Final Presentation

advertisement

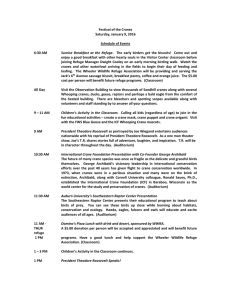

Research Project Presentation Steve Howarth Presentation Outline Project Title Project Hypothesis Project Background Project Objectives Research Method Scope of the Research Survey Results Literature Review Conclusion Recommendations Benefits of the Research Project Title “The development and implementation of an effective management and monitoring system, to ensure that cranes comply with statutory requirements”. Hypothesis “The non-compliance to statutory requirements will decrease upon the implementation of the inspection regime” Project Background In January, 2001, the Labour Department conducted a survey of the cranes and lifting appliances on the KCRC’s West Rail project. It was found that 34% of the cranes were not fitted with an automatic safe load indicator, or if fitted, it was not functioning correctly. Shanghai Project Objectives To develop an inspection and enforcing system for ensuring compliance to the statutory requirements; To implement the system; Project Objectives (cont) To revise and improve the system, following comments from those concerned in the implementation, and To review the effectiveness of the system, in ensuring compliance to statutory requirements. Scope of the Project KCRC’s, West Rail and East Rail Extensions projects; 23 construction sites; Surveys conducted monthly over a 6 month period, May – Oct, 2001; All cranes. Research Method Participatory Action Research (PAR) based on Lewin’s Cyclic Model Review Act Plan Review Conduct a survey of all cranes being used on the 2 projects to establish if there is a high rate of noncompliance to statutory requirements. Plan Review the Hong Kong Legislation to identify what the statutory requirements are; Develop an inspection checklist; Plan (cont) Train the surveyors to use the inspection checklist; Conduct a survey of all the cranes being used on the 2 projects to establish if there was a problem with the statutory compliance. Act The Hong Kong Legislation was reviewed and 12 statutory requirements were identified; Statutory Requirements •Form 1. Report of Results of Weekly Inspection of Lifting Appliances •Form 2. Certificate of Test and Thorough Examination of Anchoring or Ballasting of Cranes •Form 3. Certificate of Test and Thorough Examination of Cranes, Crabs and Winches •Form 4. Certificate of Test and Thorough Examination of Lifting Appliances (Except Cranes, Crabs and Winches) •Form 5. Lifting Appliances Certificate of Thorough Examination in the Preceding Twelve Months •ASLI not fitted or not functioning properly •Obstructed view •Safe working load markings •Jib angle indicator fitted •Anti- collision device fitted •Over hoist limit switch fitted •Safety latch fitted on the hook Act (cont) The inspection checklist was developed by a team of staff; Crane and Lifting Appliance Safety Inspection Form Contract Location Date and Time of Inspection: Type of Crane Conducted by: Ref. Number: (Tick as appropriate) Crawler Crane Tower Crane Hydraulic Crane Gantry Crane Piling Rig Lorry or Train Mounted Crane Brand/model Identification Number: Owner Year of Manufacture Contractor’s own plant permit or labelling system Form 1 Maximum SWL (Form 3) No Yes Issue Date Latest Dated: Form 2* (if necessary) Dated: Form 3 * Dated: Form 4* (if necessary) Dated: Form 5* Dated: Registration Number: Name of RPE Operator’s Certificate* Name: Issued by: Valid until: Class: Safety Devices Yes No ASLI fitted, working and being used* Over hoist/travel limit switch* (for Crane only) Safety latch on the hook Unobstructed view SWL marking/Radius chart Jib angle indicator (telescopic or lattice jib) Anti-collision devices functioning properly* Permit to Move* The latest Permit Dated: Permit to Operate* The latest Permit Dated: (tower crane) Compliance to Permits* Compliance to the Permit to Operate Remarks Yes No Compliance to the Permit to Move PVC holder issued * Major safety requirement. Non-compliance will lead to suspension of operation. Conclusion Compliance with requirement Non-compliance Suspended from operation Yes Yes No No Act (cont) The surveyors were trained to use the inspection checklist; A survey was conducted of all the cranes being used on the 2 projects. Results of the Initial Survey Monthly Non-Compliance Rate 14.00 12.00 10.00 12.32% ERE Monthly Non-Compliance Rate WR Monthly Non-Compliance Rate 8.00 339 cranes were 6.00 Inspected: 4.00 276 WR 2.00 63 ERE 0% 0.00 May 6 more surveys were conducted using the PAR method Review Act Plan Results of the 2nd Survey 30.00 25.00 ERE Monthly Non-Compliance Rate 25.00 ERE Cumulative Non-Compliance Rate 20.00 WR Cumulative Non-Compliance Rate 16.57 20.00 15.00 12.32 15.00 10.87 10.00 10.00 5.00 5.00 0.00 0.00 May 0.00 Jun Cumulative Non-Compliance Rate Monthly Non-Compliance Rate WR Monthly Non-Compliance Rate Results of the 6th & Final Survey 30.00 ERE (Monthly) Percentage of Non-compliances 25.89 WR (Monthly) 25.00 ERE (Cumulative) WR (Cumulative) 20.00 16.57 15.00 12.32 10.87 9.23 10.00 7.29 9.05 8.91 7.39 5.71 6.38 5.00 2.60 3.55 2.49 0.67 0.00 7.14 6.23 0.00 MAY JUN JUL AUG 3.05 1.65 SEP 3.57 2.39 OCT Example of an Inspection Item Survey Result – Form 1, Non Compliance 24,828 items were inspected AS or no tf N N o o o o Fo rm Fo rm Fo rm Fo rm 4 3 2 1 o Fo un ct rm io 5 ni n g N o pr O op N v er er o ly Sa H o fe is ty tS La wi tc tc h h on th N e o H O Sa oo bs fe k tru W c te or d ki Vi ng ew Lo ad N M o ar Ji ki b ng A ng s N le o In An di tica C to ol r l is io n D ev ic e LI no tf i tt ed N N N Percentage Non-compliance Summary of the Results by Project 4.50 4.00 3.50 WR 3.00 ERE 2.50 2.00 1.50 1.00 0.50 0.00 Statutory Requirement or no tf N N o Fo rm 4 3 2 1 0.58 o Fo un rm ct io 5 ni ng N pr o O op N ve er o rH ly Sa oi fe st ty S La wi tc tc h h on th N e o H O Sa oo bs k fe tru W ct or ed ki Vi ng ew Lo ad N M o ar Ji ki b ng A ng s N le o In An di tica C to ol r l is io n D ev ic e LI no tf i tt ed Fo rm Fo rm Fo rm 1 AS o o o 0.5 N N N Percentage Non-compliance Summary of the Results by Item 3.5 3.19 3 2.22 2.5 2 1.79 1.5 1.26 0.68 0.68 0.39 0.39 0.1 Statutory Requirement 0.63 0.34 0 No’ of Cranes Inspected by Month Total 2,069 Types of Cranes Inspected 1400 1226 WR ERE Total Number of Cranes 1200 1000 769 800 600 449 410 352 400 213 210 220 214 200 58 3 6 Lorry or Train Mounted Tower 0 Crawler Hydraulic Literature Review •Hong Kong Safety Legislation; •Crane and Lifting Appliance Legislation in Hong Kong; •Crane and Lifting Appliance Legislation in Other Countries; •Safety Management; •Risk Perception; •Human Behavior; •Supervisors Role, and •Senior Managers Role. Conclusion •The inspections and the inspection checklist were successful in reducing the number of non-conformances; •The survey has identified areas of weakness in the safety management systems of the Contractor; •There is no penalty system in place, other than from the Contractor, for the operator. Conclusion - Hypothesis “The non-compliance to statutory requirements will decrease upon the implementation of the inspection regime” TRUE – The results show that the number of non-conformances did decrease following the implementation of the inspection regime. Recommendations •Incorporate the inspection checklist into a safety procedure for all sites; •Continue the inspections and continue to record and report the non-conformances; •Implement effective Contractor safety management systems to ensure statutory compliance; Recommendations (cont) •Discuss with the Labour Department and the operator’s license issuing authority, the nonconformances and discuss measures for improvement; •Make the safety procedure available to other projects in Hong Kong. Benefits from the Research •Improved compliance to statutory requirements; •Elimination of crane incidents; •Increased inspections and monitoring; •Formalised inspection procedure; Benefits from the Research •Standardised inspection procedure; •Improved quality of the inspections; •Is now being used on other non KCRC projects (cont) Questions