Systems Level Design Review Presentation

advertisement

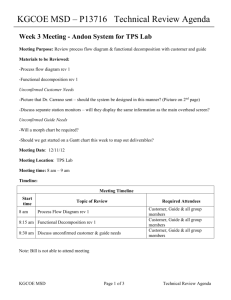

MSD 1 System Level Design Review Biomass Compressor TEAM 13432 Terminology Biomass – any grown organic matter to be used in the system Compressor – increases pressure on the biomass FVP – force versus power TIE – team industrial engineering TC – team compression TSP – team slicing and packaging Goals • Present design criteria and customer needs for approval by customer • Update customer in regards to concept generation • Settle upon final systems architecture for approval by customer EDGE Website https://edge.rit.edu/edge/P13432/public/Home One Page Summary Concept Generation Functional Analysis House of Quality PUGH Baseline Pugh Diagram Loose Biomass Hydraulic Twiner Auger Flywheel Twiner Guillotine Worm Gear Unbound Weight Datum Design 1 Design 2 Design 3 Design 4 Budget Production Standards 2 0 - 0 + - 1 0 + - - + Efficiency 1 0 - + + + Ease of Use 3 0 0 + + + Safety 2 0 - - - - Size 3 0 - 0 - - Noise 3 0 - + 0 + Description Selection Criteria Vibrating Wire Vibrating Wire Pnumatic Flywheel Glue Hemp Wrap PUGH Refined criteria auger weigh flywheel hydraulic t twiner twiner guillotine wormgear unbound vibe wire pneumatic glue vibe wire flywheel hemp wrap budget prod standards 2 0 + + - - 1 0 0 - 0 - efficiency ease of use/mainte nance 1 0 + + - + 3 0 0 - + - safety 2 0 + 0 + + size 3 0 + 0 + + noise 3 0 0 - 0 + System Architecture Feasibility Analysis Feasibility Analysis What the mechanical testing will answer 1. What does the force v. displacement curve look like? 2. Does moisture have an effect on the results? 3. Is the compressed material isotropic or an-isotropic? 4. What are the effects of the three different materials? 5. What is Poisson’s ratio for the materials tested? 6. What are the effects of the orientation of the material on resulting forces? 7. What is the force needed to eject the brick from the compression chamber? 8. Do the results scale? 9. What are the effects of dwell time in compression chamber? 10. What is the maximum achievable density of brick? 11. How does friction affect the compression and ejection of the biomass? Feasibility Analysis Steel 1018 CD Sut (psi) Sy (psi) E (psi) Critial Load (psi) Factor of Safety Max Load (psi) Load Marin Factors ka kb (axial) kc (axial) kd ke kf Se (psi) Factor of Safety¹ 64000 54000 29000000 43277.79754 2 21638.89877 15000 0.896862925 1 0.85 1 0.99 1 24150.72483 1.3158098 Flywheel Calculations (back of the envelope) Flywheel Calculations Position (°) Factor 90 -0.013 100 -1.765 110 -3.629 120 -5.796 130 -8.401 140 -11.904 150 -17.405 160 -27.559 170 -56.667 179 -612.080 179.9 -7957.720 INGREDIENTS: 1. Sun-cured Chopped Grass Hay (Timothy and Orchardgrass), 2. Sun-cured Chopped Alfalfa, Vegetable Oil. • • • • • OVERVIEW 2 lbs bricks Goal is to promotes Water Intake for Proper Hydration Convenient, Lightweight and Easy to Use Quickly Expands in a Bucket of Water to About One Flake of Moist Hay Compressed Blend of Premium Grass and Alfalfa Hay NUTRIOTIONAL INFO: Crude Protein (min) ................ 8.00% Crude Fat (min)........................ 1.50% Crude Fiber (max) .................... 37.00% Ash (max) ................................ 9.00% http://purinahorsesupplements.com/media/pdf/HydrationHayBlockOriginalSellSheet-FINAL-Sep-24-2012.pdf Schaetzel family hay brick production • Purchasing a hydraulic machine ($350,000) • Plant plans on using 20 tons of hay per day • Economically unfeasible to transport hay more than 100 miles away http://www2.ljworld.com/news/2008/mar/31/county_residents_have_hot_idea_new_type_biofuel_ha/ Schedule for MSD 1 Work Breakdown Structure Team Action Items Phase Define Action Item Date: 2013-03-21 Responsibility Start Date Target Actual Completion Completion Comments Meet with Customer All 03/08/13 Narrow scope Define specs Project roles Dani All All 03/08/13 03/21/13 03/08/13 03/22/13 03/22/13 03/15/13 03/15/13 3/15/13 Project Manager and Lead Engineer roles chosen, Documentation Officer and EDGE specialists created. Subgroups created to attack individual parts of machinery. 03/15/13 03/08/13 03/15/13 Week 9/10 Week 8 Week 8 Week 8 Week 8 Week 8 Week 8 Week 8 Week 8 Week 5 Week 8 Week 7 Week 5/6 Week 5 MSD II MSD II MSD II 04/05/13 03/21/13 03/21/13 Design process Measure Research Examples Brainstorm Preliminary Ideas Measure Design Performance Create Cad Drawings Analyze Analyze Cost Analyze Feasibility Analyze Energy Consumption Analyze Location Analyze Optimization Analyze Safety Minimize Noise Select Materials Analyze Failure Mechanics Create B.O.M. Implement Select Final Design Customer Approval Select Prototype Method Assemble Prototype Control Measure Compression Improve Repeatability Measure Weight Improve Safety Measure Energy Consumption Create Instruction Manual Create PFMEA Create Fault Tree Analysis All Leila, Ahkil All All All All Customer MSD II MSD II MSD II MSD II MSD II MSD II MSD II 3/8/13 Group meeting with customer to explain initial details 3/16/13 Angela, Jackson, Josh, Sean, Akhil Taveled to Overmoyer farms to see original design and process. 03/21/13 03/21/13 1. 2. 3. 4. 5. W O R K S PA C E O S H A R E G U L AT I O N S M AT E R I A L F L O W F L O O R L AY O U T EOQ & ROP PRODUCTION TIMES: a) b) c) d) e) 6. 7. 8. Mean time to repair Utilization times Throughput rate WIP Raw Processing time MAINTENANCE MANUAL N E T E N E R G Y C A L C U L AT I O N S S E N S O R A R R AY / C O N T R O L S a) b) c) d) Emergency Switch Brick and Cycle Counters Light Indicators Hazard Area Protection Questions / Concerns