Developing a blueprint

for an energy efficiency

asset class

Lessons from institutional

entrepreneurship

WHITE PAPER

Miriam Fischlein, Cindy McComas, Timothy M.

Smith

Informing an Emerging Energy Efficiency Asset Class

Institutional entrepreneurship for developing an energy efficiency asset class

Abstract

With energy efficiency investments, initial investments are recouped over time by means of

accumulated savings from reduced energy use. Financial actors require verification and assurance

to make loans based on such future energy savings, and no firm rules exist to provide this.

Although the finance sector is showing increasing interest in energy efficiency, it remains on the

fence, because energy efficiency investments are perceived as an unknown and risky entity.

Energy efficiency projects often provide excellent returns on investment and many projects use

proven technology, but there is little experience among financial actors with this type of project

financing. Lack of access to financing poses a substantial hurdle for energy efficiency projects in

industry.

The persistent gap between economically justifiable and actual implemented energy efficiency

investments has puzzled researchers and practitioners for over four decades. Economists have

characterized this gap as market failure, while behaviorists believe it is caused by individual,

interpersonal, organizational, or cultural factors. Accordingly, they have focused on the degree to

which market and behavioral factors lead to less than optimal outcomes and where policy

intervention might correct for them. This study takes a different approach, aiming to understand

the interaction between organizational structures and their environments in perpetuating the

energy efficiency gap. Developing new rules for a widely accepted asset class for energy efficiency

may contribute to closing the energy efficiency gap. The study employs the institutional

entrepreneurship framework to identify potentially influential change agents for creating an

energy efficiency asset class. It also draws on prior examples of successful asset class

development to map out a blueprint for establishing an energy efficiency asset class.

The authors would like to acknowledge the following persons who have made contributions to this project:

Suvrat Dhanorkar, CSOM Graduate Student; Rolf Nordstrom and Lola Schoenrich, Great Plains Institute;

Danny Zouber, NorthSky Capital; Alfie Marcus, CSOM; Skip Laitner, ACEEE; and representatives from Trane

Company, Ingersoll Rand, and Egan Company.

© 2011 Green Patents and Platforms for Collaboration. All rights reserved. No portion of this paper may be

reproduced without permission of the authors. White papers are research materials circulated by their

authors for purposes of information and discussion. They have not necessarily undergone formal peer

review and may be submitted for publication.

1

Introduction

Concerns about the environmental impact of energy use and the security of future energy

supplies continue to mount, putting energy efficiency once again back in the spotlight. Energy

efficiency investments are a no or low cost solution to these issues; particularly in the industrial

sector, many energy efficiency projects carry the promise of substantial financial returns (UNEP,

2009). Even now, financial programs to increase adoption of industrial energy efficiency practices

are numerous. Most of these efforts are government funded or run by utilities in the context of

demand side management. Yet these tools have not provided sufficient incentive for companies

to take action on energy efficiency investments at a seemingly justifiable scale. It is estimated that

energy use can vary by a factor of 2 to 3 between the most and least energy efficient firms in a

sector (De Beer, 2000) and that the average firm implements less than two thirds of

recommended and economic projects (Anderson and Newell, 2004; DeWahl, 2010). Although $43

billion was spent on energy efficiency improvements in the United States alone in 2004,

amounting to 1.7 quads of energy savings (Ehrhardt-Martinez and Laitner, 2008), the market

potential is much larger according to analysts. Energy cost savings could amount to $900 billion by

the year 2020, with investment opportunities on the order of $170 billion annually (Farrell and

Remes, 2008).

To achieve this investment potential, utility and government-driven programs alone will not

suffice. As part of the increased focus on energy efficiency, policymakers are evaluating the role

of private sector companies in delivering cost effective energy savings to end users (Satchwell et

al., 2010). Energy service companies (ESCO) are devising innovative methods to deliver complete

packages for technology delivery and financing to industrial companies. Financial institutions in

search of new markets and new technologies to invest in are exploring financial tools that meet

the needs of businesses of all types. New instruments are beginning to emerge that might address

the shortcomings of existing programs by targeting more directly the motivations of industry to

implement energy efficiency. Finally, technology vendors are seeking markets and customers to

sell new, more energy efficient technologies to in the residential, commercial, and industrial

sectors. Many equipment vendors are financing projects through their own organizations or by

partnering with third parties.

The present study aims to illuminate the activities of these private actors and their potential role

in developing a new asset class for energy efficiency. In doing so, it offers a novel approach to

bridging the energy efficiency gap. For over four decades, researchers and practitioners have

been puzzled by the gap between economically justifiable and actual implemented energy

efficiency investments. Economists have characterized this gap as market failure, while

behaviorists believe it is caused by individual, interpersonal, organizational, or cultural factors.

Accordingly, they have focused on the degree to which market and behavioral factors lead to less

than optimal outcomes and where policy intervention might correct for them. This study takes a

2

different approach, aiming to understand the interaction between organizational structures and

their environments in perpetuating the energy efficiency gap.

Establishing a separate asset class for energy efficiency may contribute to narrowing the energy

efficiency gap, because it would develop new inter-organizational routines. We draw upon the

institutional entrepreneurship literature which indicates that change agents may be able to

influence a company to take steps toward energy efficiency by creating new rules and routines. In

this sense, we can describe the energy efficiency gap as the result of a structured organizational

environment creating barriers to the adoption of industrial energy efficient technologies and

practices. Structures and norms within organizations are fairly stable and difficult to change via

financial incentives, demonstrated by the relatively slow utilization of government or utility

incentive programs for energy efficiency. It may take active (re)engineering of organizational

environments, norms, and institutions to attain a new equilibrium where energy efficiency

investments become a standard business activity. We draw on lessons from the development of

other asset classes to lay out a pathway for energy efficiency investments.

Industrial energy efficiency: current state and potential

In this study, we focus on industry, the most energy-consumptive of all sectors. It produces a large

amount of climate-forcing gases and other environmental pollution. In 2009, energy use in the

United States was 94.79 quadrillion Btu and fell into four broad sectors (EIA, 2011d): industrial

(30%), transportation (29%), residential (22%), and commercial (19. Just as in the United States,

industry consumption dominates energy use in the world’s largest economies (Table 1).

Electricity consumption

(1,000 GWh)

All sectors

2,842

Industry

1,926

Germany

526

India

Japan

China

USA

Total energy consumption

(1,000 tons oil equ.)

68%

All sectors

1,371

Industry

655

48%

242

46%

236

55

23%

602

279

46%

408

115

28%

964

304

32%

319

87

27%

3,814

915

24%

1,542

295

19%

Table 1. Industrial energy and electricity consumption 2008, selected countries. Note: tTe discrepancy in

the size of the industrial sector results from difference between the IEA and the US classification system.

Source: IEA (2011)

3

The potential for energy in this sector is especially large, not only due to its size. Energy efficiency

projects in industry are often big and offer more bang for the buck, due to scale effects and the

point-source nature of industrial pollution. Energy efficiency improvements also seem to be

associated with productivity increases (Worrell et al., 2003). The industrial sector is theworld’s

largest energy consumer, using about 37% of delivered energy worldwide (Abdelaziz et al.,

2011).The proportion of industrial energy use in OECD countries is roughly half that of non-OECD

countries, explained by both structural differences in the relative importance of industry and

service sectors, and differences in technology (EIA, 2010). Industrial energy-use in non-OECD

countries is growing much faster, too (Abdelaziz et al., 2011). Among the world’s largest

economies, the industrial sector is particularly dominant in China, where industry demand

accounts for more than two thirds of electric energy consumption and close to half of all energy

consumption.

As the leading user of energy across the world, the industrial sector appears to be a prime target

for increasing energy efficiency. In the United States, older estimates for achievable energy

savings potential in the industrial sector average slightly more than 14% (Nadel et al., 2004). More

recently, several regional studies have cited an energy savings potential of up to 25% in the

industrial sector by 2025 (reviewed in Chittum et al., 2009). Certain areas of activity and certain

end uses show particularly high savings potential. A handful of sectors dominate both electricity

and total energy use, notably petroleum and coal extraction and refining, chemicals, paper, and

metals (Table 2). While energy efficiency investments may offer the greatest returns in these

areas, opportunities exist even in the less energy intensive sectors. For many industrial products,

energy use per ton output can vary by a factor of 2 to 3 across different facilities (De Beer, 2000),

indicating potential areas of improvement.

With regard to energy consumption by end use, the largest potential for savings exists in core

production processes. On average, these processes take up close to 60% of an industrial facilities’

energy consumption, compared to lighting and HVAC at 10%, and boiler fuel at 30% (Table 2).

Companies can realize 25-30% energy and cost savings by making improvements to core industrial

processes such as compressed air, steam, process heat, motors, pumps, and fan systems, as well

as recovery of waste heat (DeWahl, 2010).

Since the mid-1990s, industrial energy consumption has been on a downwards trend both in

absolute and relative terms, whereas energy use has continued to rise in the commercial,

residential and transportation sectors (EIA, 2011c). Relative declines in industrial energy use can

be attributed to a structural shift in economic output from industry to services. However,

industrial energy use has also decreased in absolute terms, while industrial output has continued

to grow. The on-going reductions in energy intensity for the U.S. industrial sector point to an

increasing interest in energy efficiency over the past two decades.

4

END USE

INDUSTRY SECTOR

Electricity Use

All Energy Use

Petroleum and Coal

137

6,864

Chemicals

517

5,149

Paper

247

2,354

Primary Metals

458

1,736

Food

251

1,186

Nonmetallic Minerals

147

1,114

Transportation

195

477

Wood Products

91

451

Fabricated Metal

143

396

Plastics and Rubber

182

337

Machinery

111

204

Textile Mills

66

178

Computer/Electronics

94

142

Beverage/Tobacco

30

107

Electrical

44

103

Printing

45

85

Textiles

20

72

Miscellaneous

33

66

Furniture

32

61

Apparel

7

14

Leather

1

3

84

2,830

Process Heating

379

2,942

Process Cooling and

Refrigeration

Machine Drive

226

33

1,731

213

255

-

48

163

Facility HVAC (g)

285

393

Facility Lighting

215

-

Other Non-Process Use

82

130

End Use Not Reported

29

278

Boiler Fuel

Electro-Chemical Processes

Other Process Use

Table 2. Energy and electricity use in MMBtu by US industrial sectors and end uses, 2006. Source: EIA

(2011a)

5

Nevertheless, a gap persists between theoretically economic investments in energy efficiency and

those actually undertaken. Despite high rates of return to be gained, firms seem to underinvest in

energy efficiency (DeCanio, 1993). Experience has shown that companies participating in energy

efficiency incentive programs realize only a third to half of all recommended projects (Anderson

and Newell, 2004; DeWahl, 2010). Discount rates for energy efficiency are orders of magnitude

higher than typical interest rates on business loans (Sanstad et al., 1995).

Investments in the energy efficiency sector remain moderate at this point in time, although the

pace of growth is crisp. Worldwide venture capital and private equity investments in the energy

efficient technology sector reached $2.1 billion in 2009, a 4% growth rate over the previous year

(UNEP, 2010). The same year, R&D spending on energy-efficient technologies reached $ 16.8

billion (UNEP, 2010). Following the 2008 financial crisis, a proportion of stimulus funds across the

world aimed at jumpstarting the green economy. 30% of these green stimulus funds went

towards energy efficiency, for a total of $56 billion (UNEP, 2010). Overall, McKinsey and Company

estimate the global investment potential for energy efficiency at $170 billion annually through

2020 with average annual returns of 17 percent (Farrell et al., 2008). Overall, energy efficiency

investments appear to be on the upswing, but have not unfolded their full potential.

Understanding the energy efficiency gap: theoretical underpinnings

For over four decades, researchers and practitioners have been puzzled by the gap between

economically justifiable and actual implemented energy efficiency investments. Economists have

characterized this gap as market failure, while behaviorists believe it is caused by individual,

interpersonal, organizational, or cultural factors. Accordingly, they have focused on the degree to

which market and behavioral factors lead to less than optimal outcomes and where policy

intervention might correct for them. Energy efficiency programs have targeted market failures

and behavioral factors within companies. This study takes a different approach: it suggests that

the energy efficiency gap is rooted in deep institutional structures that can only be overcome by

creating new rules of the game. In this section we review explanations for the energy efficiency

gap and propose to employ lessons from institutional entrepreneurship to overcome it.

Explaining the energy efficiency gap

Market failure is the most prominent diagnosis of the energy efficiency gap. Market imperfections

include public good attributes of information, high transaction costs, and information

asymmetries, as well as uncertainty about future energy prices, technical and political

developments (Jaffe and Stavins, 1994; Golove and Eto, 1996; DeCanio and Watkins, 1998;

6

Gillingham et al., 2009). Uncertainty is a major factor in explaining the energy efficiency gap.

Compared to the residential and commercial sectors, industry is more heterogeneous,

complicating the implementation of energy efficiency programs (Chittum et al., 2009). Realizing

energy efficiency in an industrial setting brings a degree of uncertainty and change to the

organization. These uncertainties can be related to new equipment, needed training, impacts on

product quality, lack of technical expertise, lack of long-term strategic thinking, and meeting

customer needs.

Asymmetric information can also hamper energy efficiency where there is an inability to quantify

the certainty of operating cost savings. In this case, the likelihood to repay a loan from energy

savings cannot be calculated, making it unlikely to be granted (Golove and Eto, 1996). In a similar

fashion, the buyers of new equipment cannot verify the actual energy savings, but must trust the

manufacturer’s assurances. Where the energy efficiency gap is diagnosed in orthodox fashion as

market failure, external information provision and policy intervention are often proposed as the

best strategies for prompting firms to bridge the gap (Sexton and Sexton; Seligman and Darley,

1977; Anderson and Newell, 2004; Matsukawa, 2004).

Purveying additional external information is a powerful approach, but it is also problematic,

because it is aimed at rational decision makers. A number of scholars have argued that the energy

efficiency gap is not (solely) due to market failure, but is also caused by institutional and

behavioral barriers. Accordingly, they propose to change behavioral biases and organizational

barriers through tools like risk management or decision support (Busenitz and Barney, 1997; Mills

and Knoepfel, 1997; Mills, 2003b). With regard to financial aspects of energy efficiency

investments, several such organizational barriers exist.

In most firms, there is an institutional separation between capital and operating budgets

(Gillingham et al., 2009). Therefore, incentives for investing in energy efficiency are split. There is

also an opportunity cost of investing in energy efficiency over other capital improvements (Jaffe

and Stavins, 1994). Energy management generally has a low status and does not figure high on

the priority list of managers concerned more with product specific improvements (DeCanio, 1993;

Rohdin and Thollander, 2006; Thollander et al., 2007). Another decision bias disadvantaging

energy efficiency investments is that managers tend to show higher sensitivity to up-front

investment costs than on-going operating costs (Hassett and Metcalf, 1993; Jaffe and Stavins,

1994; Anderson and Newell, 2004).

Managers also use a variety of shortcuts and decision rules when making investment decision;

these do not always favor energy efficiency investments. Busenitz and Barney (1997) have

demonstrated that under conditions of uncertainty and limited information, managers do not

follow a rational decision making model, but instead rely on biases and heuristics. Energy cost as a

share of operating costs is one such heuristic that seems to influence managers’ decisions on

investing in energy efficiency (Elliott and Pye, 1998). Energy costs account for roughly 2% of

7

operating costs for the entire manufacturing sector, but they can reach up to 20% for aluminum,

hydraulic cement, and industrial gases, or be as low as 1.2% for electronics and 0.6% for the

computer industry (Elliott and Pye, 1998). As a rule of thumb, the proportion of energy costs to

overall operating costs seems to be roughly equal to the share of capital investment going

towards energy efficiency (de Groot et al., 2001). This does not reflect the real importance of

energy costs, which, although a “minor component of a facility owner’s operating costs [are] a

major source of budget risk” (Jackson, 2010). They are difficult to predict and can fluctuate

widely, meaning that controlling energy costs should attract greater attention. Nevertheless,

managers seem to be more prone to use proportion of cost as an investment rule than relative

risk.

One more decision bias working against energy efficiency investments is firms’ focus on payback

period. Most firms prioritize payback time over discount rate in investment decisions. In order to

be implemented, energy efficiency projects have been shown to require at least a 12% return rate

or a payback period of less than 2 years (DeCanio, 1993). The problem with this decision bias is

that the payback rule of thumb “cannot distinguish between shorter or longer lived investments

nor […] between investments that are intrinsically more risky because of weather impacts or

other factors that vary across investment options” (Jackson, 2010), meaning that the payback

period applied has to be conservative to eliminate risky options. The short payback times

required for energy efficiency are at least partially caused by management compensation rules,

which are often tied to short-term performance and discourage longer term investments

(DeCanio, 1993; Bunse et al., 2010). In addition, it is thought that energy efficiency investments

encounter these higher ‘hurdle rates,’ because their uncertain and irreversible nature results in a

high option value (Hassett and Metcalf, 1993). However, Sanstad, Blumstein and Stoft (1995) note

that for energy efficiency investments, the “consumer must decide whether to include energy

saving attributes as part of a purchase that is being made primarily for other purposes.”

Consequently, they point out that option value alone does not adequately explain the high

discount rates for these types of projects. The term ‘energy efficiency gap’ indeed implies that

managers employ higher than economically rational discount rates (Jaffe and Stavins, 1994), as

they should invest in all projects with a positive net present value (DeCanio and Watkins, 1998).

Overall, it seems that commonly implemented energy efficiency programs aimed at providing

additional information may not adequately address the organizational barriers towards energy

efficiency investments. Energy efficiency investment decisions are inherently complex, because

they often involve multifaceted process changes and estimated returns are uncertain. If energy

efficiency investment is to grow successfully, its perception needs to be reshaped. Managers will

need to move away from seeing it as a low-priority, uncertain investment, to perceiving it as a

high value added, front of the line investment. Policy intervention may not be the only pathway

toward achieving this goal, but the private sector also has an important role to play. Not only are

firms increasingly putting into place methods to track energy use and assess efficiency

8

investments, but there is also nascent pressure from the insurance and banking industry to take

into account environmental and energy risk in investment decisions. Leveraging influential actors

outside of institutions and their power to reshape existing routines for energy efficiency

investment may represent a novel way to address the energy efficiency gap.

Overcoming the energy efficiency gap through institutional entrepreneurship

The present study proposes to look to institutional entrepreneurship theory to identify both key

actors and key actions to build new institutions favoring energy efficiency investments.

Institutional entrepreneurship refers to the “activities of actors who have an interest in particular

institutional arrangements and who leverage resources to create new institutions or to transform

existing ones” (Maguire et al., 2004). While institutionalist theory has traditionally emphasized

structure over agency, institutional entrepreneurship reestablishes agency as an important

element. In this theory, agency accounts for intentional action by individuals aimed at creating

and shaping institutions (Garud et al., 2007).

The development of this institutionalist sub-theory goes back to DiMaggio (1991) who attributes

the rise of new institutions to the actions of resourceful and organized agents who “see in them

an opportunity to realize interests that they value highly.” Institutional entrepreneurship

therefore highlights the tension between the forces of conformity and path dependency

emanating from existing institutional structures and the “entrepreneurial forces that bring about

change” (Garud et al., 2007) in these same institutions. Path dependency is understood here as

the institutional and technical lock-in caused by prior decisions and institutional design.

Institutional entrepreneurship is anchored in neo-institutionalism, which emphasizes that

institutions and formal organizations are shaped more strongly by environmental pressures and

cultural belief systems, and less by internal, rational processes. Neo-instutionalists argue that

institutions first and foremost strive for survival and legitimacy, not for efficiency. In accordance

with Barnett (2006) and others (Suchman, 1995; Fombrun, 1996; Ruef and Scott, 1998) legitimacy

can be described as an important signal of social acceptability that is subjectively bestowed upon

an organization by societal constituents (Deephouse and Carter, 2005; Thomas, 2007). In the neoinstitutionalist view, institutions are the “rules of the game” (North, 1990). They can be

understood as “humanly devised schemes, norms, and regulations that enable and constrain the

behavior of social actors and make social life predictable and meaningful” (Hargrave and Van de

Ven, 2006). Formal or informal, their primary purpose is to reduce uncertainty, by defining rules

and structuring environments. They are stable social structures created through repeated

interaction; constantly recreated and sustained over time through socialization (Scott, 2001).

While stability can be positive, these social structures also discourage beneficial changes.

9

In fact, institutionalists argue that institutional pressure does not necessarily result in efficiency,

because information is incomplete, actors have cognitive limits and institutions are often not

concerned with outcomes, but with processes. This cognitive turn in neo-institutionalism accounts

for intrinsic restraints in action (Scott, 2001). For instance, sometimes actors may not be able to

conceive of any different way to act. This view portends that taken for granted scripts play an

important role in structuring action. Generally, when uncertainty is high, the number of players is

low or information is scarce, players look to institutions to orient their behavior (North, 1990).

Therefore, the notion of institutions suggests inherent stability. By shaping the rules of the game,

institutions create path dependencies; they are slow to change. Based on the institutionalist

approach, it is conceivable that there exist stable patterns and routines applied to energy

efficiency investment decisions. The institutional practices of energy efficiency investment exist

both inside and outside the firm. The persistent energy efficiency gap indicates that they are

highly stable.

Nevertheless, organizations do change, and institutional entrepreneurship provides a window into

how this happens despite and because of institutional forces. Among theories of institutional

change, institutional entrepreneurship stands out as an approach that emphasizes agency and

interests over structure. Other approaches to explaining institutional change focus on common

stages and dynamics in the development of institutions (life-cycle models) or external changes

and their interaction with internal organizational factors to create change (evolutionary models).

While insightful, neither of these approaches leave much room for intentional shaping of

institutions. The study of institutional entrepreneurship fills these gaps by emphasizing elements

such as the importance of actors engaging in framing, the creation of shared understanding and

beliefs, and resource mobilization. It may give some guidance on how to shape new financial

instruments that can overcome existing energy efficiency investment practice that are locked in at

a modest level.

As Aldrich & Ruef (2006) have pointed out, in new populations, “mimetic isomorphism – copying

the most common or highly valued structure in the population […] is not an option”, because

what is legitimate is still undefined. Entrepreneurship research has shown that legitimacy is an

important factor in new venture success, since it facilitates the acquisition of other resources

(Delmar and Shane, 2004). Against this backdrop, institutional entrepreneurship attempts to

create new rules of the game, while attempting to legitimize them. Framing processes play an

important role in legitimizing new institutional rules. McAdam et al. (1996) understand them as

“conscious strategic efforts by groups of people to fashion shared understandings of the world

and of themselves that legitimate and motivate collective action.” Therefore, framing constitutes

an active shaping of commonly shared meanings. Framing puts the spotlight on the importance of

shared beliefs, ideas, and values, but also new ideas. Framing often means that actors refer to

existing ideas or institutions. In the sustainability arena, supporters of novel environmental

practices have often taken that route. Brown et al (2009) study the emergence of the Global

10

Reporting Initiative (GRI) as the preeminent corporate sustainability reporting tool and as an

“established norm of behaviour of socially responsible businesses.” They find that despite the

comparative powerlessness and limited resources of GRI’s backers, they were able to balance

diverse interests and create a new institution without putting in question existing ones. Arguably,

modeling environmental reporting on financial reporting helped to advance environmental

reporting in the case of the Global Reporting Initiative (Etzion and Ferraro, 2010).

Besides framing, resource mobilization seems to be central to successful institutional

entrepreneurship. Dorado (2005) theorizes that interested actors mobilize resources through

both planned activities of resource mobilization and collective action and the fortuitous

convergence of events. Actors mobilizing resources to establish new institutional practices are

often called change agents. Institutional entrepreneurship approaches have been used in

different contexts to describe and illuminate institutional change processes and the role of

change agents. A number of studies in the healthcare industry examine how institutions emerge

around technological innovations or how encrusted systems react when challenged by new

conditions. Maguire (2004) analyzed how advocate networks for AIDS patients have successfully

changed not only FDA permitting systems for new medications, but also challenged preconceived

notions about which research and patient care strategies are ‘right’ and ‘wrong’. Van de Ven and

Garud (1993) have looked at the development of the cochlear implant industry. They show that

institutionalization is a process that occurs over long time frames and involves multiple actors,

who both cooperate and compete. They also point to the fact that ‘institutional arrangements

and resource endowments’ that may be functional at the outset can hinder innovation in later

stages.

These and other studies offer insights into the important role of resourceful actors in proposing

and establishing legitimate new routines. Based on the insights gained from institutional

entrepreneurship into the importance of change agents and framing processes, the following

sections present an overview of actors influencing energy efficiency investments and review the

development of other asset classes to propose some pathways towards an energy efficiency asset

class.

11

Actors influencing energy efficiency investments

Prior research frames the energy efficiency gap either as market failure to be addressed by policy

intervention, or as behavioral bias at the firm level. Little attention has been paid to institutional

and stakeholder pressure’s role in shaping the decision context for energy efficiency investments

at the firm level. Accordingly, initial activity in this area was driven by governmental actors,

followed by utility programs. More recently, other private actors, such as insurance companies,

private investors, banks, and energy service companies have gained importance. Energy efficiency

programs offered by governments and utilities are important, but the efficiency gap continues to

persist. New instruments are now beginning to emerge that might address the shortcomings of

the existing programs by targeting more directly the motivations of industry to implement energy

efficiency. The private, non-utility sector plays an increasingly important role in driving energy

efficiency investments. The present section gives a brief overview of the role of each of these

actors in driving industrial energy efficiency.

Governments

Governmental actors have long taken an

active role in supporting increasing energy

efficiency through financial instruments.

Governments are ramping up energy

efficiency activities at all levels: federal,

state, and local.

The National Energy Policy Act of 2007

aims to reduce energy intensity by 2.5%

per year each year between 2007 and

2017. In the wake of the recession, there

has been a significant increase in federal

funding for energy efficiency programs

through the American Recovery and

Reinvestment Act (ARRA). The federal

government grants a variety of corporate

tax credits for commercial buildings,

industrial energy investments, and energy

efficiency compliance manufacturing. It

also runs market transformation programs

like Green Lights and Energy Star. Federal

Box 1. Property Assessed Clean Energy

Based on the historic model of issuing

municipal bonds to fund public projects, the

PACE financing structure enables local

governments to raise money through the

issuance of bonds or other sources of capital

to fund energy efficiency and renewable

energy projects. Property owners benefiting

from the improvement repay the bond

through property assessments. PACE allows

a property owner to install improvements

without a large up-front cash payment. The

debt is repaid over a set number of years for

those property owners who choose to

attach the cost of the energy improvement

to their property tax bill. The financing is

secured with a lien on the property and in

the event of foreclosure; the energy

financier is paid before other claims against

the property. PACE allows for the

repayment obligation to transfer

automatically to the next property owner if

the property is sold. While innovative, PACE

has recently been classified as a higher risk

program by Fannie Mae and FHFA due to

the decline in the housing markets.

Source: DOE (2011)

loan programs for energy efficiency

12

include Qualified Energy Conservation Bonds and a loan guarantee program by the Department of

Energy. The federal government also facilitates financing with initiatives like the Better Buildings

Challenge, which brings together six financial firms and numerous customers. It aims to increase

the energy efficiency of commercial buildings by 20%. Additionally, the federal government aims

to transform markets as a first mover and early adopter of energy saving technologies.

Consequently, many federal programs require retrofitting of federal buildings or set certain

efficiency standards for new building and equipment. Energy Savings Performance Contracting is a

tool widely used in federal and MUSH (municipalities, universities, schools and hospitals) settings.

Here, the value of the energy efficiency investments is “not the equipment cost, but the creation

of ongoing savings over time” (Christmas, 2011). This model used in the public sector could

potentially be replicated in the commercial and industrial markets, if loan guarantees by the

government and performance guarantees by the contractor were to be combined.

State level activities include the establishment in 24 states of statewide energy savings goals to be

obtained from adoption of an Energy Efficiency Resource Standard (EERS), legislative or state

regulatory directives to obtain all cost effective demand side resources (Barbose et al., 2009). For

example, in Minnesota, the Next Generation Energy Act of 2007 sets a goal for all utilities to

achieve an energy savings goal of 1.5% of gross annual retail energy sales Other state

government-run programs mostly provide passive incentives for energy efficiency, offering tax

rebates and loans to businesses and individuals. Direct loans and loan guarantees are the most

popular types of programs used by US states, followed by rebates on personal, corporate, sales

and property tax (DSIRE, 2009). Local and state governments are also turning to financial markets

to finance energy efficiency loan programs by issuing bonds (see Box 1).

While important and widely used, these financial tools require that an organization is already

interested in investing in energy efficiency and knows about the availability of the program.

Government-driven programs are also hampered by the fall-out of the recession. As states and

the federal government struggle to address budget deficit, funding is becoming less secure.

Government programs have been quite successful in the residential sector, but have struggled to

gain penetration in the industrial sector. Successful industrial energy efficiency programs require

expertise in the targeted industry, explaining perhaps why most government-run programs shy

away from process improvements, targeting instead low hanging fruits such as lighting.

Electric Utilities

Energy efficiency activities spearheaded by electric and gas utilities have come into widespread

use in the past three decades. These activities are often called demand-side management (DSM)

and “involve actions on the demand- or customer-side of the electric meter, either directly caused

or indirectly stimulated by the utility” (Gellings and Chamberlin, 1988). By the mid-1980s, utility13

based DSM had spread throughout the United States primarily as a load management tool for

delaying the need for new power plants (Loughran and Kulick, 2004). Originally, the term

therefore referred to programs aimed at producing desired changes in a utility’s load shape, but it

has since become closely associated with energy efficiency and conservation (Gillingham et al.,

2006) and expanded to include natural gas as well as electric energy. Currently, demand side

management is being utilized by close to 50% of all electric utilities (EIA, 2011b), and is employed

in almost every US state . In 2009, utilities reported cumulative energy savings from industrial

energy efficiency of 14.9 million Megawatt-hours (MWh), achieving a savings equivalent to 0.6%

percent of total retail sales (EIA, 2011b).

Funding for utility-run energy efficiency programs is generally collected through a mandatory

surcharge on customer bills, often referred to as a systems-benefits charge (Chittum et al., 2009).

Depending on state policy, energy efficiency finance programs are either run directly by utilities,

or funds are channeled through energy finance companies. Typical utility programs include rebate

programs, low interest loans, training and marketing, technical assistance, direct installation of

efficient technologies, or some combination of these measures. Another tool increasingly used by

utilities is on-bill financing, where loans – either provided directly by the utility or provided by

third party financiers and guaranteed by the utility – are repaid through the electricity bill over

time (Freeling, 2011). Industrial energy efficiency projects are highly attractive to utilities, because

they can achieve substantial energy savings in a single project and transaction costs are lower

than for residential projects. However, with utility-driven DSM, the pressure for adopting energy

efficient technologies is relatively weak, given that utilities have little direct influence over firms

and no direct knowledge of their operational process.

Insurance Industry

Insurance companies are relatively new players in the energy efficiency world. They have an

interest in energy efficiency investments due to their loss prevention benefits with regard to

climate change (Mills and Knoepfel, 1997; Schmidheiny and Zorraquín, 1998). Energy efficiency

can serve as a risk management tool (Mills, 2003a), because energy saving technology has

ancillary benefits, i.e., it also uses raw materials more efficiently, reduces health risks, business

interruption risk (greater reliability), and the risk of catastrophic events (e.g., fire, water leaks

etc.). Consequently, insurance companies are now starting to build these risk management

aspects into their insurance products. Increasingly, environmental indicators are becoming an

added basis for rate decisions (Schmidheiny and Zorraquín, 1998). Insurance companies provide

discounts to companies for energy efficient technology or offer to bundle business interruption

insurance with energy efficiency technology, which is often more reliable (Mills and Knoepfel,

1997). As the investment in energy efficient technology often hinges on the potential to recoup

14

the cost in energy savings, insurers are also starting to offer “energy-savings insurance” (Mills,

2003b), which covers the risk of new technology not achieving the promised energy savings.

Insurance involvement in energy efficiency is however hampered by several factors. In the United

States, the insurance industry is highly regulated, and insurers have to defend their rates in rate

cases. Therefore, there is insufficient flexibility to adjust for energy efficiency benefits in rates

(Mills, 2003a). In addition, insuring energy efficient technologies is a relatively new phenomenon

and so insurance companies are currently lacking high quality actuarial data to base their rates

and decisions on (Mills, 2003a). Finally, insurance companies, though among the biggest

institutional investors, tend to invest primarily in ultra-safe government bonds, minimizing their

potential role as investors in energy efficiency (Schmidheiny and Zorraquín, 1998). Nevertheless,

there seems to be some interest in energy efficiency investments due to their long-term fixed rate

characteristics, which makes them attractive instrument for the insurance industry with regard to

meeting their annuity commitments (Freeling, 2011).

Financial industry

Financial institutions participate in energy efficiency investments in their function as lenders and

investors. Similar to other operations and process loans, banks supply loans for investments in

energy efficiency, including as third party financers in ESCO contracts. Most loans provided by

commercial banks are therefore simply a form of project financing. Overall, commercial banks

have little direct participation in energy efficiency finance to date. According to Freeling (2011),

even where banks work with energy service companies to supply energy efficiency loans,

“performance guarantees, largely, are offered to the borrower to ensure the improvement prove

cost effective, but are not collateralizing the loans, nor necessarily, of particular concern to the

commercial banks involved.” This indicates that banks do not currently understand, nor take

advantage of the special characteristics of energy efficiency investments to reduce the

uncertainty associated with such project finance. Energy efficiency loans are often small and

considered risky.

Nevertheless, in an effort to provide capital to help reduce carbon emissions and energy

consumption, banks are beginning to support programs tailored to support energy efficiency

improvements. This is seen as the first step toward coordinated industrial energy efficiency

finance. For example, the Bank of America recently announced a new $55 million competitive

program to encourage energy efficiency improvements in older buildings through low cost loans

and grants (Bank of America, 2011). The energy cost savings realized over time will create cash

flow to repay the loan.

15

Another important impetus for energy efficiency finance comes from the investment industry.

Institutional investors have devised new rules for sustainable investment. An increasing number

of social and environmental funds target their investments specifically towards sustainable

companies. A number of such private equity and mutual funds have been created in the past two

decades. Ethical mutual funds have reported performance on par with conventional funds (Bauer

et al., 2005). A potential new trend in the investment sector is the securitization of energy

efficiency loans, where the risk of individual loans would be spread out by bundling and

repartitioning a large number of loans.

Overall, energy efficiency can be described as an up and coming investment sector, with very

good returns for the amount of risk involved. According to estimates by the McKinsey Global

Institute, global investments on the order of $170 billion annually through 2020 ($38 billion in the

US) in energy efficiency could deliver annual returns at a rate of 17 percent (Farrell et al., 2008).

The WilderHill New Energy Global Innovation Index, tracking 88 advanced clean energy

companies, lists energy efficiency as its best performing sector in 2010, with average share prices

up 19.5% from the previous year (Bloomberg New Energy Finance, 2011).

Energy Service Companies

Energy Service Companies (ESCOs) have been important in financing and implementing energy

efficiency projects, focusing on “improving the energy efficiency of facilities owned by others”

(Rivest, 1995). These organizations provide a service that encompasses energy audits, proposals

for improvements, installation and maintenance, performance contracts--all with the purpose of

offsetting the upfront costs with energy savings (Painuly et al., 2003). Their business model is

based on the principle of letting the customer outsource the risk of the energy efficiency

investment. In contrast to conservation consultants or energy service provider companies, ESCOs

assume at least some of the risk of performance for the projects they implement (Rivest, 1995).

They either provide financing themselves or can arrange for financing by third party providers

(Bertoldi et al., 2006). In some cases, ESCO even operate and own the facility (Goldman et al.,

2005).

ESCOs operate around the world, but their relevance and role can differ from country to country.

They are very active in Europe, where they have long been sustained by favorable regulation and

have mostly targeted the public sector (Bertoldi et al., 2006). In the United States, the ESCO

segment is somewhat smaller than in Europe, while also favoring the public and institutional

sector. In developing countries, ESCOs are gaining importance, but more sustained government

action will be required to achieve similar levels of activity as in industrialized countries (Painuly et

al., 2003). Developing ESCO industries is a declared objective of the World Bank, which has

16

implemented several dozen programs to that end (Sarkar and Singh, 2010). In some industrializing

countries, ESCO have made rapid gains, in particular in China (Sarkar and Singh, 2010).

ESCOs also have a long history in the United States (Goldman et al., 2005). In 2008, ESCOs

represented a market of US$ 4.1 billion in the United States, growing at a rate of 7% (Satchwell et

al., 2010) and up from roughly $2 billion in 2000 (Goldman et al., 2005). To a large extent, and

similar to the European case, demand by government and educational institutions drives this

business, with only 16% of ESCO revenue coming from the private sector (Satchwell et al., 2010).

Of these, energy efficiency investments in the industrial sector accounted for only 7% of ESCO’s

business in the US, although this share is slightly larger outside the US. In the industrial sector, US

industry has been hit hard by the recession, resulting in plant closures, job losses and reduced

capital investment in facilities. Many industrial customers are reluctant to enter into long-term

contracts, because they are not sure how long the manufacturing plants will remain open or at

what operation level. Also, measurement and verification (M&V) of savings tends to be more

challenging for industrial process retrofits, which may involve technologies that are proprietary or

commercially sensitive, as a result of which outside parties on site are not typically welcome

(Satchwell et al., 2010).

ESCOs use two basic strategies for recouping the energy efficiency investment cost: guaranteed

project savings and shared savings (Rivest, 1995). Within these contract forms, the degree of risk

sharing and the involvement of the ESCO vary. In guaranteed project savings, the ESCO only

facilitates the loan and the company bears the risk and pays back the credit based on a payment

schedule or from actual energy savings, which can vary from month to month. In this type of

contract, the savings guarantee becomes a kind of collateral for the third party financer, who is

guaranteed to recoup the loan via the energy savings(Bertoldi et al., 2006). In shared savings, the

ESCO either provides the financing or signs the loan and therefore assumes both the credit and

the performance risk. Shared savings without third party financing is the predominant model used

in the European ESCO market, where most ESCOs are subsidiaries of large companies(Energy

Charter Secretariat, 2003). In the US, there is some evidence that the use of performance

guarantees is declining, as customers become increasingly confident about and familiar with

energy efficiency investments (Goldman et al., 2005).

Guaranteed project savings are preferred by ESCOs over shared savings for several reasons. First

and foremost, guaranteed project savings keeps the ESCOs balance sheets clean. A few years ago,

the ESCO world was shaken by a Financial Accounting Standards Board (FASB) ruling that required

them to disclose the value of their energy guarantees on balance sheets, because they could

potentially result in payments to customers (Mayer, 2002). Additionally, external financing

agencies may be better equipped than ESCOs to evaluate credit risks (Gilligan, 2011). In

guaranteed project savings, ESCOs also do not incur the debt directly; which might be preferable

to smaller ESCO with fewer funds, but also because third party financing is cheaper than equity

17

financing (Bertoldi et al., 2006). Finally, because the customer is also the borrower, there are no

split incentives, meaning there is greater motivation for the customer to resolve problems with

the project (Gilligan, 2011).

These new types of project financing with shared or outsourced risks can be helpful to industrial

operators in an investment climate where business is under intense competition and tends to

focus narrowly on investments in core competencies (Möllersten and Sandberg, 2004). ESCOs can

counteract some of the energy efficiency market failures, for example by providing information,

reducing uncertainty and risk, and lowering transaction cost through standardized services

(Goldman et al., 2005). Nevertheless, the continued growth of ESCO services faces some

challenges. In small projects, transaction costs may exceed energy savings, and in large process

based projects, asset specificity may preclude outsourcing (Sorrell, 2006). An international survey

of ESCOs (Vine, 2005) cites the lack of preparedness of the regulatory system, banks’ inexperience

with energy efficiency investments, and the perceived riskiness of non-asset based projects

among the prime reasons that ESCO are not more widely used.

Business to business relationships

In the business world, energy efficiency can be a side-product of new equipment ordering, or can

feature as an element of supply chain optimization. Additionally, companies are influenced by the

actions of their peers.

Sellers or suppliers of energy efficiency technologies can influence a company’s evaluation or

assessment of their technology options (Fine, 1993). Technology developers and suppliers can

organize technology demonstrations or pilots to show the energy efficient technology in

operation in a manufacturing plant. They are usually willing to install new equipment for a trial

run to allow companies to fine tune or tweak it for their production needs. These trials allow

companies to gain more confidence in the technology and more likely to invest. Suppliers may

also serve on industry association boards and develop relationships with companies. This may

make it easier to recruit companies for installation working with investors to move the technology

investment forward. Especially for small manufacturers, technology vendors take on the role of

energy efficiency (finance) providers, through capital lease to own, operating leases and

equipment rentals (Personal communication, Becker, 2011).

Under the guise of environmental management systems, life-cycle assessment, and supply-chain

optimization, energy efficiency has also made inroads into client-supplier relationships (Mosovsky

et al., 2000; Srivastava, 2007). A growing number of firms now realize that much of their

environmental impact is due to production activities at their suppliers and are encouraging and

supporting those suppliers in the adoption of, among other changes, energy efficiency.

18

Additionally, companies are increasingly realizing the cost-savings potential inherent in

implementing supply chain energy efficiency projects.

Outside parties, including ESCOs, consider this an encouraging and useful development for several

reasons. First, pressure on factories by customers can provide uniquely powerful motivation to

adopt energy efficiency. This is especially true as more customers make similar requests. Even

though compliance is only voluntary at this time, most suppliers believe that mandatory programs

are being prepared. In addition, this motivation simplifies the very first step of project

development: sales. Second, customer involvement is also believed by ESCOs and financial

partners to reduce project risk, since factories that have been accepted into the supply chains of

major customers are assumed to be more stable and sophisticated, financially and otherwise.

Some parties also believe that customer involvement in energy efficiency promotion

simultaneously reduces credit risk associated with project finance for smaller firms, but this is

speculative at this point. Third, customer pressure to adopt energy efficiency also performs a

useful aggregation function, bringing together groups of firms with similar opportunities. For

ESCOs, this aggregation simplifies the task of serving especially smaller firms, narrowing the

addressable markets from hundreds of thousands of firms to those that produce for major

customers.

Industry peers can also have a significant impact on a firm’s decision to invest in new energy

efficient technologies. When technologies show increasing returns in the number of firms

adopting, then a single firm will typically make its technology choices after considering which

technology others are likely to invest in. For example, if a new energy efficient technology

innovation is viewed as particularly risky when it is first developed, a company will view it as less

risky if many other companies being to adopt it. There may also be economies of scale associated

with the manufacture, service and distribution of a technology such that significant benefits

accrue from investing in the energy efficiency technology with the largest possible market share.

19

Energy efficiency investments as an emerging asset class

The wide variety of players in the energy efficiency finance world demonstrates that actors

external to firms might play an important role in inducing them to invest in energy efficiency.

Above, we have highlighted the financial tools currently used by these external actors, and

pointed to both opportunities and challenges towards their growing importance in the future. We

now build on this review to develop recommendations for establishing energy efficiency as a

distinct asset class.

Institutional entrepreneurship could form a new pathway towards energy efficiency. There are

multiple examples of institutional entrepreneurs creating new inter-organizational routines and

norms to establish a new market sector (Munir and Phillips, 2005), create legitimacy for a new

field of activity (Maguire et al., 2004; Child et al., 2007), push for sustainability (Brown et al., 2009;

Montiel and Husted, 2009; Etzion and Ferraro, 2010), or develop standards for interoperability

(Sanjay et al., 2002). Conceivably, some of these same tactics could be used to develop a new

asset class for energy efficiency.

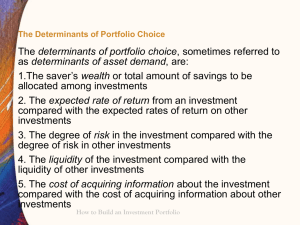

An asset class can be defined as “a set of assets that bear some fundamental economic similarities

to each other, and that have characteristics that make them distinct from other assets” (Greer,

1997). Establishing energy efficiency investments as a separate asset class has multiple benefits,

such as driving growth of this sector by creating a commonly accepted set of risk assessment rules

and investment benchmarks. As a separate asset class, energy efficiency would benefit from

strategic asset class allocation, which is undertaken to spread risk across several types of

investments. Ideally, fund managers seek to spread investments over distinct asset classes whose

value development over time is independent of each other.

At the broadest level, asset classes fall into three groups (Greer, 1997): capital assets (equities,

bonds, income-producing real estate; valued based on net present value), consumable or

transformable assets (commodities, valued based on demand and supply) and store of value

assets (e.g., fine art, currency). While describing asset classes in terms of their value base is

useful, in practice, the term asset class more often refers to a specific investment tool. Investors

describe equities, bonds, and money market instruments as the three core asset classes. To these

are added real estate and commodities. Other types of investments are generally termed

alternative asset classes. We will follow this latter distinction here in exploring the potential for

energy efficiency investments to be recognized as a new alternative asset class.

Based on the above definition, energy efficiency investments harbor some important

characteristics of a new asset class: They are independent of other asset classes, as their value

does not depend directly on that of most other asset classes. Energy efficiency investments have

the desirable characteristic of long-term fixed rate investments, with dependable payments over

a period of time (Freeling, 2011). Energy efficiency investments could also be described as

counter-cyclical, as their value is not tied to those of stocks or equity in a recession.

20

Energy efficiency investments do however have some correlation with commodity prices. As

energy prices go up, so does the value of energy efficiency investments; which can act as a hedge

against rising commodity prices. Similarly, as energy prices fall, so does financial gain to be

garnered from energy savings. For industrial facilities investing in electrical energy efficiency, this

is buffered by the relative stability of electrical rates over time. In contrast, investments in

thermal energy efficiency may be more strongly exposed to fluctuations in fuel prices. Overall,

despite the correlation with commodities, energy efficiency investments are sufficiently

independent of other major investment classes – such as stock, bonds and money market

accounts – to provide a reasonable foundation for a new alternative asset class.

Energy efficiency investments have potential to gain the status of an independent asset class; as

of yet, they have not reached critical mass. While energy efficiency investments possess the

characteristics necessary for the creation of a separate asset class, multiple hurdles will have to

be overcome to achieve this goal. Rules governing energy efficiency investments and loans need

to be reinvented, and tools need to be developed to bundle these assets into securities. In the

remainder of this section, we look to examples from the financial sector to describe the process of

asset class formation and draw lessons for an energy efficiency asset class.

New asset classes are not created out of thin air; and backers of an energy efficiency asset class

can learn from the historical development of new classes. Alternative asset classes such as

derivatives (Canter et al., 1997; Van Lennep et al., 2004) and new types of securitized assets

(Forrester, 2008) have grown tremendously over the past decades. Within 20 years of its creation,

the asset-backed securities market had reached $584 billion (Edwards, 2001), cresting at $888

billion in 2008 (Agarwal, 2010). Historically, securitization has happened in sectors that are both

relatively large and have predictable cash-flows, but are characterized by insufficient funding,

(Gorvett, 1999). As described in more detail in section II, energy efficiency investment

opportunities cut across all sectors and could reach several hundred billion dollars in the coming

decades (Farrell et al., 2008). Like credit card loans before the 1990s, energy efficiency loans have

predictable cash flows, but insufficient funding. These characteristics suggest that securitization is

a promising pathway for this class of investments.

Where assets are securitized, cash flows derived from similar assets with different levels of risk

are bundled into investment packets and resold to investors, providing both a risk management

tool and an investment opportunity. In securitization the “key to success is whether the asset

class can be commoditized, i.e., whether its cash flows are stable and predictable and relate to a

service provided en masse to the public” (Welsher and Penrose, 2004). Energy efficiency

investments are inherently capable of fulfilling these conditions. Not only do investments in

energy efficiency create predictable financial savings over time, but they have tremendous

growth potential, given the extensive opportunities for energy efficiency across industrial facilities

and commercial buildings.

While the potential dangers of securitization, especially with regard to mortgage-backed

securities, have become widely known in the aftermath of the 2008 real estate crisis, they should

21

not rule out this pathway for energy efficiency. Many of the problems in mortgage backed

securities were related to insufficient vetting of the securitized assets as well as unrealistically

optimistic ratings of mortgage-backed securities. As other successful securitization efforts have

shown (e.g., insurance securitization, see Gorvett, 1999), these problems are not inherent to

securitization itself, and could be avoided with careful rule-setting and a deliberate credit rating

system.

To attain asset class status for energy efficiency investments and allow for rapid growth of the

sector, careful rules will have to be set up vet the risk of investment opportunities. The example

of REIT (real estate investment trusts) index return data shows that the existence of a commonly

accepted metric for judging the quality of an investment can be key for a new investment sector

to take off (Mull and Soenen, 1997). One potential yardstick for energy efficiency investments is

value at risk. Used for example in target date funds to reallocate assets over time (Lewis and

Okunev, 2009), value at risk describes the maximum expected loss in value for an asset over a

given time period and at a given confidence level. In other words, it is a measure of the

probability of an adverse event.

As outlined by Jackson (2010) conservative rules of thumb on payback times designed to rule out

risky investments often inadvertently eliminate long term, but less risky energy efficiency

investments. She suggests applying the value at risk tool to energy efficiency. Jackson’s (2010)

proposed measure, energy budgets at risk (Ebar) “applies historical energy use data, weather

data, engineering-based efficiency savings analysis and other factors to quantitatively determine

the risk associated with any efficiency investment.” This and similar proposals building on existing

and accepted financial metrics will prove useful in driving acceptance of energy efficiency

investments as a separate asset class. They bridge the language barrier between engineers and

financial investors and reduce transactions costs for assessing project risk.

To address the confidence issues and perceived riskiness of energy efficiency loans due to

underperformance of equipment, proponents of an energy efficiency asset class could also look to

the established practice of performance pricing. Performance pricing ties a loan rate directly to a

borrower’s credit rating, without having to refinance (Asquith et al., 2005). Performance

contracting for energy efficiency loans could borrow from performance pricing to include flexible

loan terms. Interest rates for energy efficiency loans could be linked to the performance of the

energy saving equipment. If savings are less than expected, interest would increase. Conversely, if

the savings surpass estimates, interest would decrease. Where interest can increase, the risk of

moral hazard to the bank is reduced, while borrowers still gain access to financing at initially low

rates; where interest can decrease, borrowers with decreasing credit risk do not have to

renegotiate the contract to benefit from better rates (Asquith et al., 2005).This might help

overcome initial barriers to financing availability for energy efficiency. Asquith, Beatty, and Weber

(2005) have shown that “riskier borrowers use interest-decreasing performance pricing,” making

this an attractive option for energy efficiency loans. These loans are often considered risky simply

because they are not well known to bankers or widely used, and could benefit from automatic

22

performance driven interest adjustments to reduce the cost of financing energy efficiency

investments.

Another significant barrier towards energy efficiency investment is the small size of many

projects. Large institutional investors are not interested in piecemeal investment. Aggregation has

been successfully used in public sector markets (Energy Charter Secretariat, 2003). Currently,

bond markets have entry barriers for investments smaller than $ 100 million, reflected in price

differences between bonds and loans (Angbazo et al., 1998). This represents a significant problem

for energy efficiency projects, as they are often small and therefore unlikely to gain access to

lower priced bond financing. One potential solution to this problem is to bundle or aggregate

energy efficiency projects, and then sell these investments as a security. As noted by Edwards

(Edwards, 2001) “the entity securitising its assets it not borrowing money, but selling a stream of

cash flows that was otherwise to accrue to it.” This model seems equally reasonable for energy

efficiency projects. T

Overall, aggregating energy efficiency investments for securitization appears to be the most

important step leading to the creation of an independent energy efficiency asset class. Table 3

provides a summary of the frames of reference that could be used to achieve securitization and

the potential role each external actor could play in aggregating energy efficiency investments for

securitization.

23

Governments

Electric

utilities

Frames of reference for

securitization

PACE

Bonds

Small Business Administration

Loan Guarantees

Energy efficiency performance

standards

On-bill financing

Insurance

industry

Loss prevention insurance

Risk management through

insurance securitization

Financial

industry

Securitization

Financial risk indices

Performance banking

Energy

service

companies

Performance contracting

Business to

business

Supply chain management

Lean manufacturing

Potential role in aggregation

Governments can match investors and

clients for loan programs and provide loan

guarantees. They can develop standard

contracts.

Utilities can utilize existing relationships

with industrial customers and knowledge of

their energy use profile; identify those

offering the best opportunities for loadshifting. Given the right financial incentives

(decoupled rates, time of day pricing, EE

performance standards), utilities can bring

together similar companies.

Insurance providers can offer standardized

insurance for energy performance

contracts. The insurance industry can lower

the transaction costs and risk of EE

investments by offering loss prevention

insurance. They also have a role to play as

institutional investors interested in annuity

style investments’

The financial industry can build on the

experience with securitization of credit card

and other assets to develop rules for EE

investments. It also can build on the

experience with metrics and financial risk

indices to develop a yardstick for evaluating

EE investments.

ESCO could expand their business into the

small business sector and develop

methodologies to streamline contracts for

firms with similar characteristics.

Downstream businesses can manage their

supply chain to make EE a part of lean

manufacturing and performance

contracting.

Table 3. Frames of reference and potential role in aggregation for various external actors

24

Conclusion

The persistence of the energy efficiency gap has many reasons, and no single solution. Instead of

diagnosing the market and behavioral failures at the root of the problem, it might be more useful

to treat the symptoms. This white paper points to the institutional entrepreneurship framework

to identify potentially influential change agents for creating an energy efficiency asset class. It

reviews the role of a set of external actors in creating new rules and routines for energy efficiency

investment. It also draws on prior examples of successful asset class development to map out a

blueprint for establishing an energy efficiency asset class. Aggregation of energy efficiency

projects and securitization of energy efficiency loans are identified as the key ingredients for

creating an independent energy efficiency asset class.

25

References

Abdelaziz, E.A., Saidur, R., Mekhilef, S., 2011. A review on energy saving strategies in industrial sector. Renewable

and Sustainable Energy Reviews 15, 150-168.

Agarwal, S., 2010. Rescuing asset-backed securities. Chicago Fed Letter January.

Aldrich, H., Ruef, M., 2006. Organizations evolving, 2nd ed. Sage, London/Thousand Oaks.

Anderson, S.T., Newell, R.G., 2004. Information programs for technology adoption: the case of energy-efficiency

audits. Resource & Energy Economics 26, 27.

Angbazo, L.A., Mei, J., Saunders, A., 1998. Credit spreads in the market for highly leveraged transaction loans.

Journal of Banking & Finance 22, 1249-1282.

Asquith, P., Beatty, A., Weber, J., 2005. Performance pricing in bank debt contracts. Journal of Accounting and

Economics 40, 101-128.

Bank of America, 2011. Press release: Bank of America announces new energy efficiency finance program.

Barbose, G., Goldman, C., Schlegel, J., 2009. The Shifting Landscape of Ratepayer Funded Energy Efficiency in the

U.S. The Electricity Journal 22, 29-44.

Barnett, M.L., 2006. Waves of collectivizing: A dynamic model of competition and cooperation over the life of an

industry. Corporate Reputation Review 8, 272-292.

Bauer, R., Koedijk, K., Otten, R., 2005. International evidence on ethical mutual fund performance and investment

style. Journal of Banking & Finance 29, 1751-1767.

Becker, P., 2011. Personal communication, Ingersoll Rand: Financing Energy Efficiency Improvements through

Vendor Relations, in: McComas, C. (Ed.).

Bertoldi, P., Rezessy, S., Vine, E., 2006. Energy service companies in European countries: Current status and a

strategy to foster their development. Energy Policy 34, 1818-1832.

Bloomberg New Energy Finance, 2011. Clean energy shares underperform in 2010. Press release 01/05/2011.

Brown, H.S., de Jong, M., Lessidrenska, T., 2009. The rise of the Global Reporting Initiative: a case of institutional

entrepreneurship. Environmental Politics 18, 182-200.

Bunse, K., Vodicka, M., Schönsleben, P., Brülhart, M., Ernst, F.O., 2010. Integrating energy efficiency performance

in production management - gap analysis between industrial needs and scientific literature. Journal of Cleaner

Production 19, 667-679.

26

Busenitz, L.W., Barney, J.B., 1997. Differences between entrepreneurs and managers in large organizations: Biases

and heuristics in strategic decision making Journal of Business Venturing 12, 9-30.

Canter, M.S., Cole, J.B., Sandor, R.L., 1997. Insurance derivatives: a new asset class for the capital markets and a

new hedging tool for the insurance industry. Journal of applied corporate finance 10, 69-81.

Child, J., Tsai, T., Lu, Y., 2007. Institutional Entrepreneurship in Building an Environmental Protection System for

the People's Republic of China. Organization Studies 28, 1013-1034.

Chittum, A.K., Elliott, R.N., Kaufman, N., 2009. Trends in industrial energy efficiency programs: today's leaders and

directions for tomorrow. American Council for an Energy-Efficient Economy, Washington D.C.

Christmas, J., 2011. Is There Hope Post-PACE?, ACEEE Finance Forum. American Council for an Energy Efficiency

Economy, Philadelphia, PA.

De Beer, J., 2000. Potential for industrial energy-efficiency improvement in the long term. Springer Netherlands.

de Groot, H.L.F., Verhoef, E.T., Nijkamp, P., 2001. Energy saving by firms: decision-making, barriers and policies.

Energy Economics 23, 717-740.

DeCanio, S.J., 1993. Barriers within firms to energy efficient investments. Energy Policy, 906-914.