Fa = (Pa - Pb) Va Fa Formula variance = Va Pb Fa - Va Pb Fb = (Fa - Fb) Va Pb Analysing the general indicators • Volume variance : – breakdown per product / market / week – also per rep? – source: budget / weekly sales – who? Sales Director and reps + regional supervisors + MD – colour maps showing areas / markets – threshold values determine colour – volume and € figure Analysing the general indicators • Price variance: – breakdown per RM / component + labour (for each – – – – category) [focus on most expensive] buyers / production director + supervisors +personnel director source: budget figures + account payable / payroll Monthly probably enough (changes don’t occur that often) tables for detail + exception reporting using icon representing the factor that has high negative variance Analysing the general indicators • Formula variance: – per product / per RM + labour – source: stock issue dockets + production sheets (sales too late) + labour hours – some figures cannot be known exactly => use surrogate or estimate – target: foremen, production staff and director – gauges, colour map of the factory, exception lists Monitoring Maintenance • Imagine down time is increasing • don’t know enough to fix the problem (1) collect appropriate data on accidents: – maintenance staff time sheets – accident report for each problem - documented by operators – match both sources of data (2) store it in a suitable DB (3) analyse based on a number of CSF (4) present analysis in computer dashboard CSF analysis for the maintenance • • • • • • • • Number of accidents per run (per unit / product) Nature of accident (several categories to be found) Location of accidents Average duration of repair (for each assembly line) Average duration of repair for each staff? Average duration of repair for each type of accident Mapping of when accidents happen establish thresholds Location (% of all accidents) Stocks Finished Goods Other Areas: 2% W3 Shipping al 2 Main Corridor 10% al 1 al 1 W2 WP2 storage W1 WP1 cooling al 2 al 1 al 2 Changing 3 - 3 - 15% Rooms Preparation ovens and Related Quality Facilities Control Stocks RM 5% 10% 8% 35% 3% 6% Time spent (% of down time) Stocks Finished Goods Other Areas: 2% W3 Shipping al 2 Main Corridor 5% al 1 al 1 W2 WP2 storage W1 WP1 cooling al 2 Changing 3 - 3 - 8% Rooms and Related Facilities al 1 al 2 Preparation ovens Quality Control Stocks RM 5% 20% 41% 8% 3% 4% When accidents happen Number of Accidents per time period 30 20 10 0 6-7 7-8 8-9 9 - 10 10 - 11 11 - 12 12 - 14 14 - 15 15 - 16 Who does what? Name Job Title Nb Acc. Avg time Gravity Steve Maint. Manager Maint. Staff Maint. Staff App. Martin Bob Mark 27 1 hour 25 4.5 35 1 hour 3 18 2 hours 3 20 1 hour 1 Analysing the types of accidents Time spent per acc. type 25% 20% 15% 40% Proportion of acc. types 15% 45% 20% 20% film jam machine fault accident Op. Error film jam machine fault accident Op. Error Conclusion on Maintenance • Great potential for computerised solution • Some added cost • Focus on: – – – – Actionable areas Areas where scope for improvement Communicate with staff Use for improvement rather than finger pointing • Evolution over time will point to policy decisions Sales Returns • Limited scope for computerised solutions because no possibility of data capture (in this case) • Technical solution – surrogate what happens to the product in a simulated environment – eg: a fridge • Holding samples of products over complete shelf life at various temperatures • Beyond product resistance – move to reputational systems Product Portfolio • Little scope for computer support because no data available – No direct contact with customers – Cannot really predict new product acceptance with lag indicators – Customers cannot tell you what they don’t know! • Use consumer panel – focus group(s) Conclusions • Dual approach on content and context • Realise limitations of computerised solutions when neither data nor model is there • Find surrogates when possible (data) • Be creative in terms of activities that can be pursued to learn more (models) • Focus on delivering value rather than software tools