STUDY OUTLINE FOR CHAPTER 4

advertisement

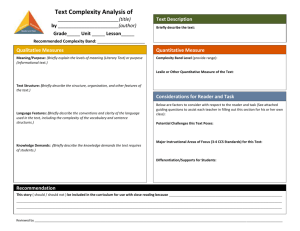

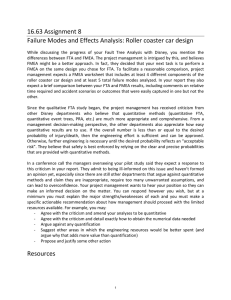

1 STUDY OUTLINE FOR CHAPTER 4 PRODUCT/PROCESS INNOVATION 1. Briefly explain the role of product/process innovation in supply chain operations management: 2. Define: New product design and development projects New process design and development projects 3. Discuss the two ways that operations managers get involved in new product and process design and development projects: 1) 2) 4. Explain how product and process design and development activities can be viewed as part of the resource and technology supply chain: 5. Define the product life cycle and briefly discuss the four phases of the life cycle: Product life cycle – 1) 2) 3) 2 4) 6. Identify the functional groups that play important roles in new product development: 1) 2) 3) 4) 5) 7. Discuss the advantages of Fast Innovators: 1) 2) 3) 8. Discuss the advantages of High-Quality Innovators: 1) 2) 9. Discuss the advantages of Efficient Innovators: 1) 2) 10. Identify the different types of organizational learning that occurs as a result of all innovation projects, whether or not they are successful: 11. Discuss characteristics of a culture supportive of process improvement and customer service: 1) 2) 3 3) 12. Define the following: Open innovation – Innovation Portfolio Planning - 13. Compare the four primary types of innovation projects: 1) 2) 3) 4) 14. Identify the two key competencies of product/process design and development projects: 1) 2) 15. Discuss the progression of new product/process launch and learning: 16. Discuss the importance and benefits of codevelopment in bringing a major new product to market or bringing a major new process online: 1) 2) 3) 17. Identify the two risks of codevelopment: 4 1) 2) 18. Define: early supplier involvement (ESI): 19. Identify key activities and decisions at each stage of product/process innovation: Concept development – Product and process planning – Detailed design and development- Product and market testing- Commercialization- Market introduction- 20. Define: Stage-Gate Process- Concurrent Engineering- 5 21. Identify the three categories of overall resources spent in new product/process development: 1) 2) 3) 22. Discuss three benefits of integrated/concurrent engineering: 1) 2) 3) 23. Define the following: Voice of the Customer (VOC) Beta Testing Quality Function Deployment (QFD) Customer Requirements Planning Matrix / House of Quality Technical Features Deployment Matrix 24. Identify the four linked information matrices that are completed in the QFD process: 1) 2) 3) 6 4) 25. Briefly discuss the key inputs to each stage of the House of Quality construction: Customer desired traits- Assessment of competition- Technical features and target values- Interrelationships- Process plans and instructions- 26. Define failure modes and effects analysis (FMEA) and identify the two basic questions a FMEA team is tasked with answering: Failure Modes and Effects Analysis – 1) 2) 27. Discuss the five major steps from problem identification to resolution in FMEA: 1) 2) 3) 4) 5) 7 28. Explain the calculation of the risk priority number (RPN) in FMEA: 29. Define the following: Value engineering/value analysis Design for manufacture (DFM) Producibility Design for assembly Design for product serviceability Design for Six Sigma Robust design 30. Describe the steps of the value analysis process for existing products: 1) 2) 3) 4) 5) 8 31. Briefly discuss the design rules that might be part of DFM: 1) 2) 3) 4) 32. Discuss the benefits of components standardization: 33. Discuss the advantages of modular product designs: 34. Compare design for logistics, design for reverse logistics, and design for the environment: 35. Identify and define four enabling technologies for product/process innovation: 1) 2) 3) 4)