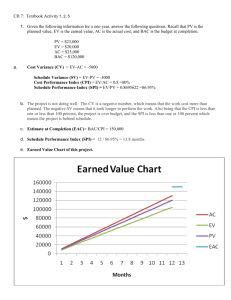

Earned Value Management - PMI La Crosse

advertisement

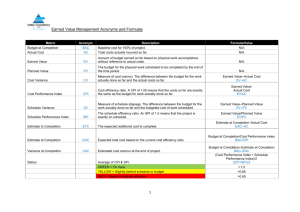

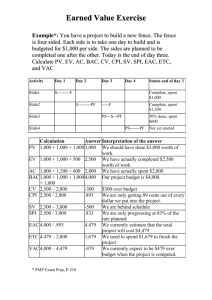

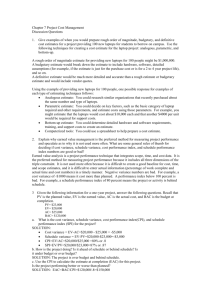

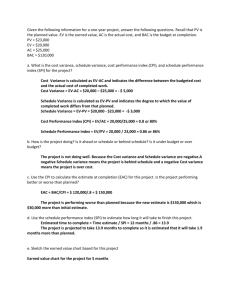

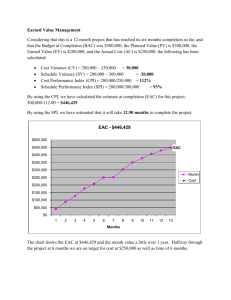

Earned Value Management a tool for project Portfolio management Jim Strong DLMP PMO Director 1 Earned Value Management: • Defined per PMI PMBOK: A management methodology for integrating scope, schedule and resources, and for objectively measuring project performance and progress. • Cost Performance is measured by determining the budgeted cost of work performed (i.e. earned value) and comparing it to the actual cost of the work performed (i.e. actual cost). • Schedule Progress is measured by comparing the earned value to the planned value. Page 2 Why Use Earned Value Management? “…to help better manage projects and portfolios of projects within the organization” •Adds another capability to the “tool box” for the organization and the Project / Program / Portfolio Manager •Allows Sponsor / Program / Portfolio Managers to “normalize” project / program data to enable an aggregate or portfolio view of the total effort Page 3 Why Use Earned Value Management? •Facilitates the analysis of project / program performance •Facilitates the monitoring and communication of the project/program/portfolio performance •Provides a means to forecast future performance based on past performance •Facilitates “lessons learned” through a review of the project performance trend Page 4 Why Use Earned Value Management? •Compliments the use of: • PERT analysis (estimating) • Dependency or Constraint analysis • Critical Chain analysis • Issue and Risk analysis • Resource analysis • Critical Path analysis Page 5 Earned Value Management: • Measures (key terms): • Planned Value (PV) = Budgeted Cost of Work Scheduled (BCWS) • Actual Cost (AC) = Actual Cost of Work Performed (ACWP) • Earned Value (EV) = Budgeted Cost of Work Performed (BCWP) • BAC = Budget at Complete; Total budget, Expense and Capital planned for the project / program • ETC = Estimate to Complete: team’s updated estimate to complete the work remaining • EAC = Estimate at Complete; Total of Actuals and estimated cost of work remaining to complete the scope of work for the project / program • Calculated EAC = Total of Actuals and estimated cost of work remaining to complete the scope of work for the project / program; factored by Cost performance to date Page 6 Earned Value Measurement: • Cost Variance • CV = EV – AC Positive numbers are favorable • Schedule Variance • SV = EV – PV • Performance Indices • Cost Performance Index = or > than 1.0 • CPI = EV / AC is favorable • Schedule Performance Index • SPI = EV / PV • To Complete Performance Index (work remaining / remaining budget) • TCPI = (BAC – EV) / (EAC – AC) • Measurement Guidelines: • Green – favorable variance to negative 9% variance • Yellow – negative 10% to negative 19% variance • Red - >20% negative variance Page 7 Establishing the project / portfolio Earned Value Baseline Each task in a project plan has a value… formed by labor or material cost…. allocated over time Value of each of the Tasks from project Plan…. form the Planned Value PV BAC BAC = cum PV at end of project $ Time Page 8 Monitoring the Project performance – capturing cost of work performed – Actual Cost (AC) Hours … Or material / vendor costs…. Are expended to complete each task $ $ Cap $ Cumulative $ Costs to complete the Tasks from project Plan…. form the Actual cost $ Unfavorable Cost Variance AC PV BAC EAC = AC + Estimate to Complete (ETC) $ EV Time Now Time Page 9 SPI / CPI (cum) “worm” Chart (example) • 1.0 is optimal • Cost and schedule performance; tracked over time to indicate trend • SPI must close to 1.0 to complete the project; CPI can be at any level at completion • TCPI can be used to predict future performance based on past performance 1.0 Favorable CPI SPI Time Measurement Guidelines: Green – favorable variance to negative 9% variance Yellow – negative 10% to negative 19% variance Red - >20% negative variance Page 10 Three EV “snake” charts to ponder (1 of 3) $ “Green”, CV favorable CV = +200 CPI = 1.1 PV EV AC “Green”, SV < 10% SV = -150 SPI = 0.95 Time Possible Scenarios: Unfavorable Schedule Variance: • Resources not applied at the start of the project in a timely fashion • Effort continues behind schedule; not making up project delays • What tasks are creating the unfavorable schedule variance? • Are there specific technical or other issues / risks driving the variance? • Opportunity - Can we apply more resources to pull in the schedule? Favorable Cost Variance: • Tasks not taking as much time as estimated or planned • Tasks completed by lower cost resource • Opportunity - Can we apply more resources to pull in the schedule? Page 11 Three EV “snake” charts to ponder (2 of 3) “Green”, CV favorable CV = +300 $ CPI = 1.2 Possible Scenarios: EV AC PV “Green”, SV favorable SV = +200 SPI = 1.1 Time Favorable Schedule Variance: • Tasks not taking as much time as planned • Slack time / schedule buffer built into project plan • Not as many issues encountered • Anticipated risks well and applied mitigation into plan or effort to date • Planned effort “padded”?; what is the basis of estimate – higher rate of probability applied to project (100% probability versus most likely 50/50?) Favorable Cost Variance: • Tasks not taking as much effort as estimated or planned • Tasks completed by lower cost resource • Check for any material / labor costs not realized • Is the favorable CV long term? What is the EAC? Does TCPI support the EAC? • Should we re-baseline the project and put funding back into the Management Page 12 Reserve for the Program / Practice? Three EV “snake” charts to ponder (3 of 3) $ “RED”, CV > 20% CV = -200 CPI = 0.79 AC PV EV “Yellow”, SV >9% SV = -100 SPI = 0.9 Possible Scenarios: Unfavorable Schedule Variance: • Effort continues behind schedule; team not making up project delays • What tasks constitute the majority of the variance? • Do issues continue to linger or are they being resolved? • Is / are there technical issues / risks driving the negative variance trend? Unfavorable Cost Variance: • Tasks taking more effort than estimated • What tasks constitute the majority of the variance? How much effort remains? • Do we have the right skill level of resources versus plan? • Are we managing the scope, do we have scope creep? (Change Request log?) • What is the EAC? Should we cancel the project? Page 13 Considerations for Implementing • Time recording system, or equivalent manual process, absolutely required to capture actual labor costs • Quality estimates for the project tasks • Allow adequate time for creation of requirements and task estimates • Creation of project performance measurement plan – • Usually in the form of MS Project (project schedule) • Forms the basis for the “Planned Value” (PV) • Large material costs need not be included in the EV as they can represent major “step functions” in the EV plans; possibly masking the labor effort of the project Page 14 Recommendations •Gain Leadership support •Train the PMs and core Project teams •Start small, consider pilot •Keep it simple: keep EV milestones and associated cost accounting activity points to a minimum (i.e. 600 line MS project plan lines may consolidate to 20 EV milestones or less) Page 15 Earned Value Management ‘Gold Card’ PMB EAC Control Accounts BAC PMB Schedule Variance $ Work Packages Planning Packages Cost Variance TERMINOLOGY AC PV EV time Time Now Completion Date VARIANCES Favorable is Positive, Unfavorable is Negative, Green if <10%, 10%<Yellow<20%, Red >20% Cost Variance CV = EV – AC CV % = (CV / EV) *100 Schedule Variance SV = EV – PV SV % = (SV / PV) * 100 Variance at Completion VAC = BAC – EAC OVERALL STATUS % Schedule = (PVCUM / BAC) * 100 % Complete = (EVCUM / BAC) * 100 % Spent = (ACCUM / BAC) * 100 BCWS = PV BCWP = EV ACWP = AC BAC PMB CA Budget At Completion Performance Measurement Baseline Control Account WP PP PV EV AC EAC SLPP TCPI Work Package Planning Package PLANNED VALUE EARNED VALUE ACTUAL COST Estimate At Completion Summary Level Planning Package To Complete Performance Index Total budget for total contract thru any given level time-phased budget plan Lowest CWBS element assigned to a single focal point to plan & control scope / schedule / budget Near-term, detail-planned activities within a CA Far-term CA activities not yet defined into WPs Value of work planned to be accomplished Value of work accomplished Cost of work accomplished Estimate of total cost Far-term activities not yet defined into CAs Efficiency needed from ‘time now’ to achieve an EAC (DAU = Defense Acquisition University, US DoD training & policy support for their acquisition workforce) (tool downloaded from https://acc.dau.mil/CommunityBrowser.aspx?id=17810) Modified for DLMP PMO use 02/06/2007 TRIPWIRE METRICS Favorable is > 1.0, Unfavorable is < 1.0, Okay>0.91, 0.90>concern>0.80, escalate<0.79 Cost Efficiency CPI = EV / AC Schedule Efficiency SPI = EV / PV BASELINE EXECUTION INDEX (BEI) (Schedule Metric) BEI = # of Baseline Tasks Actually Completed / # of Baseline Tasks Scheduled for Completion CRITICAL PATH LENGTH INDEX (CPLI) (Schedule Metric) CPLI = (Critical PathBaseline Duration + Float Duration) / Critical PathBaseline Duration TO COMPLETE PERFORMANCE INDEX (TCPI) TCPIEAC = Work Remaining / Cost Remaining = (BAC – EVCUM) / (EAC – ACCUM) ESTIMATE AT COMPLETION # EAC = Actuals to Date + [(Remaining Work) / (Efficiency Factor)] EACCPI = ACCUM + [(BAC – EVCUM) / CPICUM ] = BAC / CPICUM EACComposite = ACCUM + [(BAC – EVCUM) / (CPICUM * SPICUM)] EVM Home Page = https://acc.dau.mil/evm eMail Address: EVM.dau@dau.mil DAU POC: (703) 805-5259 (DSN 655) Revised December 2006 Page 16