Univ. of Maryland interview - Alabama Department of Education

advertisement

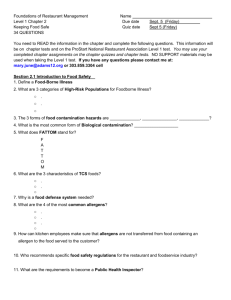

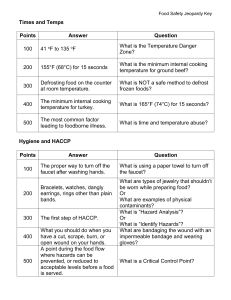

Serving It Safe Jean Weese, Ph.D. R.D. Extension Food Safety Specialist Emily Campbell, Janice Hall, Susan Hill, Bridgette Griffin, Janet Johnson, Angela Treadaway, Kristin Woods Regional Extension Agents Alabama Cooperative Extension System Introduce Yourself: 1. Name and Job Title 2. School and School District 3. What do you hope to learn during this workshop? To Ensure Food Safety… Empower employees Help them understand Hold them responsible Public Health Regulations State and local public health department codes are different than those presented. We will attempt to present the regulations for Alabama NEW TEMPERATURE DANGER ZONE 41° F - 135° F Danger Zone in the 2005 Food Code 45° F to 140° F Alabama Danger Zone (Alabama will transition into the new Zone but it will be over a 10 year period of time) Serving It Safe Chapter 1 Food Safety is Top Priority Food Safety is a Top Priority Foodborne Illness in Alabama - 2003 788 cases Salmonellosis 320 cases Shigellosis 218 cases Giardiasis 186 cases Campylobacteriosis 57 cases Cryptosporidiosis 24 cases Hepatitis A 17 cases E. coli 0157:H7 13 cases Listeriosis Activity 1 Could this happen in our foodservice operation? If If “yes”, describe why “no”, what food safety measures are in place to prevent such a problem from occurring Foodborne Illness “food poisoning” carried by food or water must be diagnosed by a laboratory analysis that identifies the illness. Foodborne Outbreak happens when two or more people become ill from eating a common food confirmed when a laboratory analysis shows the source to be a specific food 3 TYPES OF FOOD CONTAMINANTS 1. BIOLOGICAL pathogens spread mostly by foodhandlers unsanitary facilities and equipment pests Contaminants continued…. 2. CHEMICAL - sanitizers, pesticides, detergents, polishes, cleaning agents, caustic chemicals Train employees Clear labels and stored away from food Measure correctly Use test kits to check concentration Wash hands afterwards Wash fresh fruits and vegetables Monitor pest control operators Metal containers – use only NSF and UL labeled Contaminants continued…. 3. PHYSICAL – easily seen and often reported any foreign objects dirt, hair, mail polish, insects, glass, staples, bone Scoop for ice Store toothpicks, etc. below food Shields on lights Clean can openers Remove staples, etc. in receiving area away from food Avoid temp equipment fixes that could fall off Use hair restraints No nail polish, jewelry No pencils behind ears Only approved food containers for storage Never re-use single use containers What must be done to keep food safe? 1. Where does hazard occur in your operation? 2. How can hazard contaminate food? 3. How do you prevent contamination? Activity 2 Where are the hazards ? Think-Pair-Share Food Safety is Top Priority ACTION PLAN – HANDOUT Serving It Safe Chapter 2 Prevent Foodborne Illness— Understanding Microorganisms What happens in the body? Harmful microorganisms ingested Period of time Symptoms Laboratory test necessary Contamination Occurs Receiving Preparation and serving Cross-contamination Employee to food contact Unsanitary facilities and equipment Disease-spreading pests MAIN CAUSES OF FOODBORNE ILLINESS Poor personal hygiene Time/temperature abuse Cross-contamination Practice Good Personal Hygiene Clean body Clean clothing Clean hands Proper glove use Establish good personal hygiene procedures Control Time & Temperature Temperature danger zone: 45° - 140°F Not to exceed 4 hours, except cool-down Document temperatures & time Includes receiving, storage, preparation, holding, serving, cooling, and reheating Pass food through danger zone quickly Control Time & Temperature Chilling Food Alabama Code 140° to 70° within 2 hours 70° to 45° within 4 hours Use the Tools! Food thermometers Only way to judge internal temperature Common types Bi-metallic stemmed thermometer Digital thermometer Easily accessible for employees DETERMINE TEMP WHEN FOOD IS: Received In Hot-holding Cabinets Being Cooked On Service Line Cooled for Later Cold Storage Leftover Reheated Use Thermometers Correctly! •Clean and sanitize after every use. •Insert into center, thickest part; to cover sensor •Wait till rests; 15 seconds •Take three measurements Calibrate Routinely Calibration of Thermometer Two Methods: Ice-Point Method Boiling-Point Method Hands-On Activity Calibrate a Food Thermometer Using the Ice-Point Method Use the Tools! How to use a food thermometer How to Use a Thermometer Clean and sanitize between uses Calibrate them regularly Insert thermometer stem or probe into thickest part of product Wait steady reading before recording temperature Never use mercury or spirit-filled glass thermometers to check food temperature Cross - Contamination Hand to food Food to food Equipment to food Prevent Hand-to-Food Cross-contamination Wash hands correctly and often Cover cuts, sores, wounds Avoid nail polish and artificial nails Avoid jewelry Use single-use gloves correctly WASH HANDS BEFORE….. Beginning food preparation Putting on disposable gloves Serving customers WASH HANDS AFTER….. Upon arriving at work and after breaks Leaving restroom & again at kitchen Eating, drinking, smoking, chewing Using phone or handkerchief Handling inventory or raw food Touching or scratching body Coughing or Sneezing AND ALSO AFTER….. Clearing or cleaning tables Cleaning dirty plates and utensils Handling garbage Handling money Touching dirty aprons or surfaces Using cleaning utensils Gloves Are for single-use only Must never replace hand washing Should be right for the task Must be safe, durable, and clean Must fit properly – buy variety MUST BE USED PROPERLY 4-10 Change your gloves….. As soon as soiled or torn Before beginning a different task After handling raw meat Before handling cooked or ready-to-eat Prevent Hand-to-Food Cross-contamination How to Wash Hands Correctly Prevent Food-to-Food Cross-contamination Store raw foods below cooked foods. Do not mix leftover food with fresh food. Wash all fresh produce in cold running water. Do not prepare raw meat and raw fruits or vegetables on the same surface. Cross Contamination: Equipment Issues Assign specific equipment to specific types of food. 5-3 Prevent Equipment-toFood Cross-contamination Properly clean and sanitize equipment before use and before being used to prepare another food Prevent Equipment-to-Food Cross-contamination Designate Separate Work Areas Change to clean utensils when replenishing steam table. Clean & Sanitize after each use Equipment Work Surfaces Utensils Use Specific Containers with Clear Labels Never Re-use single-use containers or wraps Prevent Equipment-to-Food Cross-contamination Sanitize wiping cloths Rinse & Store in clean sanitizing solution after each use Check concentration frequently Preventing Foodborne Illness Practice good personal hygiene Control time and temperature Prevent cross-contamination Responsibilities of Foodservice Manager Knowing and implementing regulations Solving problems of noncompliance Maintaining current knowledge Training employees Holding employees responsible Responsibilities of Foodservice Employees Learning about food safety Following food safety requirements and guidelines What To Do? How should the foodservice manager respond if symptoms of foodborne illness are reported to the foodservice? Proper Managerial Response Keep cool and calm! Seek guidance Stop serving any suspect food Keep samples Report to & cooperate with health officials Report all gathered information Only health professionals to give advice Direct media to school district reps Only designated personnel notifies parents Proper Managerial Response Gather information from your own kitchen Determine handling before and during prep Interview employees Have documentation available Keep names and phone numbers of officials to be contacted. Small Group Activity Case Study: Field Trip Frenzy Time to Think How safe is your kitchen? Think-Pair-Share Prevent Foodborne IllnessUnderstanding Microorganisms ACTION PLAN – HANDOUT Serving It Safe Chapter 3 Basic Facts about Microorganisms Common Causes of Foodborne Illness Bacteria Viruses Fungi – molds & yeasts Parasites 3 ways bacteria can cause foodborne illness Single cell that can grow and reproduce Produce toxins Produce spores Bacteria Characteristics Describe the bacteria Symptoms of foodborne illness Foods involved in outbreaks Prevention strategies Viruses that cause foodborne illness Norwalk & Norwalk-like viral agents Hepatitis Fungi that cause foodborne illness Molds Toxins can be dangerous Discard molded food Yeasts Discard any food with unnatural color or smell Parasites that cause foodborne illness Cyclosporiasis Giardiasis Trichinosis How do microorganisms grow? Why are bacteria considered Vegetative? What is a Spore? How do microorganisms grow? Stages of growth: Lag phase Log phase Stationary phase Death phase Controlling growth of microorganisms F A T T O M Food Acidity Temperature Time Oxygen Moisture F- Food How food contributes to growth of bacteria: Definition of PHF Potentially Hazardous Foods Included on Menus Animal products Vegetables and plant products Shelf-stable foods, once opened Raw fruits and vegetables Raw seed sprouts and garlic-in-oil mixtures Controlling the growth of bacteria in Food: Reputable supplier Avoid cross-contamination Safe internal temperature and test with food thermometer A- Acidity pH range of 4.6 to 7.5 Control of acidity to control growth of bacteria T- Temperature Temperature Danger Zone - 45°F to 140°F Some bacteria can survive between 32°F and 45°F Controlling temperature: Control temperature of food during storage, preparation, holding, cooling, reheating, and service Use food and equipment thermometers Dry Store at 50-70° Temperature control continued... Cook to required internal temperature Keep foods out of danger zone T- Time Microorganisms need time to grow One bacterium = one million in four hours Controlling Time to control bacterial growth: Store foods quickly, especially in refrigerator and freezer (PHF) Prepare foods as close to service time as possible Check temperatures over time Cook foods to safe internal temperatures for proper time Time control continued… 140 to 70 in 2 hours; 70 to 45 in 4 hours Mark date and time for all refrigerator & freezer foods Reheat leftovers to 165°F for 15 seconds O- Oxygen Aerobic Anaerobic Controlling oxygen M- Moisture Bacteria need water for growth Aw Low moisture foods resistant to bacteria Controlling Moisture to control growth of bacteria Small Group Activity Case Study – Food Mystery Think-Pair-Share Basic Facts about Microorganisms ACTION PLAN – page 83 Serving It Safe Chapter 4 A Clean and Sanitary Foodservice Personal Hygiene Personal hygiene & work attire are important Establish guidelines for good personal hygiene Proper hand washing Dress for Food Safety Success • • • • • Clean, appropriate uniform Clean apron Avoid jewelry Wear hair restraint Wear safe shoes Common Sense - or maybe not! Know when & how to wash hands Taste food the correct way Never taste food containing raw ingredients of animal origin Follow rules for eating, smoking, etc Report illnesses to manager Never wear apron to the restroom Food-safe Facility • Clean floors, walls, & ceilings Clean & sanitary serving areas Good ventilation Clean employee restrooms Clean & neat trash collection areas Effective pest control program Pest Control Guidelines Keep them out! – deny food water and shelter ongoing pest control program – licensed operator fill openings around pipes, fittings screens, in good repair self-closing doors, air doors tight-fitting lids on labeled containers store food off floor 6” inspect foods and destroy infested clean grease traps Cockroaches Any place that is dark, warm, moist and hard to clean Holes, boxes, seams of bags folds of paper Seeing one in day is sign of serious infestation Strong oily odor Feces like pepper grains Dark capsule-shaped egg cases Flies Enter through tiny holes size of pinhead Contaminate with mouth, hair, feces, feet Lay eggs in warm decaying material, away from sun Rodents Signs: Droppings Gnawing Tracks in dust Nesting materials Holes in baseboards and walls Activity Food-Safe Facility Checklist Definitions Clean – no visible food particles Sanitary – number of microorganisms has been reduced to a level that is not harmful Sanitizing Methods Heat Chemical Heat Sanitizing Manually Dishwashing Machine Chemical Sanitizing Chlorine Iodine Quaternary Ammonium Compounds (Quats) Chemical Sanitizing – Three-Compartment Sink Step 1: Clean & sanitize sinks Step 2: Scape and pre-soak Wash in 1st sink, 110° Rinse in 2nd sink, 110° Sanitize in 3rd sink, 171° Step 3: Air dry Step 4: Store Heat Sanitizing- Dishwashing Machine Wash at 150° Rinse at 180° Large Equipment Step 1: Unplug (electricity and accidental start) Step 2: Remove loose food particles Step 3: Wash, rinse, sanitize removable parts Step 4: Wash, rinse, sanitize non-immersible parts Step 5: Clean non-food contact surfaces Step 6: Re-sanitize external food-contact surfaces Who is responsible for food safety? Manager Employees Think-Pair-Share A Clean and Sanitary Foodservice ACTION PLAN – page 92 Serving It Safe Chapter 5 A Process for Preventing Foodborne Illness Foodservice Process 1. 2. 3. 4. Purchasing Receiving Storing Preparing 5. Cooking 6. Holding and Serving 7. Cooling 8. Reheating Purchasing-Vendor Federal and State health standards Clean delivery trucks with adequate refrigeration and freezer units, correct temperatures, separate raw and fresh foods Standardized food sanitation written policy and procedures Train employees in sanitation Purchasing-Purchaser Work with vendor Food delivery schedule Vendor standardized procedures in print Purchase specification Vendor sanitation report Food Safety Guidelines for Receiving Train employees for receiving duties Organize space, equipment and lighting for receiving efficiency Inspect delivery trucks Inspect food immediately RECEIVING Packaged – insert between two packages Milk – open a carton and insert two inches in Frozen – insert between two packages Receiving Receiving Decisions Activity Safe Food Storage Dry storage-long holding for less perishable items Refrigerator-short-term for perishable items Deep-chilling unit-spec. foods for short time Freezer-long term food storage Small Group Activity 1. Share information most applicable to your operation 2. Give at least 1 example of how you can use these guidelines in your operation 3. Share information about your school’s food storage Preparing Foods Safely Thaw foods safely 4 safe methods to thaw frozen foods Preparing Foods Safely Freezing does not kill bacteria. Thawing – 4 Safe Methods 1. In refrigerator at 41°F 2. Under flowing water 70°F 3. In microwave – cook immediately Not for schools 4. As part of cooking process Preparing Foods Safely Complete pre-preparation safely Follow food safety guidelines for prepreparation Preparing Foods Safely •Pre preparation: Assemble recipe ingredients Weigh or measure ingredients Assemble small equipment & utensils Cautions: Prep is usually done at room temp Commonly a point of cross contamination Guidelines for Preparation continued…. •Wash hands first •Prepare no further in advance than necessary •Small batches; refrigerate immediately at or below 41°F •Wash fresh fruits and vegetables regardless of how it will be served •Use scrub brush on thick skinned produce Guidelines for Preparation continued….. Avoid cross-contamination Wash hands correctly first Raw separate from Ready-to-Serve Wash, rinse, sanitize cutting boards, utensils, equipment, all food contact surfaces after each contact with a food. Wash hands again. Batter, breading, marinades for one recipe only. Use as recipe states. Guidelines for Preparation continued….. Report cans of bad food to manager, purchaser, and vendor Keep can, lid and box with important tracking numbers Mark can as “Do Not use” Afterwards, discard according to state and district procedures Be especially careful with PHF Preparing Foods Safely Follow food safety guidelines for panned foods to be cooked later Follow food safety guidelines for cold foods that will not be cooked Guidelines for Panned Foods to be Cooked Later Wash hands, use gloves properly 20 minute limit for preparation, then chill to hold Avoid cross-contamination Cover during storage Document internal temp during holding Guidelines for Cold Foods Not to be Cooked Wash hands, use gloves Chill safely prepared ingredients before combining in recipe Small batches; cold store immediately Prepare no further in advance than necessary Hold below 41°F; and document Avoid cross-contamination Wash, rinse, sanitize cutting boards, utensils, equipment, all food contact surfaces after each contact with a food. Wash hands again. Cooking Foods Safely • Follow food safety guidelines for cooking foods • Cook to minimum safe internal temperatures Guidelines for Cooking Foods Safely •Follow manufacturer’s directions and follow recipes •Stir frequently to ensure even heat •Avoid overloading fryers •Regulate portion size and thickness for cooking together and uniformly •Never interrupt cooking Guidelines for Cooking Foods Safely Continued… Use food thermometer on equipment and food thermometers • Check in several places, thickest parts • Don’t touch pan or bone with thermometer • Use serving utensil or single use gloves • Taste food correctly • Reach safe internal temperatures • Poultry and casseroles – 165°F • Ground Meats – 155°F • Fish – 145°F Holding and Serving Food Safely Follow food safety guidelines for Holding and Serving Follow food safety guidelines for Employees on the Service Line Follow food safety guidelines for Sanitary Self-service Guidelines for Holding and Serving Foods Safely Use hot-holding equipment for service, not reheating Use refrigeration or ice surrounding items Stir at intervals Check temps every 30 minutes; sanitize thermometers Document temperatures while in TDZ Cover hot holding equipment; retain heat Monitor temp of hot-holding equipment Don’t refresh pans, change pans Guidelines for Employees on Service Line Use good personal hygiene Wash hands and arms correctly Use cleaned, sanitized long-handled ladles and spoons Don’t touch parts of plates, food trays, flatware that will touch food or mouths Single-use gloves, tongs to serve by hand Clean and sanitize equipment after each use Use lids and sneeze guards Always wash hands between tasks Always clean and sanitize prep areas and equipment between tasks Discard garnishes from service line Guidelines for Safe SelfService Monitor customers in self-service Post signs of advice for customers Remove contaminated foods Use packaged foods to avoid contamination Monitor and document internal temps of self service foods every 30 minutes Cooling Food Safely Follow steps for safe cooling Chill hot food to 70° within 2 hours and then to 45° in an additional 4 hours Store cooked foods above raw foods in the refrigerator/freezer Guidelines for Cooling Foods Safely Avoid cross-contamination: cover loosely Reduce food mass Use shallow, pre-chilled pans less than 4 inches deep Stainless steel better chills faster than plastic Guidelines for Cooling Foods Safely Continued….. Use ice-water bath Use quick-chill unit Pre-chill in freezer before refrigeration, stir Provide air flow around foods; no stacking NEVER cool food at room temperature Stir frequently; cold paddles, washed and sanitized Measure and document temps during cooling Cover and label cooled foods with name, date, time of preparation Cooling Properly From 140°F down to 70°F in 2 hours From 70°F to 45°F in additional 4 hours Foods not reaching 70°F within 2 hours must be reheated immediately to 165°F for 15 secs. Reheating Foods Safely Follow guidelines for reheating food Take foods through the temperature danger zone quickly Guidelines for Reheating Foods Safely Pass through TDZ quickly Reheat previously cooked food to 165°F, 15 sec. internal temp Heat to 165°F, 15 sec., when adding precooked food to recipe Heat sauce, soup, gravy to 165°F15 sec. Never reheat in hot-holding equipment Never mix leftovers with fresh batches Food held at 41°F or less may be held 7 days Assure refrigeration can hold leftovers at 41°F or below Think-Pair-Share A Process for Preventing Foodborne Illness ACTION PLAN – HANDOUT Serving It Safe Chapter 6 Introduction to Hazard Analysis and Critical Control Point (HACCP) Introduction to HACCP A preventative process, food safety system To reduce risk of foodborne illness By proper food handling Through Monitoring procedures and Recordkeeping Focus is on food Five Risk Factors Foods from unsafe sources Poor personal hygiene Inadequate cooking Improper holding temperatures Contaminated equipment HACCP helps. . . Identify hazardous foods and procedures Develop procedures to control Monitor use of procedures Verify that system is working Basic Food Safety Procedures Personal hygiene Facility design—clean and sanitary Vendors Food specifications Routine cleaning and sanitation Equipment maintenance Seven Principles of HACCP 1. 2. 3. 4. 5. 6. 7. Identify hazards Identify Critical Control Points (CCP) Establish critical limits (CL) Establish monitoring procedures Establish corrective actions Establish verification procedures Establish record keeping procedures HACCP: Prevent foodborne illness Identify hazardous foods and procedures Develop procedures to reduce risk Monitor use of procedures Verify that food is safe to eat 1. Identify Hazards Track each food Review menus Group foods Potentially hazardous food Evaluate Rank 2. Identify Critical Control Points CCPs Hazard can be controlled Hazard can be prevented Loss of control Unacceptable health risk 3. Establish Critical Limits CL Standards Observable Measurable Usually temperature and time pH Humidity Salt concentration Available chlorine 4. Establish monitoring procedures Use CL Monitor Potentially Hazardous Food Identify deficiency outside CL Train on how to monitor 5. Establish Corrective Action CCP does not meet CL Need for corrective action Examples 6. Establish Verification How often are corrective actions needed? What tests can be done? Use routine inspection from public health. 7. Establish Record Keeping System to document HACCP process and monitor results Records help continue to improve procedures and HACCP Seven Principles of HACCP 1. 2. 3. 4. 5. 6. 7. Identify hazards Identify Critical Control Points (CCP) Establish critical limits Establish monitoring procedures Establish corrective actions Establish verification procedures Establish record keeping procedures Questions ? Thank You! www.nfsmi.org 800-321-3054 www.aces.edu 334-844-3269