Control Charts

advertisement

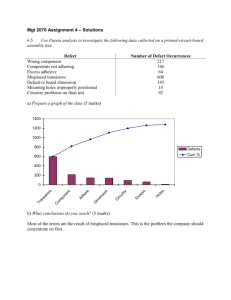

SMU EMIS 7364 NTU TO-570-N Statistical Quality Control Dr. Jerrell T. Stracener, SAE Fellow More Control Charts Material Updated: 3/24/04 1 Operating Characteristic (OC) Function for the x - Chart • The OC curve describes the ability of the x-chart to detect shifts in process quality. • For an x-chart with s known & constant mean m shifts from in-control value, m0 to another value m1, where m1 = m0 + Ks 2 Operating Characteristic (OC) Function for the x – Chart (continued) OCμ βμ P(not detecting shift on the first subsequent sample | μ) PLCL X UCL | μ μ1 μ 0 Kσ UCL - μ 0 Kσ LCL - μ 0 Kσ Φ Φ σ σ n n μ 0 n Lσ μ 0 Kσ n Φ σ μ 0 n Lσ μ 0 Kσ n Φ σ 3 Operating Characteristic (OC) Function for the x – Chart (continued) Φ Lk n Φ Lk n , where Φ y y and 1 e 2π z2 2 dz L is usually 3, the three-sigma limits 4 Example If n=5 & L=3, determine & plot the OC function vs K, where m1= m0 + Ks. 5 Example - Solution Φ3 k 5 Φ 3 k 5 OCK βK Φ L k n Φ L k n k -3.0 -2.5 -2.0 -1.5 -1.0 -0.5 0.0 0.5 1.0 1.5 2.0 2.5 3.0 b 0.000104397 0.00479646 0.070492119 0.361631295 0.777546112 0.970060633 0.997300066 0.970060633 0.777546112 0.361631295 0.070492119 0.00479646 0.000104397 1.2 1 0.8 0.6 0.4 0.2 0 -4.0 -2.0 -0.2 0.0 2.0 4.0 6.0 6 OC Function of the Fraction Nonconforming Control Chart OCp βp P(acceptin g the hypothesis that a process is in statistica l control | p) Pp̂ UCL | p Pp̂ LCL | p PD nUCL | p PD nLCL | p nUCL n d p d 1 p d 0 FnUCL F nLCL n d nLCL n d 0 p d 1 p n d d 7 OC Function of the Fraction Nonconforming Control Chart Where and [nUCL] denotes the largest integer nUCL <nLCL> denotes the smallest integer nLCL Note: The OC curve provides a measure of the sensitivity of the control chart – i.e., its ability to detect a shift in the process fraction nonconforming from the nominal value p to some other value p. 8 Example For a fraction nonconforming control chart with parameters and n = 50, LCL = 0.0303, UCL = 0.3697, Determine & plot the OC curve. 9 Example - Solution OCp βp PD 500.3697 | p PD 50 0.0303 | p PD 18.49 | p PD 1.52 | p p 0.01 0.03 0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45 0.50 0.55 P(D<=18|p) 1.0000 1.0000 1.0000 1.0000 0.9999 0.9975 0.9713 0.8594 0.6216 0.3356 0.1273 0.0325 0.0053 P(D<=1|p) P(D<=18|p) - P(D<=1|p) 0.9106 0.0894 0.5553 0.4447 0.2794 0.7206 0.0338 0.9662 0.0291 0.9708 0.0002 0.9973 0.0001 0.9712 0.0000 0.8594 0.0000 0.6216 0.0000 0.3356 0.0000 0.1273 0.0000 0.0325 0.0000 0.0053 10 Example - Solution OC(p) 1.0 0.8 0.6 0.4 0.2 0.0 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 -0.2 p 11 OC Function for c-charts and u-charts • For the c-chart OCc βc P(acceptin g the hypothesis that a process is in statistica l control | c) PX UCL | c PX LCL | c UCL d 0 e c c x LCL e c c x x! x! d 0 FUCL F LCL 12 OC Function for c-charts and u-charts • For the u-chart OCu βu P(acceptin g the hypothesis that a process is in statistica l control | u) PX nUCL | u PX nLCL | u nUCL d 0 x nu e nu x! where x nLCL 13 Example Determine & plot the OC function for a u-chart with parameter. and LCL = 6.48, UCL = 32.22. 14 Example - Solution OCu βu Px UCL | u Px UCL | u Pc nUCL | u Pc nUCL | u PnUCL x nUCL | u nUCL x nu e nu d 0 u 0.01 0.03 0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45 0.50 0.55 P(D<=33|c) 1.000 1.000 1.000 1.000 1.000 0.999 0.997 0.950 0.744 0.546 0.410 0.151 0.038 x! P(D<=6|c) 0.999 0.996 0.762 0.450 0.220 0.008 0.000 0.000 0.000 0.000 0.000 0.000 0.000 P(D<=33|c) - P(D<=6|c) 0.001 0.004 0.238 0.550 0.780 0.991 0.997 0.950 0.744 0.546 0.410 0.151 0.038 15 Example - Solution OC(u) 1.0 0.8 0.6 0.4 0.2 0.0 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 -0.2 u 16 Average Run Length for x-Charts • Performance of Control Charts can be characterized by their run length distribution. • Run Length (RL) of a control chart is defined to be the number of samples until the process characteristic exceeds the control limits for the first time. • Run Length, RL, is a random variable and therefore has a probability distribution 17 Average Run Length for x-Charts Let p = P(x falls outside control limits) Then P(RL = 1)= P(RL = 2)= = P(RL = 3)= = P(x1 falls outside CL)=p P(x1 falls inside CL & x2 falls outside of CL) (1-p)p P(x1, x2 fall inside CL & x3 falls outside of CL) (1-p)(1-p)p P(RL = i) = P(x1, x2, … xi-1 fall inside CL & xi falls outside of 18 CL) i-1 Average Run Length for x-Charts Therefore, the probability mass function of RL is PRL k 1 p K 1 p for K 1,2,... The mean or expected value of RL is μ ERL K 1 p K 1 p K 1 p 2p1 - p 3p1 - p 4p1 - p ... 1 2 3 p 1 21 - p 31 - p 41 - p ... 2 3 p a 1 p a 1 a 1 19 Average Run Length for x-Charts 1 p 2 1 - 1 - p 1 p • The Average Run Length, ARL, indicates the number of samples needed, on the average before x will exceed the control chart limits. 20 Probability of Out-Of-Control Signal and ARL • Process in control with mean m0 • p = 1 – P(LCL x UCL) = 0.0027 • ARL 1 p 1 0.0027 370, i.e., one the average we would expect 1 outof-control signal out of 370 samples. 21 Probability of Out-Of-Control Signal and ARL • Process in control with mean mm1m0+ds with constant s • What happens if the process goes out of control? • How long does it take until the control charts detects the shift? • Probability of detecting shift s s pδ 1 P μ 0 3 x μ0 3 n n 22 Probability of Out-Of-Control Signal and ARL σ σ μ 0 δσ μ0 3 μ 0 δσ μ0 3 n n 1 P Z σ σ n n 1 P 3 δ n Z 3 δ n P Z 3 δ n P Z 3 δ n 23 Example For example, if n = 5, and d = 1, p1 P Z 3 5 P Z 3 5 5.236 1 0.764 1 0.0000 0.7775 0.2225 and 1 ARL p1 1 0.2225 4.495 24