Reebok - Boston College Personal Web Server

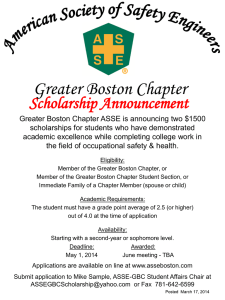

advertisement

The Impact of IT on Product Innovation Peter Burrows Sr. VP/ MIS and CIO September 27, 2005 September 27, 2005 Boston College 1 Reebok Background Multiple Brands Variety of Product Types - Footwear, apparel, fitness equipment, licensed watches, bottled water, etc - Department stores - Products may be merchandised as collections or assortments requiring coordinated delivery - Company-owned stores - Products may require special fixtures or collateral promotion material like posters, print ads, and store signage September 27, 2005 Multiple Retail Channels 2 - Sporting goods - Specialty retailers - Licensees - Wholly-owned, international Subsidiaries and distributors - Sales in 140 countries - Internet Boston College Reebok Financials 2004 Annual Sales = $4 billion An improving financial performance for the last five years: • Five consecutive years of earnings improvement. • Compounded annual growth rate of 23.4%. • Returned $226 million to shareholders in the form of dividends and share repurchases • We have generated $900 million of operating cash flow. • Our share price increased more than 400% and during the past year it outperformed the S&P 500 for the fifth consecutive year. • Cash position at December 31, 2004, $565 million • On August 3, 2005 Reebok agreed to be purchased by Adidas for $59 a share – a 34% premium. September 27, 2005 3 Boston College IT Governance IT Investment Committee Corporate Executive Management; establishes IT capital spending annually; meets once per year IT Steering Committee Brand Presidents and CFO’s/Shared Services, selects and monitors projects; meets monthly Global Process Executives Nominated owners of every key company process, referees changes to global process designs Project Steering Committee IT Project Manager F/T IT Team Members F/T Business Team Members September 27, 2005 Data Conversion Manager 4 Mandatory for any project Business Project Executive Project Knowledge Coordinator Integration Test Manager Change Management & Training Boston College Implementation Methodology of all Major Systems Investments Global One-Time Design First Usage Risk Aversion G First 1 Replication T • Any gaps to the G1T • Pilot or parallel if • Time boxed model surfaced to possible • Involve appropriate global process • Select brand or brands/countries executives location with best • Highest voice to • Only two outcomes: skills/greatest those that make – Improve model incentive to change money – Change practice • Don’t try to reach 100% consensus if process not needed for first usage September 27, 2005 5 G Second 1 Replication T • Gaps to G1T should be smaller • Project duration should be faster Boston College Example 1: Reebok Product Development • Reebok introduces thousands of new products as seasons or collections every year • To ensure a steady supply of new products we are working on 5-7 active seasons of products all at the same time • The average footwear product takes 18 months to engineer, commercialize and appear on retailer shelves, but quick to market products can move through the same process in less than 90 days. • Continuous improvement in materials present an ever increasing list of construction choices that must be tested and approved before being included in any product • Despite the availability of digital product representations of products, our industry requires physical product samples to test, approve and sell effectively • We out source almost all manufacturing so we must work collaboratively with a network of supply chain partners September 27, 2005 6 Boston College Product Development Re-Engineering Challenges • High volume process • No exact-fit, off-the-shelf software that can scale to global requirements • Geographically dispersed user base • Large percentage of users not Reebok employees • Desire to add more structure to current processes while reducing cycle times • Footwear product development different than apparel and equipment • No common workstation platforms due to nature of the work (PC’s, Mac’s, Unix workstations) • Employees want to work online/offline at the office and on the road September 27, 2005 7 Boston College One Example: Pump 2.0 • Pump 2.0 introduced in April of 2005 • The original pump technology Reebok introduced in the 1980's eventually sold more than 20 million pairs • Pump 2.0 needs no laces and inflates by itself September 27, 2005 8 Boston College Pump 2.0 Facts and Figures • The inflatable bladder and smart valve took over four years to develop and perfect in our Advanced Research department • 50 additional parts beside the bladder make up this shoe • The parts are made from 25 different materials that had to be tested and approved by labs located in China, Korea and Taiwan. • 15 different manufacturers supplied these materials from five different countries • Special tooling had to be created for manufacturing to support RF welding dies, cutting dies, midsole molds, outsole molds, flow molds, hot press molds and injection molds • Physical samples of this shoe had to manufactured for initial product review, prototype, confirmation meetings, retail and consumer feedback meetings, photoshoots, bulk sales samples for distribution to more than 30 countries, 3 rounds of fit and wear testing and final manufacturing confirmation • Hundreds of product wear testers had to be identified, provided product and then surveyed for results September 27, 2005 9 Boston College Product Development Technology THE PAST Current Environment Materials Group Marketing Factories Materials group Development • • • • • • • Sales Product Information Costing Costing Sales Islands of Information Redundant views of information Technology makes factory participation difficult Manual hand offs between groups Data integrity issues No visibility or control over process Increasing pace of market changes leading to employee stress September 27, 2005 Factories 10 Marketing Development • Increased investments in automating the product development process • Single database for all product information • Only one version of the truth • Internet based to allow factory participation • Workflow agents for electronic handoffs Boston College Key Attributes of Current Environment • Single product vault for all product information regardless of where the products are designed or what technologies are used to create them • Ability to view and comment on aspects of a product digitally, without the need to have specialized software that might have been used to create digital view • Every electronic device used in product development is connected to the network to support 100 % flow of information • Individual products can be grouped into categories, lines and seasons so the timelines can be managed as a collection that must be delivered to the market together September 27, 2005 11 Boston College Key Attributes of Current Environment • Electronic workflow to move all products through specific process gates defined for each product type • Web browser user interface • Digital product images are used in all reports and management dash boards • Collaboration with supply chain partners for 7/24 hour global engineering • Management alerts on products not hitting timelines or margin expectations September 27, 2005 12 Boston College Product Development Technology Portfolio Product Development Tools MAC-based Design Tools 2D & 3D CAD/CAM Tools PC-based Design Tools September 27, 2005 Tooling Design Software Pattern Engineering Software 13 Digital Cameras Electronic Last Design Software Wear Testing Software Material Testing Technologies QA Analysis Tools Color Matching Lab Dip Software Boston College Product Development Technology Portfolio Databases and Transaction Systems Product Development Tools Quality Analysis Database MAC-based Design Tools ERP for Supply Chain Management 2D & 3D CAD/CAM Tools PC-based Design Tools September 27, 2005 Product Vault “Single Vision of the Truth” Tooling Design Software Pattern Engineering Software 14 Digital Cameras Digital Asset Library Electronic Last Design Software Approval Materials Database Fit and Wear Test Databases Wear Testing Software Material Testing Technologies QA Analysis Tools Color Matching Lab Dip Software Boston College Product Development Technology Portfolio Communication and Collaboration Tools Databases and Transaction Systems Product Development Tools Secure E-Mail Quality Analysis Database MAC-based Design Tools Supplier Portal/E-Hub ERP for Supply Chain Management September 27, 2005 Product Vault “Single Vision of the Truth” 2D & 3D CAD/CAM Tools PC-based Design Tools Web Conferencing Secure File Transfer Servers Tooling Design Software Pattern Engineering Software 15 Digital Cameras Remote Visualization Tools Video Conferencing Digital Asset Library Electronic Last Design Software Approval Materials Database Fit and Wear Test Databases Wear Testing Software Material Testing Technologies QA Analysis Tools Color Matching Lab Dip Software Boston College Product Development Technology Portfolio Presentation Tools and Analysis Communication and Collaboration Tools Databases and Transaction Systems Product Development Tools Decision Support Information Warehouse Secure E-Mail Quality Analysis Database MAC-based Design Tools Supplier Portal/E-Hub Executive Dashboards Secure File Transfer Servers Web Conferencing ERP for Supply Chain Management Product Vault “Single Vision of the Truth” 2D & 3D CAD/CAM Tools PC-based Design Tools September 27, 2005 Line Planning tools Product Viewer Tooling Design Software Pattern Engineering Software 16 Digital Cameras Marketing and Sales Presentation Tools Custom Product catalogs Remote Visualization Tools Video Conferencing Digital Asset Library Electronic Last Design Software Approval Materials Database Fit and Wear Test Databases Wear Testing Software Material Testing Technologies QA Analysis Tools Color Matching Lab Dip Software Boston College Results So Far In the sixth inning of a nine inning game 15 Complete Seasons in footwear and apparel now managed Over 45,000 electronic files are stored in the product vault 24 reports and 35 line plan views are utilized daily by 64 different user profiles/roles 8 footwear and 9 apparel milestones are tracked as workflow gates September 27, 2005 17 Boston College Example 2: Supplier E-Hub - What is it ? Web enabled application that can be used to extend internal ERP and PLM systems to factories, transportation providers and other supply chain partners. Can facilitate: – Distribute PO’s electronically – Publish ticketing and labelling requirements – Track work in process – Obtain shipping services – Creation of advanced shipping notices – Exchange shipping documents September 27, 2005 18 Boston College Logistics Facts 40 Main Footwear Factories in 8 Countries 600 Apparel Factories in 29 Countries 450 Raw Material Suppliers 27 Freight Forwarders Transportation modes include Ship, Truck, Rail and Air 34 Custom Brokers Over 5,000 purchase orders placed each month September 27, 2005 19 Boston College Past Supply Chain Challenges Purchase Order Management Lack of complete purchase order visibility to trading partners (sales offices, factory, raw materials supplier, ticketing, consolidator, transportation, Distribution Center) to manage supply chain lead time & inventory Difficult to extend internal systems to link different supply chain parties. Difficult to accurately implement customer specific services (e.g. ASN, pre-ticketing, labeling, mark-for-store) Transportation Logistics Management Different carriers, different way to trace & track Non completeness of consignment check point Manual processes for smaller carriers, air and exceptions Last minute inventory management difficult September 27, 2005 20 Boston College the Old Way Country Liaison Offices Customs Factories Raw Material & & Component Suppliers Reebok HQ Transportation Providers Drop ship customers Reebok Trading Hong Kong Label Providers Banks Communication Methods: Fax, Mail, Couriers, site visits, EDI, proprietary file transfers September 27, 2005 21 Boston College the New Way Business-to-Business data sharing /Vendor Neutral E-Hub/ Hosted Environment (ASP model) Country/ Liaison Offices Factories Raw material & Component supplies Employees Custom-built e-HUB with LINE, a division of container port operator, Hutchinson- Whompoa in Hong Kong Reebok HQ Drop ship customers Reebok Trading Hong Kong Banks Label Providers Customs Transportation Providers Workflow, message alerts, backoffice integration with reporting capabilities September 27, 2005 22 Boston College Results So Far • Increased operational efficiency through electronic transmission of order information directly into the factory systems Improved data accuracy Reduced administration cost through data inheritance • Some factories now using same solution for raw material suppliers. • Neutral & common platform compared to having different system for each shipper/carrier • Purchase order history and version control logs benefit factories • Dashboard design with “To Do List”, “Overdue Tasks” and “Alerts” for each user level • Ability to print / re-print purchase orders on demand • Numerous pre-delivered reports to manage PO activity September 27, 2005 23 Boston College Example 3: Digital Asset Management WHAT IS IT? BENEFITS – A central repository for all digital assets capable of handling all of Reebok image types (video, products, lifestyle) - Cost reduction – Ability to push digital assets to a channel partners – A work flow system that enables a stream-lined process for creating and approving digital assets September 27, 2005 - Improved brand image - Enable better communication with distribution partners and customers requiring digital images - Allows the use of digital images in all executive dash boards 24 Boston College The Past . . . Product Development Centers E-Mail Manually Archive to CD US strain on network and mail servers Librarian Manually resize all images low, med, hi versions Print Catalogs Users requesting images September 27, 2005 25 Boston College Reebok’s New DAMS Process Diagram Lifestyle Marketing Materials Catalog Stage Prototypes Line Confirmations Product Development Centers Librarian FTP to Partners Hot Folder Product Images Footwear and Apparel Line Planning System Deployment Agent Push of Assets Product Data Access System Manual Process Reebok Websites Internal Folder Locations Global Users September 27, 2005 26 Boston College Results So Far Central Repository for all of Reebok’s digital assets. Reduction / elimination of redundant photo shoots Better control of copyrighted assets - automated expiration of assets Access to the correct and most current version of assets Store only the core asset; Render to needed format and resolution “on-the-fly”. Self-service model for image requests Reduction of CD creation costs Reduction of Shipping Costs Reduction of Product Catalog Printing Costs Instant fulfillment – reduced time-to-market September 27, 2005 27 Boston College Results So Far (cont.) Reduced network traffic: Automated upload of product assets via FTP and not E-mail View thumbnail and only download high resolution if desired Use of shortcut links in emails to reference images, instead of attaching image file Improved worker efficiency by providing a one stop location for product images and product data. Product data from Reebok’s Line Planning System automatically mated with appropriate asset Built in search tools Better control of access to assets through user groups and permissions. Browser based application accessible from any public Internet connection and does not require any client install. September 27, 2005 28 Boston College Central Repository for Reebok’s Assets September 27, 2005 29 Boston College Advice when using technology to improve product development: Obtain executive leadership at the highest possible level Balance top-down objectives for change with ample benefits for the people who work in the process Avoid long-duration, big-bang implementations Try to deliver some benefits every 3-6 months Initial focus on low hanging fruit to gather support and momentum If possible, defer most complex technology challenges until team has mastered the technology and gained confidence Retire Legacy modules along the way to increase compliance to new processes/simplify maintenance Do not accept software that is NOT a good fit Influence suppliers if you can/custom build if you cannot September 27, 2005 30 Boston College Advice when using technology to improve product development (continued): Fund full-time, business team members in project cost Pay close attention to systems technical architecture so it can scale and handle performance and allow secure collaboration outside of the firewall Adjust project calendar to recognize and accommodate seasonal product development calendars Use the project as an opportunity to clean up data Adhere in strong project methodology and focus attention on issues and off plan items. September 27, 2005 31 Boston College