Microsoft and Infosys Technologies Respond to

advertisement

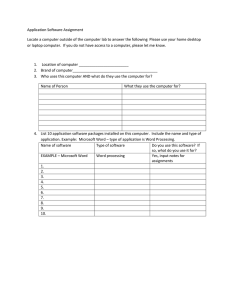

Microsoft and Infosys Technologies Respond to Supply Chain Visibility and Collaboration Challenges of Manufacturers In our last blog we noted that several high tech and electronics (HTE) company executives attending the Global Economic forum said they are placing a premium on gaining greater visibility into what is going with suppliers, customers and worldwide operations. The executives’ pain points varied by company, industry and geography, but all in all they validated the findings of a KRC Research-conducted survey that Microsoft and Infosys published in January. Among the key findings: 50 percent of business decision-makers, such as chief information officers or vice presidents of operations, reported increasing complexity in their supply chains. 65 percent reported experiencing a supply chain disruption, and said it took hours or longer from the time of the disruption to when supply chain systems reported the incident. 29 percent of high-tech manufacturers produce more than 50 percent of their manufacturing output through third parties or contract manufacturers, a trend that has increased over the past 2-3 years. nearly a third of those surveyed reported their supply chain professionals spend 25 percent of their time finding and re-working supply chain data to get it to the required level of granularity and format. For a high-tech manufacturer with 50 employees focused on managing the supply chain, this percentage of time per worker equates to $1.3 million annually in lost productivity, based on the average salary of a manufacturing manager ($105,581), according to IndustryWeek. We could go on and on about the survey results but you get the picture. A press release is posted here and the full survey findings are here. We’ll come back to these results in detail in future blogs. High tech supply chain management is a highly complex endeavor, where you have to deal with managing a constantly changing, and highly uncertain global business environment, where rapid decision making is critical for long-term success.. We recently published a case study about Samsung Electronics efforts to strengthen its ability to manage its global supply chain, particularly for the purpose of preparing for the uncertainties in the high tech business environment and drive Samsung’s competitiveness. Samsung worked with Microsoft to create an actionoriented role-based productivity solution that enables simulation and on-demand changes of business management plans leveraging cube write-back capabilities, and empower people to make these adjustments by using a user interface that is “employee-familiar”. Samsung Electronics deployed a Role-Based Productivity solution from Microsoft built on SQL Server®, and Microsoft Office SharePoint Server. The company expects its forecast accuracy for product demands to improve some 20%, which is significant when event a 1% increase in demand forecast accuracy can lead to substantial cost reduction in raw materials, logistics and production tasks. The company is expecting a 1000% ROI with enhanced demand forecast accuracy. For those high tech and electronics companies with other supply chain challenges, our solutions are built upon core Microsoft technologies, such as Microsoft BizTalk Server ,Microsoft Office SharePoint Server 2007 and Microsoft SQL Server. We’ll be talking more about how these solutions provide Supply Chain visibility and collaboration in future blogs as well. For a more thorough discussion of Microsoft in Supply Chain Management, see the HTE supply chain solution page on our Website and also a specific solution brief. Again, we’ll discuss these in more detail in future blogs. -Sanjay Ravi