Sanitizers and Disinfectants

advertisement

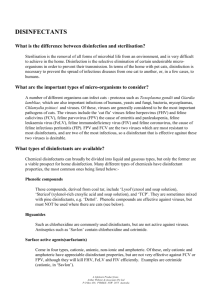

Sanitizers and Disinfectants • Sanitizer reduces to “safe levels” • Disinfectant kills 100% bacteria • Sterilant kills bacteria, endospores, fungi and viruses There are a number of classes of compounds which can be used as sanitizers and disinfectants. The efficacy of these compounds varies depending upon the environment and conditions it is used in. The selection of disinfectant should be done with care and matched for the job expected. Properties of disinfectants/sanitizers which need to be considered are: • Non toxic to chicks, embryos and humans when used properly. • Harmless (non corrosive and non staining) to the surfaces which the disinfectant/sanitizer is being applied to. • How application is made (foam, soak, spray, aerosol); formulations of inerts will differ Additionally, the selection of disinfectant should: 1. Be fast acting, even in the presence of organic matter 2. Be effective against all types of infectious agents “broad spectrum” (multiple active ingredients) 3. Easily penetrate the material to be disinfected without damaging or discoloring the material 4. Be easy to prepare and be stable when exposed to environmental factors 5. Be inexpensive 6. Not have an unpleasant odor The effectiveness of the disinfectant/sanitizer is dependent upon a number of factors: * Absence of organic matter from the area to be sanitized * The type of surface the sanitizer is applied to (surface porosity) * The diluent (hard water??) properties that the disinfectant/sanitizer is diluted in to working strength * The length of time the disinfectant/sanitizer is in contact with the surface to be sanitized * The temperature of the disinfectant solution and surface to be cleaned * Use of an effective concentration of disinfectant/ sanitizer to ensure proper killing action * pH, whether high or low, can increase or decrease potency. The optimal pH increases the degree of ionization of the chemical agent which will affect its ability to penetrate the cell * Compatibility between the cleaners and the disinfectants which are used Labeling of Disinfectants • Is required to kill 100% of the bacteria, molds and viruses claimed on label • Hard surface disinfectant – Testing performed on smooth hard surface, either glass or polished stainless steel – Standard test conditions • 10 minutes • 20 C. • A disinfectant will not kill bacterial endospores (Clostridium sp or Bacillus sp) Disinfectant Labels • Disinfectant can be labeled as: – Limited disinfectant – Agricultural disinfectant – Hospital disinfectant • Efficacy test requirements will differ for each • All may be tested in hard water and in presence of organic load (5% blood serum) but not required to be registered Certain types of disinfectants/ sanitizers are better suited for hatcheries, others for housing and others for vehicles. Hatchery Disinfectants Used for: • • • • • Water Air Premise Equipment Foot bath To Kill Microorganisms Disinfectants/Sanitizers Require: • Concentration • Time • Temperature – generally higher – cl- & I- volatile as increase temperature • pH - degree of ionization • Diluent (water) properties - Ca or Mg (hardness) • Compatibility of cleaner and disinfectant Chemical Properties • Cleaner should be compatible with disinfectant – even thorough rinse will leave some residual • Detergents are of two types, cationic (+ charged) and anionic (- charged) – Generally, cationic detergents are used on food preparation surfaces – anionic detergents are used to launder clothes. • Bacteria cell walls are negatively charged and using anionic detergents would cause microbes to be repelled Chemical Properties • Anionic - molecules have net negative charge (phenolics, cresylics, soaps) • Cationic - molecules have net positive charge (Quats) • Non-ionic - molecules have a neutral charge • If mix strong anionic with strong cationic - form a complex and destroys killing action To Kill Microorganisms Disinfectants Require (cont.): • Humidity (if aldehyde gas) • Surfaces - compatible with surface – cl- & peroxide corrosive on metals – dirt & biofilms protect microorganisms Chemical Properties • Manufacturer should consider when formulating a product – soil load & type – surface (porous, smooth, plastic, soft metal, stainless, etc.) – how application will be made (foam, soak, spray) – pH of soil to be removed (scale is alkaline, so use an acid cleaner) – Safety Chemical Properties • Hard Water - EDTA & citrates • Surfactants & wetting agents - better penetration of surfaces and cell walls • Other antimicrobials to enhance control – tributyltin oxide for mold control Mechanisms of Action of Chemical Agents • Reactions that affect proteins (DNA) • Reactions that affect cell membranes • Reactions that affect other cell components Reactions can affect the cell membrane of the microorganisms because not only do the cell membranes contain protein but also lipids which can be dissolved and thus disrupt the cell membranes. Surfactants are substances which reduce the surface tension. These substances include alcohols, detergents and quaternary ammonium compounds. Phenolics are one type of alcohol which denatures proteins but also dissolves lipids. Wetting agents and detergent solutions will not kill microorganisms but help to dissolve lipids so that other agents can get at them. Different classes of disinfectants typically found in hatchery • Halogens – Chlorine – Iodine • Quaternary Ammonium • Phenols • Alkylating Agents – formaldehyde – gluteraldehyde • Oxidizing agents – ozone – hydrogen peroxide Different classes of disinfectants normally not used in hatchery • Creosols • Dyes – gentian violet - blocks cell wall synthesis • Heavy metals – silver - silver nitrate – copper - copper sulfate – mercury - merthiolate • Alcohol • Radiation Inerts Propylene glycol Citrates EDTA • Propylene glycol – – – – – Emulsifier Humectant Solvent Cleaning Fog enhancement Inerts • Citrates – – – – – Chelates Fe and Ca Reducing agent Soil suspension Solution clarity synergism • EDTA – – – – – – – – Chelating Soil suspension Solution clarity Synergism Surfactants Penetrate Spread emulsify Chlorine • Features – Broad spectrum – Not affected by hard water – Quick kill • Limitations – – – – Corrosive, poor cleaner Poor cleaning ability Affected by pH, organic material, UV and heat No residual Chlorine Activity (hypochlorite ion and hypochlorous acid) pH 4.0 5.0 6.0 7.0 8.0 9.0 10.0 % HOCL Almost 100 99.6 95.8 69.7 18.7 2.2 0.2 Iodine • Features – Broad spectrum (Gram+/-, fungi) – Good acidic cleaner (low ppm for effectiveness, fast acting) – Effective in hard water • Limitations – Corrosive, volatile (very short residual) – Effective only at pH 1-4 – Inactivated by organic material, but better than chlorine Chlorine Dioxide • Features – Broad spectrum – Fast action – Sporicidal • Limitations – – – – Corrosive Requires activation step Offensive odor Limited use after dilution Quaternary Ammonium • Features – – – – – – – – Odorless Can be alkaline, neutral or acidic - usually alkaline Broad spectrum (reasonable) Good cleaning ability & tolerates organics Fast kill time Least corrosive Cationic Residual activity • Limitations – Not sporicidal – Interfered by calcium and magnesium, Hard water (EDTA & citrates) • Features – – – – – – – – – Phenolics Tolerate organic matter Formulated to be alkaline or acidic Broad spectrum (gram+/-, fungi) Takes low ppm for effectiveness Fast acting Tolerates hard water Good cleaning ability Anionic Residual • Limitations – So-so sporicidal – Eye irritant, can cause staining – odor Hydrogen Peroxide • Features – – – – Broad spectrum Sporicidal Solution or vapor phase effective Decomposes to water and oxygen • Limitations – – – – Corrosive Inactivated by heat and organic matter Use in high concentrations and no residual Handling hazards Peracetic Acid • Features – Broad spectrum, Sporicidal – Effective in presence of organic matter – Decomposes to non hazardous compounds – Solution or vapor phase effective • Limitations – Corrosive to soft metals – Unstable at high temperatures – Irritant