polb23925-sup-0001-suppinfo

advertisement

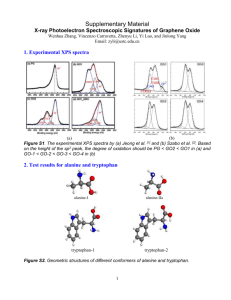

Effect of the C/O ratio in Graphene Oxide Materials on the Reinforcement of Epoxy-Based Nanocomposites Cristina Vallés1*, Fabian Beckert2,3, Laura Burk2,3, Rolf Mülhaupt2,3, Robert J. Young1, Ian A. Kinloch1* 1 School of Materials, University of Manchester, Oxford Road, Manchester, M13 9PL, UK 2 Institute for Macromolecular Chemistry, Albert-Ludwigs-University of Freiburg, Stefan-Meier-Straße 31, Freiburg, Germany 3 Freiburg Materials Research Center FMF, Stefan-Meier-Straße 21, Freiburg, Germany Correspondence to: Cristina Vallés, Ian A. Kinloch (E-mail: cristina.valles@manchester.ac.uk, ian.kinloch@manchester.ac.uk) SUPPORTING INFORMATION S1. X-ray photoelectron spectroscopy of GO and the TRGOs X-ray photoelectron spectroscopy (XPS) was used to characterize the surface chemical structure and composition of the graphene powders employed as reinforcement in the epoxy composites. The spectra were collected using a Kratos Axis Ultra X-ray photoelectron spectrometer, equipped with an aluminium/magnesium dual anode and a monochromated aluminium X-ray sources. The results obtained are shown in Figure S1. XPS survey (Figure S1a) reveals an increased C/O atomic ratio with increasing annealing temperatures. For the starting GO material a C/O atomic ratio of 4.2 was observed, which was found to increase up to 9.22, 14.5 and 42.6 when the material was thermally reduced at 400, 750 and 1000 °C, respectively. The high resolution C1s spectra (Figures S1a-d) revealed the presence of Csp2, C-O and C=O peaks at 284.5 eV, 286.74 and 288.19 eV, respectively, for the GO, whereas the Csp2 peak is the dominant peak after thermal reduction1,2. The peak corresponding to C-O is drastically reduced after the thermal treatment and the C=O peak disappeared for all the thermally-reduced materials. 1 (a) TRGO-1000 CPS TRGO-750 TRGO-400 GO 0 200 400 600 800 1000 1200 Binding Energy (eV) Csp2 Csp2 (c) TRGO-400 C: 90.22 at.% O: 9.78 at.% C/O: 9.2 C-O CPS CPS (b) GO C: 80.78 at.% O: 19.22 at.% C/O: 4.2 C=O C-O 294 292 290 288 286 284 282 294 292 Binding Energy (eV) (d) TRGO-750 C: 93.56 at.% O: 6.44 at.% C/O: 14.5 290 288 286 284 282 284 282 Binding Energy (eV) Csp2 (e) TRGO-1000 C: 97.71 at.% O: 2.29 at.% C/O: 42.6 CPS CPS Csp2 C-O C-O 294 292 290 288 286 284 282 294 Binding Energy (eV) 292 290 288 286 Binding Energy (eV) Figure S1. XPS survey (a) and high resolution C1s for the GO (b) and TRGO powders reduced at 400 °C (c), 750 °C (d) and 1000 °C (e). 2 S2. SEM of GO and the TRGO materials A Quanta 250 FEG (FEI, Hillsboro, OR, USA) scanning electron microscope was used to characterize the morphology and size of the graphene powders studied as reinforcements. The pictures were taken in high vacuum (10-3 Pa) with a LFD Detector using an accelerating voltage between 5 and 20kV. SEM pictures showing the structure and size of the flakes of GO and the TRGO materials are shown in Figure S2. 3 Figure S2. SEM pictures of the graphene powders: GO (a, b); TRGO-400 (c, d); TRGO-750 (e, f); TRGO1000 (g, h). Although these images revealed that the diameter of the GO flakes decreased with the applied thermal treatments, the observed diameters still remained quite big (≥ 50 µm) for the graphene oxide flakes even after being treated at 1000 °C. S3. Filler Orientation The orientation of the GO and TRGO fillers was evaluated using polarized Raman spectroscopy as shown in Figure S3. The data show a random orientation in all cases. 4 100 1.2 1.0 80 120 (a) 60 140 GO/epoxy - 1 wt.% D band laser in z direction 40 0.4 0.6 160 20 0.4 0 0.2 0.4 0.4 0.6 0.6 0.8 0.8 1.0 1.0 1.2 1.2 100 80 120 (c) 1.0 60 140 TRGO-400/epoxy- 1 wt.% D band laser paralel to z 40 0.8 160 20 0.2 0.0 180 0 0.2 0.4 0.6 0.8 1.0 1.2 100 1.2 80 120 (e) 1.0 0.4 160 20 140 1.4 1.2 1.0 0.8 0.6 0.4 0.2 0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 0 100 140 TRGO-400/epoxy - 1 wt.% D band laser paralel to x 40 160 20 180 0 80 TRGO-750/epoxy - 1 wt.% 60 D band 120 (f) 1.0 40 60 100 1.2 80 120 (d) TRGO-750/epoxy - 1wt.% D band 60 laser in z direction 0.8 0.6 40 0.0 180 0.2 0.4 140 0.2 0.0 180 0.6 GO/epoxy - 1 wt.% D band laser in x direction 60 0.8 0.2 1.2 80 120 (b) 1.0 0.8 0.6 100 1.2 laser in x direction 140 40 0.8 160 20 0.2 0.6 0.4 0.0 180 0 20 0.0 180 0.2 0.2 0.4 0.4 0.6 0.6 0.8 0.8 1.0 1.0 1.2 1.2 1.4 1.2 (g) 1.0 140 0.8 0.6 160 0.4 0.2 0.0 180 0.2 0.4 0.6 0.8 1.0 1.2 1.4 160 0.2 100 120 80 0 TRGO-1000/epoxy - 1 wt.% 60 D band laser paralel to z 40 20 0 1.4 1.2 (h) 1.0 140 0.8 0.6 160 0.4 0.2 0.0 180 0.2 0.4 0.6 0.8 1.0 1.2 1.4 100 120 80 TRGO-1000/epoxy - 1 wt.% 60 D band laser paralel to x 40 20 0 Figures S3. Variation of ID with the rotation of the specimen showing the random orientation of the (a, b) GO, (c, d) TRGO-400 (e, f), TRGO-750 and (g, h) TRGO-1000 in the epoxy matrix in the 1 wt.% loaded nanocomposites. A polarized Raman laser beam aligned either in the z- or in the x-direction to the surface of the specimen with VV polarization was used. The curves are least squares fits to the experimental points. 5 S4. Mechanical Properties The mechanical property data for all the nanocomposite materials studied are summarized in Table S1. Table S1. Mechanical property data obtained from the stress-strain curves in Figure 3. GO/Epoxy (wt.%) 0 0.5 1 2 3 4 5 Young’s Modulus (GPa) 1.97 0.13 2.53 0.12 2.82 0.11 2.33 0.40 2.41 0.20 2.35 0.19 2.60 0.10 Fracture Stress (MPa) 49.30 2.85 51.08 4.00 49.41 9.38 33.50 4.80 33.60 4.30 36.04 10.40 41.40 7.00 Fracture Strain (%) 3.40 1.02 2.76 0.38 2.66 0.33 1.60 0.37 1.35 0.22 1.89 0.70 2.10 0.60 TRGO-400/Epoxy (wt.%) 0 0.5 1 2 3 4 5 Young’s Modulus (GPa) 1.97 0.13 2.52 0.40 2.70 0.20 2.35 0.23 2.10 0.20 2.40 0.30 1.90 0.01 Fracture Stress (MPa) 49.30 2.85 48.80 0.97 32.00 12.80 17.95 7.51 25.84 3.00 21.00 5.00 4.00 1.85 Fracture Strain (%) 3.40 1.02 2.64 0.507 1.39 0.90 0.41 0.50 1.35 0.24 0.90 0.40 0.17 0.11 TRGO-750/Epoxy (wt.%) 0 0.5 1 2 3 4 5 Young’s Modulus (GPa) 1.97 0.13 2.39 0.30 2.71 0.20 2.44 0.30 2.56 0. 01 2.68 0.12 2.89 0.40 Fracture Stress (MPa) 49.30 2.85 27.00 3.97 21.61 14.00 26.00 3.70 9.07 3.00 13.62 4.26 6.90 1.50 Fracture Strain (%) 3.40 1.02 1.21 0.44 0.93 0.73 1.08 0.02 0.29 0.05 0.60 0.16 0.43 0.16 TRGO-1000/Epoxy (wt.%) 0 0.5 1 2 3 4 5 Young’s Modulus (GPa) 1.97 0.13 2.50 0.12 2.52 0.20 2.60 0.21 1.94 0.01 2.00 0.20 2.38 0.32 Fracture Stress (MPa) 49.30 2.85 42.41 10.41 36.75 10.73 18.46 11.18 6.15 1.10 7.20 3.00 7.08 1.42 Fracture Strain (%) 3.40 1.02 2.08 0.69 1.87 1.07 0.77 0.63 0.24 0.08 0.47 0.20 0.57 0.23 6 S5. Rheological Behavior of the Nanocomposites 106 (a) GO (b) 102 G' 108 10-1 TRGO-400 107 102 10 G' 0 10 (e) *(Pas) 104 108 G', G'' (Pa) 103 6 10-2 -1 10 G'' Epoxy 0.5 wt.% 1 wt.% 2 wt.% 3 wt.% 100 101 102 Frequency (rad/s) TRGO-750 G' 100 108 10 (g) G'' Epoxy 0.5 wt.% 1 wt.% 2 wt.% 3 wt.% 100 101 102 Frequency (rad/s) TRGO-1000 104 102 100 10-2 G' G'' Epoxy 0.5 wt.% 1 wt.% 2 wt.% 3 wt.% (f) Epoxy 0.5 wt.% 1 wt.% 2 wt.% 3 wt.% 100 101 Frequency (rad/s) TRGO-750 102 Epoxy 0.5 wt.% 1 wt.% 2 wt.% 3 wt.% 103 (h) 100 101 Frequency (rad/s) TRGO-1000 102 Epoxy 0.5 wt.% 1 wt.% 2 wt.% 3 wt.% 105 103 101 -1 10 100 102 Frequency (rad/s) TRGO-400 105 107 6 100 101 Frequency (rad/s) 103 101 -1 10 103 Epoxy 0.5 wt.% 1 wt.% 2 wt.% 3 wt.% 4 wt.% 105 107 104 102 (d) 101 -1 10 103 6 10-2 -1 10 G', G'' (Pa) 100 101 102 Frequency (rad/s) * (Pas) G', G'' (Pa) 10 (c) G'' Epoxy 0.5 wt.% 1 wt.% 2 wt.% 3 wt.% 4 wt.% 100 10-2 -1 10 * (Pas) 102 *(Pas) G', G'' (Pa) 104 GO 100 101 Frequency (rad/s) 102 Figure S5. Dynamic frequency sweeps on the studied graphene oxide dispersions in the epoxy resin conducted within the LVR (at a constant strain amplitude of 0.1%). Dependence of: G' and G'' (a) and η* (b) of GO, G' and G'' (c) and η* (d) of TRGO-400, G' and G'' (e) and η* (f) of TRGO-750, G' and G'' (g) and η* (h) of TRGO-1000 with the applied frequency. 7 10 (a) GO 108 Epoxy 0.5 wt.% 1 wt.% 2 wt.% 3 wt.% 4 wt.% (Pas) 101 -3 10 108 (c) 10-1 101 Shear Rate (s-1) TRGO-750 10-1 101 Shear Rate (s-1) (d) 10-1 101 Shear rate (s-1) TRGO-1000 106 102 103 Epoxy 0.5 wt.% 1 wt.% 2 wt.% 3 wt.% 104 102 100 -3 10 103 Epoxy 0.5 wt.% 1 wt.% 2 wt.% 3 wt.% 4 wt.% 102 108 Epoxy 0.5 wt.% 1 wt.% 2 wt.% 3 wt.% 104 100 -3 10 TRGO-400 104 100 -3 10 103 (Pas) (Pas) 106 (b) 106 (Pas) 2 10-1 101 Shear Rate (s-1) 103 Figure S6. Steady shear rate flow behaviour of the GO (a), TRGO-400 (b), TRGO-750 (c) and TRGO-1000 (d) dispersions in the epoxy at different concentrations. References 1. Rella, S.; Giuri, A.; Corcione, C. E.; Acocella, M. R.; Colella, S.; Guerra, G.; Listorti, A.; Rizzo, A.; Malitesta, C. Vacuum 2015, 119, 159-162. 2. Vallés, C.; David Núñez, J.; Benito, A. M.; Maser, W. K. Carbon 2012, 50, 835-844. 8