Automatic Control System

advertisement

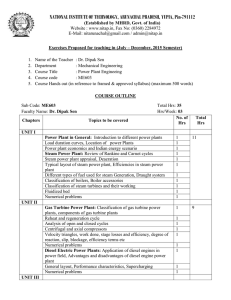

Theme: Power plant C&I (IPC) systems & Tending to Zero Forced Outage by Internalization of Best Practices Presentation Outline: 1.Some definitions & basics of Pressure, Flow & Temp. measurement 2. Categorization of C&I systems based on location of application 3. Division of power plant C&I systems based on functionality & type of application 4.Evolution of C&I systems and latest trend in technology 5.NTPC at a glance and maintenance practices of C&I systems 6. Some case studies Measurement: Pressure Outline: Some Definitions Pressure Units Manometers Elastic Pressure Sensors Electrical Pressure Sensors Pressure Switches Snubbers & Siphon Tubes Measurement: Pressure Terminology Accuracy : Closeness with which an instrument reading approaches the true value of the variable being measured. Precision : A measure of reproducibility of the measurements; i.e. given a fixed value of a variable, precision is a measure of the degree which successive measurements differ from one another. Sensitivity : The ratio of output signal or response of the instrument to a change of input or measured variable. Resolution : The smallest change in measured value to which the instrument will respond. Error : Deviation from the true value of the measured variable. Measurement: Pressure Repeatability refers to the ability of a pressure sensor to provide the same output with successive applications of the same pressure. Hysteresis is a sensor's ability to give the same output at a given pressure while increasing and decreasing the pressure. Measurement: Pressure Pressure : Definitions Definition: Force per unit area Absolute pressure Atmospheric pressure Differential pressure Gauge pressure Importance : Pressure measurement is critical for safe and optimum operation of processes such as steam generation, hydraulic equipment operation, air compression, vacuum processing etc. Measurement: Pressure Zero Reference , Gauge, Absolute, Atmospheric Pressure Any pressure above atmosphere is called gauge pressure Any pressure below atmosphere is a vacuum (negative gauge pressure) Absolute pressure (psia) is measured from a perfect vacuum Differential Pressure has no reference to either absolute vacuum or atmospheric pressure Measurement: Pressure Units The SI unit for pressure is the Pascal (Pa);1Pa= 1 N·m-2 Non-SI unit pound (Lb) per square inch (psi) and bar are commonly used Pressure is sometimes expressed in grams-force/cm2or as kgf/cm2 (KSC) 1 atm=1.03 ksc=14.696 psi=760mmHg=10000 mmWC =101325 Pa Standard pressure:Pressure of normal (standard) atmosphere is defined as standard pressure Measurement: Pressure Pressure Measuring devices Manometers using water ,mercury and other liquids of known density For measuring low pressures. Mechanical/Elastic Pressure Sensors Electrical Pressure Transducers For measuring pressure of all ranges for telemetering purposes. Manometer: A simple pressure standard May be used for gauge, differential, and absolute measurements with a suitable reference. Useful mainly for lower pressure work because the height of the column of mercury will otherwise become very high. The difference in column heights gives the pressure reading Measurement: Pressure Elastic Pressure Sensors The basic pressure sensing elements: A: C-shaped Bourdon tube , B: Helical Bourdon tube , C: flat diaphragm D: Convoluted diaphragm, E: Capsule , F: Set of bellows Measurement: Pressure Electrical Pressure Sensors 1. 2. 3. 4. 5. Potentiometer Sensor Inductive Capacitive Piezoelectric Strain Gauge Usually generate output signals in the mV range (spans of 100 mV to 250 mV). In transmitters, these are amplified to the voltage level (1to 5 V) and converted to current loops, usually 4-20 mA dc Measurement: Pressure Pressure Switches Applications • Alarm (Status) • Shutdown (Hi/Lo Limits) • Control (ON/OFF) A “switch” is an instrument that automatically senses some process variable (such as pressure) and provides an on/off signal relative to some reference point. Set Point Sensing Element Conditioning Circuit Bourdon Tube Bellows Diaphragm Strain Gauge Mechanical Switch Transistor Measurement: Pressure High Pressure In High Temperature * When high process temperatures are present, various methods of isolating the pressure instrument from the process are used. * These include siphons, chemical seals with capillary tubing for remote mounting, and purging. Snubbers & its use Chemical Seal Siphon Measurement: Pressure Pressure Snubbers To filter out pressure spikes, or to average out pressure pulses, snubbers are installed between the process and the instrument Instrument indicates avg pr. Snubber Before use After use when one is interested in the measurement of fast, transient pressures (such as to initiate safety interlocks on rising pressures), snubbers must not be used, as they delay the response of the safety system. Measurement: Pressure Chemical Seal or diaphragm Protector Chemical seals are used when media can falsify the pressure measurements due to high temperature, high viscosity or their property to crystallise Measurement: Pressure Siphon A siphon is a coiled tube. This coil provides a large cooling surface and the trap created prevents the condensate from draining away. A siphon is required for hot condensing. fluids, such as steam, to assure a liquid trap. It is used to prevent live steam from entering and damaging the device. It is used to protect the instrument from hydraulic or thermal shocks. The two most common forms of siphon tube are the 'U' and Pigtail types. Measurement: Flow Types of flow meters: 1. 2. 3. 4. 5. Orifice Flow meter Vortex flow meter Ultrasonics flow meter Coriolis Mass Flow meter Major issues for selecting flow meters Orifice Flow-meters Several sensors rely on the pressure drop or head occurring as a fluid flows by a resistance. The relationship between flow rate and pressure difference is determined by the Bernoulli equation. Measurement: Flow Orifice Flow-meters • An orifice plate is a restriction with an opening smaller than the pipe diameter which is inserted in the pipe; the typical orifice plate has a concentric, sharp edged opening. • Because of the smaller area the fluid velocity increases, causing a corresponding decrease in pressure. • The flow rate can be calculated from the measured pressure drop across the orifice plate, P1-P3. • The orifice plate is the most commonly used flow sensor, but it creates a rather large non-recoverable pressure due to the turbulence around the plate, leading to high energy consumption. Measurement: Flow Venturi Tube The change in cross-sectional area in the venturi tube causes a pressure change between the convergent section and the throat, and the flow rate can be determined from this pressure drop. Although more expensive that an orifice plate; the venturi tube introduces substantially lower non-recoverable pressure drops Measurement: Flow Pitot Tubes Pitot tubes were invented by Henri Pitot in 1732 to measure the flowing velocity of fluids. Basically a differential pressure (dp) flow meter, a pitot tube measures two pressures: the static and the total impact pressure. Pitot tubes are used to measure air flow in pipes, ducts, stacks, and liquid flow in pipes, open channels. While accuracy and rangeability are relatively low, pitot tubes are simple, reliable, inexpensive, and suited for a variety of environmental conditions, including extremely high temperatures and a wide range of pressures. Measurement: Flow Pitot Tubes A single-port pitot tube can measure the flow velocity at only a single point in the cross-section of a flowing stream. The probe must be inserted to a point in the flowing stream where the flow velocity is the average of the velocities across the cross-section, and its impact port must face directly into the fluid flow. Measurement: Flow Pitot Tubes The point velocity of approach (VP) can be calculated by taking the square root of the difference between the total impact pressure (PT) and the static pressure (P) and multiplying that by the C/D ratio, where C is a dimensional constant and D is density: The pitot tube measures the static and dynamic (or impact) pressures of the fluid at one point in the pipe. The flow rate can be determined from the difference between the static and dynamic pressures which is the velocity head of the fluid flow. Measurement: Flow Vortex Flow-meters This measuring principle is based on the fact that vortices are formed downstream of an obstacle in a fluid flow, e.g. behind a bridge pillar. This phenomenon is commonly known as the Kármán vortex street. Measurement: Flow Vortex Flow-meters This is detected by a sensor, such as capacitive sensor and fed to the electronic processor as a primary, digitized, linear signal. Capacitive sensors with integrated temperature measurement can directly register the mass flow of saturated steam as well. Universally suitable for measuring liquids, gases and steam Largely unaffected by changes in pressure, temperature and viscosity High long-term stability (lifetime K factor), no zero-point drift No moving parts Marginal pressure loss Measurement: Flow Ultrasonic flow-meters Swimming against the flow requires more power and more time than swimming with the flow. Ultrasonic flow measurement is based on this elementary transit time difference effect. Two sensors mounted on the pipe simultaneously send and receive ultrasonic pulses. At zero flow, both sensors receive the transmitted ultrasonic wave at the same time, i.e. without transit time delay. When the fluid is in motion, the waves of ultrasonic sound do not reach the two sensors at the same time. Measurement: Flow Ultrasonic flow-meters This measured "transit time difference" is directly proportional to the flow velocity and therefore to flow volume. By using the absolute transit times both the averaged fluid velocity and the speed of sound can be calculated. Ultrasonic flow meters measure the difference of the propagation time (transit time) of ultrasonic pulses propagating in (normally an inclination angle around 30 to 45° is used) flow direction and against the flow direction. This time difference is a measure for the averaged velocity of the fluid along the path of the ultrasonic beam Measurement: Flow Ultrasonic flow-meters Advantages: With homogeneous fluids, the principle is independent of pressure, temperature, conductivity and viscosity Usable for a wide range of nominal diameters Direct meter installation on existing pipes Non-invasive measurement No pipe constrictions, no pressure losses No moving parts. Minimum outlay for maintenance and upkeep Measurement: Flow Coriolis Mass Flow-meters If a moving mass is subjected to an oscillation perpendicular to its direction of movement, Coriolis forces occur depending on the mass flow. A Coriolis mass flow meter has oscillation measuring tubes to precisely achieve this effect. Coriolis forces are generated when a fluid (= mass) flows through these oscillating tubes. Sensors at the inlet and outlet ends register the resultant phase shift in the tube's oscillation geometry. Measurement: Flow Coriolis Mass Flow-meters The processor analyzes this information and uses it to compute the rate of mass flow. Advantage This principle is used in a huge range of industry sectors, including pharmaceuticals, chemicals and petrochemicals, oil and gas, food etc. Measurement: Flow Major issues for selecting flow-meters Accuracy Repeatability Linearity Reliability Range/Span Dynamics(Response time) Safety Maintenance Cost Measurement: Temp. Measurement Devices Thermocouples Resistance Thermometers Thermistors Bimetallic Thermometers Acoustic Pyrometers Local Instruments Measurement: Temp. Thermocouple IT IS BASED ON ‘SEEBECK’ EFFECT WHICH SAYS THAT WHEN HEAT IS APPLIED TO A JUNCTION OF TWO DISSIMILAR METALS AN ‘EMF’ IS GENERATED WHICH CAN BE MEASURED AT THE OTHER JUNCTION T/C Connection COMPENSATING CABLE HOT JUNCTION TO DDC CARDS TERMINAL END CJC BOX Measurement: Temp. Thermocouple Types of T/C:E,J,K,T,R,S,B K (Chromel & Alumel; Ni-Cr &Ni-Al) Type: mostly used in power plant for low temp. application ) R (Platinum & Platinum-Rhodium) Type: Used for high temp. application. Highly resistant to oxidation & corrosion Advantages: Disadvantages: - Low Cost - Sensitivity low & low voltage output - No moving parts, less likely to be broken. susceptible to noise -Wide temperature range. - Accuracy not better than 0.5 °C -Reasonably short response time. - Requires a known temperature - Reasonable repeatability and accuracy. reference Measurement: Temp. RESISTANCE THERMOMETER (RTD) THE RESISTANCE OF A CONDUCTOR CHANGES WHEN ITS TEMPERATURE IS CHANGED .THIS PROPERTY IS UTILISED TO MEASURE THE TEMPERATURE. Rt = Ro (1+βdT) β = TEMP CO- EFFICIENT OF RESISTANCE ; dT = TEMPERATURE DIFFERENCE When discussing RTDs, following must be considered: WHERE • • • • • • Wiring configuration (2, 3 or 4-wire) Self-heating Accuracy RTD types: Stability 1. Platinum (Range -200 °C to 600 °C ) Repeatability 2. Copper (Range -100 °C to 100 °C ) Response time 3. Nickel (Range -60 °C to 180 °C ) Measurement: Temp. THERMISTORS THERMISTORS ARE GENERALLY COMPOSED OF SEMICONDUCTOR MATERIALS.THEY HAVE A NEGATIVE COEFFICIENT OF TEMPERATURE SO RESISTANCE DECREASES WITH INCREASE IN TEMP. Making use of Negative Temperature Coefficient characteristics, thermistor and can be applied in temperature compensation, inrush current limit, precision temp. control (temp. coefficient very large compared to RTC & T/C) etc. BIMETALLIC THERMOMETERS ALL METALS EXPAND OR CONTRACT WITH TEMPERATURE THE TEMPERATURE COEFFICIENT OF EXPANSION IS NOT THE SAME FOR ALL METALS AND SO THEIR RATES OF EXPANSION AND CONTRACTION ARE DIFFERENT USAGE: IN PROCESS INDUSTRIES FOR LOCAL TEMPERATURE MEASUREMENTS OVERLOAD CUTOUT SWITCH IN ELECTRICAL APPARATUS Measurement: Temp. ACOUSTIC PYROMETER Acoustic Pyrometer is a non-contact measurement device that obtains highly accurate instantaneous gas temperature data in any area of the boiler, helping improve combustion efficiency. For measurement of temperatures across large spaces of known distance in a noisy, dirty and corrosive environment such as a coalfired utility boiler, or a chemical recovery boiler. The Velocity of Sound in a medium is proportional to the Temperature. LOCAL INDICATION LIQUID IN GLASS THERMOMETER MERCURY IN STEEL THERMOMETER BIMETALLIC THERMOMETER Power Plant C&I systems 1.Field instruments/ input & output instruments a) Various measuring instruments like Transmitters, RTD, Thermocouples, Pr. & temp. gauges, speed & vibration pick ups etc. (Analog inputs) b) Various Pr., Temp. & limit switches, for Interlock , protections & feedback of control element (Binary inputs) c) Output devices like solenoids, EP converters, Positioners etc. for controlling final control element d) Final control elements like Power cylinder, Pneumatic/ motorized actuators etc. Power Plant C&I systems 2. Control Systems a) Various control cabinets for acquiring field signal (both analog & binary inputs), processing the signals as per control logic and issuing output command to output devices (Binary & analog). b) Various control desk devices like command consoles, Push button modules, indicators, recorders, CRTs, PC based Operator Work Stations (OWS) etc. for human machine interface for monitoring & control of the plant c) Power supply system(UPS)/ chargers with battery backups to ensure uninterrupted power supply of desired quality for the control system Power Plant C&I systems 3. Analyzers The availability, reliability & efficiency of boiler unit hinge around the close control of chemical regimes of working fluid i.e. water/steam as well as combustion in the boiler. The instruments monitoring the chemical regimes and combustion are generally called analytical instruments. These instruments fall under three category i) Water/ Steam Analyzers ii) Gas analyzers iii) Smoke monitors HIGH PURITY WATER IS ESSENTIAL TO MINIMISE SCALING CORROSION CARRY OVER EMBRITTLEMENT Power Plant C&I systems ANALYZERS AND MEASURMENT LOCATION a) ON LINE gas analyzers for measurement of flue gas oxygen, carbon mono-oxides, carbon di-oxides, oxides of sulpher & nitrogen at various location of boiler. b) ON LINE analyzers for measurement of conductivity, pH, silica, dissolved oxygen, phosphate, hydrazine, chloride, sodium etc. at various points in the water & steam cycle of boiler & turbine area (SWAS-steam & water analysis system). c) ON-LINE opacity monitors for measurement of dust concentration in flue gas d) ON LINE analyzers for measurement of conductivity, pH, silica, dissolved oxygen etc. at various ION exchangers of DM plant . Power Plant C&I systems TYPICAL VALUES OF CHEMICAL PARAMETERS BEING MEASURED (SWAS) SAMPLE PARAMETER DM WATER a) Conductivity b) Cation Conductivity Condensate pump discharge (CEP) a) Conductivity b) Cation Conductivity Economizer Inlet Boiler water a) Conductivity b) Cation Conductivity UNIT µS/cm µS/cm c) pH <5 <0.3 9.0-9.2 d) Na+ ppb <5ppb e) Dissolve oxygen (DO) ppb <10 c) Hydrazine a) Conductivity µS/cm ppb <5 <0.3 µS/cm 100 10-20 9.1-9.4 b) pH Sat & Main steam LIMIT <0.3 c) Silica ppb 100 a) Conductivity b) Cation Conductivity µS/cm <5 <0.3 Power Plant C&I systems 4. Laboratory Instruments & Setup Activities of C&I Lab CALIBRATION REPAIR TESTING with proper documentation & records CALIBRATION: Pressure switch , Transmitter , Gauge Temperature switch , Transmitter , Gauge Flow Transmitter Level Switch Power Plant C&I systems 4. Laboratory Instruments & Setup REPAIR: 1. ELECTRONIC CARDS 3. POWER SUPPLY MODULES TESTING: 1. ELECTRONIC MODULES 2. RELAYS 3. POWER SUPPLY MODULES Power Plant C&I systems 4. Laboratory Instruments & Setup a) Different standard instruments with traceability up to national standard . These insts. include Standard Gauges, Multimeters, Resistance boxes, mA sources, oscilloscope, signal generator etc. for calibration of measuring instruments. b) Dead Weight tester, Comparator, Temperature bath, Vacuum pump, manometer, soldering stations etc. c) Test benches with standard power supply sockets (e.g. 24VDC, 48VDC, 220VDC, 110VAC, 230VAC etc.) in each bench depending on requirement. d) Laboratory should be air-conditioned with monitoring of temp., humidity and barometric pressure. Also, proper provision for handling electronic cards (floor mats, ESD protective bags/ anti static bags etc.) Power Plant C&I systems 4. Laboratory Instruments & Setup Essential Tools/ Infrastructure for Repairing & testing 1. IN-CITCUIT IC TESTER 2. ESD WORK STATION 3. ULTRASONIC CARD CLEANER 4. STORRAGE OSCILLOSCOPE 5. LOGIC ANALYSER 6. THERMOCOUPLE SIMULATOR 7. VIDEO PATTERN GENERATOR 8. EPROM PROGRAMMER Power Plant C&I systems C&I systems of Boiler - FSSS (Furnace safeguard supervisory system) - Open loop control system (interlock & protections) of boiler auxiliaries - Secondary Air Damper control system (SADC) - Hydrastep for drum level measurement - Measurements, Protection & Control of Coal Feeders Power Plant C&I systems FSSS FUNCTIONS OF F.S.S.S 1. FURNACE PURGE SUPERVISION 2. OIL GUNS ON/OFF CONTROL 3. PULVERISERS/FEEDERS ON/OFF 4. SECONDARY AIR DAMPERS CONTROL 5. FLAME SCANNER INTELLIGENCE 6. BOILER TRIP PROTECTIONS CONTROL Power Plant C&I systems FSSS WHY AT ALL A PROTECTIVE SYSTEM IS REQUIRED FOR THE BOILER? THE BOILER’S FURNACE IS CONTINUOUSLY FED WITH HIGH CALORIFIC VALUE ATOMISED FUEL WHICH IS IN THE PROCESS OF CONTINUOUS BUT CONTROLLED COMBUSTION. COMBUSTION-THE PROCESS COMBUSTION IS A RAPID BURNING OF OXYGEN WITH FUEL RESULTING IN RELEASE OF HEAT. AIR IS ABOUT 21% OXYGEN AND 78% NITROGEN BY VOLUME. MOST FUELS CONTAIN CARBON, HYDROGEN AND SULPHUR. A SIMPLIFIED COMBUSTION PROCESS COULD BE CARBON+OXYGEN=CARBONDIOXIDE+ HEAT HYDROGEN+DO =WATER VAPOUR + HEAT SULPHUR +DO =SULPHURDIOXIDE+ HEAT WHICH MEANS THAT THE FINAL DESIRED PRODUCT OF THE PROCESS IS HEAT WHICH WE REQUIRE TO BOIL THE WATER Power Plant C&I systems FSSS COMBUSTION-THE PROBLEM : WHEN THIS CONTROLLED BURNING GOES OUT OF CONTROL DUE TO AN IMBALANCE IN THE FUEL/AIR RATIO, THERE IS EITHER A FUEL RICH MIXTURE OR A FUEL LEAN MIXTURE. IN BOTH CASES THE FLAME QUALITY BECOMES POOR. THERE IS A CHANCE OF FUEL ACCUMULATION WHICH CAN LATER ON IGNITE SUDDENLY AND CAUSE EXPLOSIONS. SO FSSS IS USED FOR SAFE AND ORDERLY STARTUP AND SHUTDOWN OF BOILER THROUGH VARIOUS INTERLOCKS AND PROTECTIONS THE PROTECTIVE SYSTEM IN THE BOILER IS DESIGNED BASICALLY TO PREVENT OCCURRENCE OF SUCH SITUATIONS BY TAKING ADVANCE ACTIONS. Power Plant C&I systems N.F.P.A Guide line & Boiler Protection N.F.P.A- National Furnace Protection Association, USA Deals with protection for various types of furnace Protection of Pulverized fuel fired boiler is governed by Section-85c Different categories of protection: a) Mandatory, b)Mandatory & automatically generated, c) Optional but alarm has to be there Power Plant C&I systems BOILER FLAME & FLAME SCANNERS It looks rather static, but in reality the fire energy fluctuates rapidly. The Fuel and Oxygen in the uncontrolled fire constantly burn as in small explosions and then sucks new Fuel & Oxygen to the flames. This process causes the flame flicker. Flicker frequency for oil flame is more than that of coal flame. Power Plant C&I systems INTENSITY RELATIVE TO WAVELENGTH Power Plant C&I systems FLAME SCANNERS -UV Scanners -Visible Range Scanners (Safe scan-1&2)-Used for both Oil & Coal Flame -IR Scanners (UR600 of ABB) SAFE FLAME SCANNER Power Plant C&I systems C&I systems of Turbine - ATRS (Automatic Turbine Runup system) Turbine Governing System - Turbovisory Instruments & turbine protections - Interlock, Protection & Control of HPBP system - Open loop control system (interlock & protections) of turbine auxiliaries Interlock & protections of Seal Oil & Stator water system - - Power Plant C&I systems C&I systems for control & MIS -Automatic Control System (ACS) -DATA Acquisition system(DAS) -Distributed Digital Control Monitoring and Information System Power Plant C&I systems AUTOMATIC CONTROL SYSTEM & POWER PLANT CONTROL LOOP PROCESS: Process refers to the method of changing or refining raw materials to create the desired end product. The raw materials may undergo physical, chemical, or thermal state changes during the Process. Process is of Two Types : A) Continuous and B) Batch Continuous Process is one where the change of state of Input into Output occurs continuously. Ex.: Power Plant Process, Petroleum Industry etc. Batch Process is one where a Batch of the Product is produced and the Process stops till production of next Batch is started. Ex.: Automobile Production Power Plant C&I systems AUTOMATIC CONTROL SYSTEM & POWER PLANT CONTROL LOOP PROCESS CONTROL: Process control techniques are developed over the years to have Quality of the end product Economy of production Ability to cater to emergencies and bring the process to safe shutdown. CONTROLLED CONDITION: The physical quantity or condition of a process or machine which is to be controlled CONTROL SYSTEM: An arrangement of elements interconnected and interacting in such a way that it can maintain some condition of a process or machine in a prescribed manner Power Plant C&I systems AUTOMATIC CONTROL SYSTEM & POWER PLANT CONTROL LOOP OPEN AND CLOSED LOOP CONTROL: A Closed Loop Control (CLCS) is one where a Process Variable is measured, compared to a Set Value and action is taken to correct any Deviation or Error from Set Value. The continuous Measurement of PV and its’ comparison to Set Point closes the Loop. An Open Loop Control(OLCS) is one where the PV is not compared with Set Value and action taken, but action is taken without regard to conditions of PV. Power Plant C&I systems AUTOMATIC CONTROL SYSTEM & POWER PLANT CONTROL LOOP OPEN LOOP CONTROL: Open Loop Control is accomplished by the following means: Group Control Sub-Group Control Sub-Loop Control Drive Level Control Programmable Logic Control(PLC) Group Control : Start and Stoppage of a Group of equipment is accomplished by Group Control(GC). Ex. :CEP GC, Equipment Cooling GC etc. Power Plant C&I systems AUTOMATIC CONTROL SYSTEM & POWER PLANT CONTROL LOOP OPEN LOOP CONTROL: Sub-Group Control : Start and Stoppage of an equipment with its’ associated auxiliaries in Step-Sequence manner is done by SubGroup Control. Operator intervention is not required in Sub-Group Control(SGC). Sub-Loop Control: Start and Stoppage of auxiliaries of an equipment is carried out by Sub-Loop Control(SLC) Drive Level Control : Start and Stop or Opening and Closure of a Drive is carried out by Drive Control. The Drive logic shall have Protection, release ,auto and manual commands and these are executed as per pre-determined logic. Power Plant C&I systems AUTOMATIC CONTROL SYSTEM & POWER PLANT CONTROL LOOP CLCS TERMINOLOGY: Desired Value or Set Point : The value of the variable/parameter which needs to be controlled at the required condition. Process Variable(PV) : The present value of the Parameter of Process at that particular instant. This is sometimes referred as Measured Value. Error/Deviation : It is the Difference between Set Point and Process Variable, and can be +ve or –ve. It has three components: a) Magnitude b) Duration and c) Rate of change. Controller : A Controller is a device that receives data from a Measurement Instrument, compares the data with the Set Point and if necessary, signals a Control element to take Corrective action. This Corrective action ensures that the PV shall always be maintained at the Set Value. The Controller can be a) Electronic, b) Pneumatic and c) Hydraulic type. Power Plant C&I systems AUTOMATIC CONTROL SYSTEM & POWER PLANT CONTROL LOOP Controller types: Functionally, Controllers can be a) Continuous and b) Step Controllers. Depending on the control loop; controller action can be adjusted as (i) Direct acting:-Increase of process value increases controller output (ii) Reverse acting:- Increase of process value decreases controller output Control Element : The Control or Correcting Element is the part of the Control System that acts to physically change the Manipulated Variable. Ex. : Control Valves, Louvers or Dampers, Solenoids, Pump Motors etc. Power Plant C&I systems AUTOMATIC CONTROL SYSTEM & POWER PLANT CONTROL LOOP Bump less Transfer : The arrangement where the transfer from auto to manual mode does not affect the process. Proportional Control : The Proportional (P) action responds only to a change in the magnitude of Error(e) i.e. controller output changes by an amount which is proportional to error. Output change of Controller in % = (Error change in %)(Gain), where Gain is called the Controller gain. The reciprocal of Gain is termed as Proportional Band(PB) and is expressed in %. Proportional Band(PB): The change in deviation required to cause the output of the controller to change from one extreme to the other. Integral Control : In Integral Control, the Controller output is a function of the Duration of Error(e). Power Plant C&I systems AUTOMATIC CONTROL SYSTEM & POWER PLANT CONTROL LOOP Hence, the Controller output is the time Integral of Error and the time set is Integral Action Time(IAT) i.e. IAT can be defined as time taken for the integral action to change output by the same amount as the proportion action . Usually, both P and I Controls are combined and the Controllers are tuned to minimize Error(e) and controller is termed as PI controller. Derivative Control : Derivative or Rate Controller’s output is Proportional to the rate of change of Error(e). The Control action is termed as D. The action is to apply an immediate response that is equal to the P+I action that would have occurred some time in the future. Power Plant C&I systems AUTOMATIC CONTROL SYSTEM & POWER PLANT CONTROL LOOP Important Closed Loop Controls in a Thermal Power Plant: a) Furnace Draft Control b) Boiler Drum Level Control c) HOT well & D/A level control d) Main Steam Temperature Control e) Air and Fuel Flow to Boiler Control f) SH & RH spray control g) Coordinated Master Control(CMC) h) Turbine Speed, Pressure and Load Control Power Plant C&I systems AUTOMATIC CONTROL SYSTEM & POWER PLANT CONTROL LOOP Coordinated Master Control This is an integrated automatic control of unit operation. There is a continuous co ordination between boiler and turbine control to maintain a balance between steam generation and steam consumption. • Boiler Follow Mode (BFM) • Turbine Follow Mode (TFM) • Co-ordinated Master Control (CMC) • Runback Mode Power Plant C&I systems AUTOMATIC CONTROL SYSTEM & POWER PLANT CONTROL LOOP Boiler Follow Mode (BFM) • Unit load control from turbine local load set point • Change in turbine load set point will modulate turbine CVs • Boiler master output gets corrected to maintain throttle pr dev. • Boiler control will follow turbine control • BLI signal as feed forward signal for boiler firing rate control • Result - Boiler acts as throttle pr controller where turbine is in load controller mode Power Plant C&I systems AUTOMATIC CONTROL SYSTEM & POWER PLANT CONTROL LOOP Turbine Follow Mode (TFM) • Unit target load set point goes to boiler master • Change in BLI will modulate turbine CVs • Boiler master output gets corrected to maintain Unit load dev. • Turbine control will follow boiler control • Load deviation as feed orward signal for boiler firing rate control • Result - Boiler acts as load controller where turbine is in pressure controller mode Power Plant C&I systems AUTOMATIC CONTROL SYSTEM & POWER PLANT CONTROL LOOP Coordinated Master Control • Unit load is set from unit master. • Unit master demand is limited by unit capability , TSE margins and unit max/min load set points. • Unit target load is derived from unit master after the limitations. • Unit target load is used as feed forward signal to the boiler firing rate control. • Turbine control utilises the unit load as turbine load set point after adapting the same by steam generation delay. • In TG throttle pressure is maintained by correcting the BMD output depending on the throttle pr dev. • Result: Balance is achieved between steam generation and steam consumption PROPER COORDINATION BETWEEN BOILER CONTROL AND TURBINE CONTROL Power Plant C&I systems DATA ACQUISITION SYSYTEM-DAS WHY DAS IS REQUIRED IN THERMAL POWER PLANTS ? SAFE & RELIABLE OPERATION OF THE UNIT OR EQUIPMENTS ASSIST CONTROL ROOM OPERATORS BY PROVIDING TIMELY ANNUNCIATION OF ALL ABNORMAL CONDITIONS PROVIDE DETAILED INFORMATION ON THE PLANT PERFORMANCE PROVIDE MANAGEMENT WITH ACCURATE RECORDS ON THE PAST PLANT PERFORMANCE FOR ANALYSIS Power Plant C&I systems DATA ACQUISITION SYSYTEM 3 MAJOR FUNCTIONS OF DAS: DATA ACQUISITION DATA PROCESSING DATA REPRESENTATION The Major Parts Process Control Units ( PCU ) Computer Interface Unit ( CIU ) Termination Units ( TU ) Buffer Terminal Cabinets ( BTC ) Power Plant C&I systems DATA ACQUISITION SYSYTEM TYPES OF DATA (Input): Analog & Digital Analog inputs: 1. Thermocouple Input ( mV ) K-Type T/C ( Cr-Al ) : For temp < 600 Deg C& used in Flue Gas path after FSH outlet. R-Type T/C ( Pt-Pt-Rh ) : For temp > 600 Deg C used in PSH & FSH region of FG path. 2. RTD Input ( Resistance ) Pt-100 RTD : For Brg. Temp measurement. Cu-53 RTD : For HT motor & Generator Stator winding temp. measurement. Power Plant C&I systems DATA ACQUISITION SYSYTEM Analog inputs: 3. 4 – 20 Ma Input Coming from Pr. / Flow Transmitters. Coming from Signal Distribution Cards of automatic control system 4. 0 – 10 Volt Input Coming from ATRS cabinets Used for Turbine Brg. Temp. /Vibration measurement. DIGITAL INPUTS These are coming directly from switches or relay contacts of other systems (FSSS, ATRS, ACS etc.) Power Plant C&I systems DATA ACQUISITION SYSYTEM DIGITAL INPUTS (TYPES) LOW RESOLUTION : The scanning time of inputs is 1 second. HIGH RESOLUTION : The scanning time is 1 millisecond. These are called Sequence Of Events ( SOE ) Inputs. PULSE INPUT : For calculation of Total Coal Flow, Total Air Flow etc. Power Plant C&I systems DATA ACQUISITION SYSYTEM FUNCTIONS OF DAS: Alarm Management. Production of hardcopy print outs in different printers. Operator Guidance Messages. Graphic Displays of plant sub-systems. Trending of analog variables on recorders. Sequence Of Events ( SOE ) recording following unit / equipment trip conditions. Efficiency calculations Power Plant C&I systems DATA ACQUISITION SYSYTEM DATA PROCESSING: It has the following parts COMPUTER PROCESSING UNIT ( CPU ) BULK ( SOLID STATE ) MEMORY WITH BATTERY BACKUP MAGTAPE UNIT COMMUNICATION CABINET & MODEM MOVING HEAD DISC DRIVE VIDEO HARD COPIER TREND RECORDER UNIT CONTROL DESK & PROG. ROOM CRT PRINTERS Power Plant C&I systems Features: DATA ACQUISITION SYSYTEM REAL TIME VARIABLE CALCULATION Summing, Subtraction, Maximum , Minimum, Averaging, Hourly & Daily integration, rate of changes & comparison of limits etc. ON-LINE DATABASE EDITION 1. Assign points to any process parameter 2. Scan, Off-scan , Delete , Activate , inactivate a process parameters , calculated points when reqd. 3. Change the Engg. Unit 4. Change the range , alarm limits & dead bands 5. Change the scan frequency 6. Review total analog and digital points depending on its quality flag like alarm , channel failure , off-scan etc. Power Plant C&I systems DATA ACQUISITION SYSYTEM ALARM MANAGEMENT: All the analog points which cross their normal limits or all the digital points which go into their alarm state come on the alarm CRT with associated time & blink as long as the alarms remain unacknowledged. Alarm will come in RED colour If all the pages are full (normally no. of alarm pages & alarm per page is predefined) and any new alarm comes , then oldest alarm will disappear from the alarm page as FIFO basis Alarm print out will be available in alarm printer Power Plant C&I systems DATA ACQUISITION SYSYTEM DATA REPRESENTATION: Printed outputs of displays /collection of data in different formats like : 1. Copy Screen 2 Alarm Print out 3. Log Print out CRT Displays 1. Alarm CRT display 2. Utility CRT display Power Plant C&I systems DATA ACQUISITION SYSYTEM DATA REPRESENTATION: TYPES OF TREND LOG TIME ACTIVATED EVENT ACTIVATED DEMAND LOGS SOE PRINTOUT TIME ACTIVATED LOG: Automatic Triggered Logs Sample frequency is 1 Hour.(Normally) Time of trigger can be specified PRINOUTS Power Plant C&I systems DATA ACQUISITION SYSYTEM TIME ACTIVATED LOG: Max. 15 nos. of points can be assigned Normally printed in the logging printer in UCB Examples : 1. Shift Log 2. Efficiency Log 3. Boiler Drum / Tube Metal Temp. Log 4. FSH / RH Metal temp. excursion Log EVENT ACTIVATED LOG: Automatic Triggered Logs Used for Unit or Equipment Outage Analysis Minimum Sample frequency is 10 seconds. Power Plant C&I systems DATA ACQUISITION SYSYTEM EVENT ACTIVATED LOG: Max. 36 points can be assigned in a log Logs are triggered by a Trip flag Normally printed on Logging Printer in UCB Pre & Post triggered points can be specified Examples : 1. Post Trip Analysis Log ( PTL ) 2. TG. Shutdown Analysis Log 3. Boiler Startup Log. 4. Turbine / Generator Diagnostic Logs Power Plant C&I systems DATA ACQUISITION SYSYTEM DEMAND LOG: Not Automatic Triggered Logs Logs can be printed on operator’s demand Sample frequency is generally 1 Hour. Logs are printed in Logging Printer in UCB Power Plant C&I systems DATA ACQUISITION SYSYTEM SEQUENCE OF EVENTS ( SOE ) THE MAIN FEATURES ARE: Determines First Cause Of Trip Determines sequence of events or alarms Scanning Time is 1 millisecond. It is a Stand Alone System Max. 256 nos. of Protection related digital points can be assigned Automatic Triggered when any point in alarm Power Plant C&I systems DDCMIS WHAT IS DDCMIS ? DISTRIBUTED DIGITAL CONTROL MONITORING & INFORMATION SYSTEM Distributed means there is no centralized control and control is spread across multiple units Digital means processing of process information is done in digital form using micro-processor based hardware MIS interfaces the human with process using computers Power Plant C&I systems DDCMIS TECHNOLOGICAL BACKGROUND PROGRESS OF INSTRUMENTATION USED TO IMPLEMENT AUTOMATIC PROCESS CONTROL LOCAL PNEUMATIC CONTROLLERS MINIATURIZED AND CENTRALIZED PNEUMATIC CONTROLLERS AT CONTROL PANELS AND CONSOLES SOLID-STATE CONTROLLERS COMPUTERISED CONTROLS DISTRIBUTED MICROPROCESSOR BASED CONTROL Power Plant C&I systems DDCMIS Components MAN MACHINE INTERFACE & PROCESS INFORMATION SYSTEM DATA COMMUNICATION SYSTEM (DATA HIGH WAY) CONTROL SYSTEM Power Plant C&I systems DDCMIS MAN-MACHINE INTERFACE AND PLANT INFORMATION SYSTEM (MMIPS) LATEST STATE-OF-THE-ART WORKSTATIONS AND SERVERS BASED ON OPEN-ARCHITECTURE AND INDUSTRY STANDARD HARDWARE AND SOFTWARE TO ENSURE BETTER CONNECTIVITY. e.g. HARDWARE FROM COMPAQ/DIGITAL, HP, SUN MICRO-SYSTEM OR OTHER MAJOR SUPPLIERS (LESS DEPENDENCE ON THE C&I SYSTEM SUPPLIER IN THE LONG RUN) OPERATING SYSTEM WINDOWS-NT, OPEN-VMS OR UNIX. PROVISION OF LVS CONNECTION TO OTHER SYSTEM THROUGH STATIONWIDE WAN Power Plant C&I systems DDCMIS MMIPIS FUNCTIONALITIES VARIOUS PLANT EQUIPMENT OPERATION OPERATOR INFORMATIONS THROUGH VARIOUS DISPLAYS ALARMS, LOGS, HISTORICAL AND LONG TERM STORAGE. PERFORMANCE AND OTHER CALCULATIONS Power Plant C&I systems DDCMIS DATA COMMUNICATION SYSTEM LOCAL SYSTEM BUS – It is just lines on the backplane of control panel to which all the modules are connected directly. It serves as communication medium between the modules. INTRAPLANT BUS(IPB) – It is a coaxial cable which runs through all the panels of control system and interconnects them. LOCAL AREA NETWORK(LAN) – It is a network of computers which are connected to a single point (HUB). FOR ALL BUSES REDUNDANCY IS PRESENT Power Plant C&I systems DDCMIS CONTROL SYSTEM FUNCTIONAL DIVISION SG-C&I SYSTEM TG-C&I SYSTEM BOP-C&I SYSTEM HARDWARE COMPONENTS POWER SUPPLY CONTROL PANEL ELECTRONIC MODULES Power Plant C&I systems DDCMIS CONTROL SYSTEM PROGRAMMING & CONFIGURATION MMIPIS SYSTEM M&S CLOCK DCS SG- C&I SYSTEM BOP- C&I SYSTEM TG- C&I SYSTEM Power Plant C&I systems DDCMIS SG-C&I SYSTEM BURNER MANAGEMENT SYSTEM (BMS) SOOT BLOWER CONTROL SYSTEM (SBC) SECONDARY AIR DAMPER CONTROL SYSTEM (SADC) AUXILIARY PRDS CONTROLS (APRDS) TG-C&I SYSTEM ELECTRONIC TURBINE PROTECTION (ETP) AUTOMATIC TURBINE RUN-UP SYSTEM (ATRS) AUTOMATIC TURBINE TESTING SYSTEM (ATT) ELECTRO- HYDRAULIC TURBINE CONTROL SYSTEM (EHTC) TURBINE STRESS CONTROL SYSTEM (TSC) LP BYPASS SYSTEM (LPBP) HP BYPASS SYSTEM(HPBP) GLAND STEAM PRESSURE CONTROL GENERATOR AUXILIARY MONITORING PANEL (GAMP) Power Plant C&I systems DDCMIS BOP-C&I SYSTEM CONSISTS OF OPEN LOOP CONTROL SYSTEM (OLCS) AND CLOSED LOOP CONTROL SYSTEM (CLCS) OLCS - THE SEQUENCE CONTROL, INTERLOCK OF ALL THE PLANT SYSTEMS WHICH ARE NOT COVERED IN THE SG-C&I AND TG-C&I. THIS INCLUDES MAJOR AUXILIARIES LIKE FD/ID/PA FANS, AIR-PREHEATER, BFP/CEP/CWP/ BCWP , DMCWP/CLCWP AND ELECTRICAL BREAKERS. CLCS - THE MODULATING CONTROL FOR VARIOUS IMPORTANT PLANT PARAMETERS, LIKE FW FLOW (DRUM LEVEL), FURNACE DRAFT, COMBUSTION CONTROL (FUEL FLOW AND AIR FLOW), PA HDR PRESSURE CONTROL, DEAERATOR/HOTWELL/HEATER LEVEL CONTROLS ETC. Power Plant C&I systems DDCMIS WHY DDCMIS ? VERY HIGH FLEXIBILITY FOR MODIFICATION VERY HIGH SELF-DIAGNOSTIC IN CONTROL STRATEGY VERY LOW DRIFT (ONLY IN I/O CARDS) , HENCE FREQUENT RE-CALIBRATION MUCH HIGHER RELIABILITY (BASED ON MTBF) BETTER LONG TERM SUPPORT DUE TO MUCH BETTER OPERATOR INTERFACE NO NEED OF CHANGING TECHNOLOGY Power Plant C&I systems DDCMIS SALIENT FEATURES OF DDCMIS INTEGRATED PLANT CONTROL FOR SG, TG AND BALANCE OF PLANT CONTROL IT MAY BE REMEMBERED THAT HISTORICALLY THE TERM DDCMIS USED REFER TO THE SO-CALLED “BOP-C&I” . THE SG-C&I, i.e. FSSS etc. TG-C&I i.e. ATRS, TURBINE PROTECTION etc. ORIGINALLY WERE NOT CONSIDERED UNDER DDCMIS OR DCS AS PER MANY SUPPLIERS. ONLY RECENTLY THE TYPE OF SYSTEMS FOR ALL THE SYSTEMS HAVE BECOME SIMILAR (WITH SOME DIFFERENCE WHICH WILL BE DISCUSSED LATER), WE TEND TO CONSIDER THESE SYSTEMS UNDER DDCMIS. Power Plant C&I systems DDCMIS SALIENT FEATURES OF DDCMIS INTEGRATED PLANT OPERATION THROUGH FULLY INTERCHANGEABLE OPERTAOR WORK STATIONS (OWS) FOR SG, TG AND BALANCE OF PLANT PROVISION OF EXTENSIVE SELF-DIAGNOSTICS USE OF LARGE VIDEO SCREENS FOR PROJECTIONS OF VARIOUS PLANT MIMICS ETC. PROVISION OF FAULT ALARM ANALYSIS TO GUIDE THE OPERATOR TO THE MOST LIKELY EVENT PROVISION OF ADEQUATE RELIABILITY AND AVAILABILITY WITH PROPER REDUNDANCY IN SENSOR, I/O AND CONTROLLER LEVELS. Power Plant C&I systems Global & National Power Scenario Global: Global electricity consumption 69% higher in 2020 than 2003 80% of energy provided from thermal sources Emerging trend from Thermal to Hydel and Renewable Energy sources Indian: Total installed capacity only 1362 MW in 1947 Per Capita consumption 631 units (2005-06) only with installed capacity of 1,77,000 MW GDP growth of 8%, power growth required 10% To add 1,00,000MW capacity by 2017 Liberalizations of the sector Power Plant C&I systems NTPC at a glance: Installed Capacity 34199 MW Target 75000MW by 2017 Performance: Annual Availability 91.62% Annual PLF 88.29% 11 stations among top 20 in the country NTPC Practices to achieve goal KEY THRUST AREAS Zero Human Error Implementation of trip committee recommendations judiciously / rigorously Identification of trip committee recommendations of other stations which are relevant and implement them Implementation of operation memorandum wherever applicable Dissemination of information about best practices followed across NTPC and other Power Stations Providing proper environment for C&I equipment to reduce probability of card and equipment failure C&I Trip Trend 2009-10: FORCED OUTAGE DISTRIBUTION (COAL) Coal 09-10 Relay Malfunction Tx / Sw /Fld Dev 7% 2% 4% Control System 9% 22% 17% 28% 9% 2% EHC / ATRS Power Supply / Cable Software / Card failure Human Error UPS RTD / Tc INFERENCE : 2009-10 C&I OUTAGE ANALYSIS Major factors contributing to C&I outage in 2009-10: 1. Control System related failure 2. Field Device Failure 3. Soft ware/Card Failure 4. Power Supply/Relay failure 5. Human error BEST PRACTICES COMPILED/ADOPTED IN NTPC C&I All ‘unit protections’ are provided with 2/3 logic and audio visual alarm is provided on 1/3 to operator on actuation of any one sensor wherever possible with proper approval. Use of headless RTD in tripping circuit of ID/PA/FD fans & BFPs. Resistance mapping of critical solenoids including cable during overhauls and monitoring trend to identify any defects. Marking of trip related devices and Junction Boxes marked in RED color. Regular calibration of all important instruments which have a bearing on unit safety, reliability and efficiency. Instruments are calibrated against standard instruments with traceability to NABL. BEST PRACTICES COMPILED/ADOPTED IN NTPC C&I For handling of electrostatic sensitive electronic hardware, electrostatic bags, wrist straps and other ESD handling devices are employed in control panels and lab. All Laboratories are provided with ESD proof workstations. Disable removable drives of servers and workstations. Single source responsibility for software backup of DCS and storage in fire proof cabinets in two different locations. Detailed work instruction are prepared and followed for working on all trip related devices. BEST PRACTICES COMPILED/ADOPTED IN NTPC C&I A single source responsibility is fixed for the generation and maintenance of system passwords so as to maintain system security Internal quality inspection for critical checks during overhauls to ensure quality in overhaul works Near miss situations are monitored and analyzed. The learning from this area used to formulate strategies to avoid spurious outages. All power supply voltages are monitored with a fixed periodicity and maintained within /- 10% of the rated value. BEST PRACTICES COMPILED/ADOPTED IN NTPC C&I Fuses used in UPS and protection circuits are replaced with new fuses of same rating and type during every overhaul Earth voltages in control panels are monitored on a predetermined frequency and the values are recorded for trending All bus terminators are checked during every overhaul for ensuring integrity of bus communication in DDCMIS systems Load testing of power supplies for critical applications and replacement of power supply modules or electrolytic capacitor and power transistors used in power supply if found deteriorated. Other important actions taken for forced outage reduction Rerouting of control & power cables in hot zones Panel power supply monitoring in regular intervals. CER/UCB temperature and humidity monitoring online. Insisting for performance of the A/C system Checking and tightening power supply cables during overhaul Ensuring healthiness of cabinet cooling fans. Other important actions taken for forced outage reduction Panel cooling fans supply segregation from system supply with MCB / fuse. Cleaning of air filters on panels periodically Servo valve replacement/ servicing in hydraulic drives. Individual fuse protection in 220VDC MFT for HOTV, LOTV, HORV, Scanner emergency air damper solenoids Looking from WBPDCL Santaldih Perspective KEY THRUST AREAS 1. Commissioning of non commissioned systems a) Soot blowing Steam Pr. Control valve: Status- Actuator damaged while commissioning. BHEL has placed PO on OEM M/s MIL for procurement of damaged parts b) Commissioning of SWAS analyzers: Status-Procurement of Reagents for reagent based measurement (i.e. Silica etc.) is in process. Suggested to take up with OEM (Forbes Marshall) through BHEL for commissioning of electrode based measurements (i.e. conductivity etc.) Looking from WBPDCL Santaldih Perspective c) Electromatic Relief Valve (ERV): Status- Solenoid Installed and cabling done d) APH Rotor stop alarm: Status- Issue pending with BHEL for longtime. Alternative scheme through DDCMIS suggested by fixing proximity switch on APH rotor shaft at support brg. end. e) APH fire detection alarm: Status- Issue pending with BHEL for longtime. Alternative scheme by measuring APH metal temp. using thermocouples in Air & Gas path may be thought of. Looking from WBPDCL Santaldih Perspective f) Commissioning/testing of Back up (Back up of MAX DNA system work stations)Push Button console for unit control: Suggested to test the operation of various push buttons at the time of Start up/ Shutdown of unit jointly with operation. 2. Rectification of long pending problems: a) Problem of SADC systems Status: Operation of some of the dampers erratic and needed frequent adjustment due to unreliable performance of actuator/positioner Suggested to procure 04 nos. actuator with positioner of reputed manufacturer for replacement in one elevation on trial basis Looking from WBPDCL Santaldih Perspective b) High PA flow to Mills: In auto PA flow of all mills are about 30% more than characteristic flow. PA flow curve for sliding set point may be set as per mill design. Also provision of manual set point may be explored to cater poor coal quality 3. Setting up of C&I Lab with requisite facilities 4.Enhancing reliability of Field Instruments a) Proper glanding/ sealing of field instruments, control valves, routing & dressing of cables, ensuring cleanliness & closure of all LIEs etc. Looking from WBPDCL Santaldih Perspective b) Replacement of unreliable instruments by quality instruments c) Marking of protection related JBs to avoid human error Regular walk down check in various areas to ensure the healthiness of field instruments. 5. Sealing & Cable dressing in MAX DNA panels during unit Shutdown 6. Disabling various ports for removable drives of MAX DNA work stations for system reliability 7. Installation of ON Line printers of MAX DNA system for daily LOGs. Daily LOGs are essential for analysis of different plant parameters by O&E dept. Looking from WBPDCL Santaldih Perspective 8. Cleanliness of NETWORK ROOM & EWS room to be ensured. Monitoring of Temp. & Humidity of CER, UCB , NETWORK & EWS rooms. 9.Implementation of regular cleaning schedule & preventive mtc. Schedule for Boiler, Turbine and common systems 10.Prepartion of detail job list for unit overhauling 11. Review of spares status and timely action for procurement for breakdown(corrective), preventive and overhauling maintenance.