Final Design Review Presentation

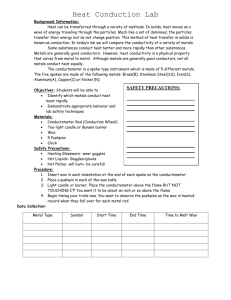

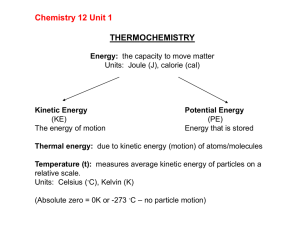

advertisement

P13651: FINAL DESIGN Contents • Revised Design • Subsystem design • Power requirements • BOM/Budget Hold Wax: Hopper • Designed to hold an entire bag of wax flakes • Reduces operator work during operation • Hopper held within base with springs to reduce affects of vibrations from vibrator For drawings see attached Transport Wax: Chute • Goal: Transport 2 gallons of wax at a time into the tank • Wax flow controlled by a door operator by a linear actuator • Ideal chute angle to transport wax flakes: 45° • Vibrator is attached to the backside of chute to improve transfer Super-Quiet Low-Impact Electric Vibrator Nonadjustable Force, 115 VAC, 1.4 Amps, 25 lbs Force http://www.mcmaster.com/#catalog/119/517/=lsgnla Melt Wax: Melting Tank • Goal: Melt 2 gallon batch of wax within 10 minutes • Aluminum tank structure • heaters around exterior wall of tank is sole provider of heat to melt the wax • Aluminum shaft and 2 stirrers induce flow and increase melt rate • Insulation surrounding tank prevent heat loss to surroundings Heat Requirements • Melted varying quantities of three sample wax in a home wax melting unit • Determined melter efficiency by comparing results from testing to known material, paraffin • Used data to determine amount of energy required to achieve customer requirement of 50 lb/hour Energy Required to Melt 50 lb of Wax 50 lb/hr KC 4088 100 lb/hr 983 1967 Cerita 28-8 1148 2296 Solucore 1149 1711 3422 Testing Melter Efficiency 39% Sample Calculations Raw Data Analyzed Data Power Required Trial Amt (lbs) Melt Time (min) Time (s) Weight (kg) Melt Rate (kg/s) Heat of Fusion (J/kg) 50 lb/hr 100 lb/hr 1 0.6 16.58 995 0.2722 0.00027 213E+3 1341 2682 2 0.6 11.82 709 0.2722 0.00038 152E+3 956 1911 3 0.6 14.98 899 0.2722 0.00030 192E+3 1212 2423 4 0.6 16.83 1010 0.2722 0.00027 216E+3 1361 2723 5 1 26.17 1570 0.4536 0.00029 202E+3 1270 2539 6 1 20.63 1238 0.4536 0.00037 159E+3 1001 2002 7 1 20.38 1223 0.4536 0.00037 157E+3 989 1978 8 1 24.37 1462 0.4536 0.00031 188E+3 1182 2365 9 1.4 35.02 2101 0.6350 0.00030 193E+3 1214 2427 10 1.4 27.50 1650 0.6350 0.00038 151E+3 953 1906 Average 182E+3 1148 2296 Power (W) 58.23 Required Melt Rate (lb/hr) 50 Required Melt 0.0063 Rate (kg/s) Required Melt Rate (lb/hr) 100 Required Melt 0.0126 Rate (kg/s) System Heaters • System will require 4 heaters to provide enough energy and cover the tank • Heaters will come up to 2.25in down from the top of the tank • Heat density of 100W/in2 Watlow Band/Barrel Heaters http:/www.watlow.com/downloads/en/catalogs/band-barrel.pdf/ Melted Wax Transport • Goal: Achieve 50 lb/hour flowrate • Flow rate out of tank controlled by a door operated by a linear actuator • Outlet through current baseplate into reservoir BOM: Metal Description Cold Roll Mild Steel Sheet A366/1008, 20"x20" 16 Gauge Metals Part Chute wall of Hopper Vendor online metals Cold Roll Mild Steel Sheet A366/1008, 10"x60" 16 Gauge Hopper bottom wall (3 sides) online metals Item # Quantity 13 1 14 1 15 2 16 4 17 1 18 1 Cold Finish Mild Steel Rectangle 1018, 6"x30"x1/8" Hopper support (Angled) 19 1 Cold Finish Mild Steel Rectangle 1018 , 1/4"x2"x36" Hopper support (Horizontal) 20 4 21 1 22 1 23 1 24 1 25 1 26 1 Cold Roll Mild Steel Sheet A366/1008, 12"x40" 16 Gauge Cold Roll Mild Steel Sheet A366/1008, 12"x24" 16 Gauge Cold Roll Mild Steel Sheet A366/1008, 12"x12" 16 Gauge Hopper box Heater box walls Heater box top DOM Mild Steel Tube A513 TYPE 5, length 36", OD=3/4", ID=0.53" with wall Support Rods thickness 0.109 " Cold Finish Alloy Sheet Steel 4130 L Brace Annealed, 10"x10"x.19" Extruded Aluminum Round 6061 T6511, Heater base length 2-1/4", OD=8" Aluminum 6061-T6 Bare Sheet, 18" x 26", Heater tank thickness=1/8" Extruded Aluminum Round 6061 T6511, Stir shaft length 24", dia 3/4" Extruded Aluminum Round 6061 T6511, Stir blades length 24" L, dia 1.5" Mild Steel BLANCHARD GROUND Plate Base plate 1018, 24"x24"x1/2" Code/Part Number Lead Time - - $ 24.00 $ 24.00 - - $ 24.00 $ 24.00 - - $ 19.20 $ 38.40 - - $ 9.31 $ 37.24 - - $ 4.82 $ 4.82 online metals - - $ 30.30 $ 30.30 online metals - - $ 17.20 $ 17.20 online metals - - $ 10.09 $ 40.36 $ 38.00 $ 38.00 online metals online metals online metals online metals online metals online metals online metals online metals online metals Unit Price Total Price - - $ 57.89 $ 57.89 - - $ 60.84 $ 60.84 - - $ 4.74 $ 4.74 - - $ 18.95 $ 18.95 - - $ 284.51 $ 284.51 Metal Sub-Total $ 681.25 BOM: Electrical Description Electrical Components Part Vendor Item # Quantity Code/Part Number Lead Time 1 12 Logic Gates Electrical Component 2 10 1% resistors for booster circuit 3 4 4 Unit Price Total Price DigiKey 4 AND, 2 NOR, 2 OR, 4 Inverter packages 5 Days $ 0.42 $ 5.04 Electrical Component Digikey - 3-5 Days $ 0.50 $ 5.00 MOSFETs for booster circuits Electrical Component Digikey - - $ 0.60 $ 2.40 2 120 V Relays Electrical Component Digikey Z774-ND - $ 2.07 $ 4.14 5 1 20 A breaker Electrical Component Lowes Square D Qo 20A breaker Ready to purchase $ 6.44 $ 6.44 6 1 12/2 Wire Electrical Component Lowes 50' of 12 AWG 12-2 Ready to purchase $ 33.24 $ 33.24 7 1 Light Switch Electrical Component Lowes Single standard 15 A light switch Ready to purchase $ 5.00 $ 5.00 8 1 Primary Drive Motor Electrical Component Grainger Dayton motor 1/3 HP GP item #5K917 Purchased $ 130.00 $ 130.00 9 2 Linear actuator for valves Electrical Component Firgelli automation - - $ 160.00 $ 320.00 10 1 Signal wire Electrical Component - 20 gauge signal wire of various colors, 10ft On hand 11 1 K-A-Watt Electrical Component - - - 12 4 Heater Electrical Component Watlow ME7L3AP1 $ - $ - $ 40.00 $ 40.00 Purchased 2 $ weeks ago 130.00 $ 520.00 Electrical Components Sub-Total $ 1,071.26 BOM: Auxilliary Item # Quantity Description 27 2 High-Temp Cast Iron Mounted STL Ball Bearing 2-Bolt Flange Mount, for 3/4" Shaft Diameter 28 1 Right-Angle Speed Reducer Shaft Input, 30:1 Ratio, 1.33" Center, Left Output 29 Auxiliary Components Part Vendor Code/Part Number Lead Time McMasterCarr 6665K33 2 Weeks $ 112.72 $ 225.44 Speed reducer/ McMasterGear box Carr 5887K321 3 Days $ 357.87 $ 357.87 2 Steel Machinable-Bore Sprocket for #25 Bore sprockets McMasterChain, 1/4" Pitch, 30 Teeth, 3/8" min Bore for roller chain Carr 6793K19 In stock $ 10.35 $ 20.70 30 1 Standard ANSI Roller Chain #25, Single Strand, 1/4" Pitch, .13" Dia, 4ft length 31 1 32 Bearing Unit Price Total Price Chain McMasterCarr 6261K171 In stock $ 14.92 $ 14.92 Very HI-Temp Mineral Wool Insulation Wire Mesh One Side, 1" Thick, 24" X 48" Sheet Insulation McMasterCarr 9328K21 In stock $ 18.79 $ 18.79 10 Reusable SS Harsh-Environment Cable Tie 45" Length, bundle dia 12 1/2" Insulation holder McMasterCarr 1853T64 In stock $ 2.36 $ 23.60 33 1 Tape Made with Kapton® Polyimide High Temperature, 6" W, 5 Yards, .0025" Thk Electrical Insulator McMasterCarr 7648A718 In stock $ 57.94 $ 57.94 34 1 2 oz., highly conductive two part epoxy to 500°F Thermally Conductive Epoxies Omega OB-200-2 In stock $ 17.00 $ 17.00 35 1 Super-Quiet Low-Impact Electric Vibrator McMasterNonadjustable Force, 115 VAC, 1.4 Amps, Hopper vibrator Carr 25 lbs Force 5802K13 In stock $ 264.63 $ 264.63 36 8 High Load Plastic Compression Spring 250 in-lbs Energy Cap, 1.11" Overall Diameter 9677K12 In stock $ 8.14 $ 65.12 Springs McMasterCarr Auxiliary Sub-Total $ 1,066.01 Manufacturing Costs Manufacturing Cost Item # Quantity 37 1 38 39 Description Part Vendor Code/Part Number Lead Time Unit Price Total Price CNC Tank Base Brinkman Lab - 2 weeks $ 500.00 $ 500.00 1 Water jet Base Plate Brinkman Lab ` 1 week $ 50.00 $ 50.00 1 Water jet L-Brace Brinkman Lab ` 1 week $ 50.00 $ 50.00 Manufacturing Sub-Total $ 600.00 Budget Breakdown Budget Breakdown Project Budget $ 5,000.00 Metal Parts $ Electrical Parts $ 1,071.26 Auxilliary Parts $ 1,066.01 Machining Costs $ Total 681.25 600.00 $ 3,418.52 Remaining in Budget $ 1,581.48