Engineering Statistics

advertisement

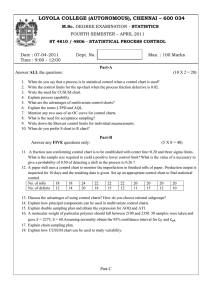

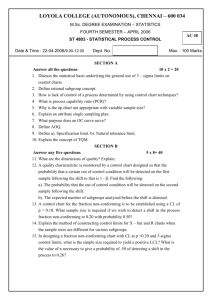

Statistical Process Control (SPC) What is Quality? Fitness for use Conformance to the standard Quality Improvement Quality improvement processes that involve statistical method; 1. 2. 3. Incoming Quality Control Statistical Process Control Outgoing Quality Control Incoming & Outgoing QC Acceptance Sampling Lot by lot sampling plan for attributes Acceptance sampling by variables Lot by Lot Sampling Plan For Attributes Types Of Sampling Plan Single Sampling Plan Double Sampling Plan Multiple Sampling Plan Sequential Sampling Plan MIL STD 105E (ISO 2859) Acceptance Sampling By Variables Types Of Sampling Plan Plan that control the lot/process fraction defective/nonconforming. Plan that control the lot/process parameter MIL STD 414 Tables Statistical Pocess Control Chance and Assingable Cause Of Quality Statistical basis for control chart Basic Principles Choice Of Control Limit Sample Size & Sampling Frequency Subgroups Analysis Of Patterns On Control Charts x Control Charts For Variables (Univariate) x and R charts x and s charts x and R charts Statistical basis of the charts Development and use of the charts Interpretation of the charts The operating characteristics function Average Run Length (ARL) for the mean chart x and s charts Constuction & Operation of the charts Control charts with variable sample size Control Charts For The Attributes Control Charts for the fraction non-conforming Development & Operation Variable sample size OC and ARL Control Charts for non-conformities Procedure with constant sample size Procedure with variable sample size OC and ARL Process Capability Analysis Using histogram Using probality plots Process Capability Ratio (PCR) Cp PCR for an of center process Normality and PCR Confidence Interval & Test on PCR PCR using control charts Chance and Assingable Cause Of Quality 2 types of variation 1. 2. Natural variability (chance) Assignable causes Process with assignable causes is said to be out of control. Basic Principles Control charts consist of Center line Upper control limit Lower control limit These limits is chosen so that when the process is in control, almost all the sample points will fall within the control limits. Choice Of Control Limit 2 types of control limits Three-sigma limits. The distance between CL and the UCL/LCL is 3 sigma. The 0.001 probability limits chart (use 3.09 sigma). The distance between CL and the UCL/LCL is 3.09 sigma. Note:3-sigma limits popular in US. 0.001 prob. limits popular in UK & Western Europe. Sample Size & Sampling Frequency Larger samples easier to detect. Use large sample if the shift of interest is small and small sample if the shift of interest is large. Frequent sampling is better. Current practice favour small but more frequent samples. Analysis Of Patterns On Control Charts Process out of control if 1. One or more points fall outside the control limits. 2. Points exhibit some non-random pattern. 3. Exhibit a cyclic behaviour. Pattern recognition Process is out of control if One point plots outside the control limit. Two out of three consecutive points plot beyond the two sigma warning limits. Four out of five consecutive points plot at a distance of the one sigma or beyond from the center line. Eight consecutive points plot on one side of the center line. x Control Charts For Variables (Univariate) x and R charts x and s charts Control Charts For Attributes •Control Chart For Fraction Nonconforming •Control Chart For Nonconformities x charts UCL x A 2 R CL x LCL x A 2 R R charts UCL D 4 R CL R LCL D 3 R S charts S UCL S 3 1 c 24 c4 CL S S LCL S 3 1 c 24 c4 Fraction Nonconfor min g Chart (p charts ) std given p(1 p ) UCL p 3 n CL p p(1 p) LCL p 3 n Fraction Nonconfor min g Chart (p charts ) (no std given ) p (1 p ) UCL p 3 n CL p p (1 p ) LCL p 3 n Nonconform ities Control Chart (c charts ) (std given ) UCL c 3 c CL c LCL c 3 c Nonconform ities Control Chart (c charts ) (no std given ) UCL c 3 c CL c LCL c 3 c Process Capability Calculated using 1. Process capability ratio (PCR), Cp. 2. Probability ; P( x LSL) P( x USL) LSL x USL x P( z ) P( z ) ˆ ˆ *need to know process std deviation Process standard deviation Process standard deviation is calculated by R ˆ d2 *use to estimate process capability Process Capability Ratio (PCR), Cp Cp USL LSL 6 And is estimated by Ĉ p USL LSL 6ˆ Interpretation What does it mean if Cp < 1 Cp = 1 Cp > 1