presentation

ENGINEERING 536

MASS TRANSFER

OPERATIONS

FALL 1997

TEAM MEMBERS:

Dr. Jim Henry, P.E.

Sean Cunningham

Mark Koss, P.E.

Sandy Koss

Tara Ostrander, E.I.

Nittaya Pittayataree

Beth Ruta

Nitipol Suksathaporn

Introduction

Study of mass transfer operations using the distillation column

Approach to the study of the distillation column included

- Literature search

- Operating the column

- Computer modeling

+ Ponchon-Savarit

+ PROII

This report will cover

- column calibrations

- experimental results

- computer modeling

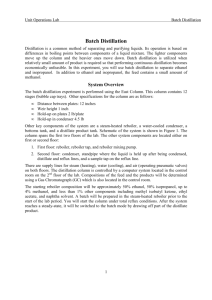

DISTILLATION COLUMN

TI

Cooling Water Supply

TI

Cooling Water Return

Electromagnetic Reflux Control

TI

TI

TI

TI

TI

TI

TI

TI

TI

TI

TI

TI

Reboiler

TI

4

5

6

1

2

3

7

8

9

10

11

12

Condenser

TI

PI

TI

LI

Distillate

Pump

Feed Pump

LI

Product Cooler

Feed Tank

(Product Tank)

Reboiler Pump

COLUMN DESCRIPTIONS

Condenser

Reflux valve

Trays

RTDs

Pumps

- Feed pump

- Reboiler pump

- Distillate pump

- Auxiliary pump

Reboiler

Level Control

- Condenser

- Reboiler

FEED LOCATIONS

Column Calibrations

Heat loss study

RTD calibration

Pump and cooling water calibration

Heat Loss Study

Previous heat loss calculations seemed excessive

Parameters of the study are

- selected reboiler amperage

- 100% reflux

- no condensate produced

Column losses are equal to the energy input into the column

Minimum amperage to maintain the temperature on tray 1 is between 6 and 7 amps

Estimated column heat loss is between 1230 Watts and 1435 Watts

66.0

65.8

65.6

65.4

65.2

65.0

70

Temperature of tray 1 at 7 amps

Reboiler Amps = 7

72 74

Time

76 78 80

Temperature of tray 1 at 6 amps

Reboiler Amps = 6

65.5

65.0

64.5

64.0

63.5

63.0

78 79 80 81

Time

82 83 84 85

RTD Calibration

Temperature is calculated by multiplying the voltage by the scale and then adding the offset

Steps to calibrate RTDs

- fill reboiler with pure methanol

- allow steady state

- set offset to zero

- set scale to one

- collect voltage readings

- repeat with water

Voltage is taken at 100 o C (pure water) and 64.5

o C (pure methanol)

Straight line was fit between the two points

Slope of the line is the scale

y intercept is the offset

Pump and Cooling Water

Calibration

Pump and cooling water calibrations seem to be reliable

Pump calibration

- by measuring the outflow of the pump for a timed period

Cooling water calibration

- by measuring the flow at the cooling water system drain at various valve openings

Pump Calibration Curve

Feed Pump Calibration Curve

600

500

400

300

200

100

0

0

Pump : 7017-21 Pattern No. 3.358.609

2

F = -2.3996M

2

+ 98.326M - 81.102

R

2

= 0.9942

4 6

Pump Setting

8 10

Conclusions

(calibrations)

Pump and cooling water calibrations seem to be reliable

Calibrations performed on the glass RTDs were unsuccessful ( repeated several times)

Replacement of the glass RTDs with stainless steel improved the calibrations

- three RTDs do not give reliable temperature indication

Recommendation

(calibrations)

Perform calibrations

- after a period of inactivity

- whenever equipment is changed or modified

Reduce time spent on calibrations

- Calibrate the RTDs individually with ice and boiling water

- UTC engineering/maintenance personnel should complete calibrations

Experimental Results

Energy and mass balance

Capacity test

Feed location impact

Reflux ratio impact

Energy and Mass

Balance

Excel spreadsheet was developed to facilitate mass and energy calculations

Calculations showed an increase in water and a decrease in methanol

Column had not reached steadystate conditions

Flowrate (gms/min)

Mixture Methanol Water

Feed 321 315

Bottoms 205 168

Distillate 116 147

12

12

0

DISTILLATION COLUMN EXPERIMENT (10/15/97)

MASS BALANCE

Inputs

Reflux Ratio=

Distillate:

Pump Setting:

RTD Reading:

Density:

1.78

1.20

64.57

0.79

Tank Temp=

Reboiler:

Pump Setting:

RTD Reading:

Density:

30.00

Feed:

2.10

Pump Setting:

75.67

%MeOH(Molar):

0.94

Density

Distillate

%MeOH (Molar)

Frac (Wt)

99.55

1.00

Flow Rate (ml/min) 15.05

Mass flow rate (g/min) 11.91

Mass MeOH (g/min) 11.88

Mass H2O(g/min) 0.03

water balance

MeOH balance

31.48 gm/min

-25.39 gm/min

Reboiler:

%MeOH (Molar)

Frac (Wt)

Feed Pump:

39.15

%MeOH (Molar)

0.53

Frac (Wt)

50.00

0.64

Flow Rate (ml/min) 336.57

Flow Rate (ml/min) 350.54

Mass flow rate (g/min) 315.13

Mass flow rate (g/min) 320.95

Mass MeOH (g/min) 168.14

Mass H2O(g/min) 147.00

Mass MeOH (g/min) 205.41

Mass H2O(g/min) 115.54

ENERGY BALANCE

5.00

0.50

0.92

ENERGY IN AT REBOILER

Reboiler (Amps) 15.43

Energy In(watts) 3394.60

CONDENSER

Cool Water Temp-in(°C)

Cool Water Temp-out (°C)

Cool Water Flow (ml/min)

Water Cp (KJ/KgoK)

Energy Out Cond(watts)

Latent Heat(watts)

19.74

20.63

9000.00

4.18

557.94 Qcond

615.07 Qlatent

RE BOILER

Delta T

MeOH Cp

Reboiler Energy

45.67

2.55

794.47 Qr

Capacity Test

Performed to determine the maximum capacity of the column to produce distillate

Parameters for the test are

- reboiler was filled with a mixture of methanol and water

- reboiler current set at 20 amps

(maximum)

- reflux set 95 % Methanol distillate

- steady-state conditions were established

- Set various feed pump settings

- Set various reflux ratios

- Determine distillate and reboiler flowrate

- Column did not produce distillate at pump setting of 7

Capacity Test Comparison

Feed Pump Feed Flowrate Percent Distillate Reboiler

Setting (ml/min) Reflux Flowrate Flowrate

5

3 192

350

(ml/min) (ml/min)

76 25 180

6

7

420

490

75 32 332

-

76 21 390

-

Feed Location Impact

Parameter

- Pump setting of 3

- Reboiler amps at 20

- 70% reflux

Results

- Tray 4 - 89%

- Tray 5 - 93%

- Tray 6 - 97%

Reflux Impact

Parameter

- Feed location tray 4

- Pump setting of 3

- Reboiler amps at 20

Results

- Reflux 50% - 78% at 43 ml/min

- Reflux 70% - 89% at 23 ml/min

Conclusions

(Experimental Results)

Design and execution of experiments

- useful way of gaining experience

- found column performed in a predictable manner

- increased the students’ level of confidence

energy and mass balance calculations demonstrated

- purity of the product was surpassed with a reduction in the quantity of the product

Based on observations from the capacity test

- maximum output of the reboiler heaters could not maintain boiling conditions above a feedwater flowrate of 420ml/min

Based on observations from the feed location experiment

optimum feed tray location - tray 6

due to the higher methanol composition in the distillate

Based on observations from the percent reflux experiment

- between 50- and 70-percent reflux

* two times the distillate flowrate

*

1.6 times the amount of methanol

Recommendation

(Experimental Results)

Review the RTD calibrations to account for the discrepancies in the mass balance

Perform additional feed location impact experiments

Take physical measurement of the distillate flow (not pump flowrates)

Computer Modeling

Pro II

Ponchon-Savarit

PRO II

Steady-state heat and material balance simulator

Simulates any number of components, streams, units, and recycle loops

Requirement

- Feed stream

- composition

- temperature

- flowrate

- pressure

- Tray efficiency

Specify two of the following parameters

- Any specific tray temperature

- Heat duty of the condenser

- Temperature of the distillate

- Composition of the distillate

- Flowrate of the distillate

- Reflux ratio

- Temperature of the bottoms

- Composition of the bottoms

- Flowrate of the bottoms

- Heat duty of the reboiler

PROII will calculate remaining parameters

PRO II - Optimizing Distillation Column

Stream Name

Stream Description

Phase

Temperature

Pressure

Flowrate

Composition

MEOH

H2O

Total Stream

Rate

Std. Liq. Rate

Temperature

Pressure

Molecular Weight

Enthalpy

Mole Fraction Liquid

Reduced Temperature

Reduced Pressure

Acentric Factor

UOP K-Value

Std. Liquid Density

Sp. Gravity

API Gravity

Vapor

Rate

Molecular Weight

Z (from Density)

Enthalpy

CP

Density

Th. Conductivity

Viscosity

Liquid

Rate

C

ATM

1

Liquid

25

0.994603

0.5

0.5

2

Liquid

65.53888

0.994603

0.925

0.075

Liquid

99.82745

0.994603

G-MOL/MIN 12.00385

6.488153

5.515693

n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a

3

6.91E-05

0.999931

G-MOL/MIN 12.00385

6.488153

5.515693

G/MIN 300.4381

201.0676

99.37048

CM3/MIN

C

ATM

350 250.4837

99.51627

25 65.53888

99.82745

0.994603

0.994603

0.994603

M*J/MIN

J/G

G/CM3

25.0285

30.98997

18.01597

0.023033

0.034942

0.041537

76.66611

173.7827

417.998

1 1 1

0.514083

0.647976

0.576169

0.006671

0.011017

0.004556

0.45835

0.552148

0.348015

9.962891

10.55651

8.76176

0.858395

0.802717

0.998535

0.859242

0.803509

0.999521

33.18008

44.60248

10.06786

G-MOL/MIN n/a

G/MIN n/a

CM3/MIN n/a n/a

J/G

J/G-C

G/CM3 n/a n/a n/a n/a

CP n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a

Molecular Weight

Z (from Density)

Enthalpy

CP

Density

Surface Tension

G-MOL/MIN 12.00385

6.488153

5.515693

G/MIN

CM3/MIN

300.4381

352.8752

201.0676

265.9261

99.37048

103.6818

25.0285

30.98997

18.01597

0.001195

0.001467

0.000611

J/G

J/G-C

G/CM3

76.66611

3.115483

0.851401

DYNE/CM n/a

173.7827

2.895487

0.756103

n/a

417.998

4.21597

0.958418

n/a

Ponchon-Savarit Theory

Graphical Method

• Plots Enthalpy Against

Composition

Provides Exact Solutions

Incorporates Effects of Heat

Losses

• Inputs of Individual Tray Losses

• Inherent Material and Energy

Balances

Ponchon-Savarit

Diagram on Excel

Inputs Needed (highlighted in yellow)

• Distillate and Bottoms

Compositions Desired

• Distillate and Bottoms Flowrates

• Heat Losses on Each Tray

Works For Up To 13 Stages

Tested For Bottoms

Concentrations down to 0.01% and Distillate Concentrations up to 97.9%

Conclusion

(Computer Modeling)

PROII

- user friendly

- fast

- not accurate

- limited by constraints

Ponchon-Savarit

- heat loss on individual trays must be known

- only valid for methanol-water mixtures

Recommendations

(Computer Modeling)

Modify the PROII model to more closely approximate the UTC distillation column

Conduct training for students on the use of modeling tools

Determine the heat losses on the individual trays (Ponchon-

Savarit)

Conclusions

(Final)

Technical

- Study of mass transfer operations using the distillation column

- Approach to the study of the distillation column included

- Literature search

- Operating the column

- Computer modeling

* Ponchon-Savarit

* PROII

- E ach student had the opportunity to participate in

- operation

- calibration

- repair

- P rovided a better understanding through

- research

- classroom discussion

- design of experiments

Accomplishments

- Ponchon-Savarit spreadsheet developed

- PROII model developed

- Energy and mass balance spreadsheet developed

- Determination of the column capacity

- Determination of heat lost to the environment

- Performed feed input experiments

Recommendations

(Final)

Allow for more continuous laboratory time

- Modify class schedule

- Maintain the distillation column components

- Establish course objectives, perform calibrations, research literature, and familiarize students with modeling programs within the first month of the semester