Production of mixed carboxylic acids from sludge using the MixAlco

advertisement

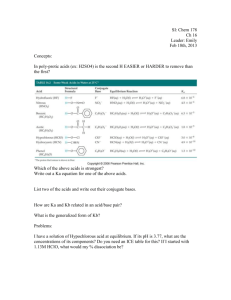

Hema Rughoonundun Research Week 2008 Outline of Presentation Introduction • The MixAlco Process Fermentation of sludge • Sludge • Materials and Methods • Results Conclusion • Energy Potential of sludge Common Energy Routes Thermochemical Common Energy Routes Sugar Less Common Energy Routes Carboxylate The MixAlco Process The MixAlco process has been developed by Dr M Holtzapple and his team from the Department of Chemical Engineering, Texas A&M University. The process is a patented technology that converts any biodegradable material (e.g, sorted municipal solid waste, sewage sludge, industrial biosludge, manure, agricultural residues, energy crops into a mixed alcohol fuels containing predominantly 2propanol, but also higher alcohols up to 7-tridecanol (Holtzapple et al., 1999). Stages of Development 1998 Pilot Scale (200lb/day) 1991 Laboratory Investigation 2007 Demonstra tion Plant (5 ton/day) 2009 Demonstration Plant (100 ton/day) MixAlco … the Process Process Mixed Alcohol Fuels Carboxylate Salts Biomass Pretreat Ferment Dewater Mixed Ketones Thermal Conversion Hydrogenate Lime Lime Kiln Calcium Carbonate Hydrogen Complex organic matter Carbohydrates, proteins, fats Fermentation Hydrolysis 1 Soluble organic molecules Sugars, amino acids, fatty acids 2 Acidogenesis Volatile fatty acids Acetic acid 3 Hydrogen, H2 Carbon dioxide, CO2 Acetogenesis 4 Methanogenesis Methane, CH4 Carbon dioxide, CO2 4 Methanogenesis Composition of the Mixed alcohols What is Mixed Alcohols Advantages of the MixAlco Process 1. Acetic acid, unlike ethanol, is biologically produced from simple sugars without the production of carbon dioxide: C6H12O6 → 2 CH3CH2OH + 2 CO2 (Biological production of ethanol) C6H12O6 → 3 CH3COOH (Biological production of acetic acid) Hence, on a Mass basis, the yield is higher for acetic acid compared to ethanol fermentation. Advantages of the MixAlco Process 2. C6H12O6 G = -48.56 kcal/mol glucose 2C2H5OH + CO2 ethanol C6H12O6 glucose 3 C2H3OOH acetic acid G = -61.8 kcal/mol The actual stoichiometry is more complex C6H12O6 6 acetate + 2 propionate + butyrate + 5CO2 + (67 mol%) (22 mol%) (11mol%) 3 CH4 + 6H2O Advantages of the MixAlco Process Substrates Lignocellulosic Municipal solid waste Any biodegradable material!! Advantages of the MixAlco Process Does not require sterile condition Does not require expensive enzymes Good Energy Yield Energy (MJ/L) Gasoline Mixed Alcohols Ethanol 34.9 29 23.4 Fermentation of Sludge using MixAlco Process Methodology I. Substrates Mixed Sludge Physical Properties Moisture % 97.92 ± 0.02 Volatile Solids 64.62 ± 0.068 Ash 35.38 ± 0.068 Fermentation of Sludge using MixAlco Process Mixed Sludge Elements % Glucose 5.267 Xylose 4.180 Mannose 4.214 Total Nitrogen 4.405 Total Phosphorous 1.298 Total Potassium 0.221 Fermentation of Sludge using MixAlco Process II. Apparatus Centrifuge bottle bioreactor (Ross, 1998) Fermentors in Roller Apparatus Fermentation of Sludge using MixAlco Process III. Conditions of Experiments Solids concentration of 50 g/L Marine Innoculum (12.5%) Temperature 550C Gas vented and sample of liquid taken every 2 days pH adjusted using ammonium bicarbonate Iodoform used as inhibitor used (0.8µL every 2 days) Fermentation of Sludge using MixAlco Process Parameters analysed pH Volume of gas Gas Composition Nitrogen, Methane and Carbon dioxide Apparatus: Gas Chromatograph (Agilent 6890 series, Agilent Technologies, Palo Alto, California) equipped with a thermal conductivity detector (TCD) Fermentation of Sludge using MixAlco Process Parameters analysed Total Carboxylic Acids Apparatus: Agilent 6890 gas chromatograph (Agilent Technologies, Palo Alto, California) equipped with a flame ionization detector (FID) and a 7683 series injector. Results Graph of Total Carboxylic acids v/s Time Total Carboxylic Acids (g/L) 12 10 8 6 4 2 0 0 2 4 6 8 10 12 14 16 18 Time (days) 20 22 24 26 28 30 Results Yield Parameters Parameter Value Average Acid Concentration (g/L) 10.72 Yield (g total acids produced/g VS fed) 0.34 Conversion (g VS digested/ g VS fed) 0.43 Total Acids Selectivity (g total acids produced/g VS digested) 0.79 Total Acid Productivity (total acids produced/ total liquid volume . Time) 0.34 Results Composition of mixed acids 12% 13% Ethanoic acid Propanoic acid 9% 66% Butanoic acid Valeric acid Conclusion Significance of results for Mauritius Sludge production by 2015 = 122,260 tonnes/ year Dry sludge (25 % solids) = 30,565 tonnes/year Assuming Volatile solids % = 65% Expected yield of Acids = 0.34 g Acids/g VS fed Energy Value of Mixed Acids = 29MJ/L Conclusion Total carboxylic acids production = 6755 tonnes/year Potential in terms of Energy = 192, 424 GJ 2. Tonne of Oil equivalent = 4596 toe 3. Money (at 82 USD per barrel) = Rs 80.4 million 4. Gasoline (60% Efficiency) = 4053 tonnes 1. Thank you