Testing - Ohio University

advertisement

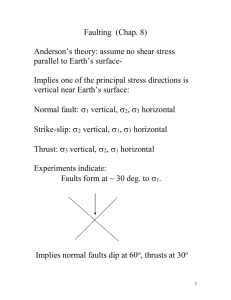

ECE 617 - Fault Testable Design Dr. Janusz Starzyk School of EECS Ohio University Athens, OH, 45701 http://www.arltesting.com/ Partially based on Prof. Vishwani D. Agrawal lecture VLSI Testing and book by S. Mourad, Y. Zorian, "Principles of Testing Electronic Systems” IC Testing Machine (IC81-0444-467) 3360-P VLSI Test System Definition of Testing Outline Reliability and testing Design Process Verification & testing Faults and their detection Fault coverage Types of tests Test applications Design for Test Test economics 0.18u VLSI silicon neurons http://www.ini.uzh.ch/node/21083 Reliability and Testing Reliability of electronics systems is no longer limited to military, aerospace or banking Used by almost everyone in the workplace Applied to smaller and smaller devices Have continually new failure modes Reliability depending on being error free Failures in both software and hardware Here we concentrate on hardware Test Objective The goal over time is to reduce the cost of manufacturing the product by reducing the per-part recurring costs: - reduction of silicon cost by increasing volume and yield, and by die size reduction (process shrinks or more efficient layout) - reduction of packaging cost by increasing volume, shifting to lower cost packages if possible (e.g., from ceramic to plastic), or reduction in package pin count Test Objective - reduction in cost of test by: - reducing the vector data size - reducing the tester sequencing complexity - reducing the cost of the tester - reducing test time - simplifying the test program A System on a Chip UDL RAM Interface Block (RT Level ) FPGA Controller (algorithm) UDL Micropro. (Layout) DSP (Netlist) RAM Verification and Testing Testing a circuit prior to fabrication is known as design verification Verification is certainly done at various stages of the design process Most viable design verification is through simulation Testing is identifying that the fabricated circuit is free from errors Need to specify what errors testing is looking for DFT Cycle Behavioural Descript ion Gate Behavioral DFT Synt hesis T echnology Mapping Layout RT L Description Libraries P aramet er Extraction Logic DFT Synt hesis Libraries Manufact uring Gate Descript ion P roduct T est P att ern Generat ion low Fault Coverage? T est Application high Good P roduct Test Programming Types of Logic Faults Types of Physical Faults Faults and their Detection Physical failures are manifested as electrical failures and are interpreted as faults on the logic level Several physical defects may be mapped into few fault types The main fault type is Stuck-at Fault A fault is detected by a test pattern Test pattern is an input combination that confirms the presence of the fault Possible Defects R L A Z B Z A R1 A R2 B A (a) Z Z (b) Two technologies, two physical defects map into the same stuck-at zero fault Notation used - A SA0, A@0, or A/0 Detecting Stuck-at Faults A Z B Inputs AB 00 01 10 11 Fill in the blanks in faulty response A/0 and A/1 FF Response 0 0 0 1 A/0 B/0 0 0 0 0 Faulty Response Z/0 A/1 0 0 0 0 B/1 0 0 1 1 Z/1 1 1 1 1 Detecting Stuck-at Faults A Z B Inputs AB 00 01 10 11 FF Response 0 0 0 1 A/0 0 0 0 0 B/0 0 0 0 0 Fault y Response Z/0 A/1 B/1 0 0 0 0 1 0 0 0 1 0 1 1 Z/1 1 1 1 1 Detecting Stuck-at Faults A Z B Inputs AB 00 01 10 11 Fault Free Response 0 0 0 1 A/0 0 0 0 0 Faulty Responses B/0 Z/0 A/1 B/1 0 0 0 0 0 0 1 0 0 0 0 1 0 0 1 1 Z/1 1 1 1 1 Sequential Circuit R 1 Q A S Inputs FF SR Response 0 0 1 0 01 00 10 11 2 Faulty Response A/0 S/0 R/0 A/1 S/1 R/1 0 1 1 0 0 0 0 0 X X 1 1 0 1 0 1 0 0 1 1 1 1 1 1 Types of Testing Types of Tests The exhaustive test used to detect the faults on a 2-input AND gate is not practical for circuits with 20 or more primary inputs Pseudo-exhaustive: exhaustive for components in the circuits segmentation or partitioning A random test is also viable to detect faults, but pseudo-exhaustive tests are more realistic for Stuck-at Faults Deterministic or fault oriented tests Functional Testing Exhaustive & pseudo-exhaustive testing : Partial dependence circuits: -a circuit in which primary outputs (PO) depend on all the primary inputs (PI) - each output tested using 2ni inputs (ni < n shows inputs affecting PO) Functional Testing Exhaustive & pseudo-exhaustive testing Example : Exhaustive test for each gate Functional Testing Exhaustive & pseudo-exhaustive testing Partitioning technique : the circuit is partitioned into segments such that each segment has small number of inputs each segment is tested exhaustively usually inputs & output of each segment are not PIs or POs so we need to control segment inputs using PIs and observe its outputs using PO - this lead to sensitizing partitioning Functional Testing Example : Consider the following circuit : Functional Testing Example: the following shows 8 input vectors to test exhaustively h. Functional Testing Example: Add vectors 5 - 8 to test exhaustively g and 9 -10 to test exhaustively y Functional Testing Example: Add missing combinations to vectors 4 and 9 to test exhaustively x Types of Testing Verification testing, characterization testing Verifies correctness of design and correctness of test procedure May require correction of either or both Manufacturing testing Factory testing of all manufactured chips for parametric and logic faults, and analog specifications Burn-in or stress testing Acceptance testing (incoming inspection) User (customer) tests purchased parts to ensure quality Verification Test Very expensive Applied to selected parts Used prior to production or manufacturing test May comprise: Scanning Electron Microscope tests Bright-Lite detection of defects Electron beam testing Artificial intelligence (expert system) methods Repeated functional tests Manufacturing Test Determines whether manufactured chip meets specification Must cover high % of modeled faults Must minimize test time (to control cost) No fault diagnosis Test at rated speed or at maximum speed guaranteed by supplier Burn-in or Stress Test Process: Subject chips to high temperature and over-voltage supply, while running production tests Catches infant mortality cases These are damaged or weak (low reliability) chips that will fail in the first few days of operation Burn-in causes bad devices to fail before they are shipped to customers Manufacturing Test Scenarios Wafer sort or probe test Done before wafer is scribed and cut into chips Test devices are checked with specific patterns to measure: • Gate threshold • Polysilicon field threshold • Poly sheet resistance, etc. Packaged device tests Types of Tests Parametric – measures electrical properties of pin electronics – delay, voltages, currents, etc. – fast and cheap Functional – used to cover very high % of modeled faults – test every transistor and wire in digital circuits – long and expensive http://www.ece.unm.edu/~jimp/vlsi/slides/c1_intro-8.gif Functional Test ATE and Manufacturing World – any vectors applied to cover high % of faults during manufacturing test Automatic Test-Pattern Generation World – testing with verification vectors, which determine whether hardware matches its specification – typically have low fault coverage (< 70 %) Levels of testing Levels Chip Board System • Boards put together • System-on-Chip (SoC) System in field Cost – Rule of 10 Mixed Signal VLSI Circuit It costs 10 times more to test a device as we move to higher levels in the product manufacturing process Levels of testing Other ways to define levels – these are important to develop correct “fault models” and “simulation models” Transistor Gate RTL Functional Behavioral Architecture Focus: Chip level testing – gate level design Typical Test Program 1. Probe test (wafer sort) Catches gross defects 2. Contact electrical test 3. Functional & layout-related test 4. DC parametric test 5. AC parametric test Unacceptable voltage/current/delay at pin Unacceptable device operation limits Rise/fall Time Tests Set-up and Hold Time Tests Propagation Delay Tests 1. Apply standard output pin load (RC or RL) 2. Apply input pulse with specific rise/fall 3. Measure propagation delay from input to output Delay between 5 ns and 40 ns (ok) Delay outside range (fails) On Line Testing Embedded checkers – error detection Periodic diagnostic programs Watchdog checkers Circuit Under Test N Encoded Output N N P Checker On- vs Off-Chip Testing High Bandwidt h High Bandwidt h Low Bandwidth Source/ sink External t est Off chip test Embedded t est Logic Logic RAM RAM Analog Analog External t est Embedded t est On chip test Test Specifications & Plan Test Specifications: Functional Characteristics Type of Device Under Test (DUT) Physical Constraints – package, pin numbers, etc. Environmental Characteristics – power supply, temperature, humidity, etc. Reliability – acceptance quality level (defects/million), failure rate, etc. Test plan generated from specifications Type of test equipment to use Types of tests Fault coverage requirement Test Data Analysis Uses of ATE test data: Reject bad DUTs Fabrication process information Design weakness information Devices that did not fail are good only if tests covered 100% of faults Failure mode analysis (FMA): Diagnose reasons for device failure, and find design and process weaknesses Improve logic and layout design rules Cost of Testing Testers cost over $1 000 000 VLSI Test System TS600 Cost of Testing Design for testability (DFT) Chip area overhead and yield reduction Performance overhead Software processes of test Test generation and fault simulation Test programming and debugging Manufacturing test Automatic test equipment (ATE) capital cost Test center operational cost Cost of Manufacturing Testing Example test cost: 0.5-1.0GHz, analog instruments,1024 digital pins: ATE purchase price = $4.272M Running cost (five-year linear depreciation) = Depreciation + Maintenance + Operation = $0.854M + $0.085M + $0.5M = $1.439M/year Test cost (24 hour ATE operation) = $1.439M/(365 x 24 x 3,600) = 4.5 cents/second Good Bad PCB for 16 channel pin card for IC tester henning-eng.com/pcb800.htm Time to Market Revenues Test Economics Loss of Revenues Time to Market T Time in Months The life cycle of a product is shorter than its design cycle Time to market needs to be shorten Testing is necessary for reliability and for improving yield VLSI Defects Good chips Faulty chips Smaller dies Wafer yield = 78/88 = 0.88 Defects Wafer Unclustered defects Wafer yield = 12/22 = 0.55 Clustered defects (VLSI) Wafer yield = 17/22 = 0.77 Yield and Defect Level Defect Level % DPM 10000 1 5000 0.1 Y=50% Y=90% 1000 500 0.01 100 50 0.001 10 .01 99.99 0.1 99.9 1 99 10 TT% 90 C% Yield Test transparency Fault coverage > Multi-site Testing One ATE tests several (usually identical) devices at the same time Both probe and package test DUT interface board has > 1 sockets Usually tests 2 or 4 DUTS at a time Usually test 32 or 64 memory chips at a time Limits: # instruments available in ATE, type of handling equipment available for package Example VLSI Test Systems Advantest T3347B Low-cost Parallel Testing of Four High-end MCU and Testing of Large ASIC 40 MHZ testing speed. Accommodates up to 512 I/O pins. Simultaneous testing of up to four devices per station. ADVANTEST Model T6682 ATE T6682 ATE Block Diagram T6682 ATE Specifications Uses 0.35 mm VLSI chips in implementation 1024 pin channels Speed: 250, 500, or 1000 MHz Timing accuracy: +/- 200 ps Drive voltage: -2.5 to 6 V Clock/strobe accuracy: +/- 870 ps Clock settling resolution: 31.25 ps Pattern multiplexing: write 2 patterns in one ATE cycle Pin multiplexing: use 2 pins to control 1 DUT pin T6682 Pattern Generation Sequential pattern generator (SQPG): stores 16 M vectors of patterns to apply to DUT, vector width determined by # DUT pins Algorithmic pattern generator (ALPG): 32 independent address bits, 36 data bits Scan pattern generator (SCPG) supports JTAG boundary scan, greatly reduces test vector memory for full-scan testing T6682 Test Data Analysis Uses of ATE test data: Reject bad DUTS Fabrication process information Design weakness information Devices that did not fail are good only if tests covered 100% of faults Failure mode analysis (FMA) Diagnoses reasons for device failure Finds design and process weaknesses Allows improvement of logic & layout design rules T6682 Probe Card Probe card – custom printed circuit board (PCB) on which DUT is mounted in socket may contain custom measurement hardware Probe needles come down and scratch the pads to stimulate/read pins Membrane probe – for unpackaged wafers contacts printed on flexible membrane, pulled down onto wafer with compressed air LTX FUSION HF ATE Specifications Intended for SOC test digital, analog, and memory test supports scan-based test Modular can be upgraded with additional instruments enVision Operating System maximum 64 M vectors memory storage 1 or 2 test heads per tester, maximum of 1024 digital pins, 1 GHz maximum test rate Analog instruments: DSP-based synthesizers, digitizers, time measurement, power test, radio frequency source and measurement capability (up to 4.3 GHz) ADVANTEST Model T2000 ATE Scalable Architecture Microsoft Windows 2000 C++(Microsoft Visual Studio Professional) OTPL(Open Architecture Test System Programming Language) Re-configurable Program Structure for test data and algorithm T2000 System Software Emulator Wave Tool (Logic Analyzer, Oscilloscope). ADVANTEST T6577 Tests SoC/Mixed-Signal Devices Supports for a maximum of 1024 logic and/or I/O channels. Performs parallel test of up to 32 devices Supports baseband, DVD read channel, and jitter test At-speed test of high-speed memory interfaces Test rates of up to 667 Mbps maximum of eight channels