Chapter 4 - Activity-Based Costing Systems

advertisement

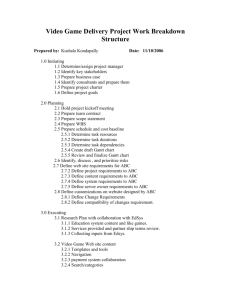

Activity-Based Costing Systems Chapter 4 Traditional overhead allocation system Single predetermined rate is used to allocate overhead to products Easy to use Assumes all overhead is correlated with the activity base Assumes all overhead costs are related to all products Does not consider the product’s consumption of resources other than the base An ideal system Treat indirect costs like direct costs Accurate assignment of the resources consumed by the individual cost objects Different types and amounts of overhead charged to different cost objects No allocation based on estimates Not possible Cost element shared by many cost objects Cost element not related to cost objects Not cost effective to trace accurately Activity-based costing Recognizes Not all costs are related to the same cost driver Not all costs are incurred at the unit level Unit level Batch level Product level Customer level Facility level Activity-based costing Recognizes That activities are performed to produce or support the cost object Those activities consume resources Can identify resources with the activities Can identify the activities with the cost objects Can be used for any cost object Not GAAP for financial reporting Activity-based costing Traditional allocation method Costs Products Activity-based allocation method Costs Activities First stage Products Second stage Implementation of an ABC system Step 1 – Develop activity dictionary List of activities related to the cost object How precise? Only major activities if purpose is better cost information More detailed if purpose is process improvement Will probably have an “other” activity Implementation of an ABC system Identify activities (cost pools) Interview employees Process flowcharts Etc. At which level do they occur? Unit, batch, etc. May not want to allocate facility level costs to products Implementation of an ABC system How are the activities performed? Inputs and outputs What causes the activity to commence? Production order, material requisition, etc. How can the activity be measured? Transactions, time, etc. For use as possible cost drivers Implementation of an ABC system Step 2 – Determine the significant costs related to each activity Resources used Employee time Wages and benefits Assets Depreciation, taxes, insurance, etc. Consumables Supplies, utilities, maintenance, etc. “Other” Implementation of an ABC system Exhibit 1 Alpha Manufacturing Company First-stage allocation percentages Material handling Indirect labor 10% Indirect materials Set-up Assembly Testing and inspection Rework Packaging Breaks and meetings 5% Other Total 15% 5% 50% 5% 5% 5% 100% 20% 45% 20% 10% 5% 100% Depreciation 15% 5% 25% 15% 10% 30% 100% Insurance and taxes 10% 5% 30% 20% 5% 30% 100% 5% 5% 50% 5% 5% 30% 100% 25% 20% 5% 25% 100% Utilities Repairs and maintenance Factory administration Other 25% 10% 90% 100% 100% 100% Implementation of an ABC system Exhibit 2 Alpha Manufacturing Company First-stage allocation Indirect labor Cost $ 1,600,000 Material Testing and Breaks and handling Set-up Assembly inspection Rework Packaging meetings Other Total $ 160,000 $ 240,000 $ 80,000 $ 800,000 $ 80,000 $ 80,000 $ 80,000 $ 80,000 $ 1,600,000 10% 15% 5% 50% 5% 5% 5% 5% 100% Indirect materials $ $ 250,000 - $ 50,000 $ 20% 112,500 $ 45% 50,000 $ 20% 25,000 $ 10% 12,500 $ 5% - 75,000 $ 15% 25,000 $ 5% 125,000 $ 25% 75,000 $ 15% 50,000 $ 10% 150,000 $ 30% - 22,500 $ 10% 11,250 $ 5% 67,500 $ 30% 45,000 $ 20% 11,250 $ 5% 67,500 $ 30% - 40,000 $ 5% 40,000 $ 5% 400,000 $ 50% 40,000 $ 5% 40,000 $ 5% 240,000 $ 30% - 43,750 $ 25% 35,000 $ 20% 8,750 $ 5% 43,750 $ 25% - 0% Depreciation Insurance and taxes Utilities Repairs and maintenance Factory administration $ $ $ $ 500,000 225,000 800,000 175,000 $ 1,250,000 $ $ $ $ $ 43,750 $ 25% - $ - - 0% Other $ 200,000 $ - $ 5,000,000 $ $ 341,250 $ - 0% 0% Total $ 0% - $ 0% $ 366,250 $ - 0% - $ 0% $ 828,750 $ - 0% - $ 0% $ 1,045,000 $ - 0% - $ 0% $ 215,000 $ 0% - $ 0% $ 593,750 $ $ 250,000 100% $ 500,000 100% $ 225,000 100% $ 800,000 100% $ 175,000 100% 0% $ - 0% 0% $ - 0% 0% $ - 0% 0% $ 0% 0% 125,000 $ 1,125,000 $ 1,250,000 10% 90% 100% - $ 0% $ - 0% 205,000 200,000 $ 100% $ 1,405,000 200,000 100% $ 5,000,000 Implementation of an ABC system Step 3 – Determine cost drivers and rates What activity measures correlate with each cost? Measurable Statistically or logically have a cause-and-effect relationship with the cost Predict or explain the consumption of resources with reasonable accuracy Based on practical capacity for the activity Unused capacity is its own “activity” Implementation of an ABC system Exhibit 3 Alpha Manufacturing Company Driver base quantities Job Driver base Pounds moved A B C D E Total 410 9,600 90 5,700 2,000 17,800 10 60 6 44 40 160 3,500 108,000 800 54,000 21,700 188,000 Number of tests performed 14 120 10 90 31 265 Rework hours 80 400 30 48 42 600 Cubic feet of packaged goods 30 1,100 5 385 280 1,800 4,000 85,000 500 34,000 26,500 150,000 350 12,000 50 4,500 3,100 20,000 Set-up hours Pieces assembled Total direct labor hours Number of units produced Implementation of an ABC system Exhibit 4 Alpha Manufacturing Company Driver rate calculations Activity Material handling Activity cost $ Driver base 341,250 Pounds moved Set-up 366,250 Set-up hours Assembly 828,750 Pieces assembled Testing and inspection 1,045,000 Number of tests performed Driver quantity Driver rate 17,800 $ 160 $ 188,000 $ 265 $ 3,943.40 per test performed 600 $ 358.33 per rework hour 1,800 $ 329.86 per cubic foot packaged 1.37 per direct labor hour Rework 215,000 Rework hours Packaging 593,750 Cubic feet of packaged goods Breaks and meetings 205,000 Total direct labor hours 150,000 $ 1,405,000 Number of units produced 20,000 $ Other Total $ 5,000,000 19.17 per pound moved 2,289.06 per set-up hour 4.41 per piece assembled 70.25 per unit produced Implementation of an ABC system Step 4 – Assign costs to cost objects Determine the amount of each activity consumed by the cost object Multiply by the rate for that activity Total the activity costs for each cost object Divide total by quantity of the cost object to determine unit cost Implementation of an ABC system Exhibit 5 Alpha Manufacturing Company Second-stage allocation Job A Activity Driver rate Material handling $ Set-up $ Assembly $ Testing and inspection $ Rework Packaging 10 22,891 3,500 3,943.40 per test performed $ $ Breaks and meetings $ 1.37 per direct labor hour Other $ Job D Cost assigned 60 137,344 15,429 108,000 14 55,208 358.33 per rework hour 80 329.86 per cubic foot packaged 30 70.25 per unit produced 5,700 6 13,734 476,090 800 120 473,208 28,667 400 9,896 1,100 4,000 5,467 350 24,588 $ 44 100,719 3,527 54,000 10 39,434 90 143,333 30 10,750 48 362,847 5 1,649 385 85,000 116,167 500 683 34,000 12,000 843,000 50 3,513 4,500 350 $ $ $ Activity quantity 2,000 $ 2,736,034 485.73 Job E Cost assigned 109,277 170,004 $ Activity quantity 1,725 $ $ Activity quantity 90 Units in job Cost per unit Job C Cost assigned 184,045 4.41 per piece assembled $ Activity quantity 9,600 2,289.06 per set-up hour 410 Job B Cost assigned 7,860 Total job cost 19.17 per pound moved Activity quantity Cost assigned 17,800 40 91,563 160 366,250 238,045 21,700 95,659 188,000 828,750 354,906 31 122,245 265 1,045,000 17,200 42 15,050 600 215,000 126,997 280 92,361 1,800 593,750 46,467 26,500 36,217 150,000 205,000 316,125 3,100 217,775 20,000 1,405,000 $ 1,309,735 12,000 50 4,500 228.00 $ 1,500.31 291.05 $ Activity quantity 38,343 75,015 $ Total Cost assigned $ 709,212 3,100 $ 228.78 $ 341,250 $ 5,000,000 Advantages of ABC Better allocation of costs Not perfect Useful for estimating costs of future projects Can be extended to activity-based management “Now that we know what it costs, how can we do it more efficiently?” Advantages of ABC Cost object can be anything Product Service Process Customer Employee Location Etc. Advantages of ABC Aids in recognizing, measuring and controlling complexity Promotes understanding of why costs are incurred Shifts focus from managing costs to managing activities When to use ABC High proportion of indirect costs Complex products or processes High volume vs. low volume products Diverse indirect costs Cost accounting system hasn’t evolved Distrust of current system Different products place different demands on resources Disadvantages of ABC Costly to implement Costly to maintain Likely to meet substantial resistance Not the “real” system “Why do you want to know what I do?”