Wayne (resaved) - Trinity College Dublin

advertisement

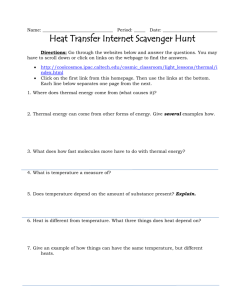

Distributed Micro Generation Trinity College Dublin Mr. Wayne O’Connell oconnew@tcd.ie 086 406 9902 Agenda • Developing Energy Background • Developing Research Goals • Trinity College R&D • 3 year project goals / Summary 1880-1900 A Golden age of Electricity Provisioning Thomas Edison Charles Parsons Nikola Tesla TCD Population 1885 = 1.45bn 2010 World Electrical Grid Penetration Off- Grid Population , 1.45bn OECD/IEA 2010 Biomass as a Primary Energy Source Costs of Biomass • Homemade paraffin lamp 500m fires lamps / every night – – – – – Mother/child mortality Accidents Deforestation CO2 emissions / Black Soot Violence Child cooking in kitchen hut Cooking Technology Cost of No Access GDP / Energy Consumption If you could change the price of one thing in the developing world to alleviate poverty by far you would pick energy … Bill Gates , 2010 Universal Modern Energy Access • Electricity Cooking UMEAC = 250kWhr /year - $33bn for 20 yrs Research Goals • Define Project Outcome – Physical Processes Available – Needs Assessment • Understand Resources available – Technology – People – Money • Additional Constraints – Pollution – Economics • Scale Outcomes • What is Energy – What do we mean when we want to deliver or provision energy? • Important things to consider – Amount required – Cost to generate / convert – Cost to operate • Adverse impacts? Needs Assessment Vs UMEAC (BoP) • What is required to deliver base level services Device # Voltage (V) Time (hrs) Current( A) Energy (Whr) LEDs 2 3.7 4 0.35 12 Phone 1 3.7 2 0.5 3 Fan 2 12 5 0.2 12 Radio 1 6 3 02 3 OLPC 1 7 3 3 18 Inc.. 50% Total buffer • 75 W Hr/ day = 25 kWhr / year • Assumes Biomass/Solar for Cooking • Compare to UMEAC = 250kW/hr 75 Scope for Baseline energy Delivery to get people on the ladder at much lower cost !!! Stove Technology Rocket Stove Gasifier Stove Fuel Oil Stove Charcoal Stove The A Solution !! Heat for Cooking (10-20%) Waste Heat (75%-90%) Heat for Electricity (3-5%) Charcoal (Biochar) for Fertilizer Carbon Negative Why University/Trinity Research • • • • Lots of experience on nano-materials which are vital for next gen thermoelectrics – CRANN – Materials Indentified / Screening Accomplished Engineering Tradition (ZT / $) – Centre For Energy Devices – Collaboration with Bio-Engineering to develop differentiated low cost high temperature device Thermal Conductivity Instrumentation Design Capability Ongoing Collaboration with developing world – Irish DFA (Malawi) – Clinton Global Initiative – Strong industrial relationships - INTEL • Brand Trinity open doors overseas for collaboration – Irish Aid / European Commission / Center For Climate Justice – Open Carb Thermoelectricity Direct Heat Conversion to Electricity Snyder, “Complex Thermoelectric Materials” Thermal Conductivity Most Accurate in Ireland (plane perpendicular) R. Kempers, P. Kolodner, A. Lyons & A.J. Robinson, 2008, “A High-Precision Apparatus for the Characterization of Thermal Interface Materials” Review of Scientific Instruments, 80, 095111(2009). doi:10.1063/1.3193715 Thermal Resistance RTIM T T a b Q Effective Thermal Conductivity k eff QL L ATa Tb AR Unique Features Precision calibrated thermistors; temperature uncertainty of ±0.001K Robust uncertainty analysis for all measured and calculated quantities Simultaneous measurement of electrical resistance Phase 2 (Tony Robinson) Films / Nanowires Test Concept Development In plane Combined ZT Biggest Challenge Personnel Resources (New Blood /Grep /IRCSET) ???? TCD Stove Characterization Bio-Engineering Collaboration Opp. • Early Discussion with Kevin (O’Kelly) • Leverage institutional knowledge of functional ceramics – Joints • Kevin has relationships with Schvets/Gunkos synthesis Post Doc from a sabbatical partner • Device Development, 2-3 stage process – Goal is 1/10 the cost of existing devices at > 50% of output • Absolutely disruptive !!! (Not just for this application _ – Co-Generation , Industrial Energy Harvesting System Benefits • Stove – 1.0 – 3 T CO2 offset per year ($20-$60) – 80% + reduction in particulates/ IAP • Reduction in CO and other VOC’s • Impact on Bronchial Health – Reduction in Time Spent Collecting Wood • Reduced burden on women and children • Deforestation – Crop Fertilization (if gassifier/biochar used) • Carbon Sequestration (500 yr lifetime) • Electricity – Night Light = 3 Extra Hours – Mobile Phones / Laptop = Information Age – Income Generation / Socialization / Comfort Key Differentiation of future TCD Device • Features Advantage Benefits Ferrite TEG Material Low Cost Device Cost Reduction (Ceramic) Material Abundance Future Cost Trajectory/Scale Material Robustness Long life implies lower op cost per installed capital $ High Temp Capability Reduces Engineering integration Cost Compared to current material Ceramic Material Sandwich Well understood manuf. process Low Cost and Scalable process Direct Sintering of Heat Sink to TEG Reduced System cost through simplified thermal eng 3 yr Goals Year 1 – 3 W Power Plant (Rocket) 10 Whr battery Storage 2 LED / Mobile Phone / Radio System Validation Proof of Concept and Utilization in Malawi Year 2 – 10W Power Plant (30Whr Storage) 50% x cost / efficiency improvement Gasifier / Fuel Oil Versions Biochar / Fertilizer Model Franchisee Model Solar Demonstration Patent Portfolio CDM Application Year 3 – 20W Power Plant (250Whr Storage) Solar/Thermal Combination Electric Devices Distribution Power 3W Cost 10W Device RoadMap 25W Energy Capacity 10Wh 30Whr 75Whr Year 1 BoM $100 $125 $ 200 Year 1 Price $150 $185 - Year 2 BoM $50 $70 $100 Year 2 Price $70 $105 $150 Year 3 BoM $20 $35 $68 Year 3 Price $30 $50 $105 $37.5 bn for 300m stoves (1.5 m users) Universal Modern Energy Access Case • Electricity Cooking Reducing the Cost of Electricity Access Globally - Who is resourced to Pay Carbon Philanthropy Fossil Fuel Sub Mobile/ICT (Capoor and Ambrosi, 2009) In Summary • Today more people lack access to electricity than were alive when Edison invented modern electricity provisioning • Access to energy/electricity is one of the key determinants of developing world growth • Micro-Generation from Biomass is a viable low cost strategy for 1st level electricity/energy delivery to the BoP • Trinity is determined to play a leading academic social and economic role in topical energy programme with our development partner(s), Irish Aid Team (TCD) • Tony Robinson/ Kempers et al – PI/Lecturer in Thermodynamics/Test • Chloe Kinsella / Sean ?Shane – Gold Medal TCD Graduate - M.Sc. Student ESBi - Energy Trading • Seamus O’Shaughnessy/Aonghus – Heat & Mass Transfer • Maurice Deasy – MSc Student • Igor Schvets / John Boland – CRANN (Materials) • Kevin O’Kelly et al – Bioengineering