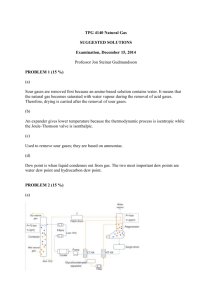

Energy Requirement of Regeneration Unit

advertisement

Kinetics of CO2 Absorption into MEA-AMP Blended Solution Roongrat Sakwattanapong Adisorn Aroonwilas Amornvadee Veawab Faculty of Engineering University of Regina Saskatchewan, Canada Presented at the Annual Research Review Meeting, University of Texas at Austin, Jan 10-11, 2008 1 Outline Introduction & Research Motivation Research Objective CO2 Absorption Experiments Experimental Results and Discussion Kinetic Model for MEA-AMP System Conclusions Acknowledgement 2 Introduction CO2 capture technology Reduction in GHG emissions Low pressure flue gas amines Performance of CO2 absorption o Chemical absorption into Higher performance [Smaller unit] Lower cost CO2 Treated Gas Process Design Liquid Solvent (Lean) ABSORPTION COLUMN REGENERATION COLUMN Absorption solvents Feed Gas Liquid Solvent (Rich) 3 Introduction (Solvent Characteristics) MEA Absorption efficiency or rate rCO2 = k2 [CO2][Amine] DEA k2 ~ 6000 k2 ~ 550 to 7500 to 1600 m3/kmol-s m3/kmol-s MDEA k2 ~ 5 m3/kmol-s Heat of reaction (kJ/mol CO2) 85.6 76.3 60.9 Energy requirement for regeneration (kJ/kg CO2) High Medium Low 0.5 0.5 1.0 CO2 solubility (mol CO2/mol Amine) Blended-alkanolamines Blended alkanolamines have been receiving a great deal of interest. Low energy requirement with acceptable absorption rate 4 Research Motivation MDEA-based solvents Low rate of CO2 absorption. AMP can absorb CO2 with the similar capacity with MDEA but at a much higher rate. The knowledge of CO2 absorption kinetics for MEA-AMP is minimum and limited. Aroonwilas and Veawab, 2004. (Ind. Eng. Chem. Res.) 5 Research Objective To measure kinetic rate of CO2 absorption into aqueous MEA-AMP solution To investigate the effects of process parameters on the kinetic rate of the blend. (The parameters of interest are temperature, total amine concentration, and MEA-AMP mixing ratio.) To understand the kinetic rate data using reaction mechanism model 6 CO2 Absorption Experiment Wetted Wall Column Diameter = 12 mm, OD (stainless steel) Column height = up to 100 mm. Temperature measurement at different locations Wetted Wall Cell Water Bath Heat Exchanger Feed Tank Saturation Cell Bubble Flow Meter Equalizer Gas out Condenser Gas in Receiver Gas Flow Meter 7 CO2 Absorption Experiment (cont’d) 8 System Verification Measurement of diffusion coefficient for CO2-water system T = 298 – 325 K 2 2 2 2044 HCO2 2.8249 106 exp T 2h d tc 3 VL 2/3 3 g 1/ 3 109 DCO2 (m2/sec) DCO 2 NCO HCO 2 tc 2pCO 2 4 3 2 This study Versteeg and van Swaaij, 1988 Nijsing et al., 1959 Yoon et al., 2003 Rowley et al., 1997 Perez and Sandall, 1973 Takahashi et al., 1982 Perry and Green, 1984 1 0 3.0 3.1 3.2 3.3 3.4 3.5 1000 K/T 9 System Verification (cont’d) Measurement of reaction rate constant for CO2-MEA system Temperature = 298 – 318 K (at Various liquid flow rates) MEA concentration = 1 – 4 kmol/m3 pCO 2 HCO 2 ,MEA DCO 2 ,MEAk2,MEA MEA k2,MEA NCO ,MEAHCO ,MEA 2 2 p CO 2 2 1 DCO ,MEA MEA 2 20000 1 kmol/m3 1.5 kmol/m3 17500 2 kmol/m3 3 kmol/m3 15000 k2,MEA(kmol/m3-sec) NCO 2 ,MEA 4 kmol/m3 Hikita et al., 1997 Horng and Li, 2002 12500 Versteeg et al., 1996 10000 7500 5000 2500 3.1 3.15 3.2 3.25 1000/T (K) 3.3 3.35 3.4 10 System Verification (cont’d) Measurement of reaction rate constant for CO2-AMP system Temperature = 298 – 318 K (at Various liquid flow rates) AMP concentration = 1 – 4 kmol/m3 2000 1 kmol/m3 1.5 kmol/m3 2 kmol/m3 1500 3 kmol/m3 k2,AMP (m3/kmol.s) 4 kmol/m3 Alper, 1990 Saha et al., 1995 1000 500 0 3.1 3.15 3.2 3.25 1000/T(K) 3.3 3.35 3.4 11 Test Condition for MEA-AMP Blend Test Parameters Condition Molar mixing ratio Temperature Total amine concentration MEA : AMP 1 : 0 (xMEA = 1.0) 4 : 1 (xMEA = 0.8) 1 : 1 (xMEA = 0.5) 1 : 4 (xMEA = 0.2) 0 : 1 (xMEA = 0.0) 298, 303, 308, 313, and 318 K 1.0 , 1.5, 2.0, 3.0, and 4.0 kmol/m3 12 Experimental Results Overall rate constant (kOV) Parametric effects on kOV (Temperature, Amine conc., MEA-AMP mixing ratio) NCO 2 ,Blend pCO 2 HCO 2 ,Blend DCO 2 ,Blend kov kov NCO ,Blend HCO ,Blend 2 2 pCO 2 2 1 DCO ,Blend 2 Regression of diffusion coefficient and Henry’s constant for MEA-AMP blend. HN2O-mixed (kPa.m 3/kmol) DN2O-mixed (109 m 2/s) 2 7000 1.75 6500 6000 Reported data Reported data 1.5 1.25 1 5500 5000 4500 0.75 Mandal et al., 2005 4000 Mandal et al., 2005 Li and Lai, 1995 Li and Lai, 1995 0.5 0.5 0.75 1 1.25 1.5 1.75 Corre lation from this s tudy 2 3500 3500 4000 4500 5000 5500 6000 6500 Corre lation from this s tudy 7000 13 Effect of Temperature General representation 80000 1 kmol/m3 70000 1.5 kmol/m3 2 kmol/m3 60000 kOV (1/sec) 3 kmol/m3 4 kmol/m3 50000 40000 30000 20000 10000 0 3.1 3.15 3.2 3.25 3.3 3.35 3.4 1000/T (K) MEA : AMP = 1 : 1 14 Effect of Temperature (cont’d) Individual Mixing Ratio 0.0 0.2 Effect of Temperature at xMEA = 0.5 0.8 1.0 80000 1 1kmol/m3 kmol/m3 70000 2 2kmol/m3 kmol/m3 MEA : AMP ratio 4 : 1 (xMEA = 0.8) 1 : 1 (xMEA = 0.5) 1 : 4 (xMEA = 0.2) 0 : 1 (xMEA = 0.0) 60000 kOV (1/sec) 1 : 0 (xMEA = 1.0) 1.5 1.5kmol/m3 kmol/m3 3 3kmol/m3 kmol/m3 4 4kmol/m3 kmol/m3 50000 40000 30000 20000 20000 10000 10000 0 0 3.1 3.1 3.15 3.15 3.2 3.2 3.25 3.25 3.3 3.3 3.35 3.35 3.4 3.4 1000/T (K) 15 Effect of Amine Concentration General representation 80000 [MEA]/[Total] = 1.0 70000 [MEA]/[Total] = 0.8 [MEA]/[Total] = 0.5 60000 [MEA]/[Total] = 0.2 [MEA]/[Total] = 0.0 50000 kOV (1/sec) 40000 30000 20000 10000 0 0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 Total Concentration (kmol/m3) T = 318 K 16 Effect of Amine Concentration (cont’d) Individual temperatures Effect Effectof ofTotal TotalConcentration Concentrationatat308 298 303 318 313KK 80000 [MEA]/[Total] [MEA]/[Total]==1.0 1.0 70000 [MEA]/[Total] [MEA]/[Total]==0.8 0.8 [MEA]/[Total] [MEA]/[Total]==0.5 0.5 60000 k (1/sec) kOVOV(1/sec) [MEA]/[Total] [MEA]/[Total]==0.2 0.2 [MEA]/[Total] [MEA]/[Total]==0.0 0.0 50000 40000 30000 20000 10000 0 0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 Total Concentration (kmol/m3) 17 Effect of Mixing Ratio General Representation Effect of Mixing Ratio at 318 K 80000 1 kmol/m3 70000 MEA : AMP ratio 1.5 kmol/m3 2 kmol/m3 60000 4 : 1 (xMEA = 0.8) 50000 1 : 1 (xMEA = 0.5) 1 : 4 (xMEA = 0.2) 0 : 1 (xMEA = 0.0) kOV (1/sec) 1 : 0 (xMEA = 1.0) 3 kmol/m3 4 kmol/m3 40000 Without Synergy Effect 30000 20000 10000 0 0 AMP 0.2 0.4 0.6 [MEA]/[Total] 0.8 1 MEA 18 Effect of Mixing Ratio (cont’d) Individual Temperatures Effect Effectof ofMixing MixingRatio Ratioat at298 318 303 308 313KK 60000 80000 11M kmol/m3 1kmol/m3 kmol/m3 50000 70000 1.5 1.5 kmol/m3 kmol/m3 M 1.5 kmol/m3 22M kmol/m3 2kmol/m3 kmol/m3 60000 33M kmol/m3 3kmol/m3 kmol/m3 40000 kOV(1/sec) (1/sec) kOV 44M kmol/m3 4kmol/m3 kmol/m3 50000 30000 40000 30000 20000 20000 10000 10000 00 0 0 Single AMP 0.2 0.2 0.4 0.4 [MEA]/[Total] 0.6 0.6 [MEA]/[Total] 0.8 0.8 1 Single1 MEA 19 Kinetic Model for MEA-AMP System Xiao et al. (2000) proposed a model based on a hybrid reaction rate Ali (2005) expressed the reaction rates of both AMP and MEA based on the zwitterion mechanism (for low amine concentration) k2 RR'NH COO CO2 RR NH k ' 1 CO2-MEA System rCO2 , MEA k 2, MEA CO2 MEA 1 k 1 k B B B RR'NH COO B BH RR'NCOO k CO2-AMP System rCO 2 ,AMP k2,AMP CO2 AMP k 1 1 k B B Xiao, J., Li, C.W., and Li, M.H., “Kinetics of absorption of carbon dioxide into aqueous solutions of 2-amino-2-methyl-1-propanol + monoethanolamine,” Chemical Engineering Science, 55(1), 161-175 (2000). Ali, S.H., “Kinetics of the Reaction of Carbon Dioxide with Blends of Amines in Aqueous Media Using the Stopped-Flow Technique,” International Journal of Chemical Kinetics, 37(7), 391-405, July 2005. 20 Kinetic Model (cont’d) Overall reaction of CO2-MEA-AMP System rov k ov CO2 rCO 2 ,MEA rCO 2 ,AMP rCO * kOV kOH [OH ] [ MEA] 1 k2, MEA 1 k2, MEAk H 2 O k1 [ H 2O ] k2, MEAk MEA k1 [ MEA] k2, MEAk AMP k1 [ AMP] 2 ,OH [ AMP] 1 k2, AMP 1 k2, AMPk H 2 O k1 [ H 2O ] k2, AMPk AMP k1 [ AMP] k2, AMPk MEA k1 [ MEA] Apparent reaction rate * k app kOV kOH ] [OH k 2, AMP 15.095 k 2, MEA k MEA 1.4825 416.32 T (K ) k 2, MEA k AMP 0.0003 0.0852 T (K ) k 1 k 2, AMP k MEA k 2, AMP kW k 1 k 2, MEA 171.18 1.758 T (K ) k 2, AMP k AMP k 1 4340.3 T (K ) 0.0067 k 1 k 1 k 2, MEA kW k 1 49450 T (K ) 0.5979 1.2459 0.0027 93.29 T (K ) 353.78 T (K ) 0.7754 T (K ) 21 Speciation [MEA], [AMP], [H2O], [OH-] CO2 Absorption Reaction R ' NH 2 (1) K1 H 2 O R ' NH 3 H 3 O R ' NH 2 (2) K2 H 2 O R ' NHCOO HCO3 R ' NH 2 (3) K3 CO2 2 H 2 O H 3 O HCO3 (4) K4 2 H 2 O H 3 O OH (5) K5 H 2 O HCO3 H 3 O CO3 (6) K6 CO2 RHN 2 H 2 O RNH 3 HCO3 R' NH 3 R' NHCOO CO2 2 HCO CO 3 2 3 RNH 2 RNH (7) Electro-neutrality (8) MEA Balance (9) AMP Balance 3 H O OH 3 (10) Carbon Balance x i 1 .0 H 2 O 22 Comparison (Model & Experimental data) Basic Calculation at 298 KKK Bacis Calculation at 308 Basic Calculation at 313K Basic Calculation at 318K Basic Calculation at 303 100000 100000 100000 kkk kapp,predict app,predict app,predict app,predict 10000 10000 10000 Ali (2005) AliAli (2005) (2005) (2005) 1 Ali kmol/m3 1 kmol/m3 1 kmol/m3 11kmol/m3 kmol/m3 1.5kmol/m3 kmol/m3 1.5 1.5 1.5 kmol/m3 1.5kmol/m3 kmol/m3 2 2kmol/m3 kmol/m3 2 kmol/m3 2 kmol/m3 2 kmol/m3 3 kmol/m3 33kmol/m3 kmol/m3 kmol/m3 43 kmol/m3 3 kmol/m3 4kmol/m3 kmol/m3 4 4kmol/m3 4 kmol/m3 1000 1000 1000 Single AMP Single AMP Single MEA Single Single Single AMP AMP AMP Single MEA Single Single Single MEA MEA MEA 100 100 100 100 100 100 1000 1000 1000 10000 100000 kkkapp,exp app,exp app,exp k app,exp 23 Conclusions The overall rate constant increases with the absolute temperature. At the same mixing ratio, the overall rate constant increases when the total concentration increases. An increase in MEA concentration in the blended solution causes the overall rate constant to change in a nonlinear manner. Rate constant => 1:1 < 4:1 < 1:0 < 1:4 < 0:1 (MEA:AMP) Existing model developed for low amine concentration provides reasonable prediction for single amine, but not for the blend. 24 Further work Mechanism of CO2 absorption into MEA-AMP blended solution will be further investigated. CO2-loaded solution will be tested. Degraded solution will be tested. Empirical correlation of absorption kinetics will be developed. 25 Acknowledgement Faculty of Graduate Studies and Research (FGSR), University of Regina Faculty of Engineering, University of Regina The Natural Sciences and Engineering Research Council of Canada (NSERC) 26 Thank You 27